Title Page

-

HAZID Title

-

HAZID Site

-

Conducted on

-

Report Prepared by:

ATTENDEE SIGNOFF SHEET

ATTENDEES PARTICIPATING IN THE HAZID

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

-

Add signature

HAZID Checklists to be used:

-

- MANUAL HANDLING HAZID CHECKLIST

- HIGH VOLTAGE HAZID CHECKLIST

- FALL PREVENTION HAZID CHECKLIST

- NOISE CHECKLIST HAZID CHECKLIST

- PLANT HAZID CHECKLIST

- CHEMICAL HAZID CHECKLIST

- CONFINED SPACE ENTRY HAZID CHECKLIST

MANUAL. HANDLING HAZID Checklist

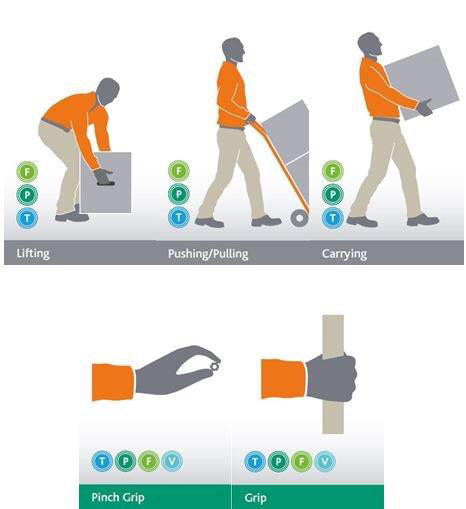

MANUAL HANDLING VISUAL CHECKLIST

-

MANUAL HANDLING Any activity that requires a person to exert force to lift, lower, push, carry or otherwise move, hold or restrain any animate or inanimate object.

-

MUSCULOSKELETAL DISORDER (MSD) Any injury to, or a disease of the musculoskeletal system, wether occurring suddenly or over time. It does not include and injury caused by crushing, entrapment or cutting resulting from mechanical operation of plant.

-

FORCE The amount of muscular effort required to perform a movement and can be: Repetitive force - using force repeatedly over a period of time. Sustained force - force is continuous without a break. High force - physically very demanding ( heavy ). Sudden force - jerky or unexpected movements.

