Title Page

-

Date

-

Customer name

-

Site Address

-

RA Document Number

-

Time Restrictions

Main Site Hazards

-

Main Site Hazards

- Exposure Harmful Gases

- Site Access / Egress

- Slips , Trips , Falls

- Workplace Transport

- Working at height

- Confined Spaces

- Moving Plant

- Overfill / Spill Protection

- Onsite Pressure systems

- Noise levels

- HAV - Hand Arm Vibrations

- Mechanical Hazards

- Vehicle Overturning

- Site Lighting

- Lone working

- Highways Traffic

- Site Security

- Electrical Systems

- Other Contractor's

-

Is a Site Safety Induction required?

-

Site Access instructions & Restriction - State any Height / Speed / Access Restrictions

-

Access Rating

-

Required Site Specific PPE

- Safety Footwear

- Hard Hat

- LEP - Light Eye Protection

- High Visibility Clothing

- Gloves

- Blackline G7 Lone working Gas Atmospheric Monitor

- Overalls

- Chemical Gloves

- Chemical Suit

- Specialised PPE

- AS/FR Overalls

- Visor

- AS/FR Clothing

-

Site Rating

Project Requirements

-

Task details

-

Specific Site Instructions

-

Site contact

-

Vehicle Requirements

- 6-Wheeler

- 8-Wheeler

- Articulated

- Urban Trailer

-

Length of hose Required

-

Hose Diameter

-

Loading Point connection type

- BSP - Thin Thread

- URT - Thick Thread

- Bauer / Lever lock

- Camlock

- Storz

- Table d

- Flange connections

- Quick Release / Dry brake

- RJT (Dairy / Brewery ) fitting

- Unicone

- API Bottom Loading Fitting

-

Use this Webpage as a guide to what fitting is required https://hydraquip.co.uk/product-category/industrial-hose/industrial-hose-fittings/ - If you are in doubt take a picture and discuss with management.

-

Any Additional Notes

Site Fuel grade and capacities

-

Fuel Grades - Add Capacity in notes

-

Point 1

- Diesel

- Super Diesel

- Unleaded

- Super Unleaded

- AdBlue

- Gas Oil

- Kerosene

- Aviation Fuel

- Heating Oil

- N/A

-

Point 2

- Diesel

- Super Diesel

- Unleaded

- Super Unleaded

- AdBlue

- Gas Oil

- Kerosene

- Aviation Fuel

- Heating Oil

- N/A

-

Point 3

- Diesel

- Super Diesel

- Unleaded

- Super Unleaded

- AdBlue

- Gas Oil

- Kerosene

- Aviation Fuel

- Heating Oil

- N/A

-

Point 4

- Diesel

- Super Diesel

- Unleaded

- Super Unleaded

- AdBlue

- Gas Oil

- Kerosene

- Aviation Fuel

- Heating Oil

- N/A

-

Point 5

- Diesel

- Super Diesel

- Unleaded

- Super Unleaded

- AdBlue

- Gas Oil

- Kerosene

- Aviation Fuel

- Heating Oil

- N/A

SITE HAZARDS

Site Plan

Site Entrance / Exit

-

Is vehicle access to site and delivery point safe? Does the driver need to stop on the carriageway to enter the site? Is it safe to park the vehicle at the entrance whilst opening the site gate? Are there any overhanging trees that could damage vehicles or tanks driving in? Is there any Shrubbery that may obstruct vision when entering or exiting the site? Is the access road busy with other traffic? Does the access road have a footpath for pedestrians? Is there risk of collision with pedestrians? Is there sufficient room for manoeuvre into and out of the site? Can U-turns be performed safely without causing damage to the vehicle? Are there any difficult reverse manoeuvres? Any housekeeping issues, e.g. pallets or Skips in the way? Narrow spaces, low pipework etc.?

-

Add a photo of the site entrance and route to the loading points and important locations onsite .

-

Add a photo or PDF copy of the site plan here

Collection / Discharge points

-

Highlight on the Map the loading / unloading positions.

-

Add a photo of the collection point

-

Step by Step Loading Instructions - State the required instructions for the driver to follow. Include any valves to be opened and panels to be used

Emergency Actions

-

Actions to be taken in the event of an emergency

-

Onsite medical Equipment - State what is available onsite

-

Onsite Emergency Showers - State Location

-

Close Defibrillator station - Use this website as a tool to find the closest Defib Station https://www.defibfinder.uk/

-

Closest Medical centre / Accident and emergency Hospital - State Name and full address

-

All Emergency MUST be reported to the onsite contact and Suttons planning / operations teams

Site Delivery / Loading Risk Assessment

-

Use the Notes and Media sections below each question to give details of existing controls. Where you see anything that is below standard or requires urgent attention, give recommendations or create an action for rectification.

