Title Page

-

Site conducted

-

Diary started date & time

-

Area Manager

- Darren Partridge

- Len Edwards

- Jon Adams

- Mark Robinson

- Phil Bosomworth

- Simon Griffiths

- Dominic Rowley

Kitchen Opening

Section 1 - Daily Kitchen Opening Checks

-

1.1 Are the kitchen team wearing the correct uniform?

-

1.2 Is the standard of cleaning reflective of yesterdays daily cleaning schedule?

-

1.3 Are the hand wash facilities all fully stocked with soap, disposable drying towels and hot water available?

-

1.4 Are there separate indicated bottles of correctly diluted 802 available for raw and ready to eat?

-

1.5 Are all fridges and freezers operating within the critical limits and all food is in date?

-

1.6 Is there separate, clearly defined colour coded equipment and PPE (aprons, gloves and clingfilm holders) for preparation of raw and ready to eat foods available?

-

1.7 Is there a clearly defined and separate raw food preparation area available that is clearly marked with signage?

-

1.8 Are there 2 fully working, cleaned, numbered and sanitised probes available?

-

1.9 Are the Chargrill trays clean and free from grease and filled with ice or water? (these should also be checked at points through the day) USE N/A IF NO CHARGRILL IN KITCHEN

-

1.10 Choose 3 hand contact points. Are they clean and free from grease and food debris?

-

1.11 Has all faulty equipment been logged or chased for repair?

-

1.12 Name & signature of person completing opening tasks

Section 2 - (SOP 3) AM Fridge Temperatures (all units below 5°c) - Every Monday AM you must check every unit with a food probe to ensure temperature. Temperature must be recorded with (.) to indicate a probe used i.e. 3.4°c

-

2.1 AM Fridge 1

-

2.2 AM Fridge 2

-

2.3 AM Fridge 3

-

2.4 AM Fridge 4

-

2.5 AM Fridge 5

-

2.6 AM Fridge 6

-

2.7 AM Fridge 7

-

2.8 AM Fridge 8

-

2.9 AM Fridge 9

-

2.10 AM Fridge 10

-

2.11 AM Fridge 11

-

2.12 AM Fridge 12

Section 3 - (SOP 4) AM Freezer Temperatures (all units below -18°c) - Every Monday AM you must check every unit with a food probe to ensure temperature. Temperature must be recorded with (.) to indicate a probe used i.e. 3.4°c

-

3.1 AM Freezer 1

-

3.2 AM Freezer 2

-

3.3 AM Freezer 3

-

3.4 AM Freezer 4

-

3.5 AM Freezer 5

-

3.6 AM Freezer 6

-

3.7 AM Freezer 7

-

3.8 AM Freezer 8

-

3.9 AM Freezer 9

-

3.10 AM Freezer 10

-

3.11 AM Freezer 11

-

3.12 AM Freezer 12

Working Day

Section 4 - (SOP 1) Daily Delivery Temperature Monitoring

-

4.0 Any deliveries today?

-

4.1 Please select supplier

-

4.3 Product checked

4.4 Delivery temperature

-

Delivery 2

-

4.5 Please select supplier

-

4.6 Product checked

4.7 Delivery temperature

-

Delivery 3

-

4.8 Please select supplier

-

4.9 Product checked

4.10 Delivery temperature

-

Delivery 4

-

4.11Please select supplier

-

4.12 Product checked

4.13 Delivery temperature

Section 5 - (SOP 10) Cooling - Total cooling time must not exceed 4 hours (90 minutes to room temperature, then 2 hours 30 minutes to get below 5°c) (If using a blast chiller please record final cooling temperature in the temperature after 90 minutes and write (BC in notes) ensuring that the total cooling time is recorded as 90 minutes)

