Title Page

-

Date of audit

-

Scope the audit

-

Prepared by

General Information

-

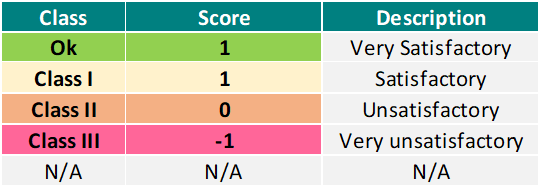

Score Ranking

-

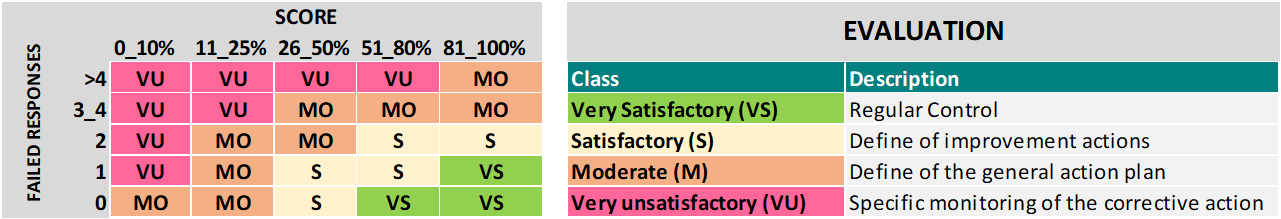

Evaluation Chart

-

All the items with Class III score must be defined at least one corrective action.

-

In the items with Class II & III score should be added an evidence or the issue description

A) HSE Management

-

The questions marked with "C" (critical question), the section of Class III will be taken as Failed response in the final result of the audit

1.0 Pre audit checks

-

1.1 When was the last audit completed for the site and are all actions identified completed?

-

1.2 Where H&S actions are identified, are root causes identified and corrective action taken?

2.0 HS management systems

-

2.1 QHSE Policy up to date and well publicized?

-

2.2 Are site objectives and targets set and are they on site ?

-

2.3 Does the site have a Health and Safety board and is all information correct and current?

-

2.4 Accidents, Near Miss, Incidents reported (Procedure known/ last NM Reported/ Investigations completed) "C"

-

2.5 System to ensure investigations are done, closed out rate measured, corrective action taken and effectives.

-

2.6 QHSE procedures manual (or equivalent) exists and is readily available?

-

2.7 KPI's and PPI's set for the facility and measurements of performance made?

-

2.8 Review the general safety documents; Emergency Plan, Risk Assesment.. Check if is updated, is available on site "C"

-

2.9 QHSE Performance reported to the workgroups and the company?

3.0. Environmental/Welfare Management

-

3.1 Welfare facilities suitable for the needs of the area

-

3.2 Sanitation, washing facilities

-

3.3 The toilet facilities has sanitary water, cleaning papel dispenser...

-

3.4 Drinking water available

-

3.5 Septic and Water tank are installed properly and there is a peridically maintenance and inspection systm

-

3.6 Waste management coordinator appointed.

-

3.7 Environmental hazards properly controlled

-

3.8 Environmental impact assessment done for the site, reviewed and maintained & stored in the sites dossier? "C"

-

3.9 Waste and effluent stream monitoring and reporting in place and consistent with regulatory requirements

-

3.10 Waste survey completed and waste reduction targets set?

-

3.11 Waste segregated (chemical, contaminated packaging. Separate and labelling of waste types with MSDSs?

-

3.12 Waste disposal via accredited contractors with tracking? "C"

-

3.13 Spill kits available and fit for purpose? Who inspects and are records available? (Staff trained in use)

4.0 Emergency Management.

-

4.1 Emergency plan prepared and current periodic updated? "C"

-

4.2 Emergency plan defines actions for incident scenarios including fire.

-

4.3 Emergency assembly point defined, signed and appropriate.

-

4.4 Emergency plan including command structure

-

4.5 Has the site a up to date Fire Risk Assessment? (Who completed/ when/ outstanding actions/ next review date) "C"

-

4.6 Has all ignition/ fuel sources been identified and controlled? (Gas bottles/ fixed wiring/ gas heating)

-

4.7 Emergency drills done

-

4.8 Staff have appropriate knowledge and training in fire procedures (Who has received training/ when)

-

4.9 Check First-aid kit (take a picture of the First-aid kit, add comments)

5.0 Regulatory Compliance Review

-

5.1 Register available on site of applicable Acts, regulations, permit, license, code of practise etc.. A register maintained under document control? "C"