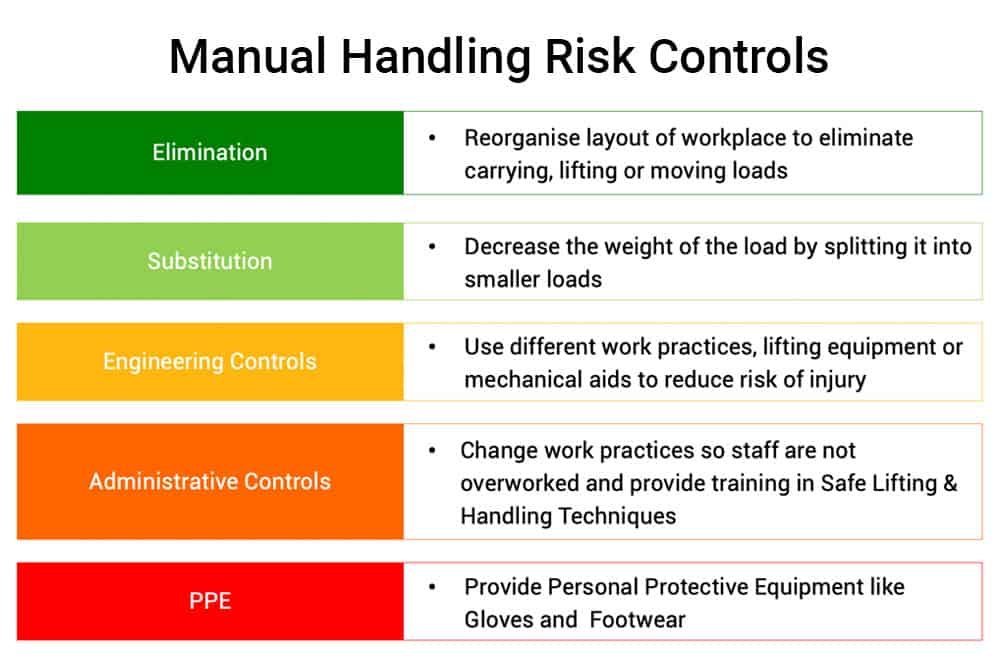

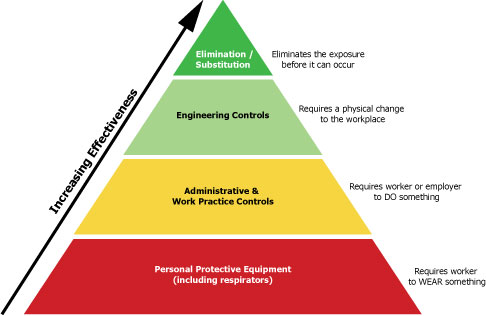

Manual Handling Hazards, Risks and Controls

-

Manual handling is activity that requires physical effort such as lifting, carrying, pushing, pulling, reaching, stretching twisting etc. This might include handling hoses, operating valves, making and breaking connections, opening or fastening lids etc.

-

Does the task involve manual handling

-

Describe the hazardous activity

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

Describe 'Other'

-

What existing controls are in place to reduce the risk?

- Fork Lift Truck

- Drum handler

- Automatic Curtain

- Automatic self opening rear trailer door

- Pallet truck

- Hand Trolley

- Mechanical Hoist

- Reduce size of load

- Minimise distance of carry

- Minimise duration

- Rest schedule is built into the process

- Hand Tools

- Adjustable Seats in vehicle

- manual handling Training

- Procedure - DHB CORE 18

- Suitable Glove ( EN388 )

- Other ( Specify )

- Slip resistant safety footwear ( EN20345 )

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 15 or higher then additional controls to reduce risk will need to be found before the activity is carried out. If the value is between 9 and 14 then additional controls should be put in place. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Fork Lift Truck

- Drum handler

- Automatic Curtain

- Automatic self opening rear trailer door

- Pallet truck

- Hand Trolley

- Mechanical Hoist

- Reduce size of load

- Minimise distance of carry

- Minimise duration

- Rest schedule is built into the process

- Hand Tools

- Adjustable Seats in vehicle

- manual handling Training

- Procedure - DHB CORE 18

- Suitable Glove ( EN388 )

- Other ( Specify )

- Slip resistant safety footwear ( EN20345 )

-

What is the other control?

