Title Page

-

Conducted on

-

Prepared by

-

Location

General

-

Instructions

------------------------------

1. Observe and identify workplace hazards on site which could cause harm to workers. Follow and repeat the steps below for all hazards identified

2. Click "Add Hazard" to begin documenting risk assessment

3. Describe hazard and take photo and include annotations where required

4. Assess the risk rating based on risk matrix reference at bottom of template

5. Attach any photos, notes or corrective actions by clicking on the paperclip icon

6. Select the appropriate controls with reference to the hierarchy of controls at bottom of template

Complete the risk assessment by providing general recommendations and signature

Generate and export report in PDF, Word or Web Links -

Enter description of procedure, task or worksite being assessed

ACCESS AND EGRESS

DOOR CLOSERS

HAZARDS IDENTIFIED

-

"Lack of evidence that door closers are being checked for integrity, tension and functionality

-

Doors that slam shut

-

Doors that are difficult to open "

-

Photo of hazard (optional)

RISKS

-

Manual Handling Injuries

-

Impact

-

Crush/ pinch

-

Entrapment

-

Amputation

RISK OF

-

"Manual handling injuries

-

Impact

-

Crush/ pinch

-

Entrapment

-

Amputation

CURRENT CONTROLS IN PLACE

-

What Current Controls Are in Place?

RISK RATING

People

-

1-2 Employees

-

3-7 Employees

-

8-15 Employees

-

16-50 Employees

-

50+ Employees

Injury

-

Scrach or bruise

-

Laceration or mild ill effect

-

Break of minor bone or minor illness (temporary)

-

Break of major bone or major illness (permanent)

-

Loss of one limb, eye, hearing (permanent)

-

Loss of two limbs or eyes(permanent)

-

Fatility

Likelihood

-

Almost impossible - ony in extreme circumstances

-

Highly unlikely - though conceivable

-

Unlikely - but could occur

-

Possible - but unusual

-

Even chance - could happen

-

Probable - not surprising

-

Likely - to be expected

-

Certain - no doubt

Ocurrence

-

Annually

-

Monthly

-

Weekly

-

Daily

-

Hourly

-

Constantly

Total Risk Calculation

-

Total Risk Rating High (Over 500 PxIxLxO)

-

Total Risk Rating Medium (51-500 PxIxLxO)

-

Total Risk Rating Low (050 PxIxLxO)

NEW CONTROLS TO BE PUT IN PLACE

-

Ensure Door closers are checked on a regular basis

-

Ensure staff awareness of defects. Reporting lines clear.

-

Ensure Door closers are adjusted to the correct speed i.e. They do not slam shut.

-

Ensure Hold open fire door retainers in use.

-

Ensure Broken door closers are repaired

AUTOMATIC DOORS

RISK OF

HAZARDS IDENTIFIED

-

"Lack of evidence of regular servicing/ planned preventative maintenance in place.

-

Lack of planned preventative maintenance

-

No evidence of maintenance or servicing or visual inspections

-

Insufficient or incomplete records

-

Lack of safety signage

-

Moving parts moving past fixed parts

-

Non compliance to safety distances between final stopping point of door and adjacent structure or wall

-

Incorrect settings or distances for protective leaves/ pocket screens

-

Non compliance with minimum detection distances

-

Sensor failure"

RISK OF

-

"Entrapment of head or body

-

Crushing/ pinching where two leaves come together

-

Crushing/ pinching at two closing edges

-

Pinching"

CURRENT CONTROLS IN PLACE

-

What Current Controls Are in Place?

RISK RATING

People

-

1-2 Employees

-

3-7 Employees

-

8-15 Employees

-

16-50 Employees

-

50+ Employees

Injury

-

Scrach or bruise

-

Laceration or mild ill effect

-

Break of minor bone or minor illness (temporary)

-

Break of major bone or major illness (permanent)

-

Loss of one limb, eye, hearing (permanent)

-

Loss of two limbs or eyes(permanent)

-

Fatility

Likelihood

-

Almost impossible - ony in extreme circumstances

-

Highly unlikely - though conceivable

-

Unlikely - but could occur

-

Possible - but unusual

-

Even chance - could happen

-

Probable - not surprising

-

Likely - to be expected

-

Certain - no doubt

Occurrence

-

Annually

-

Monthly

-

Weekly

-

Daily

-

Hourly

-

Constantly

Total Risk Calculation

-

Total Risk Rating High (Over 500 PxIxLxO)

-

Total Risk Rating Medium (51-500 PxIxLxO)

-

Total Risk Rating Low (050 PxIxLxO)

NEW CONTROLS TO BE PUT IN PLACE

-

• No entry sign

-

• Keep clear sign

-

• Emergency break-out sign

-

• Automatic door sign

-

• Disabled person sign

-

• Direction of travel sign

-

• Existing standards

-

• Glass safety Deacyl

-

Servicing and maintenance

-

*To be completed by a competent person in accordance with manufacturers guidelines and relevant standards

-

* Log book available

-

* Doors comply with EN 16005 regulations"

ROLLER SHUTTERS

HAZARDS IDENTIFIED

-

"No evidence of regular servicing/ planned preventative maintenance in place.