-

5.2 Environmental license or requierments held (NIMA, Registered in the Registry of Small Producers of Hazardous Wastes, DIA, etc.) "C"

-

5.3 Awareness training on regulations for staff

6.0 Control of Contractors.

-

6.1 Procedure for management of contractors with selection based on competence checks.

-

6.2 System of contractor site induction, emergency and hazard training; health assessment where appropriate? "C"

-

6.3 Conductors working on site produce equipment inspections and are controlled by permit to work where appropriate?

-

6.4 Staff have appropriate knowledge and training in the management of contractors procedure?

-

6.5 Inspections plan to contractor was implemented?, is there any safety inspection/audit to contractor?

-

6.6 Access Control system is implemented on site "C"

B) General Factilities; Subestation, WTG, PV Plant, Warehouse, etc.

7.0 Check the conditions of the access roads, ditches, vegetation...

-

7.1 Check the conditions of the access roads, ditches, vegetation...

-

7.2 There is info Pannel or signs with the main access and the general safety norms of the site

8.0 Command Building

-

8.1 General cleanliness of all areas

-

8.2 Housekeeping standard clearly set, inspected and enforced

-

8.3 Unobstructed routes and width adequate for needs

-

8.4 Smoking controls in place with designated smoking area.

-

8.5 Lighting ventilation etc. satisfactory for the area and working correctly

-

8.6 Storage facilities neat, tidy, signed and accessible

-

8.7 Check safety signs (emergency posters, extinguishers posters, electrical risk, first-aid kit posters, signs of do not enter ins restricted areas, evacuation map, coordenates map of the site...) "C"

-

8.8 Evacuation routes are free from obstructions (Periodically inspections completed/ by whom)

-

8.9 Emergency exit marked and checked for appropriateness

-

8.10 Emergency lighting (last service date/ Monthly inspections completed/ whom)

-

8.11 Fire detection system installed (smoke, heat detectors)

-

8.12 Fire alarm tests and drills completed (service date/ weekly test, using various call points/ 6 monthly fire evacuation)

-

8.13 Emergency equipment e.g. Fire extinguishers (last service date/ Monthly inspections completed/ whom) "C"

-

Checked accessibility, good apparent condition of conservation, insurance, seals, inscriptions, hose, etc.

Checked the state of charge (weight and pressure) of the extinguisher and the gas pump bottle (if any) state of the mechanical parts (nozzles, valves, hoses, etc)

Check the correct fire control system, fire dections, (if is aplicable) -

8.14 Emergency equipment and exits signage are free of obstruction

-

8.15 Check general waste disposal state (organisation, cleanliness, element disposal and identification, possible waste leaks...)

9.0 Sites

-

Facilities Audited

-

9.1.1 The equipments were checked and were installed properly

-

9.1.2 Is there electrical safety equipments to make the manoeuvres in electrical cabinets and electrical subestation, such as insulating carpet, dielectrical gloves, voltage tester, etc.

-

9.1.2.1 The equipments were checked and were installed properly "C"

-

9.2.1 Check the state of electrical equipment; fenses, signs, etc.

-

9.2.2 Is there electrical safety equipments to make the manoeuvres in electrical cabinets and electrical subestation, such as insulating carpet, dielectrical gloves, voltage tester, etc.

-

9.2.2.1The equipments were checked and were installed properly "C"

-

9.2.3 Management system or control of the fauna and vegetation on plant

-

9.3.1. Check the state of wind turbine identification mark

-

9.3.2 Check cleanliness on the outside of the wind turbine

-

9.3.3 Check the external stairs (possible damage, missing components or other defects)

-

9.3.4 . Check the state of the main door and lock state

-

9.3.5 Check interior WTG lighting and emergency lighting

-

9.3.6 Check the signs in turbine; Coordenates Map, 5 Golden Rules, electrical risk, Emergency contact numbers...

-

9.3.7 WTG state of the cleaning

-

9.3.8 Check the state and inspection card of Fire Extinguisher

-

9.3.9 Check the state and inspection cards of Lift Cabine and Safety Line "C"

-

Lift; Check the correct status of the lift, the periodical annual official inspection is done, the instructions manual is updated and available, the dialy check control is available in the lift.