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

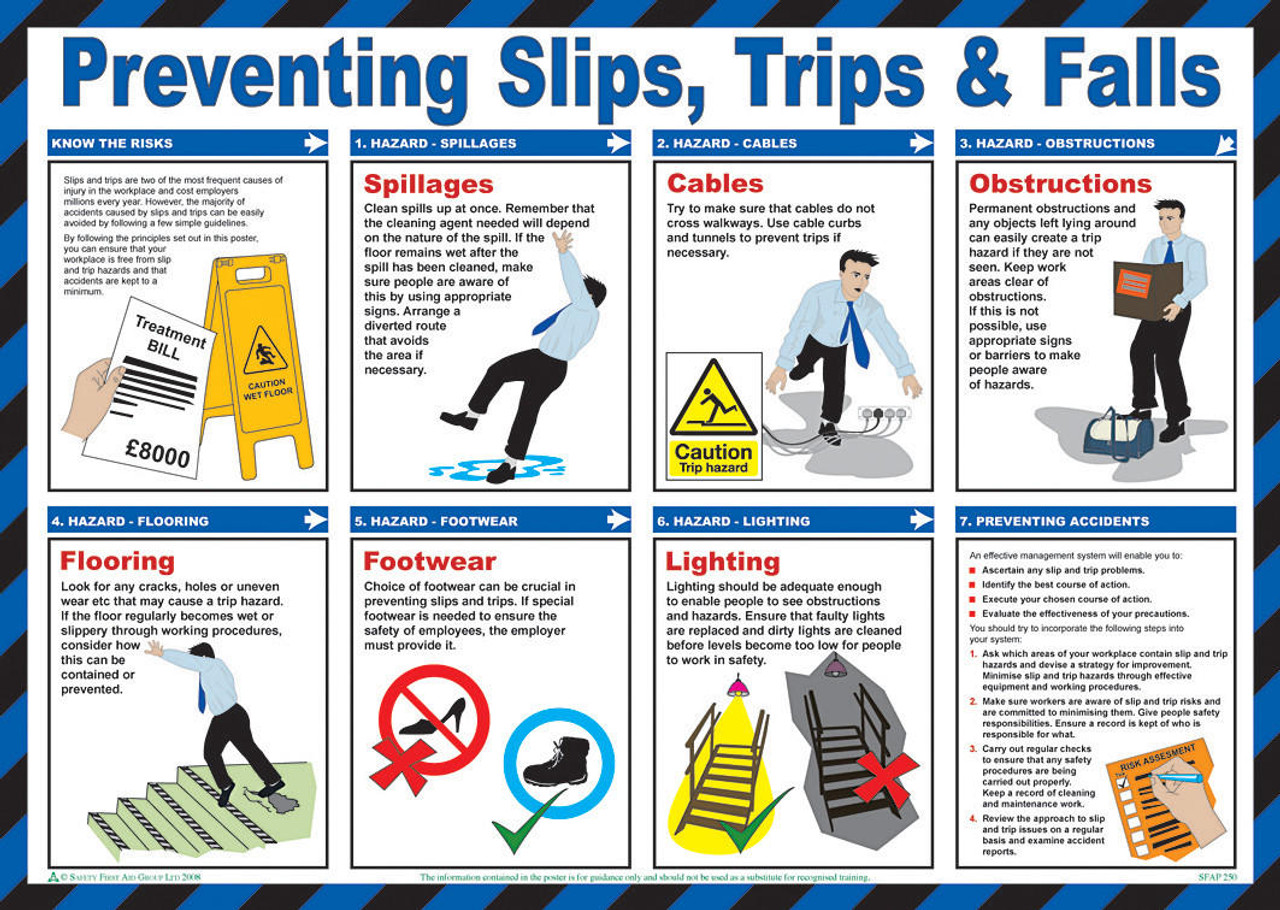

Slips, Trips and Falls

-

Does the task involve slips, trips or fall hazards?

-

Does the task involve slips, trips or fall hazards?

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Move the task from the hazardous area

- Hand holds

- On Site Lighting

- Hand Held or Head Torch

- Slip resistant tape

- Slip resistant paint

- Slip resistant floor surfaces

- Grated surface

- Drainage

- Training (Specify)

- Procedure (Specify)

- Designated walkways

- Housekeeping

- Winter preparedness

- Repair trip hazard

- Signage

- Edge marking

- Slip resistant safety footwear (EN20345)

- Other

-

What is the other control

-

Initial likelihood

- 1 - Extremely unlikely

- 2 - Unlikely

- 3 - Possible

- 4 - Likely

- 5 - Almost certain

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

Should additional controls be put in place?

-

Select control measures

- Move the task from the hazardous area

- Hand holds

- On Site Lighting

- Hand Held or Head Torch

- Slip resistant tape

- Slip resistant paint

- Slip resistant floor surfaces

- Grated surface

- Drainage

- Training (Specify)

- Procedure (Specify)

- Designated walkways

- Housekeeping

- Winter preparedness

- Repair trip hazard

- Signage

- Edge marking

- Slip resistant safety footwear (EN20345)

- Other

-

Describe the other measure.

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Working at Height,

-

Is any required work at height covered by adequate protection, e.g. handrails, adequate platforms etc? Are pits at ground level guarded and railed to prevent falling in? Are there any sharp edges on the handrail or steps? Please detail any hazardous work at height required for the delivery.

-

Does the task involve the hazard of working at height?

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Move the task to ground level

- Use ground operated equipment

- Use ground level sampling techniques

- Load from ground level (bottom loading)

- Permanent ground operated vent valve

- Temporary ground operated vent valve

- Use fixed gantry

- Mobile elevated work platform (MEWP)

- Double handrail

- Single handrail

- Anti drive away interlocks

- Hand holds

- Slip resistant tape

- Slip resistant paint

- Slip resistant floor surfaces

- Grated surfaces

- Edge protection

- Fixed Scaffolding

- Mobile Scaffold tower

- Toe - boards

- Catch netting

- Inflatable airbags

- Fixed permanent Ladder

- Mobile Stepladder

- Cordless tools

- Training (Specify)

- Procedure (Specify)

- Removal of slip / trip hazards

- Cordon area off below working space

- Marshall area below working space

- Tie on or footing of ladders

- Fall arrest harness and life line

- Slip resistant safety footwear (EN 20345)

- Suitable gloves (EN388)

- Tool belt

- Safety helmet with chinstrap (EN397)

- Other (Specify)

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 15 or higher then additional controls to reduce risk will need to be found before the activity is carried out. If the value is between 9 and 14 then additional controls should be put in place. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Move the task to ground level

- Use ground operated equipment

- Use ground level sampling techniques

- Load from ground level (bottom loading)

- Permanent ground operated vent valve

- Temporary ground operated vent valve

- Use fixed gantry

- Mobile elevated work platform (MEWP)

- Double handrail

- Single handrail

- Anti drive away interlocks

- Hand holds

- Slip resistant tape

- Slip resistant paint

- Slip resistant floor surfaces

- Grated surfaces

- Edge protection

- Fixed Scaffolding

- Mobile Scaffold tower

- Toe - boards

- Catch netting

- Inflatable airbags

- Fixed permanent Ladder

- Mobile Stepladder

- Cordless tools

- Training (Specify)

- Procedure (Specify)

- Removal of slip / trip hazards

- Cordon area off below working space

- Marshall area below working space

- Tie on or footing of ladders

- Fall arrest harness and life line

- Slip resistant safety footwear (EN 20345)

- Suitable gloves (EN388)

- Tool belt

- Safety helmet with chinstrap (EN397)

- Other (Specify)

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Workplace Transport

-

Are pedestrians segregated from vehicles on the way to and from the Collection/delivery point? Are there proper crossings, barriers etc. in place? Is the driver exposed to moving vehicles while in the collection / delivery area? Do vehicles emerge from blind corners into areas used by pedestrians? Is there site speed limits and are they well displayed? Are there any other moving vehicles moving the site .

