Title Page

-

Build Title

-

Conducted on

-

Prepared by

-

Safe Latch Plan Inspection

Latch Inspection

-

Ford Part Number

- LH Front Manual ML34-15219A65-AA

- RH Front Manual ML34-15219A64-AA

- LH Front Power ML34-15219A65-BA

- RH Front Power ML34-15219A64-BA

- LH Rear Power ML34-16264B53-BA

- RH Rear Power ML34-16264B52-BA

- LH FD Power Peps ML34-15219A65-CA

- RH FD Power Peps ML34-15219A64-CA

- LH RD Power Peps ML34-16264B53-CA

- RH RD Power Peps ML34-16264B52-CA

-

Magna Part Number 12070010000

-

Magna Part Number 12070020000

-

Magna Part Number 12070030000

-

Magna Part Number 12070040000

-

Magna Part Number 12070050000

-

Magna Part Number 12070060000

-

Magna Part Number 12070070000

-

Magna Part Number 12070080000

-

Magna Part Number 12070090000

-

Magna Part Number 12070100000

-

Magna Part Number 12070110000

-

Finish Good Serial Number

-

Confirm evidence of inspection with pictures where applicable

-

Latch Serial Number

-

Chassis Serial Number

-

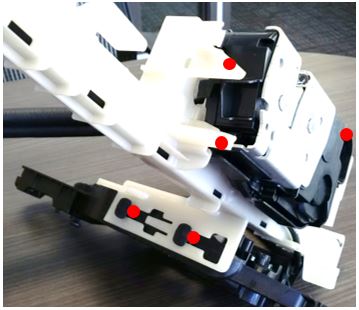

Correct Engagement of FGL Latch & Handle Chassis to the MFB Visual Aid

-

Verify correct engagement of FGL Latch & Handle Chassis to MFB

-

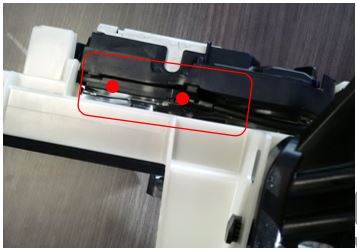

Verify correct engagement IS cable to the FGL Latch x 2 Positions Visual Aid

-

Verify correct engagement IS Cable to the FGL Latch x 2 positions

-

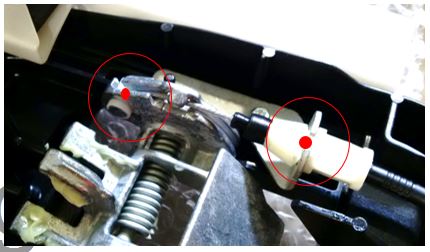

Verify Correct Engagement OS Cable to the FGL Latch x 1 position Visual Aid

-

Verify correct engagement OS Cable to the FGL Latch x 1 position

-

Verify Correct Engagement OS Cable to the Handle Chassis x 1 position Visual Aid

-

Verify correct engagement OS Cable to the Handle Chassis x 1 position

-

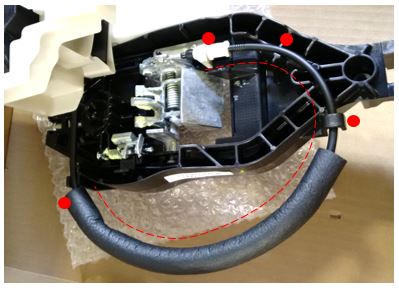

Verify Routing of OS cable in the Chassis Tab Visual Aid

-

Verify routing of OS cable into the Chassis tab

-

OS Cable properly routed into the Handle Chassis Visual Aid

-

OS cable properly routed into the Handle Chassis

-

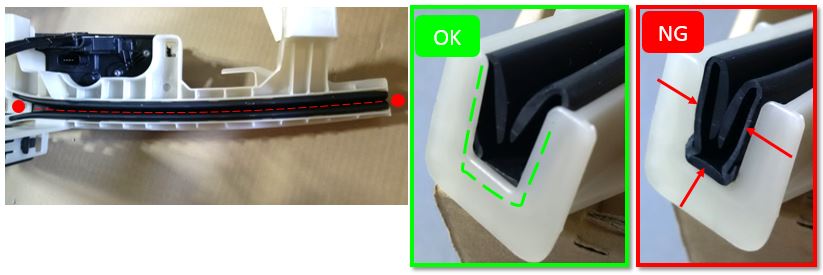

Run Guide Seal secured into MFB at Both Ends Visual Aid

-

Run Guide Seal secured into MFB at both ends.

-

Presence of Rod Key Cyl fully engaged to the FGL and Chassis. (Manual Version Only)

-

SDL MM free of visible damage on MFB, Cables, Seal, Latch and Chassis.

-

Correct Labeling at Single component and Full Pallet

-

Quality Inspector

-

Inspector Signature

-

Management Approval (when necessary)

-

Management Signature (when necessary)

-

Finish Good Serial Number

-

Confirm evidence of inspection with pictures where applicable

-

Latch Serial Number

-

Chassis Serial Number

-

Correct Engagement of FGL Latch & Handle Chassis to the MFB Visual Aid

-

Verify correct engagement of FGL Latch & Handle Chassis to MFB

-

Verify correct engagement IS cable to the FGL Latch x 2 Positions Visual Aid

-

Verify correct engagement IS Cable to the FGL Latch x 2 positions

-

Verify Correct Engagement OS Cable to the FGL Latch x 1 position Visual Aid

-

Verify correct engagement OS Cable to the FGL Latch x 1 position

-

Verify Correct Engagement OS Cable to the Handle Chassis x 1 position Visual Aid

-

Verify correct engagement OS Cable to the Handle Chassis x 1 position

-

Verify Routing of OS cable in the Chassis Tab Visual Aid

-

Verify routing of OS cable into the Chassis tab

-

OS Cable properly routed into the Handle Chassis Visual Aid

-

OS cable properly routed into the Handle Chassis

-

Run Guide Seal secured into MFB at Both Ends Visual Aid

-

Run Guide Seal secured into MFB at both ends.

-

SDL MM free of visible damage on MFB, Cables, Seal, Latch and Chassis.

-

Correct Labeling at Single component and Full Pallet

-

Quality Inspector

-

Inspector Signature

-

Management Approval (when necessary)

-

Management Signature (when necessary)