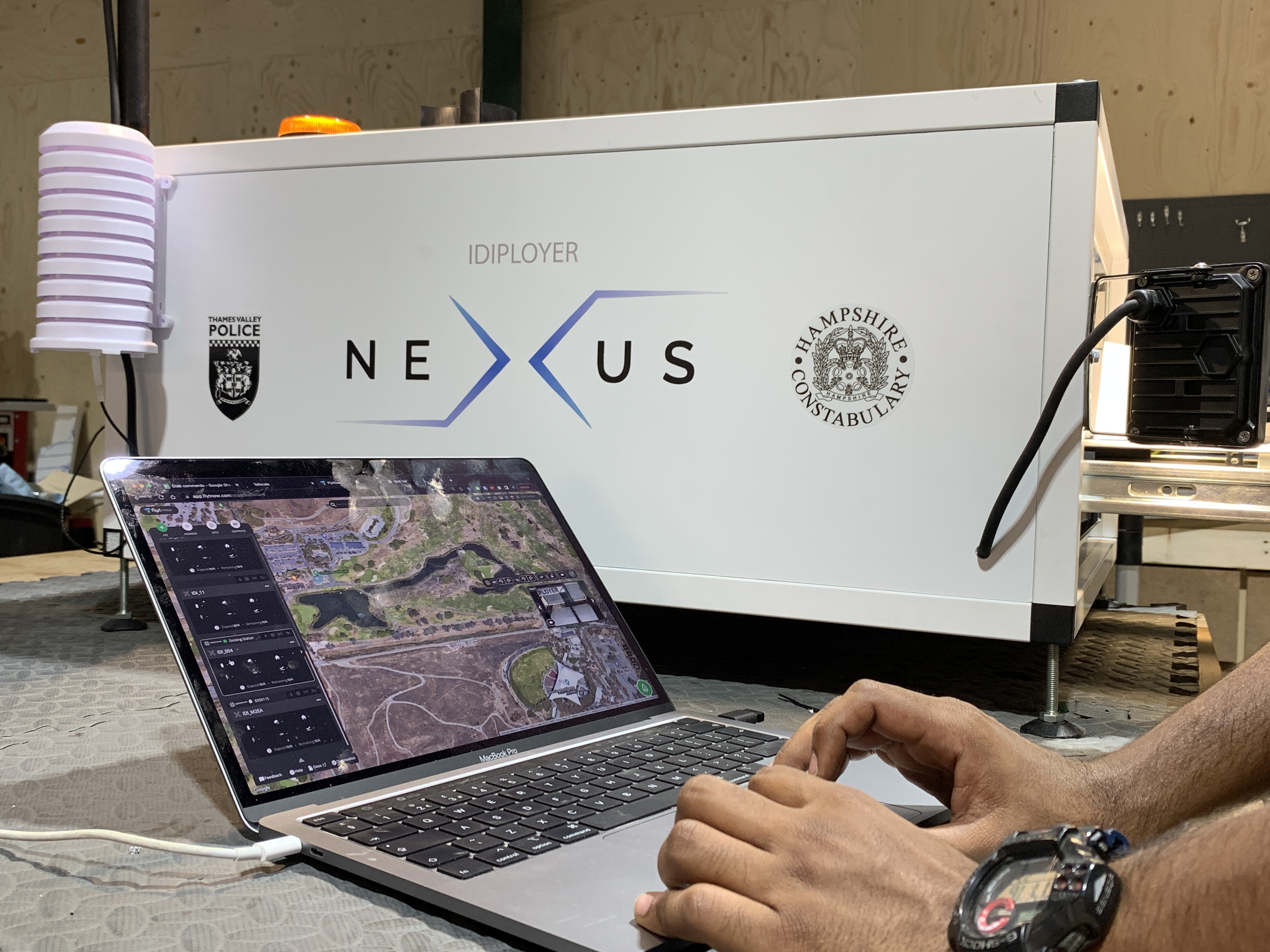

Title Page

-

Asset Number

-

Company Name

-

Dock Location

-

Conducted on

-

Prepared by

Tools Required

-

Lithium Grease

-

Hex Screw Driver (2mm)

-

Hex Screw Driver (2.5mm)

-

Hex Screw Driver (3mm)

-

M4/M5 Spanner

-

Moisture Meter

-

Electrical Testing Devices

-

No invasive Cleaning materials

-

Other Items may be required, please take adequate tools for hardware maintenance.

Spare Parts Supplied for maintenance

-

Spare Screws and Nuts

-

Charge Flex PCB

-

POGO Pins x 2

Mechanical Inspection

Externals of the Docking Station

-

Ensure the Dock is level, adjust as required.

-

Check Front Door Gasket for Cracks Splits or wear and tear

-

Check Grommets on Lights and Cable Entry for wear and tear

-

Check Antenna, Beacon and Wind sensor are secured and tightly sealed to panel

-

Check all Panels for damage

-

Visually inspect the Top Landing TAG for wear and tear

-

Check Lights on the landing platform do not interrupt with the opening of the drawer.

Rear Panel Inspection

-

Check Isolator Switch is tight and sealed.

-

Check Ethernet Ports is tight and sealed.

-

Check Mains Power inlet is tight and sealed.

-

Check all Locks mechanisms are tight and secure, ensure they seal the panel when tightened.