-

Does the task involve the hazard of Workplace Transport

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Pedestrian only areas

- Pedestrian free areas

- Lighting

- Barriers

- Cones

- Cordons

- Marked Pedestrian walkways

- Pedestrian crossings

- Speed limiters

- Convex mirrors

- Speed bumps

- Vehicle mirrors

- Training (Specify)

- Procedure (Specify)

- One way system

- Drive through facility

- Speed limits (Specify)

- Traffic marshalling

- Housekeeping

- Speed checks

- High visibility clothing (EN 471)

- Other (Specify)

- Traffic management ( NRSWA )

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 15 or higher then additional controls to reduce risk will need to be found before the activity is carried out. If the value is between 9 and 14 then additional controls should be put in place. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Pedestrian only areas

- Pedestrian free areas

- Lighting

- Barriers

- Cones

- Cordons

- Marked Pedestrian walkways

- Pedestrian crossings

- Speed limiters

- Convex mirrors

- Speed bumps

- Vehicle mirrors

- Training (Specify)

- Procedure (Specify)

- One way system

- Drive through facility

- Speed limits (Specify)

- Traffic marshalling

- Housekeeping

- Speed checks

- High visibility clothing (EN 471)

- Other (Specify)

- Traffic management ( NRSWA )

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Site Vehicle Access / Exit (manoeuvering)

-

Is vehicle access to site and delivery point safe? Does the driver need to stop on the carriageway to enter the site? Is it safe to park the vehicle at the entrance whilst opening the site gate? Are there any overhanging trees that could damage vehicles or tanks driving in? Is there any Shrubbery that may obstruct vision when entering or exiting the site? Is the access road busy with other traffic? Does the access road have a footpath for pedestrians? Is there risk of collision with pedestrians? Is there sufficient room for manoeuvre into and out of the site? Can U-turns be performed safely without causing damage to the vehicle? Are there any difficult reverse manoeuvres? Any housekeeping issues, e.g. pallets or Skips in the way? Narrow spaces, low pipework etc.?

-

Does the task involve the vehicle having to park on a public Highway

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Pedestrian only areas

- Pedestrian free areas

- Lighting

- Barriers

- Cones

- Cordons

- Marked Pedestrian walkways

- Pedestrian crossings

- Speed limiters

- Convex mirrors

- Speed bumps

- Vehicle mirrors

- Training (Specify)

- Procedure (Specify)

- One way system

- Drive through facility

- Speed limits (Specify)

- Traffic marshalling

- Housekeeping

- Speed checks

- High visibility clothing (EN 471)

- Other (Specify)

- Traffic management ( NRSWA )

-

What is the other control

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Pedestrian only areas

- Pedestrian free areas

- Lighting

- Barriers

- Cones

- Cordons

- Marked Pedestrian walkways

- Pedestrian crossings

- Speed limiters

- Convex mirrors

- Speed bumps

- Vehicle mirrors

- Training (Specify)

- Procedure (Specify)

- One way system

- Drive through facility

- Speed limits (Specify)

- Traffic marshalling

- Housekeeping

- Speed checks

- High visibility clothing (EN 471)

- Other (Specify)

- Traffic management ( NRSWA )

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Exposure to Hazardous Substances

-

Does the task involve exposure to fire or explosion (Flammable liquids, solids, gases, dust, oxidisers, combustibles) hazard?

-

Does the task involve exposure to hazardous substances?

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Wash out

- gas free purge

- Reduce amount of substance

- Suitable tank or container

- Suitable seals / gaskets

- Suitable hoses

- Suitable couplings/adaptors

- Dry-break couplings

- Anti drive-away interlocks

- Local extraction ventilation

- Forced air ventilation

- Natural ventilation

- Vapour recovery

- Training (specify)

- Procedure (specify)

- Housekeeping

- Atmospheric alarms

- Signage

- Labelling

- Gloves / gauntlets (EN 374)

- Overalls

- Chemical suit (EN 465)

- Dust mask

- Respirator (EN136) with suitable cartridge

- Self-Contained Breathing Apparatus

- Externally air fed hoods

- Light eye protection (EN 166)

- Goggles (EN 166)

- Full face visor (EN 166)

- Safety footwear (EN 20345)

- Safety rubber boots (EN 20345)

- Safety shower

- Eye wash bottle

- Eye wash bath

- Antidotes (specify)

- Neutralising agents (specify)

- Other (specify)

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Wash out

- gas free purge

- Reduce amount of substance

- Suitable tank or container

- Suitable seals / gaskets

- Suitable hoses

- Suitable couplings/adaptors

- Dry-break couplings

- Anti drive-away interlocks

- Local extraction ventilation

- Forced air ventilation

- Natural ventilation

- Vapour recovery

- Training (specify)

- Procedure (specify)

- Housekeeping

- Atmospheric alarms

- Signage

- Labelling

- Gloves / gauntlets (EN 374)

- Overalls

- Chemical suit (EN 465)

- Dust mask

- Respirator (EN136) with suitable cartridge

- Self-Contained Breathing Apparatus

- Externally air fed hoods

- Light eye protection (EN 166)

- Goggles (EN 166)

- Full face visor (EN 166)

- Safety footwear (EN 20345)

- Safety rubber boots (EN 20345)

- Safety shower

- Eye wash bottle

- Eye wash bath

- Antidotes (specify)

- Neutralising agents (specify)

- Other (specify)

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Fire / Explosion Hazards / Heat

-

Does the task involve being exposed to hazards created by pressure?.

