Title Page

-

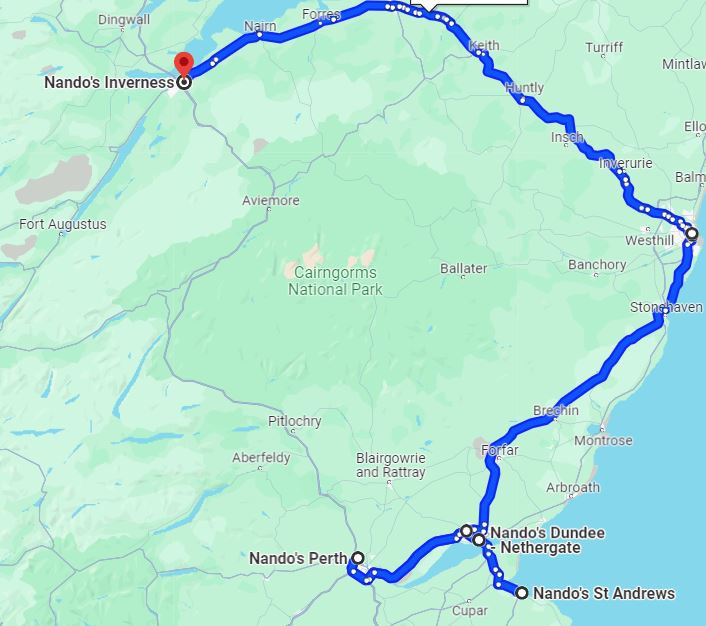

Site conducted`

- Dundee Camperdown

- Dundee Nethergate

- St Andrews

- Perth

- Aberdeen Union Square

- Aberdeen Belmont Street

- Inverness

-

Conducted on

-

Conducted by

Q2 Changes - Each change is in the relative section

-

FOG being disposed of incorrectly, clear separation of FOG types not evident & restaurant

team cannot clearly describe process. -

Non-halal chicken found in halal restaurant

-

First microwave reheat temperature not recorded on Grillers’ temperature check sheet

-

No evidence of scheduled, logged food donation for the week prior on Foodiverse

-

Safety comms from this month’s The Sauce not clearly displayed for staff to see

Purchases

Criticals

-

High risk food from unapproved suppliers (specify what)

Standards

-

Cold food transferred from another restaurant in unrefrigerated transport.

-

Hot food transferred from another restaurant not in hot box.

-

No paperwork available for any transferred food.

-

Food on site not from approved local purchasing guide list.

Delivery

Criticals

-

Chilled Food delivered above 8oC (ROI 5oC)

-

Frozen Food delivered above –12oC (ROI -18oC)

-

Non-halal chicken found in halal restaurant

Standards

-

Delivery vehicle unclean

-

Raw meat stored above ready to eat foods

-

Temperature of delivery not written on delivery note

-

Temperatures written on delivery note outside target ranges

-

Blown cans accepted

-

Risk Assessment for delivery vehicles not being followed

Storage

Criticals

-

Food in fridge above 8oC (ROI 5oC)

-

Raw food above or touching cooked/ready to eat

-

Food past manufacturers use by date (specify what and date marked)

Standards

-

Food not rotated (but nothing out of date)

-

Product stored uncovered

-

Product stored at risk of cross contamination

-

Food defrosting unrefrigerated

-

Food stored on floor in walk in fridge or freezer

-

Ready to eat food in freezer above -12oC (ROI -18oC)

-

Food in fridge above 5oC (but below 8oC, ROI 5oC)

-

Food in fridge above 8oC (ROI 5oC) (but managed as per refrigeration breakdown procedure)

-

Goods beyond manufacturer’s BBE date.

-

Open food not stored in appropriate food grade containers.

-

Livers not in suitable gastronomes.

-

Safety Manual process for food donations not followed correctly.

Food Labelling

Criticals

-

Manufacturer's marked "Use By" date extended by labelling.

-

Goods in fridge beyond in-house “use by” label.

