QC - Inspection Report (Full)

-

Manufacturing Order #

-

Client/Job Name

-

Product Name

-

Inspector/Report prepared by

-

Location

Inspection

-

Product ID / SKU / Serial

FORMWORK

-

Formwork Inspection Date

-

Dimensional accuracy & Squareness (Appendix A)

-

Squareness & Location of openings and block outs (Shop drawing)

-

End & Edge details (Shop drawing)

-

Mould Conditions & Cleanliness (2.4)

-

Seams / Silicone joints (2.4)

-

FORMWORK Pass/Fail/Notes/Photos

-

Formwork re-inspection Date

-

Dimensional accuracy & Squareness (Reinspection)

-

Squareness & Location of openings and block outs (Reinspection)

-

End & Edge details (Reinspection)

-

Mould Conditions & Cleanliness (Reinspection)

-

Seams / Silicone joints (Reinspection)

-

FORMWORK Pass/Fail/Notes/Photos

-

Formwork Sign-off

PRE-POUR/PRE-SPRAY

-

Pre-Pour/Pre-Spray Inspection Date

-

Design length / Width / Depth (Appendix A)

-

Retarders / release agent applied (2.4)

-

Flex and gravity anchors / Inserts (2.5/shop drawing)

-

Lifting hardware (Shop drawing/engineering)

-

Frame alignment (if required) (Shop drawing)

-

Frame coatings (Paint/HDG, etc...) weld dimensions (Appendix A)

-

PRE-POUR/PRE-SPRAY Pass/Fail/Notes/Photos

-

Pre-Pour/Pre-Spray re-inspection Date

-

Design length / Width / Depth (Reinspection)

-

Retarders / release agent applied (Reinspection)

-

Flex and gravity anchors / Inserts (Reinspection)

-

Lifting hardware (Reinspection)

-

Frame alignment (Reinspection)

-

Frame coatings (Paint/HDG, etc...) weld dimensions (Reinspection)

-

PRE-POUR/PRE-SPRAY Pass/Fail/Notes/Photos

-

Pre-Pour/Pre-Spray Sign-off

POST-POUR

-

Post-Pour Inspection Date

-

Cast Date

-

Temp/Humidity

-

Face mix (Colour, mix type + thickness) (Shop drawing)

-

Backer mix (Grade, thickness, etc...) (4.2)

-

Compaction (4.2.4)

-

Bonding pads (size, elbow) (4.2.6)

-

Integral ribs / Diaphragm (4.2.7)

-

Inserts & Embedments (4.2.8)

-

Cast test Billets (5.2.4)

-

POST-POUR Pass/Fail/Notes/Photos

-

Post-Pour re-inspection Date

-

Cast Date (Reinspection)

-

Temp/Humidity (Reinspection)

-

Face mix (Colour, mix type + thickness) (Reinspection)

-

Backer mix (Grade, thickness, etc...) (Reinspection)

-

Compaction (Reinspection)

-

Bonding pads (size, elbow) (Reinspection)

-

Integral ribs / Diaphragm (Reinspection)

-

Inserts & Embedments (Reinspection)

-

Cast test Billets (Reinspection)

-

POST-POUR re-inspection Pass/Fail/Notes/Photos

-

Post-Pour Sign-off

FINAL QC

-

Final QC Inspection Date

-

Curing period (eg. 7 days)

-

Surface finish, colour uniformity, cracks or spalls (Sample/Appendix B)

-

Deflection / Warpage / Bowing / Squareness (Appendix A)

-

Bonding pads / Ferrule mushies / Inserts (Appendix A)

-

Chamfers & Radius quality (Visual Inspection)

-

Openings (Shop Drawing)

-

Handling / Lifting devices (Shop Drawing)

-

Skin to frame clearance (mm) (Shop Drawing)

-

Sealer applied (Shop Drawing/Specification)

-

Product ID label attached (2.6)

-

FINAL QC Pass/Fail/Notes/Photos

-

Final QC re-inspection Date

-

Curing period (Reinspection)

-

Surface finish, colour uniformity, cracks or spalls (Reinspection)

-

Deflection / Warpage / Bowing / Squareness (Reinspection)

-

Bonding pads / Ferrule mushies / Inserts (Reinspection)

-

Chamfers & Radius quality (Reinspection)

-

Openings (Reinspection)

-

Handling / lifting devices (Reinspection)

-

Skin to frame clearance (mm) (Reinspection)

-

Sealer applied (Reinspection)

-

FINAL QC Reinspection Pass/Fail/Notes/Photos

-

Final QC Sign-off

QA Records

-

Flexural test - MOR / LOP

-

Bulk density & absorption

-

Flex / gravity anchor pull out

-

KG'S / Hours recorded

-

Photographs saved to Google photos

Testing Documents

-

Reports (PDFs)

Final Sign Off

-

Is this product in an acceptable condition?