-

Lack of planned preventative maintenance

-

Lack of maintenance or servicing or visual inspections

-

Insufficient or incomplete records

-

Lack of safety signage

-

Moving parts

-

Unauthorised Staff operating roller shutters"

RISKS

-

"Entrapment

-

Crushing/ pinching

-

Malfunction

-

Breakage

-

Failure

-

Impact

-

Collision

-

Fatality

-

Electrocution"

CURRENT CONTROLS

-

What Current Controls Are in Place?

RISK RATING

PEOPLE

-

1-2 Employees

-

3-7 Employees

-

8-15 Employees

-

16-50 Employees

-

50+ Employees

INJURY

-

Scrach or bruise

-

Laceration or mild ill effect

-

Break of minor bone or minor illness (temporary)

-

Break of major bone or major illness (permanent)

-

Loss of one limb, eye, hearing (permanent)

-

Loss of two limbs or eyes(permanent)

-

Fatility

LIKELIHOOD

-

Almost impossible - ony in extreme circumstances

-

Highly unlikely - though conceivable

-

Unlikely - but could occur

-

Possible - but unusual

-

Even chance - could happen

-

Probable - not surprising

-

Likely - to be expected

-

Certain - no doubt

OCCURENCE

-

Annually

-

Monthly

-

Weekly

-

Daily

-

Hourly

-

Constantly

Total Risk Rating

-

Total Risk Rating High (Over 500 PxIxLxO)

-

Total Risk Rating Medium (51-500 PxIxLxO)

-

Total Risk Rating Low (050 PxIxLxO)

NEW CONTROLS

Maintenance and Servicing

-

* Competent Contractor in place and regular servicing and maintenance taking place, where relevant.

-

* Maintenance documentation on file.

Training

-

*Only authorised Staff are permitted to use the roller shutters.

-

*Staff must report any defects such as door not rolling smoothly, leaks, sparks, uncontrolled movement etc.

-

*Roller shutters comply with BS EN 13241-1:2003 Industrial, commercial and garage doors and gates

-

undefined

PASSENGER GOODS AND LIFTS

HAZARDS IDENTIFIED

-

"Lack of awareness

-

Lack of Staff training

-

Lack of resources

-

Lack of proactive routines

-

Lack of safe working practices

-

No evidence of regular checks

-

No evidence of servicing/ maintenance

-

No evidence of thorough examination every 6 months

-

Lack of suitable safety signage

-

No evidence of documented emergency procedure in the event of breakdown

-

No evidence of Staff trained to carry out emergency rescue procedure in the event of breakdown

-

No emergency contact numbers available

-

Lift machinery accessible to unauthorised personnel

-

Lack of regular testing of emergency phone/ alarm/ bell

-

"

RISKS

-

"Entrapment

-

Crushing/ pinching

-

Malfunction

-

Breakage

-

Failure

-

Impact

-

Collision

-

Slips, trips, falls"

CURRENT CONTROLS

-

What Current Controls Are in Place?

RISK RATING

People

-

1-2 Employees

-

3-7 Employees

-

8-15 Employees

-

16-50 Employees

-

50+ Employees

Injury

-

Scrach or bruise

-

Laceration or mild ill effect

-

Break of minor bone or minor illness (temporary)

-

Break of major bone or major illness (permanent)

-

Loss of one limb, eye, hearing (permanent)

-

Loss of two limbs or eyes(permanent)

-

Fatility

Likelihood

-

Almost impossible - ony in extreme circumstances

-

Highly unlikely - though conceivable

-

Unlikely - but could occur

-

Possible - but unusual

-

Even chance - could happen

-

Probable - not surprising

-

Likely - to be expected

-

Certain - no doubt

Occurrence

-

Annually

-

Monthly

-

Weekly

-

Daily

-

Hourly

-

Constantly

Total Risk Rating

-

Total Risk Rating High (Over 500 PxIxLxO)

-

Total Risk Rating Medium (51-500 PxIxLxO)

-

Total Risk Rating Low (050 PxIxLxO)

NEW CONTROLS

Emergency Response

-

* Develop an emergency procedure/ rescue plan in the event of lift entrapment.

-

* Document and communicate to Staff.

-

* Alarm/assistant button in place.

-

* Emergency Lighting in place.

