Information

-

Facility

-

District

-

Conducted on

-

Prepared by

-

Location

-

Report Issued To:

1. Hazard Classification

-

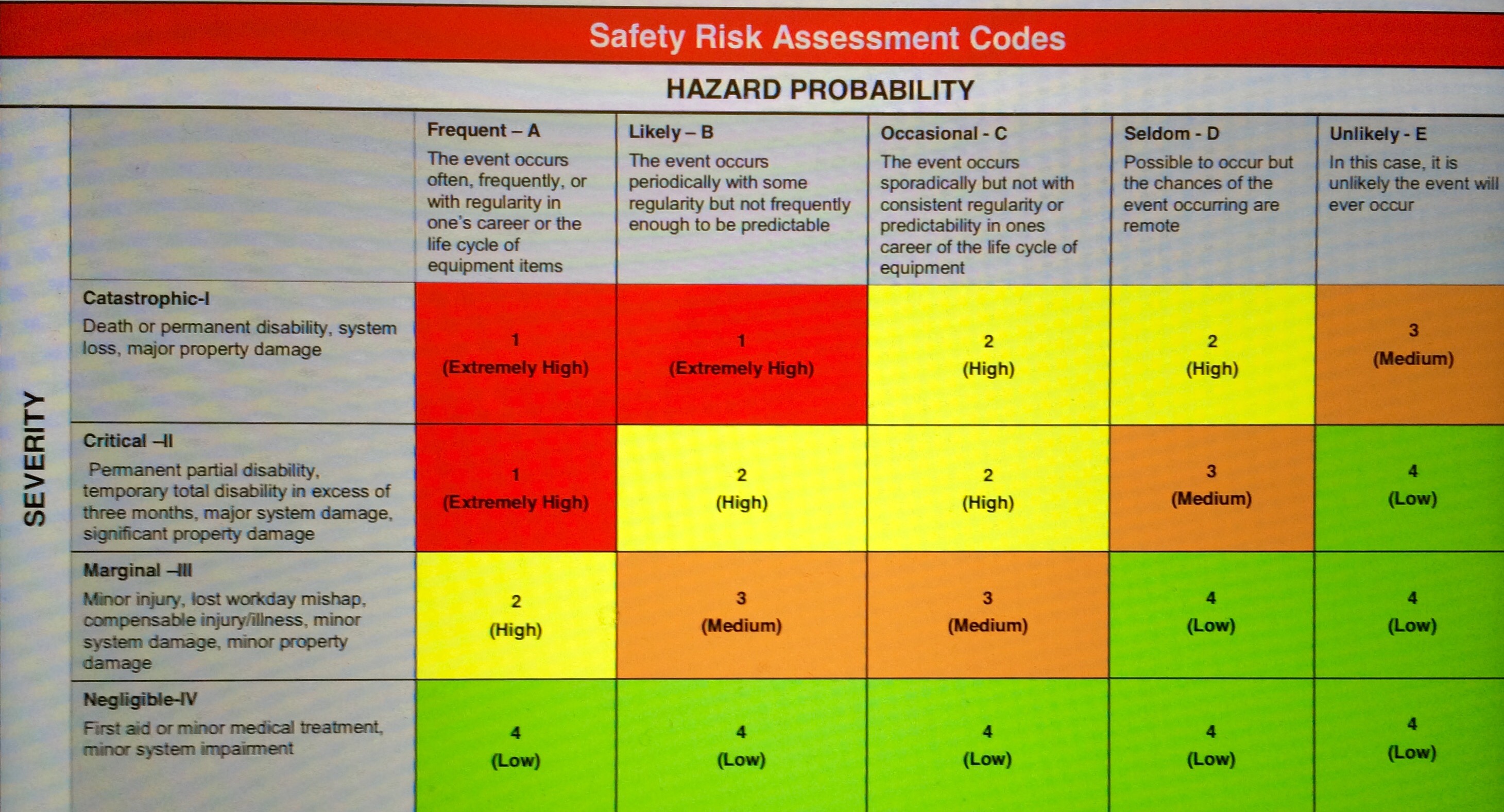

A hazard class rating will be inserted by the inspector [Reference: 6709.12, 11.4]. Hazards found during an inspection shall be classified so that managers can allocate time and dollars for their correction in order of priority based on the degree of danger present. Hazards shall be classified as: imminent danger, serious, and non-serious based on the following criteria:

1. Imminent danger hazards risk assessment code 1 (RAC 1) would likely cause death, severe injury or high property losses immediately, or before the hazard can be eliminated through normal procedures. Immediate employee protection and abatement is required. An example is a leaking propane gas cylinder in crew quarters.

2. Serious hazards risk assessment code 2/3 (RAC 2/3) are those in which there is high probability that serious injury, illness, or extensive property damage would result unless corrective action is taken. Abatement shall be accomplished within 14 days. An example is a broken stair tread.

3. Non-serious hazards risk assessment code 4 (RAC 4) are those that could cause injury, illness, or property damage. Abatement shall be accomplished in 30 days. An example is a broken window in a workshop.

Note: In the event a hazard cannot be corrected in the time allotted (contractor not available or contracting issues) a plan must be in place to correct the hazard as soon as possible. All employees must be notified of the hazard to limit exposure.

2. POSTINGS

-

Is the Summary of Occupational Illnesses and Injuries posted February thru April? 29 CFR 1904.35

-

Is the required OSHA workplace poster displayed in a prominent location where all employees are likely to see it? OSH Act 1970

-

Are emergency telephone numbers posted where they can be readily found in case of emergency? 29 CFR 1910.38

3. A.E.D.

-

Is accessory pack complete?

-

Are the chest electrodes current?

-

Does the Battery have a minimum charge of 25%?

4. GENERAL WORK ENVIRONMENT

-

Are all area's kept organized and clean? 29 CFR 1910.22.(a)

-

Is combustible scrap, debris, and waste stored safely and removed from the worksite promptly? 29 CFR 1910.106(e)(9) (iii) H&SC 34.2.8

-

Are toilets and washing facilities sanitary? 29 CFR 1910.141(d)

-

Are all work areas adequately lighted? 29 CFR 1910.22(a) H&SC 37.23

-

Are safety equipment items available, mounted, and current? (e.g., fire extinguishers, smoke and CO detectors, and first aid kits) 29 CFR 1910.157(c)(1) 29 CFR 1910.151(b) H&SC 34.2.1

-

Are fire extinguishers mounted 4 inches minimum off the ground maximum of 5 feet from the top of extinguisher weighing less then 40 lbs. and 3.5 feet from the top of extinguisher weighing more then 40 lbs. NFPA 10

-

Are enclosed workplaces constructed, equipped, and maintained, so far as reasonably practicable, as to prevent the entrance or harbor age of rodents, insects, and other vermin? 29 CFR 1910.141(a)(5)<br><br>

5. WALKWAYS

-

Are aisles and passageways kept clear and in good repair?29 CFR 1910.22(b)(1) H&SC 39.13.2

-

Are non-slip materials available in areas with wet surfaces? 29 CFR 1910.22(a)(2) H&SC 39.13

-

Is there safe clearance for walking in aisles where vehicles are operating? 29 CFR 1910.176(a)

-

Are materials or equipment stored so sharp objects can not obstruct the walkway? 29 CFR 1910.22(a)(3)

-

Are standard guardrails provided wherever aisle or walkway surfaces are elevated more than 4 feet above any adjacent floor or the ground? 29 CFR 1910.23(c)

6. STAIRWAYS

-

Are standard stair rails and handrails present on all stairways having four or more risers? 29 CFR 1910.23(d)(1) H&SC 39.13.6.c

-

Are all stairways at least 22 inches wide? 29 CFR 1910.24(d)

-

Do stairs have at least 6.5 feet of overhead clearance? 29 CFR 1910.24(i)