-

Clean Diagnostic LEDs

Drawer and Landing Pad

-

Check Door tilts to 125 degrees from the Pad edge

-

Check Door tilt meeting point on the underside of the platform for wear and tear.

-

Clean hinge of any debri and grease with Lithium Grease.

-

Check tightness of Screws on the Landing Pad and Door Panel

-

Check Door Spring is tensioning and secure.

-

Check Landing TAG for wear and tear, replace if required and clean

-

Check drawer in/out motion with the handle, grease as required.

-

During motion check, physically move the drawer around and check for any loose connections or rattling or parts.

-

Pull the drawer out half way and check the sprung panel moves freely.

-

Check all Screws on the Rail mechanisms to the platform are tight and secure.

-

Check black bar at the end of the platform is tight and angled forward.

-

Check Limit Switches on the door frame are secure and you can hear a click when depressed.

-

Check Drone Take off markers are secure.

-

Check the Drive belt to Landing Pad connection is tight and secure.

Dock Internal Hanger from Drawer Side

-

Check the Side positioning panels are Secure and slides the drone into the central position.

-

Check the Charging connection that drops down in the centre is secure.

-

Check the POGO pin springs on the charge block move in and out freely.

-

Take a photo of the Charge Servo Arm position

-

Remove Charge and Button Press Servo and inspect for damage, replace in the position as per previous photo

Dock Internals from the Rear Access Panel

-

Check Connections on the LED panel are all secure

-

Check Isolator connections are tight and Secure

-

Check MCB Connections are tight and Secure

-

Check the Rubber Seal is free of cracks and splits.

-

Check all wires are secured with clips.

-

Check AMFE is tight and secure.

-

Check Motor is tight to the Brackets and Black Rail

-

Test the Black Drive bar is light and secure, nothing should move including the base panel.

-

Check the Rear of the positioning Bars are tight and secure.

-

Check the tension of the Belt, 2 fingers side by side should leave a mark on the skin.

-

Check the Webcam postilion on the top of the panel.

Moisture Detection

-

Check the front of the Hanger inside for Moisture

-

Check inside the rear panel for moisture - through the marked points.

Electrical Inspection

-

Remove the External LandSure Device and Cooler Unit inlet ducting.

-

Unlock the 4 access locks, check the open freely and are not loose.

-

Check lock plates on the inside of the dock are secure

-

Ensure Fans are prevented from spinning during blowing air.

-

Clean the access panel with electric or battery operated compressed air blower.

-

Clean the hinge and grease as required.

-

CHeck All electrical components wires and connections are seated and secure, ensure mounting is secure.

-

Raspbery Pi

-

Odriod

-

RC

-

Check Brackets are tight

-

Check Servo arm for damage - replace i the same position if removed.

-

Check Antenna cables are secure and tight.

-

Arduino

-

Motor Driver

-

RUT955 Router

-

Wire distrubution WAGOs

Power Supplies

-

Check all Connections and Tighten Screws and Mounts for each Unit

-

24v

-

Check Voltage and Trim if required.

-

12v

-

Check Voltage and Trim if required.

-

5v

-

Check Voltage and Trim if required.

-

17.5v

Electrical Testing

-

Compete your Business and/or Country specific electrical conformance testing.

Testing the Dock post Maintenance.

-

1. Secure the locks and place the dock back on the feet. Replace the Cooling Ducting and LandSure Device.

-

2. Plug the Unit into the supply and power up the unit

-

3. Login to the FlytNow Dashboard

-

4. Once connected complete the following checks.

Dashboard Checks

-

Toggle RC on

-

RC should appear online on the Dashboard - 10-30 seconds.

-

Toggle UAV On

-

Confirm with webcam

-

UAV should appear online on the dashboard within 10-30 Seconds.

-

Toggle Open Enclosure

-

Confirm with webcam

-

Dashboard should indicate Docking Station is open

-

Toggle Close Enclosure

-

Confirm with dashboard

-

Dashboard should indicate Docking Station is open

-

Toggle UAV off

-

Confirm with webcam

-

UAV should appear offline on within 5 seconds

-

Initiate Drone Service

-

Confirm with webcam that drone has powered on and begun charging

-

UAV should appear online on the dashboard within 10-30 Seconds.

-

Monitor charge until battery % increases

-

Stop Drone Service

-

Confirm with webcam

-

UAV should appear offline on within 5 seconds

-

Toggle RC off

-

Confirm RC appears off via dashboard

-

Launch Manual Mission & Return to Docking Station

-

Full Automation successful?

-

What Failed?

-

Report to IDI vis Slack Channel

Dock Support Box

-

Date of install

-

Does the date exceed 18months

-

Replace dock support Box with new or refurbished system.

-

Complete Maintenance Checks

-

Open both side doors, clear dust and debris.

-

Clean the outside of the dock, ensure the fan covers are clear of debris

-

Check wiring is secure

-

Check 24v voltage, trim as required.

-

Turn on and test air flow through inlet and outlet.

-

Outlet Cool

-

Review Maintenance Cycle or replace.

-

Inlet Flow good

-

Review maintenance checks or replace.

Sign off and Completion

-

Name

-

Date and Time

-

Images of Inspection Repairs or Faults

-

Sign

-

Send Report to Dock Owner and IDI