Information

-

Leadership Gemba Walk

-

Leadership Team Member

-

Manager

-

Focus Area

- Preweigh Mixing

- Plate Stamping

- Plate Preperation

- Purchased & Yard Stock

- IAG Moulding

- Troika Moulding & Staging

- Line 1

- Line 2 & GP 12

- Stores & RM Store

- Hazchem & QA Store

- Warehouse Internal

- Warehouse External

-

Document No.

-

Conducted on

5 S

-

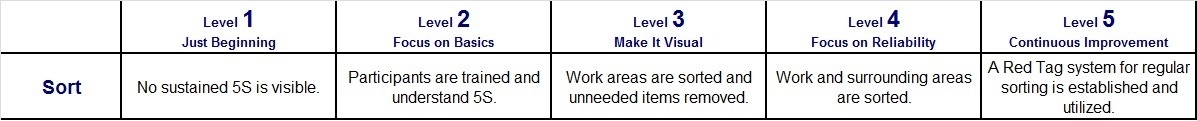

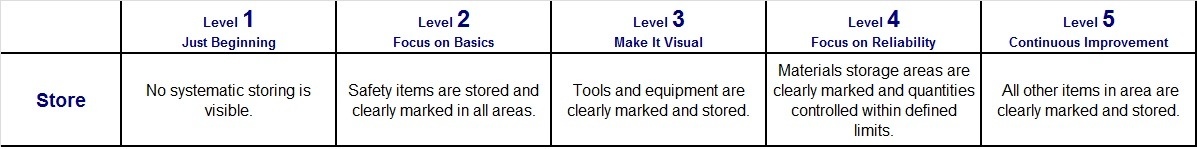

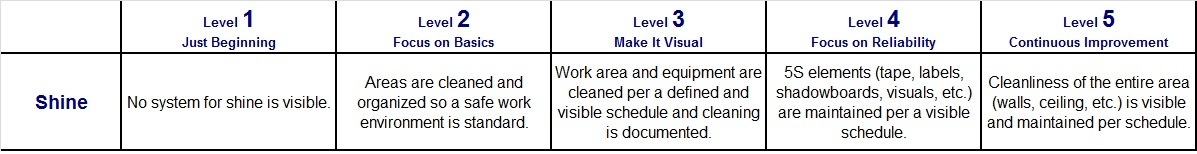

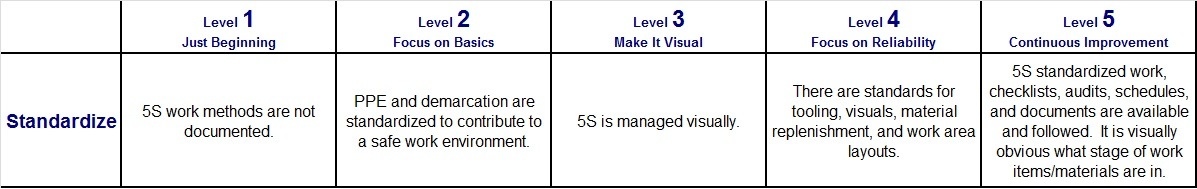

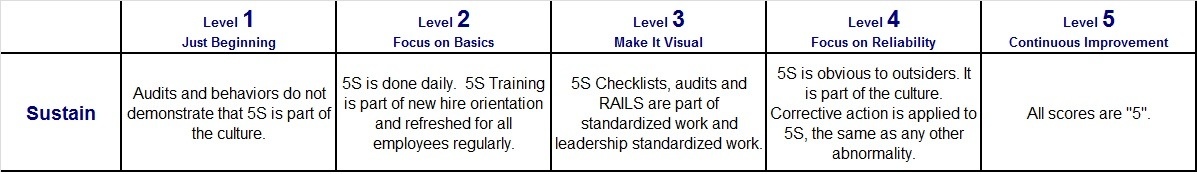

SORT: Have needed items been established & unneeded items removed from the work area? STORE: Is there a place for everything and everything is in its place? SHINE: Is daily cleaning &inspection of the equipment & work area happening to an agreed schedule? STANDARDISE: Are there defined standards for SORT, STORE & SHINE? SUSTAIN: Are gains being maintained & building further improvement?

-

Add media

-

-

-

-

-

Visual Management

-

Ability to quickly assess the state of play of an area without asking questions. Metrics: Create a visual of good & bad conditions. Andon: Highlight abnormality visually or audibly. Problem Visualisation & Tracking: Visually track progression, timing & owner of problems. Material Control: Visualise correct quantity of materials are available. Production Status: Clearly visualise the state of the work place, ahead or behind targets.

-

Add media

Waste Obersvation

-

DEFECTS: Quality escapes, Scrap / rejects, Rework. OVER PRODUCTION: Making more than needed or faster than required. TRANSPORT: Movement of product, materials. WAITING: Idle time when the operator is waiting. EXCESSIVE INVENTORY: More materials in area than required. EXCESSIVE MOTION: Any movement of a person that does not contribute to adding value. EXCESSIVE PROCESSING: Unnecessary effort which adds no value.

-

Add media

-

Agreed 5S, Visual Management, Waste Observations Just Do It Actions:

-

Agreed 5S, Visual Management, Waste Observation before next Gemba walk :