-

5.0 Has any cooling been completed today?

-

5.1 Name of product being cooled 1

5.2 Final cook temperature (must be above 75°c) 1

-

5.3 Enter date & time of cooling started 1

-

5.4 Time product placed in chiller 1

-

5.5 Click to enter time of final check (should be total of no more than 4 hours after start time) 1

5.6 Record temperature after a further 2 hours and 30 minutes 1

-

2nd Cooling

-

5.7 Name of product being cooled

5.8 Final cook temperature (must be above 75°c)

-

5.9 Enter date & time of cooling started

-

5.10 Time product placed in chiller

-

5.11 Click to enter time of final check (should be total of no more than 4 hours after start time)

5.12 Record temperature after a further 2 hours and 30 minutes

-

3rd Cooling

-

5.13 Name of product being cooled

5.14 Final cook temperature (must be above 75°c)

-

5.15 Enter date & time of cooling started

-

5.16 Time product placed in chiller

-

5.17 Click to enter time of final check (should be total of no more than 4 hours after start time)

5.18 Record temperature after a further 2 hours and 30 minutes

-

4th Cooling

-

5.19 Name of product being cooled 1

5.20 Final cook temperature (must be above 75°c) 1

-

5.21 Enter date & time of cooling started 1

-

5.22 Time product placed in chiller 1

-

5.23 Click to enter time of final check (should be total of no more than 4 hours after start time) 1

5.24 Record temperature after a further 2 hours and 30 minutes 1

Section 6 - (SOP 9 & 11) Cooking & Reheating - Core temperature must reach 75°c

-

6.1 Name of product being cooked

-

6.2 Cooked or Reheated

-

6.3 Cook method used

- Char grill

- Clam grill

- Overhead grill

- Fryer

- Microwave

- Combi oven

- Range or Hob Top

- Pizza oven

- Oven

6.4 Temperature recorded

-

Item 2

-

6.5 Name of product being cooked

-

6.6 Cooked or Reheated

-

6.7 Cook method used

- Char grill

- Clam grill

- Overhead grill

- Fryer

- Microwave

- Combi oven

- Range or Hob Top

- Pizza oven

- Oven

6.8 Temperature recorded

-

Item 3

-

6.9 Name of product being cooked

-

6.10 Cooked or Reheated

-

6.11Cook method used

- Char grill

- Clam grill

- Overhead grill

- Fryer

- Microwave

- Combi oven

- Range or Hob Top

- Pizza oven

- Oven

6.12 Temperature recorded

-

Item 4

-

6.13 Name of product being cooked

-

6.14 Cooked or Reheated

-

6.15 Cook method used

- Char grill

- Clam grill

- Overhead grill

- Fryer

- Microwave

- Combi oven

- Range or Hob Top

- Pizza oven

- Oven

6.16 Temperature recorded

-

Item 5

-

6.17Name of product being cooked

-

6.18 Cooked or Reheated

-

6.19 Cook method used

- Char grill

- Clam grill

- Overhead grill

- Fryer

- Microwave

- Combi oven

- Range or Hob Top

- Pizza oven

- Oven

6.20 Temperature recorded

-

Item 6

-

6.21 Name of product being cooked

-

6.22 Cooked or Reheated

-

6.23 Cook method used

- Char grill

- Clam grill

- Overhead grill

- Fryer

- Microwave

- Combi oven

- Range or Hob Top

- Pizza oven

- Oven

6.24 Temperature recorded

Section 7 - (SOP 12) Hot Holding Food (+ symbol for additional delivery records) Hot held food must be above 63°c at all times for a maximum of 2 hours. If it falls below this temperature then it must be used or discarded. Hourly monitoring of temperatures must be recorded below.