Safety line; to the annual official inspection is done, the safety line has CE certificate , and is signed the number of persons can use the safety line -

9.3.10 Check condition of the fall protection system at the platforms (anchor points)

-

9.3.11 Check de anchorage system of the lift (shackles, sling, anchorage point, etc.)

-

9.3.12. State of supports and fastening bolts of the brake system

-

9.3.13 Check the state of chain hoist (correct state fixings, absence of abnormal noises or oil leakage)

-

9.3.14 Check the nacelle Rescue Device (if applicable) is checked and updated "C"

-

9.3.15 Check of the evacuation signaling; anchorage point , evacuation exits, etc.

-

Obs.:

-

9.4.1 The Warehouse is in correct status of clean and order, the shelf system is proper to the different material, components, etc.

-

9.4.2 Good housekeeping prevents building up of combustible, waste or chemicals spillage)

-

9.4.3 Segregation of inappropriate materials/ reactants (Bleaches/ disinfectant/ food stuffs/ consumables)

-

9.4.4 Enough ventilation on chemical storage facility/ warehouse

-

9.4.5 Overloaded racking/poor stacking practices (Pyramid stacking)

-

9.4.6 Bulk stacks for stability (Overloaded pallets at height)

-

9.4.7 Damaged racks/stacks/pallets etc (Are inspections completed and by who/ what training has been received)

-

9.4.8 Aisles for accessibility (Blocked aisles/ fire escape routes)

-

9.4.9 Flammable/hazardous materials stored appropriately and locked away where neccesary "C"

C) O&M Activities

10.0 DOCUMENTACION/Documentation

-

10.1 Se dispone de permiso de trabajo/ It is available the work permit on site "C"

-

10.2 Existe plan de seguridad/evaluación de riesgos/ the HS Plan or Risk Assesment is available and updated on site "C"

-

10.3 La documentación de seguridad se encuentra correcta y actualizada/ The safety documentation (paperwork) is correct and updated "C"

11.0 SEÑALIZACION & PROTECCIONES COLECTIVAS/ Signalling & Collective Protection

-

11.1 La zona de trabajo se encuentra señalizada con los riesgos existentes/ The work area is signed with the main risks

-

11.2 Los huecos, aberturas, o desniveles se encuentran correctamente protegidos, con barandillas, barreras, etc./ the holes and gaps are protected properly with handrails, barriers, etc.

-

11.3 El vallado o cierre perimetral de la instalación se encuentran en buen estado/ The installation of the perimeter fence is in good conditions

12.0 MAQUINARIA Y EQUIPOS DE TRABAJO/ Machinery & work equipments

-

12.1 Se hace uso de maquinaria con marcado CE, en buenas condiciones de mantenimiento y limpieza/ The machinery is marked with CE label, and is maintained properly

-

12.2 La maquinaria dispone de las revisiones o inspecciones periódicas correspondientes/ The machinery has the checks and inspections updated

-

12.3 Los equipos disponen de protecciones y la señalización adecuada/The work equipment has the proper safeguards and signaling

13.0 EQUIPOS DE PROTECCIÓN INDIVIDUAL/ Personal protective equipments

-

13.1 Se dispone y se hace un uso correcto de los equipos de protección individual/ the ppe´s are available and the workers are using the ppe´ss properly "C"

-

13.2 Los equipos se encuentran revisados/ The ppe´s are checked

-

13.3 Se hace uso de los equipos correctamente de acuerdo a los riesgos existentes/ The workers are using the ppe´s in according to the risks involved to this area

14.0 ORDEN Y LIMPIEZA/ Housekeeping

-

14.1 La zona de trabajo se encuentra en buen estado de orden y limpieza/ The work area is in a good conditions respect to order and cleaning

-

14.2 Las vias de paso y emergencia se encuentran libres de obstáculos/ The route or transit and emergency areas are free of obstacles

15.0 PRODUCTOS QUÍMICOS/Hazard Substances

-

15.1 Los productos químicos se encuentran en sus recipientes y etiquetados correctamente/ The hazard substances are in their containers and signed properly

-

15.2 Existe un correcto orden y almacenaje de los productos/ There is a proper housekeeping and storage of the chemical products

-

15.3 Se hace un uso correcto de los productos de acuerdo a las instrucciones del fabricante/ The chemical product are using in according to the manufacture instructions "C"

16.0 MEDIDAS DE EMERGENCIA/ Emergency Measures

-

16.1 Se disponen, y se encuentran en buen estado los equipos de emergencia, rescate y evacuación/ It is available, and in a proper conditions, the emergency, rescue and evacuation equipments "C"

