Title Page

-

Annual Wind Turbine PM GE1.5

-

Annual PM - Part A

-

Turbine #:

- MLC001

- MLC002

- MLC003

- MLC004

- MLC005

- MLC006

- MLC007

- MLC008

- MLC009

- MLC010

- MLC011

- MLC012

- MLC013

- MLC014

- MLC015

- MLC016

- MLC017

- MLC018

- MLC019

- MLC020

- MLC021

- MLC022

- MLC023

- MLC024

- MLC025

- MLC026

- MLC027

- MLC028

- MLC029

- MLC030

- MLC031

- MLC032

- MLC033

- MLC034

- MLC035

- MLC037

- MLC043

- MLC044

- MLC045

- MLC046

- MLC047

- MLC048

- MLC049

- MLC050

- MLC051

- MLC052

- MLC054

- MLC055

- MLC056

- MLC057

- MLC060

- MLC061

- MLC062

- MLC064

- MLC065

- MLC066

- MLC067

- MLC068

- MLC069

- MLC070

- MLC071

- MLC072

- MLC073

- MLC074

- MLC075

- MLC076

- MLC077

- MLC101

- MLC102

- MLC104

- MLC105

- MLC106

- MLC108

- MLC109

- MLC110

- MLC111

- MLC112

- MLC113

- MLC114

- MLC115

- MLC116

- MLC117

- MLC118

- MLC119

- MLC122

- MLC123

- MLC124

- MLC126

- MLC127

- MLC128

- MLC129

- MLC130

- MLC131

- MLC132

- MLC134

- MLC135

- MLC136

- MLC137

- MLC138

- MLC139

- MLC141

- MLC142

- MLC143

- MLC144

- MLC145

- MLC146

- MLC147

- MLC148

- MLC149

- MLC150

- MLC151

- MLC152

- MLC153

- MLC154

- MLC155

- MLC156

- MLC157

- MLC158

- MLC159

- MLC160

- MLC161

- MLC162

- MLC163

- MLC164

- MLC165

- MLC166

- MLC204

- MLC205

- MLC206

- MLC207

- MLC208

- MLC209

- MLC210

- O&M

- Sub-Station

-

Conducted on

-

Completed by:

- Chad Henry

- Chris Hale

- Clayton Kalbfleisch

- Dan MacNeal

- George Turchanyi

- Heath Mitchell

- Jason Mueller

- Kevin Janisse

- Mike Howenwald

- Paul Aback

- Tyler Graper

- Shawn Hunking

- William Chambers

- Joe Abel

-

Verification #: (take picture of Turbine sticker)

Enviroment

-

Precipitation level:

Foundation Inspection

-

This inspection is part of the Safety Critical Elements and is to be done on an annual basis. Document any signs of deterioration or damage. Please take photographs of any suspected issues and upload with PM to SAP

-

Take 4 pictures of foundation connection exterior of turbine

-

Take 1 picture of foundation connection interior of turbine

Surrounding soil condition:

-

Is the earth around foundation cracking around the turbine?

-

Is there soil subsidence adjacent to the foundation? (dips or hollows)

Grout Ring Condition

-

Are there cracks that go under the tower flange?

-

Is it bonded to the tower?

-

Does it appear watertight?

-

Check if any waterproofing has been applied

Foundation Bolts - (Exterior bolts are covered with plastic caps)

-

Level of corrosion

-

Can you see marks from tension checks?

-

Switch on if the foundation has rock anchors

Rock Anchors:

-

Are they covered?

-

Are there any cracks surrounding the rock anchors?

Foundation: (Interior)

-

Any signs of corrosion?

-

Any signs of external water getting in through concrete or grout?

Concrete condition: (Interior and Exterior)

-

Foundation Condition Factor:

- No Visible Cracks

- Limited

- Extensive

- Major

- Severe

- Structural

-

Matrix Score is below 2 - nothing further required.

-

Are there any areas of crack concentration?

-

Attach pictures of fractured area.

-

Are there any bulges?

-

Attach pictures of bulged area.

-

Attach picture of widest cracks

-

Limited means some hairline cracking visible

Crack Classification Factor: (measure widest crack)

-

Crack Classification Factor:

- Watertight (<0.004")

- Very Fine (0.004-0.008")

- Fine (0.008-0.012")

- Medium (0.012-0.016")

- Extensive (0.016-0.05")

- Severe (0.05-0.1")

- Extreme (>0.1")

-

You have indicated a crack classification that is higher than a level 1 Foundation condition allows for, please adjust the Foundation Condition Factor.

-

Matrix Score is below 2 - nothing further required.