-

7.0 Any hot holding today?

-

7.1 Name of product being hot held

-

7.2 Date & time placed in to hot hold

-

7.3 Temperature when placed into hot hold

7.4 Temperature after 1 hour (must be above 63°c)

-

7.5 Time of 1 hour check

7.6 Temperature after 2 hours (must be above 63°c)

-

7.7 Time of 2 hour check

-

Hot hold 2

-

7.8 Name of product being hot held

-

7.9 Date & time placed in to hot hold

-

7.10 Temperature when placed into hot hold

7.11 Temperature after 1 hour (must be above 63°c)

-

7.12 Time of 1 hour check

7.13 Temperature after 2 hours (must be above 63°c)

-

7.14 Time of 2 hour check

-

Hot hold 3

-

7.15 Name of product being hot held

-

7.16 Date & time placed in to hot hold

-

7.17 Temperature when placed into hot hold

7.18 Temperature after 1 hour (must be above 63°c)

-

7.19 Time of 1 hour check

7.20 Temperature after 2 hours (must be above 63°c)

-

7.21 Time of 2 hour check

-

Hot hold 4

-

7.22 Name of product being hot held

-

7.23 Date & time placed in to hot hold

-

7.24 Temperature when placed into hot hold

7.25 Temperature after 1 hour (must be above 63°c)

-

7.26 Time of 1 hour check

7.27 Temperature after 2 hours (must be above 63°c)

-

7.28 Time of 2 hour check

Kitchen Close

Section 8 - (SOP 3) PM Fridge Temperatures (all units below 5°c)

-

8.1 PM Fridge 1

-

8.2 PM Fridge 2

-

8.3 PM Fridge 3

-

8.4 PM Fridge 4

-

8.5 PM Fridge 5

-

8.6 PM Fridge 6

-

8.7 PM Fridge 7

-

8.8 PM Fridge 8

-

8.9 PM Fridge 9

-

8.10 PM Fridge 10

-

8.11 PM Fridge 11

-

8.12 PM Fridge 12

Section 9 - (SOP 4) PM Freezer Temperatures (all units below -18°c)

-

9.1 PM Freezer 1

-

9.2 PM Freezer 2

-

9.3 PM Freezer 3

-

9.4 PM Freezer 4

-

9.5 PM Freezer 5

-

9.6 PM Freezer 6

-

9.7 PM Freezer 7

-

9.8 PM Freezer 8

-

9.9 PM Freezer 9

-

9.10 PM Freezer 10

-

9.11 PM Freezer 11

-

9.12 PM Freezer 12

Section 10 - Daily Kitchen Close Checks

-

10.1 No out of date food has been left in any of the fridge/freezer or dry store area's?

-

10.2 Is all food stored correctly, separating raw and cooked items and containing the correct day dot or food label where applicable?

-

10.3 Are the hand wash facilities all fully stocked with soap, disposable drying towels and hot water available?

-

10.4 All fridges and freezers are operating within critical limits and temperatures have been recorded twice for each unit?