-

Does the task involve exposure to heat, fire or explosion within the waste being collected

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Gain Waste Product Temperature - Max Temp 50°c

- Wash out

- Gas free purge

- Replace flammable with non-flammable substance

- Inerting (e.g. nitrogen blanket)

- Reduce inventory of flammable substance

- Explosion panels

- Bursting discs

- Pressure relief valves

- Anti drive-away interlocks

- Flame proof storage

- Separation from ignition sources

- intrinsically safe (Ex rated) equipment

- Vapour recovery system

- Earthing

- Bonding

- Flammable atmosphere alarms

- Sprinkler/drench system

- Non-sparking tools

- Training (detail)

- Procedure (detail)

- Isolation from electrical power

- Housekeeping

- Area zoning

- Fire marshals

- Inspections

- Evacuation procedure

- Signage

- Correct type of fire extinguisher (specify)

- Fire / smoke detection

- Fire alarm system

- Anti-static clothing (EN1149)

- Flame retardant clothing (EN 11612)

- Other (specify)

- Product Cool Down

-

Describe other

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Gain Waste Product Temperature - Max Temp 50°c

- Wash out

- Gas free purge

- Replace flammable with non-flammable substance

- Inerting (e.g. nitrogen blanket)

- Reduce inventory of flammable substance

- Explosion panels

- Bursting discs

- Pressure relief valves

- Anti drive-away interlocks

- Flame proof storage

- Separation from ignition sources

- intrinsically safe (Ex rated) equipment

- Vapour recovery system

- Earthing

- Bonding

- Flammable atmosphere alarms

- Sprinkler/drench system

- Non-sparking tools

- Training (detail)

- Procedure (detail)

- Isolation from electrical power

- Housekeeping

- Area zoning

- Fire marshals

- Inspections

- Evacuation procedure

- Signage

- Correct type of fire extinguisher (specify)

- Fire / smoke detection

- Fire alarm system

- Anti-static clothing (EN1149)

- Flame retardant clothing (EN 11612)

- Other (specify)

- Product Cool Down

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Where tanks or pipework is under pressure/Vacuum are non-essential personnel kept out of the area? Are hoses, adaptors etc. of correct type and adequately maintained? Are seals and gaskets of correct materials and in good order?

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Pressure / Vacuum Hazards ( This can include Hydraulic systems )

-

Does the task involve being exposed to hazards created by pressure?

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Reduce to lowest working pressure

- Pressure release valves

- Vacuum relief valves

- Vent valves

- Bursting discs

- Pressure gauges

- Anti drive away interlocks

- Suitable pressure rated hoses

- Suitable seals / gaskets

- Suitable couplings / adaptors

- Hose Lanyards

- Training

- Procedure (specify)

- Maintenance

- Statutory inspections

- Safety goggles (EN 166)

- Full face visors (EN 166)

- Light eye protection (EN 166)

- Other (Specify)

-

Describe other

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Reduce to lowest working pressure

- Pressure release valves

- Vacuum relief valves

- Vent valves

- Bursting discs

- Pressure gauges

- Anti drive away interlocks

- Suitable pressure rated hoses

- Suitable seals / gaskets

- Suitable couplings / adaptors

- Hose Lanyards

- Training

- Procedure (specify)

- Maintenance

- Statutory inspections

- Safety goggles (EN 166)

- Full face visors (EN 166)

- Light eye protection (EN 166)

- Other (Specify)

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Overfill Protection, Spill Protection, Crossover Protection

-

Is the receiving tank adequately bunded? Are there overfill protection devices such as automatic pump cut-out, automatic valve closure, high level alarms (do they sound/light in the driver’s area)? Can the driver see the level of the tank during offload by read-outs, sight gauges etc? Are spill kits, drain covers, bunding etc. to protect any local drains, grids, or watercourses available? Are receiving tanks and connections clearly and legibly labelled? Are there any other tanks on site holding other chemicals? Are adequate measures taken to protect against connection to wrong point, e.g. padlocks, electronic devices, different types of adaptor?

-

Does the task have a risk of loss of containment/Environmental contamination?