-

Extensive means that there are plenty of hairline sized cracks

Crack Classification Factor: (measure widest crack)

-

Crack Classification Factor:

- Watertight (<0.004")

- Very Fine (0.004-0.008")

- Fine (0.008-0.012")

- Medium (0.012-0.016")

- Extensive (0.016-0.05")

- Severe (0.05-0.1")

- Extreme (>0.1")

-

You have indicated a crack classification that is higher than a level 2 Foundation condition allows for, please adjust the Foundation Condition Factor.

-

Matrix Score is below 2 - nothing further required.

-

Matrix Score is between 2&5 water proofing will be required - please indicate this on your PM workorder

-

Major means that there are plenty of hairline and/or wider cracks

Crack Classification Factor: (measure widest crack)

-

Crack Classification Factor:

- Watertight (<0.004")

- Very Fine (0.004-0.008")

- Fine (0.008-0.012")

- Medium (0.012-0.016")

- Extensive (0.016-0.05")

- Severe (0.05-0.1")

- Extreme (>0.1")

-

You have indicated a crack classification that is higher than a level 3 Foundation condition allows for, please adjust the Foundation Condition Factor.

-

Matrix Score is below 2 - nothing further required.

-

Matrix Score is between 2&5 water proofing will be required - please indicate this on your PM workorder

-

Matrix Score is between 4&6 minor repairs will be required - please indicate this on your PM workorder

-

Matrix Score is between 6&12 major repairs will be required - please indicate this on your PM workorder

-

Severe means that there is severe cracking, concrete heave, or concrete spalling

Crack Classification Factor: (measure widest crack)

-

Crack Classification Factor:

- Watertight (<0.004")

- Very Fine (0.004-0.008")

- Fine (0.008-0.012")

- Medium (0.012-0.016")

- Extensive (0.016-0.05")

- Severe (0.05-0.1")

- Extreme (>0.1")

-

You have indicated a crack classification that is lower than a level 4 Foundation condition allows for, please adjust the Foundation Condition Factor.

-

Matrix Score is between 6&12 major repairs will be required - please indicate this on your PM workorder

-

-

Matrix Score is greater than 12 - THIS TURBINE CANNOT RUN & Do not CLIMB - Please notify Management Immediately

-

Structural means that there are structural cracks and there is severe concrete degradation.

Crack Classification Factor: (measure widest crack)

-

Crack Classification Factor:

- Watertight (<0.004")

- Very Fine (0.004-0.008")

- Fine (0.008-0.012")

- Medium (0.012-0.016")

- Extensive (0.016-0.05")

- Severe (0.05-0.1")

- Extreme (>0.1")

-

You have indicated a crack classification that is lower than a level 5 Foundation condition allows for, please adjust the Foundation Condition Factor.

-

Matrix Score is between 6&12 major repairs will be required - please indicate this on your PM workorder

-

-

Matrix Score is greater than 12 - THIS TURBINE CANNOT RUN & Do not CLIMB - Please notify Management Immediately

Tower by section

Structure

-

Pad mount transformer

-

Tower base overall condition

SCE 12MO Ladder & Stairway Inspection

-

Click for more information

-

Workscope is the Maintenance Strategy for TransAlta Maintained Wind Turbines Ladders & Stairways Reference No:(WIN.05.0190)

Entrance Stairways

Visually inspect the stairway:

-Ensure feet of stairway are resting evenly on the ground outside the turbine

-Stairs are not cracked, dented, or broken

-Excessive corrosion

-Handrails are in place and not damaged or bent

-stairway connection to tower is not loose or broken. -

Items within workscope

-

Indicate what Problems have been identified, attach pictures if helpful

SCE 14.7 Site Security

-

Click for more information

-

This notification is to ensure that the Door Assembly is in good working order as per SCE 14.7 Site Security.

An external check of any door and locking system is to be made.

Look for any abnormalities with the door or locking system.

Look for any tampering, signs of attempted forceful entry.

Door lock , seals, hinges, pivot pins and door fasteners should be examined and lubricated as required. -

Items within workscope

-

Indicate what Problems have been identified, attach pictures if helpful

Base level

-

Vacuumed area under base cabinets

-

Hoist Remote Present - change batteries if lower than 1.3VDC

Common Elements

-

Clean or replace cabinet vent filters

-

All cabinets have been vacuumed

-

Check all cable glands

-

Check all ground connections

Main Cabinet

-

Inspect console mounting

-

Overall cabinet condition

-

Plexiglass and screen have been cleaned

-

Indicate type of UPS

-

Switch on if monitor is an LCD panel

LVMD Panel

-

Overall cabinet condition

-

Check wire connections

Converter

-

Overall cabinet condition

-

Check lugs at rotor connections

-

Check coolent levels - top up if needed

-

Indicate if Pump is Leaking

Level 1 (base of ladder)