-

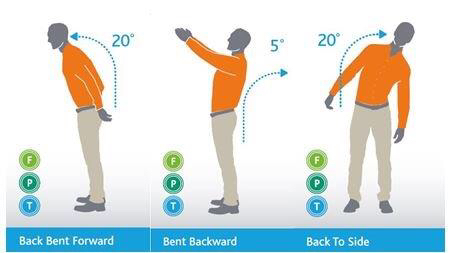

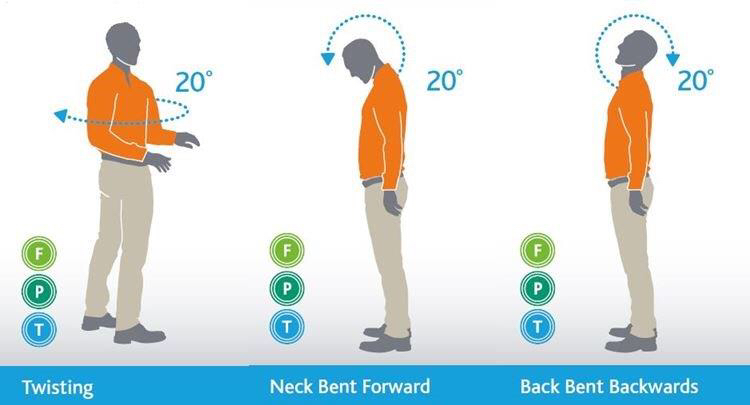

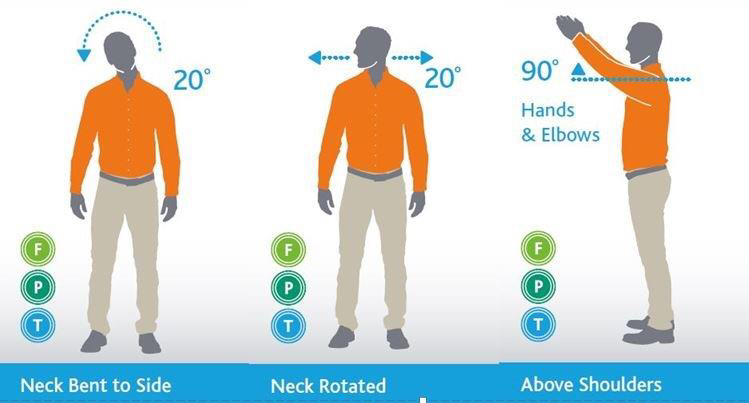

POSTURE The position of various parts of the body during any activity. Good posture occurs when a neutral position is maintained by the joints and muscles being used near the middle of the full range of motion.

-

AWKWARD POSTURES The further a joint moves towards either end of its range of motion ( away from neutral ) the more awkward the posture becomes. This puts a strain on the muscles, tendons and ligaments around the joint.

-

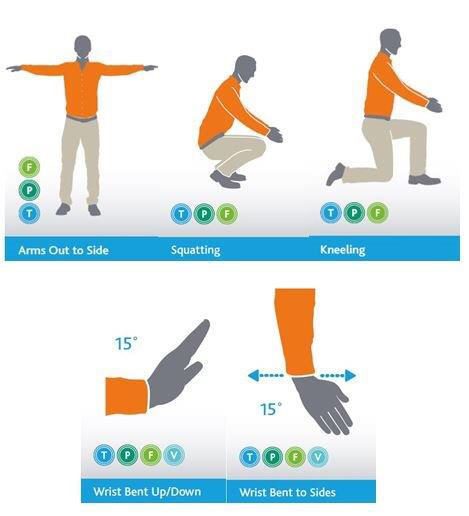

LEDGEND - If an awkward posture is identified, check the appropriate box beside its picture. V - If sustained vibration is involved F - If force is applied while in the awkward posture and the level of force is noted as a concern P - If the same posture/movement is performed repeatedly ( more than twice a minute and/or held for more than 30 seconds at a time ) T - If the task must be performed for a long period of time without a change in posture/activity

AWKWARD/STATIC POSTURES

-

-

- T - If the task must be performed for a long period of time without a change of posture/activity

- P - if the same posture/movement is performed repeatedly ( more than twice per minute and/or held for more than 30 seconds at a time

- F - If force is applied while in an awkward posture and the level of force is noted as a concern

- V - If sustained vibration is involved

- Not Applicable

-

-

-

- T - If the task must be performed for a long period of time without a change of posture/activity

- P - if the same posture/movement is performed repeatedly ( more than twice per minute and/or held for more than 30 seconds at a time

- F - If force is applied while in an awkward posture and the level of force is noted as a concern

- V - If sustained vibration is involved

- Not Applicable

-

-

-

- T - If the task must be performed for a long period of time without a change of posture/activity

- P - if the same posture/movement is performed repeatedly ( more than twice per minute and/or held for more than 30 seconds at a time

- F - If force is applied while in an awkward posture and the level of force is noted as a concern

- V - If sustained vibration is involved

- Not Applicable

-

-

-

- T - If the task must be performed for a long period of time without a change of posture/activity

- P - if the same posture/movement is performed repeatedly ( more than twice per minute and/or held for more than 30 seconds at a time

- F - If force is applied while in an awkward posture and the level of force is noted as a concern

- V - If sustained vibration is involved

- Not Applicable

-

MANUAL MATERIAL HANDLING

-

-

- T - If the task must be performed for a long period of time without a change of posture/activity

- P - if the same posture/movement is performed repeatedly ( more than twice per minute and/or held for more than 30 seconds at a time

- F - If force is applied while in an awkward posture and the level of force is noted as a concern

- V - If sustained vibration is involved

- Not Applicable

-

OTHER COMMENTS

-

Add Additional Photos

CHECKLIST SIGNOFF

-

Person completing the checklist:

Note* This is an IAuditor version of form CORP H&S 027.4

HIGH VOLTAGE Checklist

Step 1: Known Incident History

Step 2: Emergency Considerations

Step 3: Conduct a Visual Inspection

-

Is there required signage in place ?