Standards

-

Unlabelled food found in storage

-

Food labelled incorrectly (specify).

-

Pre-portioning process not followed for creamy mash

-

Pre-portioning process not followed for desserts

Preparation

Criticals

-

Raw and cooked/ready to eat foods preparation inadequately seperated

-

• Work surfaces or utensils not sanitised after handling raw products

-

Hands not washed/ gloves not changed/apron not worn and discarded after handling raw product

-

• Pre-portioning not discarded at end of day

Standards

-

Preparation in unclean area

-

Preparation in area with risk of foreign body contamination

-

Preparation in area with risk of chemical contamination

-

Preparation with utensils presenting risk of bacterial contamination.

-

Product prepared at risk of cross contamination.

-

Chilled food left out at ambient unnecessarily

-

Insufficient contact time allowed for sanitiser to be effective

Front Kitchen/Cashier Area

Criticals

-

Standards of cleanliness may adversely affect Food Hygiene Rating (specify why)

-

Rating (specify why)

-

Four or more cleanliness issues indicates breakdown in cleaning management in front kitchen/cashier area

Standards

-

• Detailed cleaning required to walls (pls specify).

-

• Detailed cleaning required to floors (pls specify).

-

• Detailed cleaning required to ceilings (pls specify)

-

• Detailed cleaning to doors or doorframes (please specify)

-

• Detailed cleaning required to wall-floor junctions

-

• Detailed cleaning required beneath hot holding equipment.

-

• Detailed cleaning required to food contact surfaces (pls specify).

-

• Detailed cleaning required to food preparation equipment (pls specify).

-

• Detailed cleaning required to refrigerators

-

• Detailed cleaning required to filters or canopy (pls specify).

-

• Detailed cleaning required to hand contact surfaces (pls specify).

-

• Detailed cleaning required to shelving/ utensil storage areas (pls specify)

-

• Detailed cleaning to equipment cabling, (specify which)

-

• (Internal) bin requires cleaning.

-

• Oil spillages/ leaks on walls or floors.

-

• Food service utensils dirty/ kept in dirty water

-

• Plates for food service not properly clean (e.g. food debris baked on).

-

• Glassware not properly clean (e.g. lipstick/ smears).

Cooking/Reheat

Critical

-

Chicken products probed after cook below 75oC

-

Rice not reheated to 75˚C throughout

-

Out of date product being cooked

Standards

-

Cooking equipment or utensils unclean

-

• Cooking equipment not set at the correct settings or reached operating temperatures

-

• Raw materials in unsatisfactory condition

-

• Recipe specifications not followed

-

• Butterfly or whole chicken cooked in mixed load programme.

-

• Oil tester not in use for acrylamide controls

-

• First microwave reheat temperature not recorded on Grillers’ temperature check sheet

Temperature Probe Care/use

Critical

-

No working temperature probe available for use.

-

• No effective antibacterial wipes available for use.

-

• Probe used for direct food test without being sanitised first.

Standards

-

Probe insufficiently clean.

-

• Unsatisfactory reading taken & not reported to manager on duty.

-

• Probe inaccurate (but last calibration checks satisfactory).

-

• Spare probe defective/ unavailable.

-

• Staff observed using probe incorrectly.

Cooled Pulled Chicken

Critical

-

Chilled pulled chicken temperature above 8°C

-

• Portioning of cooled chicken taking place at risk of

-

contamination from raw meat products

Standard

-

Detailed cleaning required to chicken cooling rack

-

• Portioned pulled chicken pots not individually labelled

-

• Portioned pulled chicken pots labelled incorrectly (see Product Matrix)

-

• Chicken on cooling rack not covered

-

• Chicken cooling rack stored at risk of cross contamination

-

• No record of temperature of chicken in walk-in fridge on Weekly HACCP Checks

-

• Portioning of pulled chicken taking place in a non-food prep area

Hot Hold

Critical

-

Hot held chicken below 63oC (Safety Manual procedure not used)