-

Check safety cable tension

-

Lights

-

Ladder sections

-

Buss Bar

-

Vacuum floor and degrease

-

Check cable splices

Level 2 (top of base section)

-

Lights

-

Ladder sections

-

Buss Bar

-

Vacuum floor and degrease

-

Check cable splices

-

12 bolts (10%) Checked Base to Mid Flange 60mm socket @ 2800Nm

Level 3 (top of mid section)

-

Lights

-

Ladder sections

-

Buss Bar

-

Vacuum floor and degrease

-

Check cable splices

-

10 bolts (10%) Checked Mid to Top Flange 60mm socket @ 2800Nm

Level 4 (saddle deck)

-

Lights

-

Ladder sections

-

Buss Bar

-

Drip loop - add armour cast if required

-

Check Yaw limit switch for wear and function

-

Vacuum floor and degrease

-

Check cable splices

Level 5 (yaw deck)

-

Lights

-

Vacuum floor and degrease

-

7 bolts (10%) Checked (outer row) Top Flange to Yaw Bearing 60mm socket @ 2800Nm

-

7 bolts (10%) Checked (inner row) Yaw Bearing to Bedplate 55mm socket @ 1900Nm

-

Grease Yaw Bearing - 1 tube stabyl

ASME B30.16-2012 Hoist Inspection Checklist Items

-

Check all functional operating mechanisms for poor adjustment and unusual sounds

-

Check hoist braking system for proper operation under load

-

Visually inspect the hook for manufacturer's identification, load identification, cracks, nicks, gouges, excessive wear, deformation, or throat opening

-

Verify the hook latch operation (if present)

-

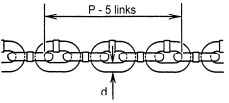

Visually inspect the load chain for damage including gouges, nicks, corrosion, and distorted links

-

Test the hoist under load and observe the operation of the chain and sprockets for abnormal conditions

-

Check the chain links for gouges, nicks, corrosion, or distorted links. Slacken the chain and check for wear at the contact points.

-

Lubricate Chain if necessary

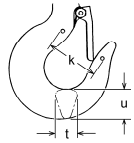

Hook Measurements:

-

Measure Hook and Record

-

-

Hook is out of Spec and needs to be replaced. Please notify your supervisor.

-

-

Hook is out of Spec and needs to be replaced. Please notify your supervisor.

Chain Measurements:

-

Measure Chain and Record

-

-

Chain is out of Spec and needs to be replaced. Please notify your supervisor.

-

-

Chain is out of Spec and needs to be replaced. Please notify your supervisor.

-

Check for evidence of loose bolts, nuts, or rivets

-

Check for evidence of worn, corroded, cracked, or distorted parts such as load blocks, suspension housing, hand chain wheels, chain attachments, clevises, yokes, suspension bolts, shafts, gears, bearings, pins, rollers, and locking and clamping devices

-

Check for evidence of damage to hook-retaining nuts or collars and pins, and welds or rivets used to secure the retaining members

-

Check for evidence of damage or excessive wear of load sprockets, idler sprockets, or hand chain wheel

-

Check for evidence of worn, glazed, or oil-contaminated friction discs; worn pawls, cams or ratchet; corroded, stretched, or broken pawl springs in brake mechanism

-

Visually check for evidence of damage to supporting structure (including jib arm) or trolley.

-

Ensure label is present and legible. It should contain information on acceptable operating procedures

-

Check the end connections of load chain

Nacelle - interior

-

Lights

-

Inspect Shrink Disc bolts

-

5 bolts (10%) Checked Hub Adapter 60mm socket @ 2800Nm

Rotor Lock

-

Check for cracks

-

Check for signs of wear

-

Check for loose or missing hardware

-

Function test high speed rotor lock

Nacelle - Exterior

SCE 9.4 Annual Fall Arrest Systems

-

Inspect Rail system for corrosion, cracks, sharp edges, burrs and deformities.

-

Inspect Rail system for loose or missing fasteners - retighten or replace if necessary

-

Inspect Met Mast for loose or missing fasteners - retighten or replace if necessary

Wind Vane

-

Heater working

-

Moves Freely

Annemometer

-

Heater working

-

Moves Freely

-

Is there a Nav Light?

-

Is the light currently on?