-

* Only trained personnel allowed to operate

Maintenance Inspections

-

* Thorough Examination must be carried out every 6 months independent of ongoing maintenance, servicing and call outs.

-

* Access must be restricted to all service panels and/ or lift plant rooms. Plant rooms are kept clear of obstruction.

-

*Regular maintenance is carried out by a competent contractor and lifts taken out of service until repairs are carried out.

-

*Ensure regular checks are conducted at all entry/ exit points to the lifts

-

* Emergency features e.g. Emergency lights, alarm button & phone are tested by a competent person.

Lift Signage

-

*lift cannot be used in the event of a fire.

-

*Maximum weight allowed, generally in kgs and number of people.

-

* Goods lift only, No Passengers.

References

-

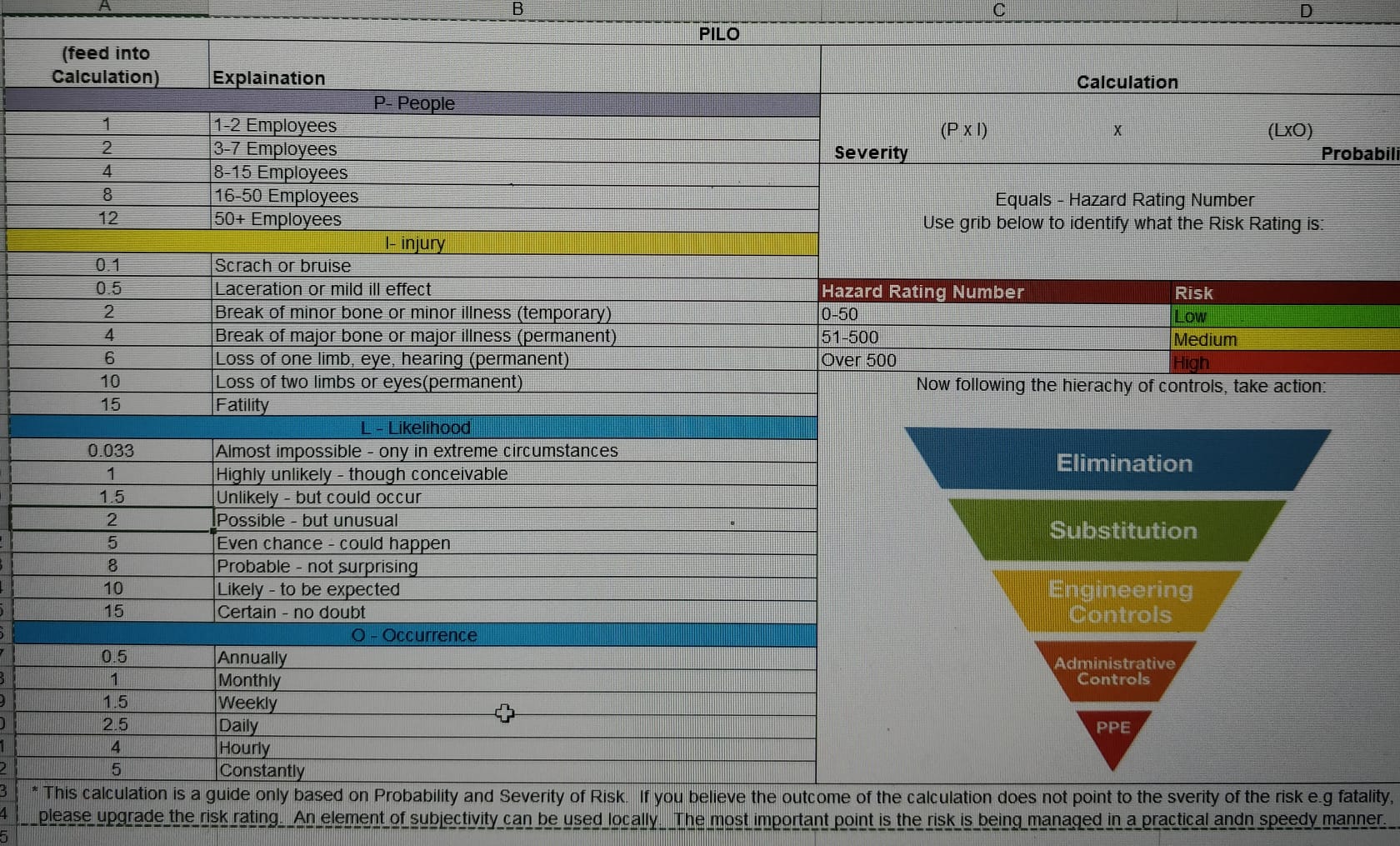

Risk Matrix Reference

-

Hierarchy of Controls Reference

Completion

-

Recommendations

-

Signature