-

• Hot held burgers below 63oC (Safety Manual procedure not used)

-

• Hot held wings below 63oC (Safety Manual procedure not used)

-

• Hot held rice below 63oC (Safety Manual procedure not used)

-

• Hot held double breasts below 63˚ (Safety Manual procedure not used)

-

• Hot held chicken thighs below 63˚ (Safety Manual procedure not used)

-

• Hot held food below 63ºC not discarded in 2 hours

-

• Hot holding equipment in use to reheat food

Standard

-

Hot holding equipment not turned on before being used

-

• Chicken below 63ºC but identified for sale within 2 hours.

-

• Burgers below 63ºC but identified for sale within 2 hours.

-

• Wings below 63ºC but identified for sale within 2 hours.

-

• Double Breasts below 63ºC but identified for sale within 2 hours.

-

• Chicken thighs below 63ºC, but identified for sale within 2 hours

-

• Rice below 63ºC but identified for sale within 2 hours.

-

• Hot held food below 63ºC but identified for sale within 2 hours.

-

• Drawers for hot hold equipment left open unnecessarily

-

• Chicken products not held in smallest practicable containers.

-

• 2-hour rule incorrectly applied.

-

• Water added to warmer drawers

Foreign Body Contamination

Critical

-

Food available for use found to be contaminated (Specify what)

Standard

-

Glass in food areas not kept on lowest shelf possible.

-

• Wine/beer de-boxed in walk in chiller but not in a container.

-

• Glasses or food containers not stored upside down.

-

• Chopping block pitted, presenting risk of contamination.

-

• Food prepared in areas with overhead damage to walls or ceilings.

-

• Damaged utensils, containers or crockery in use.

-

• Cracked or chipped glassware in use.

-

• Olive sign not displayed

-

• Lights in food prep areas not protected with diffusers.

-

• Staples or drawing pins used in food preparation areas

-

• Silicone basting brushes not in use.

-

• Presence of any other item posing a risk of foreign body contamination.

Cleaning Procedures

Criticals

-

No cleaning rota available

-

• Chemicals decanted into food containers

Standards

-

Cleaning equipment inadequate (please specify).

-

• Cleaning equipment dirty.

-

• Items missing from cleaning rota

-

• Cleaning rota lacks necessary detail (e.g. frequency, method, PPE or chemical).

-

• Cleaning tasks signed off recently but not completed satisfactorily.

-

• Colour coded equipment used in incorrect locations.

-

• Red cleaning equipment stored in food prep areas.

-

• Manager not aware of when it is appropriate to put in place enhanced cleaning measures

-

• Aprons and gloves not available for enhanced cleaning purposes

Equipment/Structure

Critical

-

Defective equipment being used without corrective action

-

being taken.

-

• Defective structural issues impacting safety not reported to the helpdesk/access maintain

-

• Restaurant trading with no hot water

Standard

-

Damaged floors not permitting effective cleaning in food preparation areas.

-

• Damaged walls not permitting effective cleaning in food preparation areas.

-

• Damaged ceilings not permitting effective cleaning in food preparation areas.

-

• Ventilation leaks or failing to extract cooking smoke.

-

• Oven seals split

-

• Other maintenance issue impacting food safety (please specify)

-

• Other maintenance issue impacting health & safety (please specify)

-

• Health & Safety or Food Safety related maintenance outstanding, but on timed schedule of planned works

Personal Hygiene

Critical

-

• Staff working when ill with diarrhoea, vomiting, or unprotected skin infections

-

• Staff fail to wash their hands at the appropriate time

-

• Staff smoke, eat, or spit in food handling areas.

Standard

-

• Hand wash basin used for anything other than hand washing.

-

• Hand wash basin obstructed, or hot water too slow.

-

• Correct hand washing procedure not followed (please specify).

-

• Customer hand wash sink ill equipped (lacks soap, paper towel or hot water to slow - please specify)

Pest Control

Critical

-

Recommendations of pest contractor not actioned by managment team

-

• Evidence of pests found on site (in food areas) not reported to contractor

-

• Enhanced pest control protocol not in use when appropriate.