-

16.2 Existe señalización de los equipos, medios de emergencia y evacuación/ There is a proper signaling of the emergency equipments

17.0 MEDIO AMBIENTE/Enviroment

-

17.1 Se realiza un correcta limpieza y gestión de los residuos/ There is a good waste management

-

17.2 Se realiza una almacenaje y señalización correcta de los residuos/ There is a proper storage and signaling of the waste area

-

17.3 El equipo de trabajos disponen de medios de recogida o contención de los residuos/ The work equipment has the equipment and the resources to contain the spills and waste

18.0 CULTURA SEGURIDAD/ Safety Culture

-

18.1 Existe una adecuada organización de los trabajos/ There is a good planning and organization of the tasks

-

18.2 Se realizan inspecciones o controles de seguridad, antes durante y después de los trabajos/ The check and safety inspections are implemented on site (previous, during , and after the works)

-

18.3 Se dispone y hace uso de la documentación de seguridad necesaria para la realización de los trabajos/ The work equipment has the safety documentation available to carry out the different tasks "C"

-

18.4 Se están realizando los trabajos bajo condiciones climatológicas adecaudas/ The weather conditions are suitable to develop the different activities

19.0 TRABAJOS ESPECIAL PELIGROSIDAD/ Task with special Risk.

-

19.1 Que tipo de trabajos se están desarrollando?/ What type of activities do it carry out on site?

- IZADO DE CARGAS/Lifting Operations

- ESPACIOS CONFINADOS/Confined Space

- TRABAJOS EN CALIENTE/Hot Works

- TRABAJOS RIESGO ELÉCTRICO/Electrical Tasks

- TRABAJOS EN ALTURA/Work at Heights

IZADO DE CARGAS/ Lifting Operations

-

Se dispone y se ha informado del procedimiento/instrucción y del plan de izado/ The work team has avaialble on site , and have been informed about the protocol/instruction and lifting plan "C"

-

Los equipos y maquinaria de izado son correctos y están en buen estado para realizar la maniobra/ The lifting equipment and machinery are in a good conditions, and are the suitable to carry out the lifting

-

Existen una organización adecuada para realizar la maniobra / There is a good organization to carry out the lifting

TRABAJO EN CALIENTE/ Hot Works

-

Existe una planificación de los trabajos/ There is a proper planning of the tasks

-

La zona de trabajos esta preparada, protegida y señalizada/ The work area have been prepared, singed and protected

-

Los equipos de emergencia se encuentran disponibles en la zona de trabajo/ The emergency equipments are available on the work area "C"

-

Se dispone y se hace un uso correcto de los equipos de protección contra riesgos térmicos/the workers have and are using the specific ppe´s against the thermal contact risk

TRABAJOS RIESGO ELÉCTRICO/Electrical works

-

Se dispone del procedimiento, instrucción y las habilitaciones necesarias para realizar trabajos de riesgo eléctrico/ The work team has the protocol, instruction and the electical competence required to carry out the electrical works

-

Se disponen y hace uso de los equipos de bloqueo y señalización/ the work team has been implemented the "LOTO" safety practices

-

Se han cumplido las 5 reglas de oro/ The five golden rules have been implemented "C"

-

Los equipos de medida y de protección son acordes al tipo y potencia de la instalación/ The measures and protection equipment are suitable to the voltage of the electrical installation

TRABAJOS EN ALTURA/ Work at heights

-

Se está utilizando equipos de protección contra caída de altura, correctos al tipo de trabajo/ The workers are using the work at height ppe´s properly

-

Los puntos de anclaje, línea de vida, etc. están en buen estado de revisión/ The anchorage point, safety line, etc. are in a good conditions and checked.

-

Se dispone de un equipo de rescate y evacuación, y los trabajadores conocen su uso/There is a rescue and evacuation equipment. The workers knows the use of these equipments "C"

ESPACIOS CONFINADOS/ Confined Space

-

Se ha establecido un protocolo o procedimiento de acceso y evacuación/ An access and evacuation protocol is implemented on site

-

Se dispone de permisos de trabajo/ It is available and implemented a work permit system

-

Se disponen de los equipos de rescate y evacuación adecuados/ It is available the rescue and evacuation equipments on site "C"

-

Se han informado y formado a los trabajadores sobre el protocolo de acceso y evacuación/ The work team have been informed and trained of the access and evacuation protocol

D) Summary and Signature

-

Other Comments

-

Site Manager/ Supervisor

-

Auditor