-

Do stairs angle no more than 50 degrees and no less than 30 degrees? 29 CFR 1910.24(e)

-

Are step risers on stairs uniform from top to bottom, with no riser spacing greater than 9.5 inches? Are these areas well lit? 29 CFR 1910.24(e) 29 CFR 1910.24(f) H&SC 39.13.6.d

-

Are steps on stairs and stairways designed or provided with a slip resistant surface? 29 CFR 1910.24(c) H&SC 39.13.6.a

-

Are stairway handrails located between 30-34 inches above the leading edge of stair treads? 29 CFR 1910.23(e)(5)(ii)

-

Do stairway handrails have at least 3 inches clearance between handrails and the wall or surface they are mounted on? 29 CFR 1910.23(e)(5)(iii)

-

Are stairway handrails capable of withstanding a load of 200 pounds applied in any direction? 29 CFR 1910.23(e)(5)(iv) UBC 1607.3.4

-

Are elevated surfaces (more than 4 feet above the floor or ground) provided with standard guardrails? 29 CFR 1910.23(c)

-

Are stairways free of defects, rubbish, slippery substances, loose materials, or obstructions that may cause slips, trips, and falls? H&SC 39.13.6b

7. EXIT DOORS AND ROUTES

-

Is a fire prevention/evacuation plan prepared for the site? Is an appropriately- detailed scale plan of the site posted in conspicuous location(s) at the site? H&SC 34.11

-

Are all personnel familiar with the plan, and are fire drills scheduled at least twice per year?H&SC 34.11.3

-

Are the directions to exits, if not immediately apparent, marked with visible signs? 29 CFR 1910.37(b)(4) H&SC 34.11.6

-

Are doors, passageways, or stairways that are neither exits nor access to exits, and which could be mistaken for exits, appropriately marked “NOT AN EXIT,” or “TO BASEMENT,” “STOREROOM,” etc.? 29 CFR 1910.37(b)(5) H&SC 34.11.6.a

-

Are exit signs provided with the word “EXIT” in lettering at least 6 inches high and the stroke of the lettering at least 3⁄4-inch wide? 29 CFR 1910.37(b)(7)

-

Are exit doors able to open from the direction of exit travel without the use of a key or any special knowledge or effort? 29 CFR 1910.36(d) H&SC 34.11.6.b

-

Are exit doors side-hinged? 29 CFR 1910.36(e)

-

Are there sufficient exit routes to permit prompt escape in case of emergency? 29 CFR 1910.36(b) H&SC 34.11.5

-

Are exit routes free of obstructions? 29 CFR 1910.37(a)(3)

-

Are exit accesses at least 28 inches in width? 29 CFR 1910.36(g)

8. ELECTRICAL SAFETY

-

Are electrical cords free of splices or taps? 29 CFR 1910.305(g)(2)(ii)

-

Are multiple plug adaptors prohibited? 29 CFR 1910.334(a)(3)(ii)

-

Are all disconnecting switches and circuit breakers each labeled to indicate their use or equipment served? 29 CFR 1910.303(f) H&SC 36.13.11

-

Do circuit breakers clearly indicate whether they are in the “on” or “off” position? 29 CFR 1910.304(e)(1)(vi)

-

Is adequate clearance provided in front of electrical service panels and disconnects? 29 CFR 1910.303(g)(1)(i) H&SC 36.13.12.a

-

Are all lights located within 7 feet of the floor, or exposed to being struck or damaged, protected? H&SC 37.23a.1

-

Are replacement bulbs within a fixture’s rating? H&SC 37.23a.2

-

Are electrical enclosures such as switches, receptacles, and junction boxes provided with undamaged, tight-fitting covers, or plates, including plugged unused opening (knockouts)? 29 CFR 1910.305(b)(1) 29 CFR 1910.305(b)(2)

-

Are defective components promptly replaced? H&SC 36.13

-

Are electrical outlets prohibited above permanently installed electric heaters? NEC 424.9