Standard

-

Manager on duty unable to access Pest Alert system

-

• Evidence of pests found on site: reported to contractor.

-

• Evidence of pests found on site (in non food areas): not reported to contractor

-

• Fly killer not clean.

-

• Fly killer sited, but inoperative.

-

• No routine pest control visit recorded in the last 12 weeks.

Back Kitchen

Critical

-

Standards of cleanliness may adversely affect Food Hygiene rating (specify why)

-

• Four or more cleanliness issues indicates breakdown in cleaning management in back kitchen

Standard

-

• Detailed cleaning required to walls (pls specify).

-

• Detailed cleaning required to floors (pls specify).

-

• Detailed cleaning required to ceilings (pls specify).

-

• Detailed cleaning required to light fittings (pls specify).

-

• Detailed cleaning to equipment cabling, (specify which)

-

• Detailed cleaning to doors or doorframes (please specify)

-

• Detailed cleaning required to wall-floor junctions

-

• Detailed cleaning required to framework, legs and feet of equipment.

-

• Detailed cleaning required to food contact surfaces (pls specify).

-

• Detailed cleaning required to food preparation equipment (pls specify).

-

• Detailed cleaning required to refrigerators

-

• Detailed cleaning required to hand contact surfaces (pls specify).

-

• Detailed cleaning required to filters or canopy (pls specify).

-

• Detailed cleaning required to shelving/ utensil storage areas (pls specify)

-

• Detailed cleaning required to sink

-

• Dishwasher not clean (not just current shift: check e.g. nozzles, limescale build-up on walls).

-

• Dishwasher pipework and fog trap surfaces not clean.

-

• Blocked drains.

-

• Ponding water.

-

• Chicken dollies require cleaning.

-

• (Internal) bin requires cleaning.

-

• Oil spillages/ leaks on walls or floors.

-

• No chemical in dishwasher.

-

• Plates not leaving dishwasher hot enough to air dry.

-

• Plates for food service not properly clean (e.g. food debris baked on).

Walk in Fridge

Standard

-

• Detailed cleaning required to floors

-

• Detailed cleaning required to walls including fan guard

-

• Detailed cleaning required to ceiling

-

• Detailed cleaning required to shelving

Walk in Freezer

Standard

-

Detailed cleaning required to floors

-

• Detailed cleaning required to walls including fan guard

-

• Detailed cleaning required to shelving

Dry Store/Coke Room

Standard

-

Detailed cleaning required to floors

-

• Detailed cleaning required to walls

-

• Build up of syrup on shelving or pipes

Bin Store/Back Yard

Critical

-

• Standards of cleanliness may attract enforcement action (specify why)

Standard

-

Bins damaged/ missing lids.

-

• Bins dirty.

-

• Bins uncovered/ overflowing

Assessment of closedown

Critical

-

Four or more cleanliness issues in this area (not from a single poor closedown)

Standard

-

Unsatisfactory closedown procedures under/behind hot hold units

-

• Unsatisfactory closedown procedures for hot hold equipment

-

• Unsatisfactory closedown procedures under/behind fridges

-

• Unsatisfactory closedown procedures for fridges

-

• Unsatisfactory closedown procedures for equipment / skirting to floor junction

-

• Unsatisfactory closedown procedures for bain marie

-

• Unsatisfactory closedown procedures for toasters

-

• Unsatisfactory closedown procedures for fat fryers

-

• Unsatisfactory closedown procedures under front grill support shelf

-

• Unsatisfactory closedown procedures for chopping block

-

• Unsatisfactory closedown procedures of voids in kitchen/ grill area

Restaurant

Critical

-

Standards of cleanliness may attract customer complaints (specify why)

Standard

-

Detailed cleaning required to walls/floors/ ceilings (pls specify)

-

• Dust seen on ledges or shelves.

-

• Cutlery streaked or dirty.