-

Physical condition:

Hub

Blade 1

-

6 bolts (10%) Checked Blade Outer Bearing bolts 50mm socket @ 2000Nm

-

Inspect bearing seals

-

Lubricate bearings

-

Inspect blades for signs of lightning damage

-

Inspect for blade leading edge damage

-

Inspect overall condition of blades

-

Inspect blade base external

Blade 2

-

6 bolts (10%) Checked Blade Outer Bearing bolts 50mm socket @ 2000Nm

-

Inspect bearing seals

-

Lubricate bearings

-

Inspect blades for signs of lightning damage

-

Inspect for blade leading edge damage

-

Inspect overall condition of blades

-

Inspect blade base external

Blade 3

-

6 bolts (10%) Checked Blade Outer Bearing bolts 50mm socket @ 2000Nm

-

Inspect bearing seals

-

Lubricate bearings

-

Inspect blades for signs of lightning damage

-

Inspect for blade leading edge damage

-

Inspect overall condition of blades

-

Inspect blade base external

SCE 9.4 Annual Fall Arrest Systems

-

Inspect Rail system for corrosion, cracks, sharp edges, burrs and deformities.

-

Inspect Rail system for loose or missing fasteners - retighten or replace if necessary

Hub - Inside

-

Inspect nose cone and hub hatch

-

Inspect for loose doors

-

Inspect hub entry bracket and manhole cover

-

Overall condition of hub internal

-

Overall condition of pinions

-

Are ring gears worn ?

-

6 bolts (10%) Checked Blade 1 T-bolts 50mm socket @ 1600Nm

-

6 bolts (10%) Checked Blade 2 T-bolts 50mm socket @ 1600Nm

-

6 bolts (10%) Checked Blade 3 T-bolts 50mm socket @ 1600Nm

-

Inspect Overall condition of all electrical boxes

-

Inspect mounting hardware

-

All hardware removed for inspection is replaced and tightened

-

Check for oil leakage on Pitch Drives

-

Inspect one brush, is brush material below level of brass brush holder?

-

Grease Pitch Ring Gears at high wear point with Ceplattyne

-

Remove excess grease around bolts

-

Clean hub internal

Tower Climbing Apparatus

Tower Landings & Ladder

SCE 12MO Ladder & Stairway Inspection

-

Inspect for damage, rust or deterioration that could affect the strength of the ladder.

-

Warning/safety labels are present

-

Peeling, flaking, or missing protective coating (this includes galvanized coating, paint, or clear coat)

-

Identification/manufacturer's tag (Identification tag must be present and legible on every ladder section)

Ladder Uprights / Rails

-

Seams are not splitting

-

Rung condition (dents, breaks, splits, and tread)

-

Ladder damage (cracks , fractures, and stability issues)

-

Modifications to Ladder system

-

Ladder hardware is correct and properly fastened

-

Connection between Ladder system and fall restraint device

-

Seating of upright sections

-

Evidence of gaps

Ladder Brackets (Ladder to Tower Wall)

-

Evidence of bolt movement

-

Proper connection to tower wall

-

Proper condition to tower uprights/rails

-

Torque marks as applicable

-

(Optional) 10% torque check on ladder brackets

Nacelle Access Ladder (Yaw Deck to Nacelle)

-

Damage (cracks, dents, and etc.)

-

Polyethylene Ladder feet (feet are installed and no crack present)

-

Ladder hooks (loosing/missing hardware, damaged, and properly attached)

Landing Hatches and Railings

-

Hardware present and tight

-

All hatches open/close properly

-

Check hatches for wear or damage

-

Check railings for wear or damage

SCE 12MO Fall arrest systems

Fall Arrest cable

-

Check cable for tension, ensuring there is no slack. Re-tension the carrier cable if necessary. As per manufacture specs

-

Inspect to ensure Cable Guides are not worn, bent and still locks onto cable.

-

Inspect cable guides for loose or missing fasteners- retighten or replace if necessary

-

Inspect Carrier Cable for damage looking for worn or bent cable strands.

-

Inspect for signs of abrasion against the ladder or structure. Replace cable if necessary.

Fall Arrest Anchor Points

-

Inspect for cracks, sharp edges, burrs and deformities.

-

Inspect for corrosion which affects the operation and strength.

-

Inspect for corrosion, tightness, damage and distortion. If welded, inspect weld for corrosion, cracks and damage.

Nacelle lid Fall Arrest Anchor Rail

-

Inspect for cracks, sharp edges, burrs and deformities.

-

Inspect for corrosion which affects the operation and strength.

-

Inspect for corrosion, tightness, damage and distortion. If welded, inspect weld for corrosion, cracks and damage.

-

Inspect for loose or missing fasteners- retighten or replace if necessary

Clean-up / Close-out Job Completion

-

All tools / equipment removed from task location

-

Task area cleaned up at end of job / shift

-

Turbine Fire extinguisher present and servicable