-

Do you require all electrical work to be performed by a licensed contractor in compliance with NEC and OSHA rules? 29 CFR 1910.303(b)(1) H&SC 36.1 and 36.12

-

Are electrical appliances such as vacuum cleaners, portable heaters, and vending machines grounded? 29 CFR 1910.304(f)(5)

-

Do all extension cords have a grounding conductor? 29 CFR 1910.334(a)(3)

-

Are extension cords protected from abrasion, crushing, kinking, and pulling? H&SC 36.13.6

-

Are exposed wiring and cords with frayed or deteriorated insulation repaired or replaced promptly? 29 CFR 1910.334(a)(2) (I) 29 CFR 1910.303(b)(iii)

9. PLUMBING, HEATING, VENTILATION, AND AIR CONDITIONING

-

Does your HVAC system provide at least the quantity of outdoor air designed into the system at the time the building was constructed? H&SC 37.12

-

Is preventive maintenance performed as recommended by the manufacturer, and records kept with the equipment? H&SC 37.12.3

-

Are chimneys, flues, and masonry inspected at least annually? H&SC 34.33

-

Are air filters inspected monthly and changed as needed, or as recommended by the manufacturer? H&SC 37.12.7

-

Are indoor air quality complaints investigated with results effectively communicated to employees? MLA, Article 27.6

-

Are temperature/pressure relief valves and drains installed on all water heaters? UPC 608.3 and 608.5 H&SC 39.9

-

Are water heaters anchored or strapped (within upper one-third of tank) for seismic protection? UPC 510.5 H&SC 39.9

-

Are water system shutoffs identified, accessible and operable? Local Regulation

10. MATERIALS HANDLING

-

Are materials stored so as to not create hazards to employees? 29 CFR 1910.176(b)

-

Are hazardous materials prohibited from being stored in refrigerators used for storing food? 29 CFR 1910.141(g)(2)

-

Are load limits conspicuously posted on storage shelves, bins, and racks? H&SC 39.64.3

-

Are materials stored in a manner to prevent sprain or strain injuries to employees when retrieving them? H&SC 39.64

-

Is there safe clearance for equipment through aisles and doorways? Are materials stored so as to allow safe passage of workers? 29 CFR 1910.176(a) H&SC 39.64.3b(3)

11. HAZCOM PROGRAM

-

Is there a "Written hazard communication program." that describes labels and other forms of warning, safety data sheets, and employee information and training that will be met? 29 CFR 1910.1200(e)(1)

-

Do you have an inventory list of the chemicals in the work area? 29 CFR 1910.1200(e)(1)(i) H&SC 61.14.1

-

Have the Forest Employees been informed of the chemicals in their work areas and all non routine tasks? 29 CFR 1910.1200(e)(1) (ii)

-

Do you have a method of informing contractors/contract employees of the chemical hazards in the their work area? 29 CFR 1910.1200(e)(2)

-

Do you have a current Hazardous Material Spill Response Plan, as part of a comprehensive Emergency Action Plan, to manage spills in the office and field? FSM 2100, Ch. 2160

-

Is each container for a hazardous substance (vats, bottles, storage tanks) labeled with product identity and a hazard warning that communicates specific health and physical hazards? 29 CFR 1910.1200(f) (5)

-

Are employees prohibited from handling hazardous chemicals that do not have an SDS? Are SDS’s readily available to employees at all times? H&SC 61.14.2

12. CONFINED SPACE

-

Employees do not enter a permit confine space. US Forest Service Policy

-

Has the Unit evaluated the workplace to determine if any spaces are permit-required confined spaces. Do you have an inventory list of all of your permit and non-permit spaces? 29 CFR 1910.146(c)(1)

-

Have you posted danger signs or by any other equally effective means, of the existence and location of and the danger posed by the permit spaces. 29 CFR 1910.146(c)(2)

-

In the last year have you had to reclassify a non-permit space to a permit required space, due to changes in the use or configuration that might increase the hazards to entrants? 29 CFR 1910.146(c)(6)

-

INSPECTION CONDUCTED BY