-

Signature

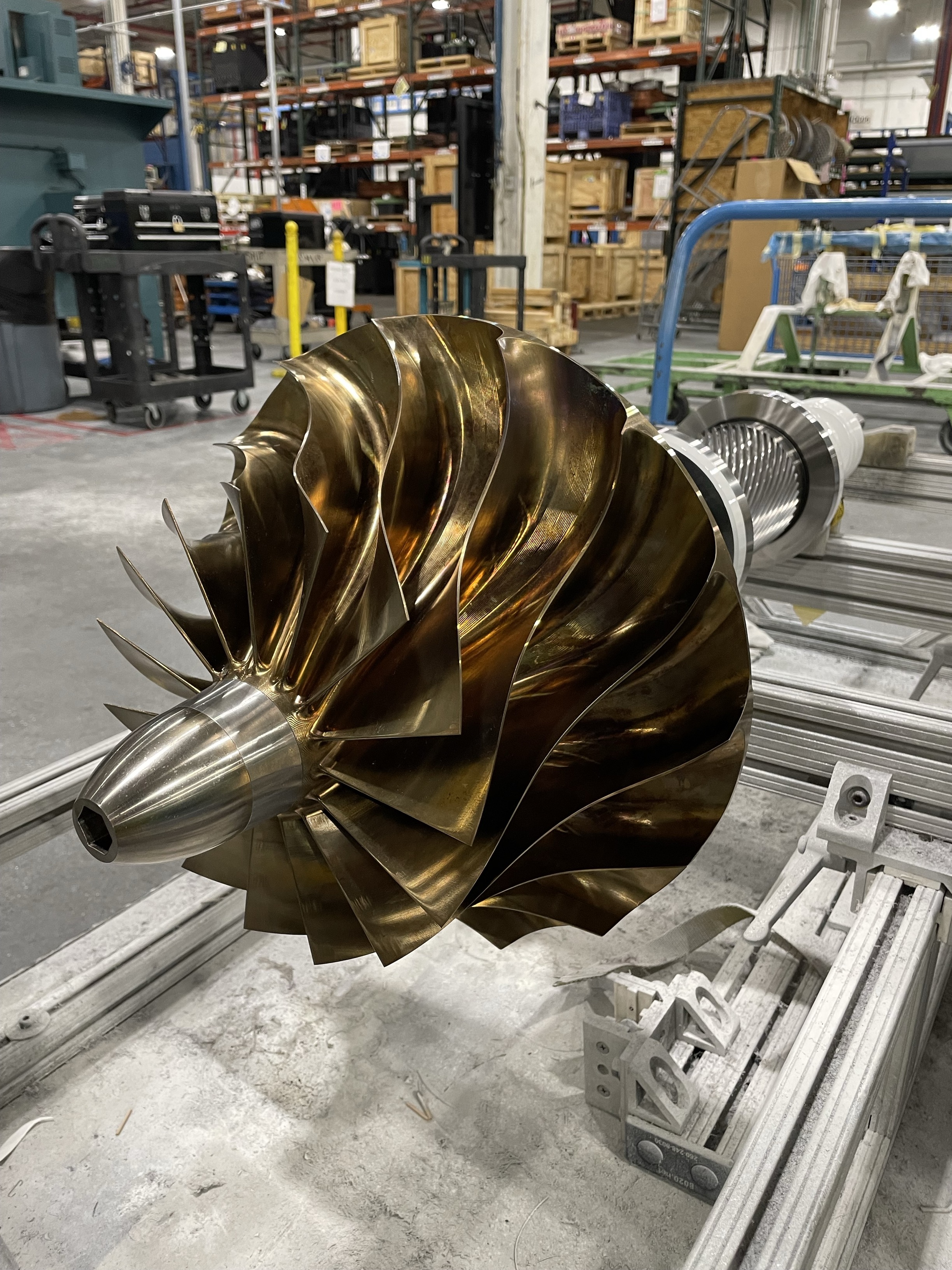

Images

-

Add Photos