Information

-

Company

-

Site

-

Audit Area

- Assy - High Bay 6

- Assy - High Bay 5

- Assy - TSM Cell

- Assy - Valve Cell

- Assy - FCM Cell

- Assy - Tbg Hgr Cell

-

Audit Area

- HB Montagem

- HB Teste

- HB FFI

- LB Montagem

- LB Teste

- LB FFI

- Tools Montagem

- Tools Teste

- Tools FFI

-

Conducted on

-

Auditor Name

-

Audit Participants

SOP10120709 - GLOBAL, MATERIAL DELIVERY AND CART STANDARDS

Section 2.0

-

Can anyone in the organization identify if a tool is missing?<br><br>

-

Detail the reason why

-

Does the operator have the correct part he/she needs, when it's needed?<br>

-

Detail the missing part(s) and the reason why

-

Does the operator have the correct tool he/she needs, when it's needed?<br>

-

Detail the missing tool(s) and the reason why

-

Can anyone in the organization identify if a part is missing?<br><br>

-

Detail the reason why

-

Could management gauge the progress of a build by seeing the parts at a particular workstation?<br><br><br>

-

Detail the reason why

Section 2.1 - Material Delivery Method - Pitch Carts

-

Are Pitch Carts in use in each area?<br><br><br><br>

-

Detail the reason why

-

Are Large Components strapped down to Cart<br><br><br><br><br>

-

Detail the reason why

-

Is the load capacity of the pitch cart suitable for the weight of the materials presented?

-

Detail the reason why

-

Are carts in good operating condition and free of damage?

-

Detail the specific areas of poor condition and/or damage.

-

Has each cart had a monthly inspection carried out?<br><br><br><br><br><br>

-

Detail the reason why

Section 2.2 - Point of Use Tooling - Tool Carts

-

Are all tools in place on Shadow Boards<br><br><br><br><br>

-

Detail the reason why

-

Are all visual indicators in place to link the tools to their respective workstation?

-

Detail the reason why

Section 2.3 - Material Cart Labelling Standards

-

Are all Material Carts labelled correctly?<br><br><br><br><br><br>

-

Detail the reason why

Section 2.5 - Part Templates

-

Are material carts populated with Foam Inserts?<br><br><br><br><br><br><br>

-

Detail the reason why

DGL0120698 - STANDARDS FOR THE CONCEPT AND METHODOLOGY SUPPORTING MODULAR FLOW

Section 8.1 - Flow Stoppage within Pitch

-

Can you see abnormal flow?

-

Detail reasons why

-

Do operators know what to do when abnormal flow occurs?

-

Detail reasons why

-

Do the operators within the flow solving issues before it effects flow?

-

Detail reasons why

-

If flow is stopped is this sign displayed on the VMB?<br>

-

Detail reasons why

-

Was the area flowing at the time of audit

Section 8.2 / 8.3 - Flow Stoppages Extending Beyond Pitch

-

If Flow is stopped and is effecting Takt, has it been removed from the line into a non flow station?<br>

-

Detail reasons why

-

Was the area flowing at the time of audit

Section 8.6 - FIFO Rules

-

If a FIFO is full, have the preceding cells stopped work?<br><br>

-

Detail reasons why

-

Was there still FIFO lane spaces available during the audit?

-

Are the lanes clearly labelled & marked?<br><br><br>

-

Detail reasons why

-

Are decisions about "what's next?" as simple to make as yes/no?<br><br><br><br>

-

Detail reasons why

-

Does the FIFO indicate what the next product is?<br><br><br><br><br>

-

Detail reasons why

Flow Rules

-

Can you see the flow of product within the value stream?

-

Detail reasons why

-

Are there visuals that tell when work will be delivered/removed?

-

Detail reasons why

-

Do the visuals communicate where the completed work will go next?

-

Detail reasons why

SOP10120699 - 5S OPERATOR REQUIREMENTS FOR MODULAR BUILD

Section 1.0 - 5S Audits and Checklists

-

Are the Operator Daily 5S Checklist and the 5S Weekly Audit Forms in use?<br>

-

Detail reasons why

-

Is the 5S Audit's Visual Management Board (VMB) system in use<br><br>

-

Detail reasons why

-

Are 5S scores consistently meeting or exceeding 3.6?

-

Detail reasons why

Section 4.1 / 4.2 - 5S Communication Board.

-

Is there a 5S Communication Board visible in the area<br>

-

Detail reasons why

SOP10120703 - VISUAL MANAGEMENT BOARD, SHARED SERVICE

-

Is the area being audited a shared service area

-

Is the Shared Service VMB in use?

-

Detail reason why

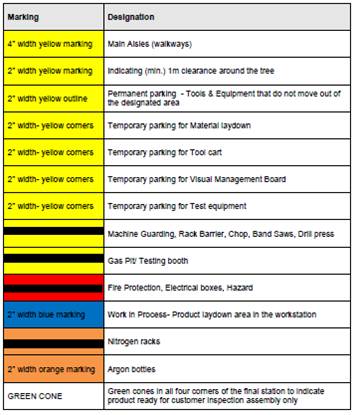

SOP10120705 - 5S FLOOR MARKING AND STRUCTURES.

Section 1.1 - Work Station Standards

-

Are permanent features marked using solid lines?

-

Detail reasons why

-

Are temporary parking indicated with 90 degree markers?<br>

-

Detail reasons why

-

Are FIFOs marked using the FIFO markings?<br>

-

Detail reasons why

-

-

Are floors marked in conjunction with the guideline<br>

-

Detail reasons why

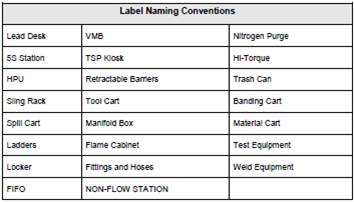

Section 1.1.1 - Floor Label Standards

-

Label background must be yellow

Label text colour must black

Label font size must be 1.5" high in all caps

Label must be centred along the edge of the floor marking and must be visible from the main aisle -

Floor Label Naming Convention

-

Are all areas marked in conjunction with the following?<br>

-

Detail reasons why

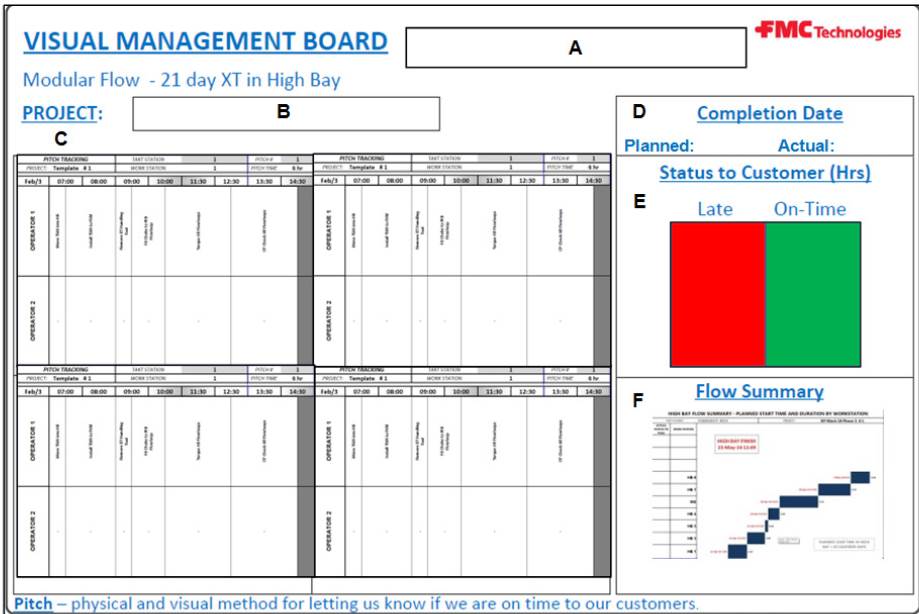

SOP10120708 - VMB (Visual Management Board)

Section 1.1.2 Standard VMB layout

-

Standard VMB Layout Image

-

Does the layout of the VMB match the standard detailed in the SOP?

-

Detail the non-conformances

-

Is the Pitch Plan current and being update by those doing the work?

-

Detail the reasons why

-

Is the "Status to Customer" section of VMB updated at the end of each pitch?

-

Detail the reasons why

-

Do operators capture flow issues and write them on the VMB as they occur?

-

Detail the reasons why

-

Are flow disruption issue resolutions updated?

-

Detail the reasons why