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Tank level content gauges

- Sight gauges

- Bunding

- Suitable hoses

- Suitable couplings / attachments

- Anti-drive away interlocks

- Dry break couplings

- Containers

- Drip trays

- Drain covers

- Absorbent granules

- Absorbent pads

- Absorbent booms

- Sand

- Soil

- Neutralising agents

- Training

- Procedure

- Dipping

- Weighting

- Hose tests

- Document checks

- Pre-delivery signatures

- Other

-

Describe other

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Tank level content gauges

- Sight gauges

- Bunding

- Suitable hoses

- Suitable couplings / attachments

- Anti-drive away interlocks

- Dry break couplings

- Containers

- Drip trays

- Drain covers

- Absorbent granules

- Absorbent pads

- Absorbent booms

- Sand

- Soil

- Neutralising agents

- Training

- Procedure

- Dipping

- Weighting

- Hose tests

- Document checks

- Pre-delivery signatures

- Other

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

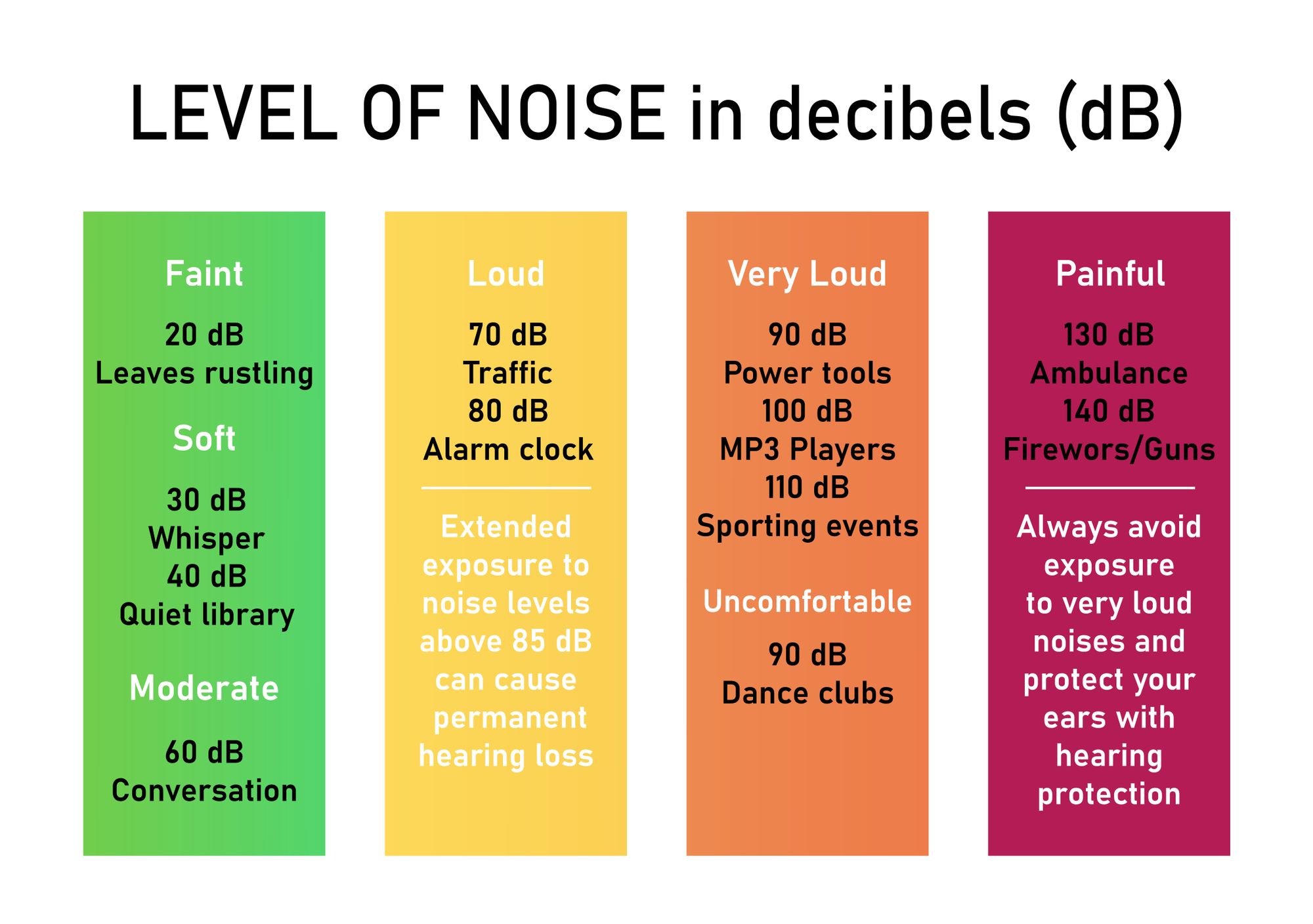

Nosie Hazards

-

Sound is measured in decibels (dB). A whisper is about 30 dB, normal conversation is about 60 dB, and a motorcycle engine running is about 95 dB. Noise above 70 dB over a prolonged period of time may start to damage your hearing. Loud noise above 120 dB can cause immediate harm to your ears.

-

Is noise a hazard when carrying out this task?

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Distance from source

- Sound proofing

- Reduced noise equipment

- Training

- Procedure

- Noise sampling

- Exclude non-essential staff for the area

- Ear plugs

- Ear defenders

- Other

-

Describe other

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Distance from source

- Sound proofing

- Reduced noise equipment

- Training

- Procedure

- Noise sampling

- Exclude non-essential staff for the area

- Ear plugs

- Ear defenders

- Other

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

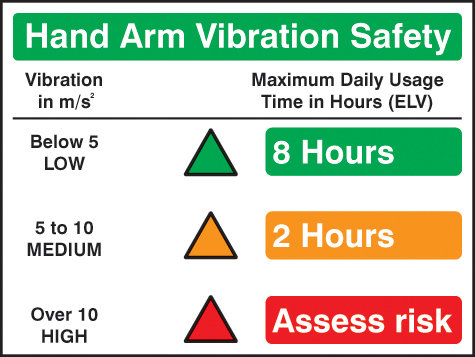

HAV - Vibration Hazard

-

📍What you should know📍. Vibration is transmitted into your hands and arms when using hand held / operated tools and machinery. Excessive exposure can affect the nerves, blood vessels, muscles and joints of the hand, wrist and arm causing Hand-Arm Vibration Syndrome (HAVS). use the HSE website https://www.hse.gov.uk/vibration/hav/vibrationcalc.htm to conduct HAV Assessments

-

Does the task have hazards that may cause Hand Arm Vibration?

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Eliminate or Reduce exposure to vibration

- Use of Lowest vibration tool

- Hand Arm Vibration Gloves

- Use devices such as jigs and suspension systems

- Procedure (Specify)

- Training (Specify)

- Monitoring exposure

- Appropriate ergonomic design

- Appropriate maintenance programmes

- Replace tools for lower vibration magnitude.

- Not on list

- Conduct a HAV RA

-

Describe other

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Eliminate or Reduce exposure to vibration

- Use of Lowest vibration tool

- Hand Arm Vibration Gloves

- Use devices such as jigs and suspension systems

- Procedure (Specify)

- Training (Specify)

- Monitoring exposure

- Appropriate ergonomic design

- Appropriate maintenance programmes

- Replace tools for lower vibration magnitude.

- Not on list

- Conduct a HAV RA

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Mechanical Hazards

-

Are there mechanical hazards to be considered when carrying out this task

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Safety tools (e.g. Captive blades)

- Fixed guards

- Adjustable guards

- Enclosures

- Interlocking guards

- Mechanical guards

- Light curtains

- Jigs

- Push sticks

- Training

- Procedure

- Maintenance

- Inspections

- Suitable gloves

- Suitable gauntlets

- Overalls

- Light eye protection

- Goggles

- Full face visor

- Other

- Mechanical Isolations

- Electrical Isolations

-

Describe other

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Safety tools (e.g. Captive blades)

- Fixed guards

- Adjustable guards

- Enclosures

- Interlocking guards

- Mechanical guards

- Light curtains

- Jigs

- Push sticks

- Training

- Procedure

- Maintenance

- Inspections

- Suitable gloves

- Suitable gauntlets

- Overalls

- Light eye protection

- Goggles

- Full face visor

- Other

- Mechanical Isolations

- Electrical Isolations

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

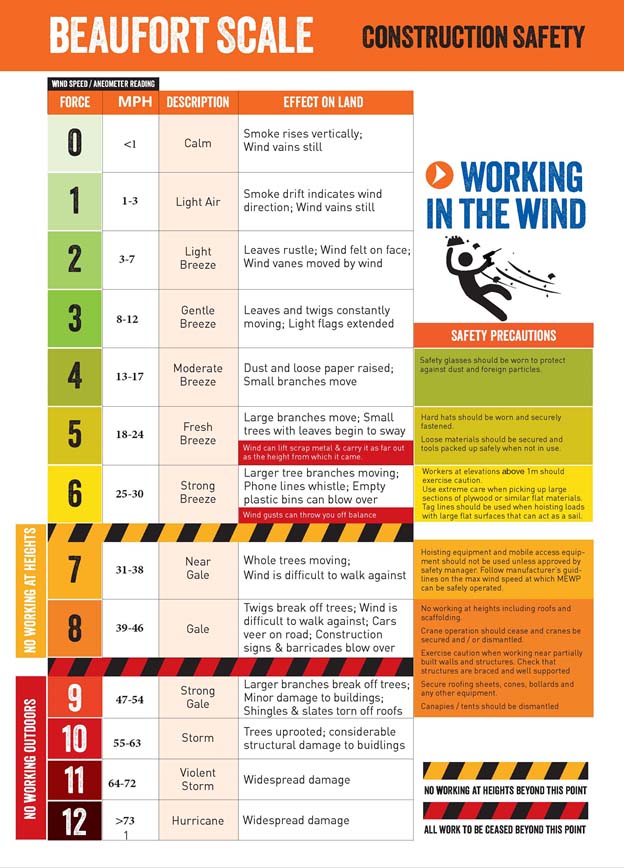

Risk of vehicle overturn or collapse

-

Check the wind speed within the area along with any access roads and loading / unloading areas. Record any Damaged or uneven ground conditions.

-

Does the task risk a vehicle overturn or collapse?

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Non-tipping (horizontal) tankers

- Speed limiters

- Tank Baffles

- Stabiliser legs

- On board weighing equipment

- Level ground

- Hard surface floor area

- Weight spreading pads/plates for landing legs

- Wind speed monitor - Anemometer

- Procedure

- Training

- Speed monitoring

- Staged lifting

- Maintenance

- Inspections

- Other

-

Describe other

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Non-tipping (horizontal) tankers

- Speed limiters

- Tank Baffles

- Stabiliser legs

- On board weighing equipment

- Level ground

- Hard surface floor area

- Weight spreading pads/plates for landing legs

- Wind speed monitor - Anemometer

- Procedure

- Training

- Speed monitoring

- Staged lifting

- Maintenance

- Inspections

- Other

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Site Lighting

-

Is general site lighting adequate, including route to and from delivery area and taking account of pedestrians? Is lighting at the delivery point sufficient to read signage, delivery notes, etc.? Are there poorly lit areas caused by position of other vehicles etc.? Does lighting encroach on mirrors while manoeuvring?

-

Does the site have sufficient lighting

-

Description of hazard.

-

What existing safeguards are in place to reduce the risk?

- Portable Lighting

- Hand held Torch

- Head Torch

- Daylight working hours

- Regular maintenance of onsite lighting

- Hazard beacons

- Atex Lighting

- Vehicle work Lights

- Visible Floor markings

- Emergency lighting

- Automatic Lighting

- Reduction of shadows wihtin the working area

-

Describe other

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Portable Lighting

- Hand held Torch

- Head Torch

- Daylight working hours

- Regular maintenance of onsite lighting

- Hazard beacons

- Atex Lighting

- Vehicle work Lights

- Visible Floor markings

- Emergency lighting

- Automatic Lighting

- Reduction of shadows wihtin the working area

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Is signage on the site adequate and clear? Does it indicate the direction of travel, i.e. one-way systems, max speed on-site? Does it cover the site hazards, any site procedures and requirements? Does it detail any fire routes, assembly points, first aid etc.?

