Title Page

-

Date of Audit

-

Scope the audit

-

Prepared by

General Information

-

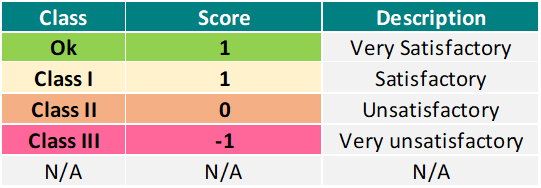

Score Ranking

-

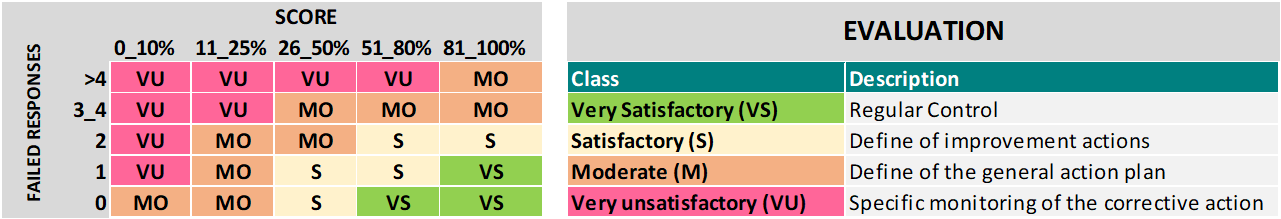

Evaluation Chart

-

All the items with Class III score must be defined at least one corrective action.

-

In the items with Class II & III score should be added an evidence or the issue description

A) HSE Management

1.0 HSE management system/Documentation

-

If lack of one or more documents or these documents are not updated to be identified as Class III with failed response ( 1.3 Safety documents)

-

1.1 QHSE Policy up to date and well publicized?

-

1.2 Does the site have a Health and Safety board and is all information correct and current? (take a pictures and add comments)

-

1.3 Review the general safety documents; Emergency Plan, Risk Assesment.. Check if is updated, is available on site

-

Emergency Plan, Risk Assesment, emergency contact numbers, Coordenates and evacuation map.

-

1.4 There is a control of the waste management records?

B) General Factilities; Command Building, subestation, WTG, PV Plant, Warehouse, etc.

2.0 Command Building, Access roads, ditches, vegetation... ( Check the H&S conditions)

-

If there ar not fire extingishers, first aids kit, or are not updated and completed (2.6, 2.10), if must be identified as Class III with failed response.

-

2.1 Check the conditions of the access roads, ditches, vegetation...

-

2.2 There is info Pannel or signs with the main access and the general safety norms of the site (take a picture and add comments)

-

2.3 General cleanliness of all areas

-

2.4 Unobstructed routes and width adequate for needs

-

2.5. Check safety signs (emergency posters, extinguishers posters, electrical risk, first-aid kit posters, signs of do not enter ins restricted areas, evacuation map, coordenates map of the site...)

-

2.6. Check First-aid kit (take a picture of the First-aid kit, add comments)

-

2.7 Emergency equipment and exits signage are free of obstruction

-

2.8 Emergency exit marked and checked for appropriateness

-

2.9 Fire detection system installed (smoke, heat detectors)

-

2.10 Validate the fire extinguishers state (take a picture to one of them, add comments)

-

Checked accessibility, good apparent condition of conservation, insurance, seals, inscriptions, hose, etc.

Checked the state of charge (weight and pressure) of the extinguisher and the gas pump bottle (if any) state of the mechanical parts (nozzles, valves, hoses, etc)

Check the correct fire control system, fire dections, (if is aplicable) -

2.11 Check de Emergency lights

-

2.12 Check the fire alarm

3.0. Environmental Conditions

-

If the waste disposal state is in a poor conditions,(3.1) and there are not segregation of the waste (3.2) must be identified the points with Class III with failed response

-

3.1 Check general waste disposal state (organisation, cleanliness, element disposal and identification, possible waste leaks...)

-

Take a picture and add comments

-

3.2 Waste segregated (chemical, contaminated packaging. Separate and labelling of waste types with MSDSs?

-

3.3 Spill kits available and fit for purpose? Who inspects and are records available? (Staff trained in use)

4.0. Welfare Management

-

No maintenance of the toilets facilites (4.5), water and septic tank (4.6), and not exist any policy or signs about the Smoking area control must be identified the points with Class III with failed response

-

4.1 Welfare facilities suitable for the needs of the area (take a picture one of them, add comments)

-

4.2 Housekeeping standard clearly set, inspected and enforced

-

4.3 Lighting ventilation etc. satisfactory for the area and working correctly

-

4.4 Smoking controls in place with designated smoking area.

-

4.5 The toilet facilities has sanitary water, cleaning papel dispenser...

-

4.6 Septic and Water tank are installed properly and there is a peridically maintenance and inspection systm

-

4.7. Check of intrusion alarm / CCTV

5.0 Sites

-

Type of the facilities on site to be audited

- SET

- PV PLANT

- WTG

- WAREHOUSE

5.1 SET AUDITED

-

No signaling in isolator switch (5.1.2) and electrical equipments (5.1.3), must be identified these points with Class III with failed response. If the electrical safety equipments (5.1.4.1.) are not installated correctly and are not reviewed, must be marked the option class III as failed response