-

• Tables/ Chairs inadequately cleaned before service.

-

• Tables/ Chairs inadequately cleaned during service.

-

• Yoghurt machine inadequately cleaned before service.

-

• Ice machine inadequately cleaned before service.

-

• Soft drink dispenser nozzles inadequately cleaned before service.

-

• Ketchup & Condiment bottles/ pourers inadequately cleaned before service.

-

• Ketchup/ Condiment bottles/ pourers inadequately cleaned during service.

-

• Plates for food service not properly clean (e.g. food debris baked on).

-

• Cupboard under coke machine not free of liquid, syrup or food debris

-

• Detailed cleaning required (pls specify)

Customer Toilets

Standard

-

Detailed cleaning required to baby changing facilities.

-

• Broken or dangerously loose toilet seats (in any cubicle).

-

• Missing soap (in any dispenser).

-

• Missing toilet paper (in any cubicle).

-

• Hand drying facilities inadequate (either gender toilet).

-

• No hot water available (either gender toilet).

-

• Detailed cleaning required (please specify).

Staff Toilets/Staff Room

Critical

-

Standards of cleanliness may attract enforcement action (specify why)

Standard

-

Detailed cleaning required to hand wash basins.

-

• Detailed cleaning required to toilet bowls or cubicles.

-

• Missing toilet paper (in any cubicle).

-

• Staff belongings not stored tidily.

-

• Toilets provided for staff out of use.

-

• Detailed cleaning required.

Plant Room

Standard

-

Grease build-up in catch trays under extraction ducting/motor

-

• Leaking extract ducting

-

• Excessive items stored

Chemicals

Critical

-

Staff using chemicals without appropriate PPE

-

• Sanitiser not available for use

Standard

-

Chemicals found in unmarked containers.

-

• Chemicals found in incorrectly labelled containers.

-

• Chemicals found without COSHH data sheets.

-

• Cleaning rota task completed with the wrong chemical.

-

• Chemical cupboard accessible to the public unlocked.

-

• PPE defective/ not available/ unfit for use.

-

• Spray sanitiser not available in food preparation areas.

-

• Blue roll in use, not stored in a handheld dispenser or wall mounted dispenser

Fire

Critical

-

Fire Exit Routes obstructed

Standard

-

Original Fire Risk Assessment not available.

-

• Over one year since most recent documented review of FRA.

-

• Corrective action from FRA/Review not completed.

-

• No documented fire drill completed in the last 6 months.

-

• Fire-fighting equipment being used inappropriately.

-

• Cooking equipment turned on without all extract filters being in place.

-

• Fire exit restricted.

-

• Staff unaware of fire assembly point

-

• Manager unable to explain how to test fire alarm

-

• Fire door wedged or propped open

Allergy Management

Critical

-

Nuts on display without dome in place

-

• Manager on duty unable to explain allergy procedure (including takeaway procedure)

Standard

-

Digital "Food & Menu Specifications" file not available.

-

• Allergy stickers not available

-

• Nut dome opening facing customers

-

• Cashier not aware of cleaning procedure for nut display

Risk Assessments

Critical

-

Risk Assessments not available.

-

• Risk Assessments not being followed- immediate risk. (Please specify)

-

• Nandoca completing task covered by a risk assessment without having been trained

Standard

-

Risk assessments not reviewed in last year.

-

• Action required by risk assessments has not been completed by stated deadline.

-

• Action required by risk assessments completed but RA not updated.

-

• Nandoca under 18 has not had a specific young persons RA completed. (Please note name of Nandoca involved)

-

• Pregnant/ nursing Nandoca has not had a specific Maternity RA completed. (Please note name of Nandoca Involved)

-

• Up to date LOLER certificate not available.

-

• Signage or documentation required by Risk Assessment not displayed/available.

-

• Risk Assessments not being followed (no immediate risk). (Please specify)

Safety Training

Standard

-

No evidence available of "Safety Essentials" training (any Nandoca who has not passed the FS and H&S test)

-

• Food Safety e-learning not completed within 12 weeks (any Nandoca with start date post 28/2/11 or started after the opening)

-

• Trainee Nandoca has not started FS training e-learning. (Allow a week for new Nandocas to be uploaded onto the e-learning package)

-

• No trained "buddy trainer" available at the restaurant.

-

• New Safety and Compliance training sign off sheets not in use for any new trainees from October 2022

Paperwork (Food Safety) - Previous 13 weeks

Critical

-

Management weekly checklist not being completed.

Standard

-

• Critical limits breached on previous grillers records: no corrective action (c.a.) noted.

-

• Critical limits breached on previous cooking records: no c.a. noted.

-

• Previous week's cooking records incomplete: no c.a. evident.

-

• Previous week's grillers record incomplete: no c.a. evident.

-

• Paperwork not immediately available for inspection when requested.

-

• Management weekly checklist paperwork review not being fully completed. *

-

• Management weekly checklist inspection not being fully completed. *

-

• Management weekly checklist calibration checks not being correctly completed.

-

• Manager on duty unable to explain management checks and use of records

-

• Consistent issue in cooking records not being resolved by management action*

-

• Consistent issue in grillers records not being resolved by management action*

-

• Safety Manual incomplete/ out of date*

Paperwork (Food Safety) - Current Week

Standard

-

Current week's cooking records incomplete: no corrective action (c.a.) evident.

-

• Current week's hot hold records incomplete: no c.a. evident.

-

• Critical limits breached on cooking records: no c.a. noted.

-

• Critical limits breached on grillers records: no c.a. noted.

-

• Current weeks grillers records incomplete: saladette temperatures not checked and recorded.

-

• Current weeks grillers records incomplete: frozen yoghurt temperatures not checked and recorded

-

• No evidence of scheduled, logged food donation for the week prior on Foodiverse

EHO/HSE Management

Critical

-

• Issue/ behaviour noted on last EHO/HSE visit observed (please specify-except R&M)

Standard

-

Most recent EHO/HSE visit report not available.

-

• Actions from last EHO/HSE visit outstanding.

-

• Manager on duty unable to explain EHO/HSE visit management procedure

Complaints Management

Standard

-

Manager on duty unable to explain AFP procedure.

-

• Manager on duty unable to explain foreign body procedure

Safe Working Practice

Critical

-

Gas or electrical equipment being repaired "in house"

Standard

-

Damaged cabling to electrical equipment.

-

• First aid box incomplete. Burns cream should not be available.

-

• Dangerous work practice observed (please specify: 1 pt for each practice seen)

-

• Work practice observed/workplace presenting slip/ trip hazard (please specify: 1 pt for each practice seen)

-

• Incorrect floor cleaning procedure observed.

-

• Work practice observed presenting risk of violence.

-

• Holes in oven gloves.

-

• CO2/He cylinders unrestrained.

-

• Manager/staff observed working alone.

-

• Highchairs missing safety features.

-

• A-boards being moved when not flat.

-

• No sharps kit available.

-

• Staff not following RA for contact with heat when disposing of FOG from ovens where observed

-

• FOG being disposed of incorrectly, clear separation of FOG types not evident & restaurant team cannot clearly describe process

-

• Personal items being plugged in and used in kitchen areas.

Training/Supervision

Critical

-

Management quarterly H&S checklist not being completed.

Standard

-

Management quarterly H&S checklist not being fully completed. (Please explain deductions)

-

• Manager on duty unable to explain management checks and use of records for checks for which that manager has signed for

-

• H&S e-learning not completed within 12 weeks (any Nandoca with black shirt - start date post 28/2/11 or trained during an opening)

-

• Trainee Nandoca has not started H&S training e-learning. (Allow a week for new Nandocas to be uploaded onto the e-learning package

-

• New Safety and Compliance training sign off sheets not in use for any new trainees from October 2022

Corrective Action

Critical

-

Any outstanding critical contravention

Standard

-

• Each outstanding standard contravention