-

Is fencing intact ?

-

Is the facility secured against un-authorised access ?

-

Are relevant environmental controls effective ?

-

Is vegetation maintained around the asset ?

-

Are there any water leaks ?

-

Is there any evidence of wildlife activity ? (possums-birds-rats, other)

-

Are there signs of corrosion ?

-

Are there unusual smells indicating PD overheating ?

-

Is there unusual noise ? (hissing due to corona, noise from vibration)

-

All earth connections in order ?

-

Are all access covers in place and secure ?

-

Is there clear access/egress from switch rooms ?

-

Is there any unauthorised storage ?

-

Is the area adequately lit ?

-

Is the area clean and tidy ?

-

Are there signs of oil leaks from HV apparatus ?

-

Are all SF6 gas indicators registering healthy pressure ?

-

Is the crushed rock layer in proper order ?

-

Is the switching equipment properly locked ?

-

Are the poles leaning, rotten or damaged ?

-

Are there adequate clearances maintained between live conductors and to earth ? (especially in overhead conductors)

-

Is switchgear/ equipment labelled ? (asset tag, pole numbers, etc)

-

Is the transformer oil bunding in good order ?

-

Do all protection relays appear to be functioning ?

OTHER COMMENTS

-

Add Additional Photos

CHECKLIST SIGNOFF

-

Person completing the checklist:

Note* This is an IAuditor version of form CORP H&S 027.3

PLANT HAZID Checklist

PLANT HAZID Checklist

Plant HAZID Steps

-

Step 1: Review all available information (Such as Design Standards, manufacturing guidelines,Standard Operating Procedures, TRAS's)

-

Step 2: Review known incident history with this plant

-

Known Incident History:

-

Step 3: List the types of work (Discuss and list tasks completed by operators and maintainers when working with the plant)

Operator Tasks

-

Task 1:

-

Task 2:

-

Task 3:

-

Task 4:

-

Task 5:

Maintainer Tasks

-

Task 1:

-

Task 2:

-

Task 3:

-

Task 4:

-

Task 5:

-

Step 4: Consideration of emergency situations, such as: (Potential for entanglement or entrapment while working with moving equipment) (Equipment failures when working at heights)

-

Emergency situations:

-

Step 5: Hazard identification and controls

Mechanical Hazards

-

Rotating shafts, pillows,sprockets and gears

-

Hard surfaces moving together

-

Scissor or shear action

-

Sharp edges

-

Cable or hose connection trip hazards

-

Broken or ejected ojbjects

Non-Mechanical Hazards

-

Emissions released by plant

-

Mist, fumes, vapours and dust, oil leaks

-

Noise

-

Laser, ultraviolet light

-

Poor light levels

-

Heat/cold, steam

-

Damaged conduits, switches, other electrical components

Access Hazards

-

Safe access for work and materials

-

Awkward work posture

-

Access or egress or and from the work area

-

Use of high force to handle components

Energy Sources

-

Step 6: isolation and lockout of energy sources (Identify and discuss plant energy sources) (Discuss how energy sources are de-energised and how isolation points are locked out when conducting operations and maintenance tasks) (If plant cannot be de-energised or isolation points cannot be locked out then improvement actions are required)

-

Electrical<br>(Mains, capacitors, batteries)

-

- The energy sources CAN be de-energised

- The energy sources CANNOT be de-energised

- The isolation points CAN be locked out

- Isolation points CANNOT be locked out

-

Fuels

-

- The energy sources CAN be de-energised

- The energy sources CANNOT be de-energised

- The isolation points CAN be locked out

- Isolation points CANNOT be locked out

-

Cold, heat or steam

-

- The energy sources CAN be de-energised

- The energy sources CANNOT be de-energised

- The isolation points CAN be locked out

- Isolation points CANNOT be locked out

-

Fluids or gasses under pressure

-

- The energy sources CAN be de-energised

- The energy sources CANNOT be de-energised

- The isolation points CAN be locked out

- Isolation points CANNOT be locked out

-

Stored energy <br>(Springs, water head)