-

5.1.1. Check the outside general state (lighting, fences, vegetation…)

-

5.1.2 Check of the electrical signs in the isolator siwtch

-

5.1.3 Check the state (signs, lock door, cables, etc.) of electrical equipment (cell, electrical box, etc.) and fire extinguisers equipments

-

5.1.4 Is there electrical safety equipments to make the manoeuvres in electrical cabinets and electrical subestation, such as insulating carpet, dielectrical gloves, voltage tester, etc.

-

5.1.4.1 The equipments were checked and were installed properly

5.2 PV PLANT AUDITED

-

If the electrical safety equipments (5.2.2.1.) are not installated correctly and reviewed periodically, and the fire extinguisers are not in good state (5.2.2.2), must be marked the option class III as failed response

-

5.2.1 Check the state of electrical equipment; fenses, signs, etc.

-

5.2.2 Is there Processing centers on site

-

5.2.2.1 The equipments were checked and installed properly

-

Electrical safety equipments to make the manoeuvres in electrical cabinets and electrical subestation, such as insulating carpet, dielectrical gloves, voltage tester, etc.

-

5.2.2.2 Extinguishers

-

Checked accessibility, good apparent condition of conservation, insurance, seals, inscriptions, hose, etc.

Checked the state of charge (weight and pressure) of the extinguisher and the gas pump bottle (if any) state of the mechanical parts (nozzles, valves, hoses, etc)

5.3 WTG AUDITED

-

If the next equipments; lift and safety line (5.3.9.), fire estinguisher (5.3.8), rescue device (5.3.13), brake system (5.3.14) and chain hoist (5.3.15) are not installated correctly and reviewed periodically, must be marked the option class III as failed response.

-

Nº/CODE WTG

-

5.3.1. Check cleanliness on the outside of the wind turbine

-

5.3.2 Check the state of wind turbine identification mark

-

5.3.3 Check the external stairs (possible damage, missing components or other defects)

-

5.3.4 . Check the state of the main door and lock state

-

5.3.5 Check the signs in turbine; Coordenates Map, 5 Golden Rules, electrical risk, Emergency contact numbers...

-

5.3.6 WTG state of the cleaning

-

5.3.7 Check interior tower lighting and emergency lighting

-

5.3.8 Check the state and inspection card of Fire Extinguisher

-

5.3.9 Check the state and inspection cards of Lift Cabine and Life Line

-

Lift; Check the correct status of the lift, the periodical annual official inspection is done, the instructions manual is updated and available, the dialy check control is available in the lift.

Safety line; to the annual official inspection is done, the safety line has CE certificate , and is signed the number of persons can use the safety line -

5.3.10 Check condition of the fall protection system at the platforms (anchor points)

-

5.3.11 Check de anchorage system of the lift (shackles, sling, anchorage point, etc.)

-

5.3.12 Check of the evacuation signaling; anchorage point , evacuation exits, etc. in nacelle

-

5.3.13 Check the nacelle Rescue Device (if applicable)

-

5.3.14 Check the status of the brake system

-

5.3.15 Check the state of chain hoist (correct state fixings, absence of abnormal noises or oil leakage)

-

Obs.:

5.4 WAREHOUSE AUDITED

-

If the flammable/hazardous materials (5.4.9) are not stored correctly and the fuel sources have been not idedentified and controlled correctly (5.4.10), must be marked the option class III as failed response

-

5.4.1 The Warehouse is in correct status of clean and order, the shelf system is proper to the different material, components, etc.

-

Storage facilities neat, tidy, signed and accessible

-

5.4.2 Good housekeeping prevents building up of combustible, waste or chemicals spillage)

-

5.4.3 Segregation of inappropriate materials/ reactants (Bleaches/ disinfectant/ food stuffs/ consumables)

-

5.4.4 Enough ventilation on chemical storage facility/ warehouse

-

5.4.5 Overloaded racking/poor stacking practices (Pyramid stacking)

-

5.4.6 Bulk stacks for stability (Overloaded pallets at height)

-

5.4.7 Damaged racks/stacks/pallets etc (Are inspections completed and by who/ what training has been received)

-

5.4.8 Aisles for accessibility (Blocked aisles/ fire escape routes)

-

5.4.9 Flammable/hazardous materials stored appropriately and locked away where neccesary

-

5.4.10 Has all ignition/ fuel sources been identified and controlled? (Gas bottles/ fixed wiring/ gas heating)

C) Summary and Signature

-

Other Comments

-

Site Manager/ Supervisor

-

Auditor