-

10.5 Are there separately indicated bottles of correctly diluted 802 & available for Raw & Ready To Eat?

-

10.6 Have all food preparation and hand contact points been cleaned following the 2 stage clean method?

-

10.7 Have the bins and floor been cleaned to a high standard and left ready for the start of the next days service?

-

10.8 Are there clean oven mitts/gloves available for the next days service?

-

10.9 Have all utensils been cleaned and sanitised, checked for damages and placed back into correct storage area's?

-

10.10 Has all daily / weekly cleaning been completed with any issues logged with corrective actions where required?

-

Name & signature of person completing close tasks

Cleaning

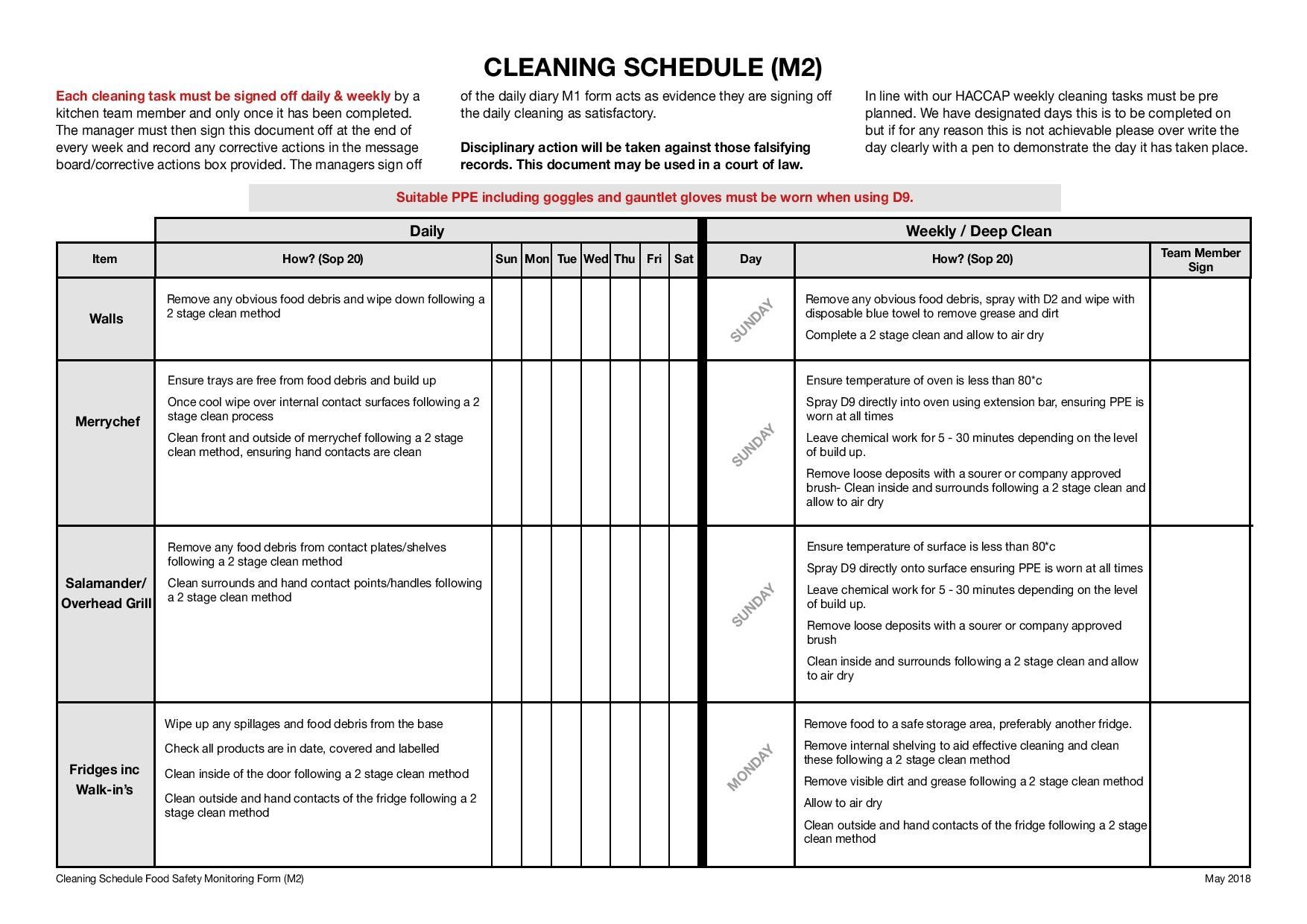

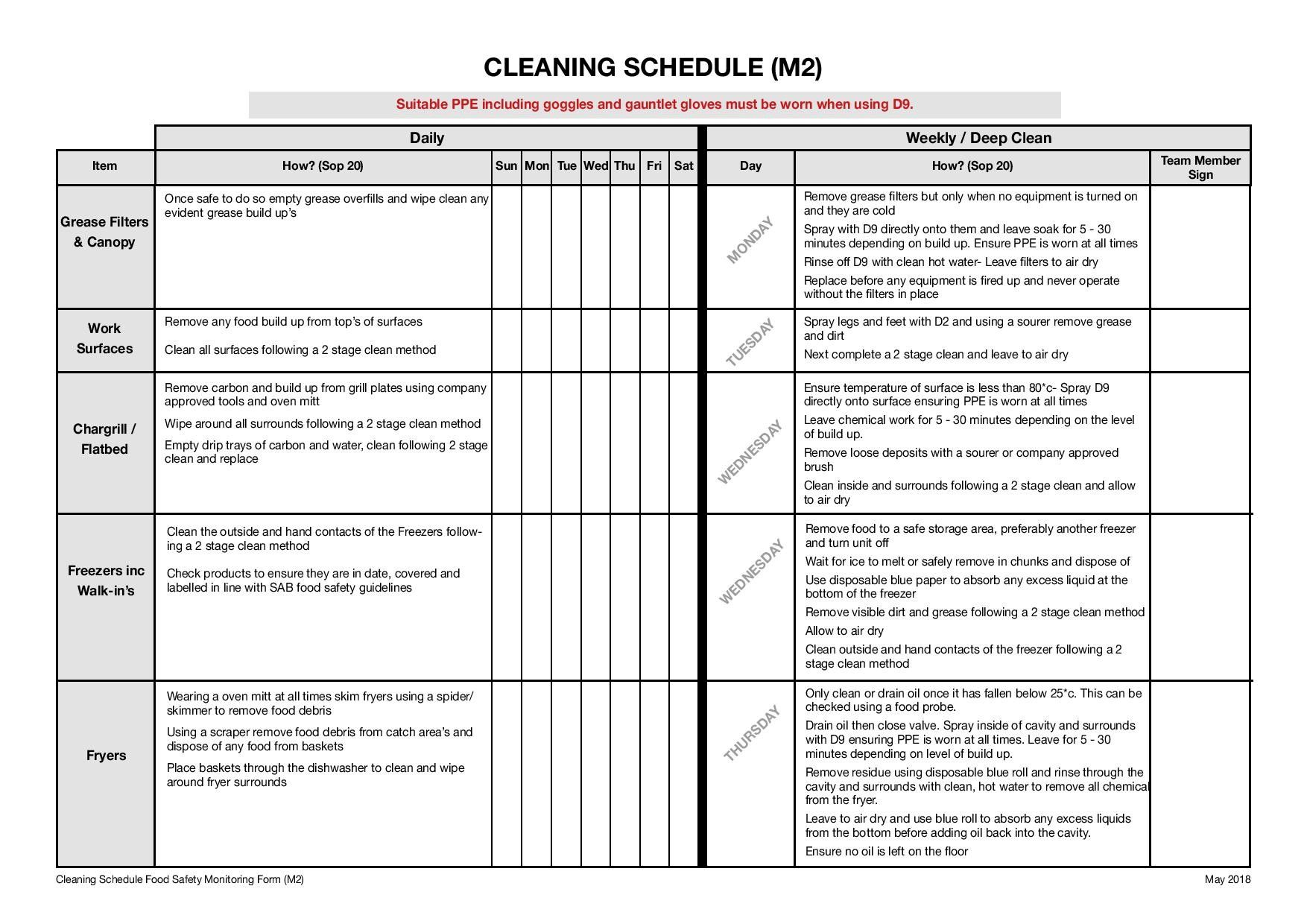

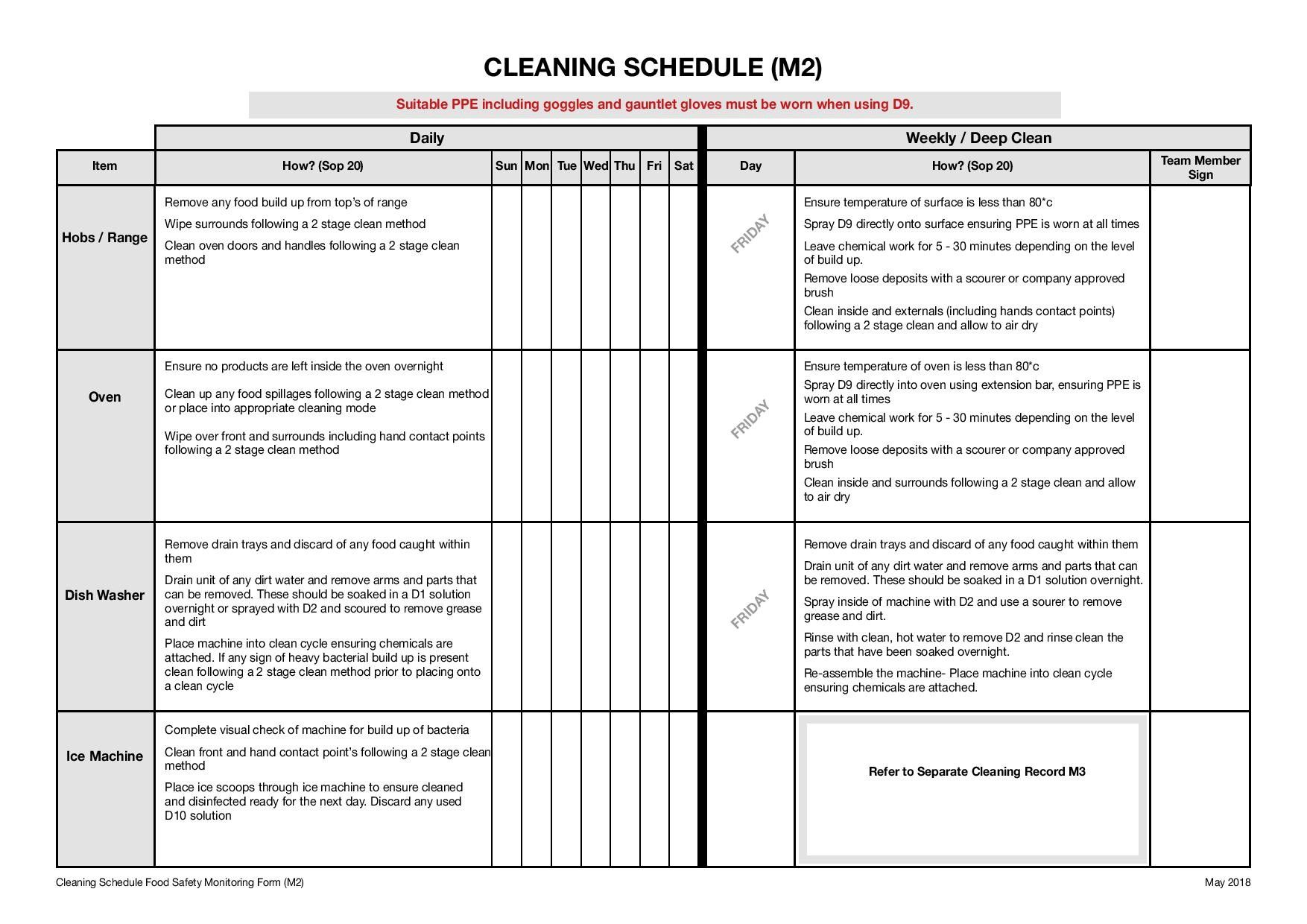

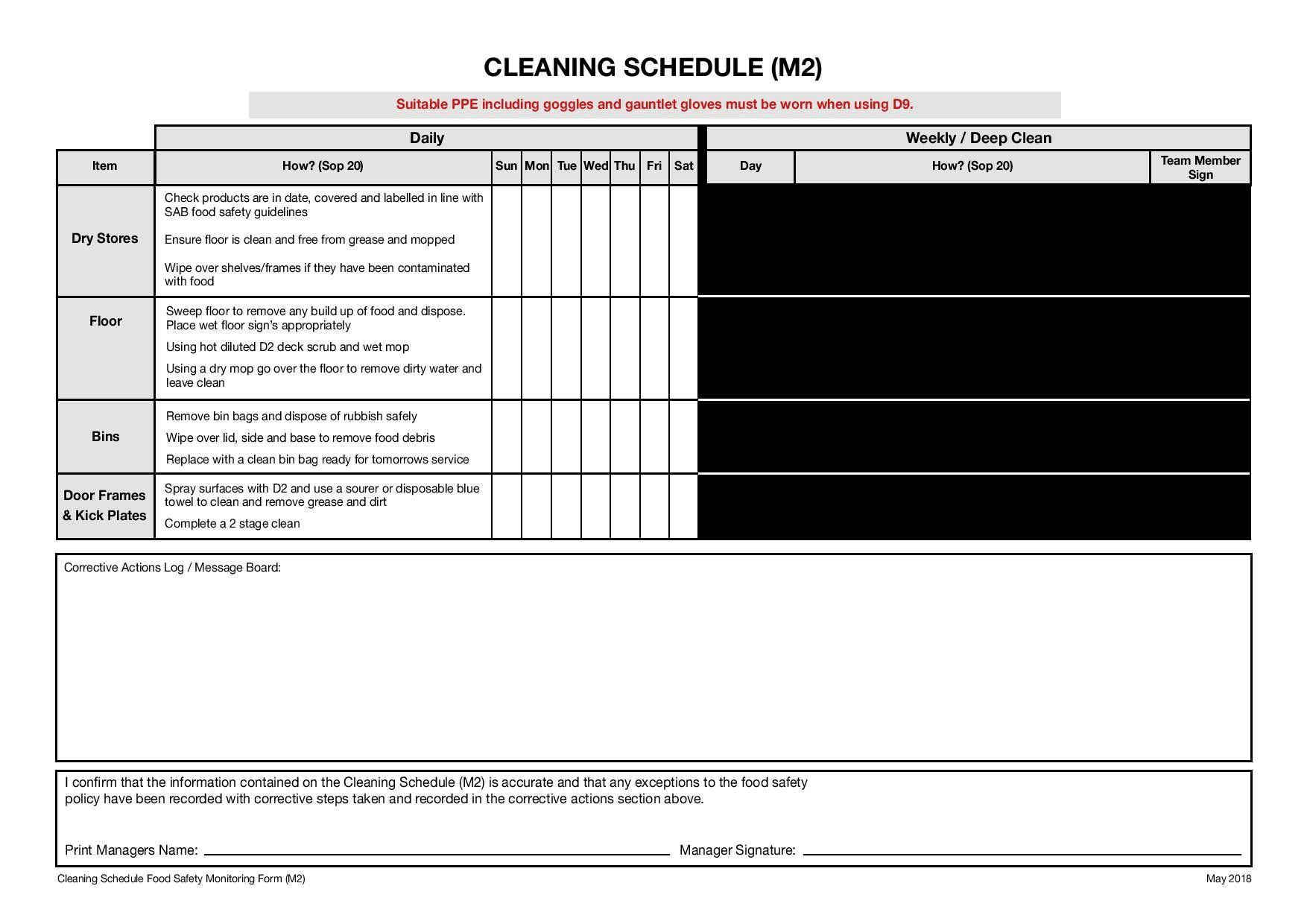

Section 11 - (SOP 20) M2 Daily / Weekly Cleaning

-

Click to see image of cleaning schedule page 1

-

Click to see image of cleaning schedule page 2

-

Click to see image of cleaning schedule page 3

-

Click to see image of cleaning schedule page 4

-

11.1 Has all daily cleaning been completed with any issues logged with corrective actions where required? Select each item below to confirm it has had a daily clean and meets the minimum standard as outlined within your wall mounted cleaning schedule.

- Walls

- Merrychef

- Overhead grill

- Fridges inc Walk-in's

- Grease filters & canopy

- Work surfaces

- Char grill / Flatbed grill / Clam grill

- Freezers inc Walk-in's

- Fryers

- Hobs / Range

- Oven

- Dish washer

- Ice machine

-

11.2 Please take a picture of the kitchen to demonstrate cleanliness

-

11.3 Name & signature of person confirming cleaning

Weekly Cleaning

-

11.4 Has weekly cleaning been completed today, as per cleaning schedule? Select each item below to confirm which item has been cleaned