-

- The energy sources CAN be de-energised

- The energy sources CANNOT be de-energised

- The isolation points CAN be locked out

- Isolation points CANNOT be locked out

-

Gravity<br>

-

- The energy sources CAN be de-energised

- The energy sources CANNOT be de-energised

- The isolation points CAN be locked out

- Isolation points CANNOT be locked out

-

Radiation

-

- The energy sources CAN be de-energised

- The energy sources CANNOT be de-energised

- The isolation points CAN be locked out

- Isolation points CANNOT be locked out

-

Chemicals

-

- The energy sources CAN be de-energised

- The energy sources CANNOT be de-energised

- The isolation points CAN be locked out

- Isolation points CANNOT be locked out

-

Step 7: Checklist for specific types of plant (Identify and discuss as a group which of the checklists below are applicable for the plant item you are assessing)

-

Operator Controls (If you answer NO to any of the following questions you have likely identified a gap and additional controls are required)

-

Are controls for the plant clearly identified ?

-

Conveniently operated by persons using the plant ?

-

Located or guarded to prevent unintentional activation ?

-

Able to be locked into the off position and all motive power disconnected ?

-

Are the controls located away from any Line of Fire risks ( operator potentially at risk if there is an unplanned release of energy)

-

Emergency stop & warning devices (If you answer NO to any of the following questions you have likely identified a gap and additional controls are required)

-

Is the emergency stop clearly marked ?<br>Coloured Red ?<br>Immediately accessible ?

-

Emergency stop cannot restart after a stop control has been used unless reset ?

-

Warning device positioned to work to best effect ?

OTHER COMMENTS

-

Add Additional Photos

CHECKLIST SIGNOFF

-

Person completing the checklist:

Note* This is an IAuditor version of form CORP H&S 027.6

NOISE HAZID Checklist

NOISE HAZID Checklist

-

List areas and equipment with noise and make a determination if a noise assessment is required.

-

Area 1:

-

Area 2:

-

Area 3:

-

Area 4:

-

Area 5:

-

Area 6:

-

Area 7:

-

Area 8:

-

Area 9:

-

Area 10:

-

Answer the following questions to determine if a noise assessment is required.

-

Are noise signs in the area ?

-

Do labels or information attached to the equipment indicate that noise greater than 60Db.

-

Do you have records of previous noise tests ? Do sound levels exceed 82Db (A) or peak sudden sounds exceed 120Db (C)

-

When standing 1mt apart, do people have to raise their voices to have a conversation ?

-

Are there any irregular or sudden loud noises ?

-

Do tasks involve tapping, hitting, bashing or other action that may generate loud noises ?

-

Does the assessor believe the work area has excessive noise ?

-

Are there any historical noise assessments for this area, plant or equipment ?

-

If you answered Yes to any of the above questions then consider whether a noise assessment is required.

OTHER COMMENTS

-

Add Additional Photos

CHECKLIST SIGNOFF

-

Person completing the checklist:

Note* This is an IAuditor version of form CORP H&S 027.5

FALL PREVENTION HAZID Checklist

Step 1: Working at heights hazard identification

-

Review the pick list and identify areas where fall hazards exist.

- Yes

- No

- N/A

Contributing factors and control measure questions ?

-

Review the following questions and discuss any contributing factors, existing controls and if further controls are required.

-

Are edges with a fall hazard protected ?

-

Are there any holes, openings or excavations that require guarding ?

-

Are there any fragile or brittle surfaces that require inspection ?

-

Are permanent access points for tanks secured ?

-

Are there trip hazards that require highlighting, treatment or guarding ?

-

Are there slip hazards that require treatment or guarding ?

-

Are access points restricted, secured and clearly signed ?

-

Are there any unusual hazards that require a hazard, warning or danger sign ?

-

Do fall arrest systems have installation and inspection plates ?

-

Do materials and equipment need to be moved into the work area ?

-

Could people be in unsafe areas below the location ?

OTHER COMMENTS

-

Add Additional Photos

CHECKLIST SIGNOFF

-

Person completing the checklist: