Information

-

-

Document No.

-

Planned Workplace Inspection (PCI Audit)

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Planned Workplace Inspection Checklists for Cylinder Operations Site (Yard, Sorting and Storage)

-

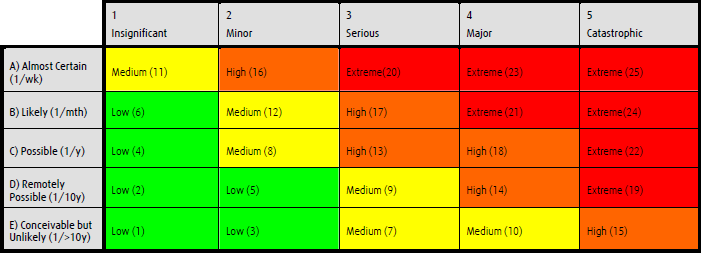

Risk matrix.

-

Minimal freestanding cylinders. Restraint hoops, pens, wall brackets and pallets in use as appropriate for vertical cylinders.

-

Risk rating?

- Yes

- No

- N/A

-

Corrective actions?

-

Date for completion of corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Horizontally stored containers properly chocked on the ground or located in suitable pallets or similar cradle devices.

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Date for completion of corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

All products stored in identified locations by gas type, ownership, full or empty and for future destination, for example test shop or trans-ship.

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Date for completion of corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Blow-down carried out only in designated areas and in accordance with approved procedures.

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Date for completion of corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Sort edges and ramps in use to facilitate safe loading/unloading from pallets.

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Date for completion of corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Where present, pallet stacking areas have specific risk controls and inspection regimes in place to ensure product integrity and stability?

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Date for completion of corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Where present, staging areas and lanes are configured so as to provide the best possible visibility for preventing MHE-MHE and MHE-pedestrian collisions ( I.e pallets one high at the end of staging lanes etc)?

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Date for completion of corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Suitable pallets in use for each different type of gas package (to result in secure load and provide acceptable level of protection).

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Date for completion of corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Site speed limits observed, including lowering in places of higher risk with blind corners, areas of low lighting at night, etc.

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Date for completion of corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Hazardous Substances?<br>1. No liquid or gas fumes/uncontrolled gas Venting or liquid draining<br>2. Hazard chemical symbols clearly labeled on all Containers<br>3. Material Safety Data sheets current <br>4. Storage containers in good condition, labeled, properly stacked and secondary containment<br>5. Appropriate natural/mechanical ventilation to reduce fumes<br>

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Environmental Issues?<br>1. Ventilation/lighting operational and appropriate<br>2. Noise level appropriate<br>3. No visible waste/material/stains/spills/wastewater discharge <br>4. Weather protection available for outdoor storage and secondary containment valves closed<br>

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Date for completion of corrective actions?

-

Date for completion of corrective actions?

-

Safety Issues?<br>1. PPE available and being worn where required<br>2. Safety signs visible & properly positioned<br>3. Safety tags used appropriately: danger/out of service/ warning tags<br>4. First Aid box available together with contents list & stocked to standard<br>5. Current list of first aiders displayed & up-to-date<br><br><br>

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Date for completion of corrective actions?

-

Physical Issues?<br>1. No leaks/corrosion <br>2. Grounds/pathways/grass in good condition<br>3. Access ways unobstructed<br>4. Good housekeeping. Surfaces clean, dry & free of unnecessary oil/grease/material <br>5. No slip, trip or head hazards<br>6. No wear and tear of equipment<br>7. Materials/equipment stacked OK, e.g. heavy items stored at lower levels<br>

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Date for completion of corrective actions?

-

Electrical Issues?<br>1. Electrical enclosures & distribution boards weatherproof<br>2. Earth leakage protection devices used<br>3. Electrical hand tools/extensions/leads, tidy, tested & tagged or recorded<br>4. Access to high voltage substations and cabinets controlled<br><br><br><br>

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Date for completion of corrective actions?

-

Work Method Issues?<br>1. Work Permit system in use<br>2. Manual handling appropriate<br>3. Work benches/area clean & tidy<br>4. Tools/equipment/materials being used correctly & in a safe manner<br>5. Clear & up-to-date written instructions available<br>6. Non smoking requirements observed<br>7. Site speed restrictions adhered to<br><br><br><br>

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Date for completion of corrective actions?

-

Security Issues?<br>1. Entrances/exits/locks/windows/gates in good condition<br>2. Employee, contractor & visitor IDs being used<br>3. Security fences intact and security cameras operational<br>

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Date for completion of corrective actions?

-

Machinery/Equipment Issues?<br>1. Valves, equipment and pipelines labeled<br>2. Unused equipment (eg, hoses, electrical equipment) Stored properly<br>3. Emergency stop buttons available, clearly marked And accessible<br>4. Machines properly guarded<br>5. Machines and surrounding areas clean & in good condition<br>6. Pallet condition satisfactory and cylinders adequately restrained<br>7. Gauges, alarms, trips, relief valves operational and regularly tested<br>8. Ladders, steps, hand rails & scaffolding secure & in good condition<br>

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Date for completion of corrective actions?

-

Emergency Issues?<br>1. Emergency procedures clearly displayed & up-to-date<br>2. Eyewash stations & emergency showers clean & in good working order<br>3. Emergency equipment and exits clearly marked & free of obstruction<br>4. Spill response equipment and supplies available<br>5. Fire extinguishers, hoses & hydrants available, clearly labeled & in test<br>

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Date for completion of corrective actions?

-

Other Hazardous Issues?

-

Risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions?

-

Residual risk rating?

- 5 Catastrophic (Fatality)

- 4 Major (Lost Time Injury)

- 3 Serious (Medical Treat)

- 2 Minor (First Aid)

- 1 Insignificant (No Injury)

- Not Applicable

-

Corrective actions completed?

-

Date for completion of corrective actions?