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Lone Working

-

Does the task involve lone working hazards?

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- G7 Gas Detector with Fall / Bump / GPS detection

- Mobile Phone Communication

- Onsite CCTV

- Procedure ( Specify )

- Vehicle CCTV

- Lone Working Risk Assessment

- Driver / Operator Mental Risk Assessment

- Training

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Additional staff

- Mobile phone

- 2-way radios

- CCTV

- Vehicle telematics

- Training

- Procedure

- Other

- Lone Worker device

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Site Security

-

Does the security of people, buildings or property represent a hazard when carrying out this task?

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Fencing

- Gates

- Locks

- Key code access

- Access cards

- CCTV

- Mobile phones

- Security guards

- Security barriers

- Training

- Procedure

- Checks

- Security patrols

- I.D. Cards / documents

- Tracking devices

- Dangerous load cards

- Numbered seals

- Other

-

Describe other

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Fencing

- Gates

- Locks

- Key code access

- Access cards

- CCTV

- Mobile phones

- Security guards

- Security barriers

- Training

- Procedure

- Checks

- Security patrols

- I.D. Cards / documents

- Tracking devices

- Dangerous load cards

- Numbered seals

- Other

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Confined Space Hazards

-

Does the task require the enter of confined spaces? (Tank entry, maintenance pits etc)

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Gas purging of vessel

- Forced air ventilation

- Local extraction ventilation

- Natural ventilation

- Confined space training

- Tank entry procedure and permit

- Pre-entry atmospheric testing

- Designated watcher

- Klaxon/alarm

- Wash-out of vessel

- Lighting

- Intrinsically safe electrical equipment

- Non-sparking tools

- Access ladders

- Safety harness with lifeline

- Rescue block

- Stretcher/spinal board

- Respirator with suitable cartridge

- Self-contained breathing apparatus

- Air fed hood – belt pack

- Air fed hood – external air supply

- Escape mask/hood

- Personal atmospheric monitor/alarm

- Lone Worker monitoring device - Blackline

- 2-way radio

- Other

-

Describe Other

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Gas purging of vessel

- Forced air ventilation

- Local extraction ventilation

- Natural ventilation

- Confined space training

- Tank entry procedure and permit

- Pre-entry atmospheric testing

- Designated watcher

- Klaxon/alarm

- Wash-out of vessel

- Lighting

- Intrinsically safe electrical equipment

- Non-sparking tools

- Access ladders

- Safety harness with lifeline

- Rescue block

- Stretcher/spinal board

- Respirator with suitable cartridge

- Self-contained breathing apparatus

- Air fed hood – belt pack

- Air fed hood – external air supply

- Escape mask/hood

- Personal atmospheric monitor/alarm

- Lone Worker monitoring device - Blackline

- 2-way radio

- Other

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Electrical Systems

-

Does the task require interaction with electrical systems that could be a hazard? (Work with or maintain electrical systems, machines or tools)

-

Describe the hazard

-

Who's at risk?

- Suttons worker

- Site staff

- Members of the public

- Representatives from other hauliers - e.g. Drivers

- Other

-

What existing safeguards are in place to reduce the risk?

- Isolation of power (including lock out / tag out)

- Work at reduced voltage

- Low voltage tools

- Use of fixed electrical power tools

- Battery powered hand-tools

- RCD

- Circuit breakers

- Correctly rated fuses

- Non-conducting tools

- Non-conducting ladders

- Certified workers

- Training

- Procedure

- Inspections

- PAT testing

- Maintenance

- Pre-use checks

- Insulated gloves

- Insulated footwear

- Insulated clothing

- Insulated mats

- Other

-

Describe other

-

Initial likelihood

-

Initial consequence

-

Initial risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

If the risk value is 16 or higher then additional controls need to be found to reduce this risk. If the value is between 9 and 15 then additional controls should be put in place if reasonably practical to do so. If the risk is considered lower than 9 then cost effective improvements should still be recommended.

-

Should additional controls be put in place?

-

Select control measures

- Isolation of power (including lock out / tag out)

- Work at reduced voltage

- Low voltage tools

- Use of fixed electrical power tools

- Battery powered hand-tools

- RCD

- Circuit breakers

- Correctly rated fuses

- Non-conducting tools

- Non-conducting ladders

- Certified workers

- Training

- Procedure

- Inspections

- PAT testing

- Maintenance

- Pre-use checks

- Insulated gloves

- Insulated footwear

- Insulated clothing

- Insulated mats

- Other

-

Describe other

-

Residual likelihood

-

Residual consequence

-

Residual risk rating

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

Summary and Sign-Off

Completion

-

In the box below you need to copy the score from the highest risk that has been encountered in the initial assessment. This best represents the risk for this activity and is the one that the business will base conducting the activity on. If in doubt ask.

-

Create a PDF of this report and email to the appropriate recipient

-

Overall risk rating with existing controls

- 25

- 20

- 16

- 15

- 12

- 10

- 9

- 8

- 6

- 5

- 4

- 3

- 2

- 1

-

Summary of the risk assessment

-

Is a periodic review of this risk assessment required?

-

On completion of risk assessment go into Schedule a set a review date - tip - control and c on the title of the risk assessment and paste it into the schedule to replace the template name

-

Note - All risk assessments shall be subject to periodic review unless it is for a one-off task that will not be repeated

-

Signature