- Walls

- Merrychef

- Overhead grill

- Fridges inc Walk-in's

- Grease filters & canopy

- Work surfaces

- Char grill / Flatbed grill / Clam grill

- Freezers inc Walk-in's

- Fryers

- Hobs / Range

- Oven

- Dish washer

- Ice machine

-

11.5 Please take a picture of the kitchen to demonstrate cleanliness

-

11.6 Name & signature of person confirming cleaning

M4 - Less Frequent

Section 12 - (SOP 18) Probe calibration (to be completed once a month)

-

Probe 1

12.1 Reading In Hot Water

12.2 Reading In Ice Water

-

12.3 Name Of Checker

-

Probe 2

12.4 Reading In Hot Water

12.5 Reading In Ice Water

-

12.6 Name Of Checker

-

Probe 3

12.7 Reading In Hot Water

12.8 Reading In Ice Water

-

12.9 Name Of Checker

-

Probe 4

12.10 Reading In Hot Water

12.11 Reading In Ice Water

-

12.12 Name Of Checker

Section 13 - (SOP 16) Transportation of food between pubs

-

13.0 Pub received from / transferring to

-

13.1 Product being transferred

-

13.2 Temperature (°c) on leaving / receiving

-

13.3 Chilled or frozen

-

13.4 Name & signature of person transferring

-

Item 2

-

13.5 Pub received from / transferring to

-

13.6 Product being transferred

-

13.7 Temperature (°c) on leaving / receiving

-

13.8 Chilled or frozen

-

13.9 Name & signature of person transferring

-

Item 3

-

13.10 Pub received from / transferring to

-

13.11 Product being transferred

-

13.12 Temperature (°c) on leaving / receiving

-

13.13 Chilled or frozen

-

13.14 Name & signature of person transferring

Section 14 -(SOP9) - Cooking Red Meat Joints below 75°c (not boned and rolled) The temperature of each red meat joint must be recorded once it has left the oven if it is being cooked to a temperature below 75°c. The core temperature must reach a minimum of 58°c. The joints can be carved and held under the lights for up to 2 hours or carved and served immediately. After 2 hours any remaining meat under the lights must be discarded and recorded as used or discarded. (This product cannot therefore be chilled, frozen or reheated)

-

14.1 Red meat joint

14.2 Temperature of red meat joint

-

Red meat joint 2

-

14.3 Red meat joint

14.4 Temperature of red meat joint

-

Red meat joint 3

-

14.5 Red meat joint

14.6 Temperature of red meat joint

-

Red meat joint 4

-

14.7 Red meat joint

14.8 Temperature of red meat joint

-

Red meat joint 5

-

14.9 Red meat joint

14.10 Temperature of red meat joint

-

Red meat joint 6

-

14.11 Red meat joint

14.12 Temperature of red meat joint

-

Red meat joint 6

-

14.13 Red meat joint

14.14 Temperature of red meat joint

-

Red meat joint 6

-

14.15 Red meat joint

14.16 Temperature of red meat joint

Sign off

Section 15 - Additional Corrective Actions / Message Board

-

15.1 Any corrective actions today?

Additional Corrective Actions

-

Additional actions

Section 16 COMPLETION

-

This Daily Temperature Monitoring Form is a legal document and will be used as evidence of effective due diligence should it ever be required.

This form should be completed daily, honestly and accurately in line with the SA Brain Food Safety Policy. Any one found to be falsifying the documents will be dealt with through the companies disciplinary processes.

1. Where the temperature recorded is in the critical limits set there are no corrective actions required and the temperature will turn Green once entered.

2. Should the temperature fall outside of the critical limits then immediate corrective actions must be recorded below that items using the "Action" option. Failure to use this will result in a 20 point deduction on your internal food safety audit and also render the document ineffective as due diligence.

PLEASE REMEMBER TO APPLY CORRECTIVE ACTIONS FOR EVERY INDIVIDUAL UNIT OUT OF CRITICAL LIMITS -

I confirm that the information contained on today's Daily Diary (M1) is accurate and that any exceptions to the food safety policy have been recorded with corrective steps and recorded in the corrective actions sections in the above audit

-

16.1 Name & signature of chef on duty

-

16.2 Name & signature of Duty Manager

-

16.3 Diary completed date & time