Title Page

-

Inspected by

-

Inspection date

Observations

-

Has there been any reports of any air leaks?

-

have you Identified the area of leak before isolating the power and/or air?

- Yes

- No

- N/A

Safety

-

Have you discharged any stored/potential electrical energy?

-

Compressed Air - Have you isolated the compressed Air?

-

Have you discharged any stored/potential air? (LOTO)

-

Have you filled out as LOTO check sheet?

-

Is there sufficient lighting in the area?

Preparation

-

Confirm The Serial Number Of The Machine S/N: 319 C0500077?

-

Do you have all the relative tools, consumables and checking equipment to perform the service?

-

Are you wearing all the required PPE?

-

Do you have a safe working area?

Running Maintenance

-

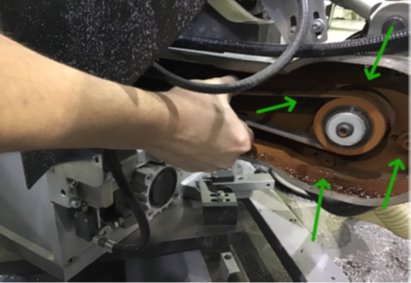

Remove belt cover and clean in and around the housing.

-

Have you cleaned in and around the belt housing?

-

Check tension and tighten. When too loose ‘screeching’

noise can be heard and will also damage belt -

Have you checked the Belt condition and tension?

-

Use threaded bolt as the ‘tensioner’.

Bolt is positioned between motor and frame.

This must be done to both blade motor belts. -

Clean out PC area, removing any dust and debris with a vacuum

-

Have you cleaned the PC base unit housing?

-

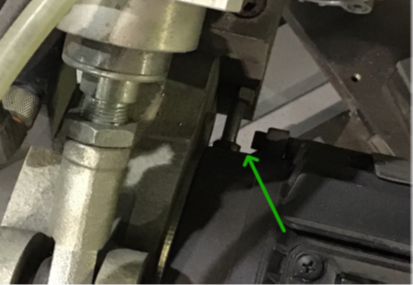

Retraction switch must be inspected

-

Is the switch in a good condition?

-

Check the guard Sensors, and clean around the area.

-

Guard Sensor Tested Working OK?

-

Check all fixings, Sensors and Solenoid Fixings and Clean around areas.

-

Fixing and sensors inspected, and tested working ok?

-

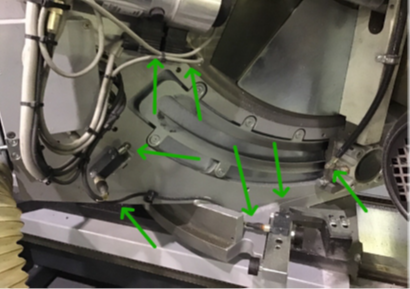

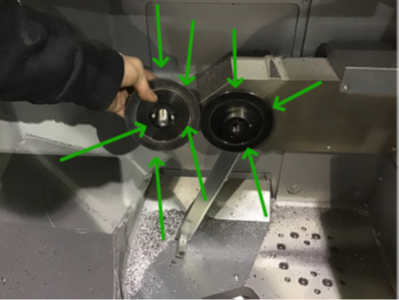

Loading profile arms must be inspected for operation and

solenoid leaks

Rectangle/arrow denotes arm and movement to inspect for

clean operation.

Circle denotes solenoid specific for each arm, you must

remove the cover plate to expose. Check for leaks and

fixing. -

loading arms inspected and tested working ok, with no signs of leaks?

-

INFORMATION

Profile ARM 1: In this case we removed the faulty coil and

used the new coil onto original body.

Profile ARM 2: Used 2nd spare coil as this arm solenoid

was also leaking.

SAP1007098 QTY.1 -

CLEANING THE SAW AREA - Remove left Saw cover and remove blade and clean out.

Clockwise to tighten. -

has the saw area been sufficiently cleaned?

-

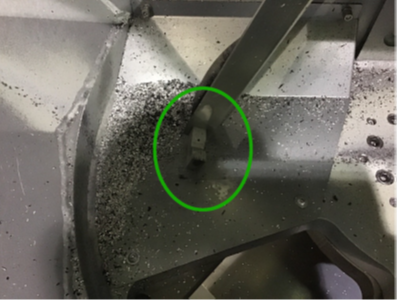

Remove flanges and clean like new!!! Vibration is usually

generated here when even small markings are on the

flanges. -

Has this area been well cleaned, and is free from damaged?

-

Have the grease points been full lubricated?

-

Check Lubrication at both nozzles in saw area.

-

Lubrication okay?

-

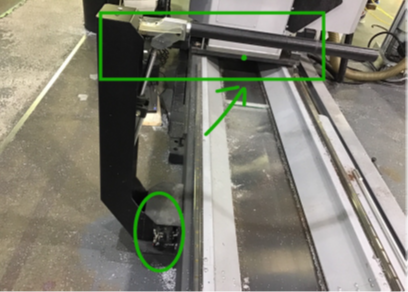

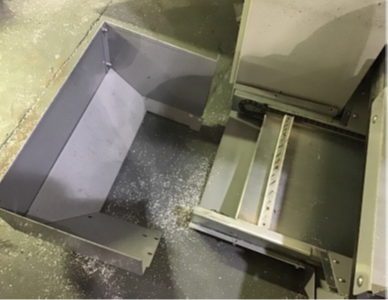

General Cleanliness of machine - blow down and vacuum any part of the machine, to ensure areas are free from swarf and contaminations,

Example -

has the machine been full cleaned and is free of swarf and other contaminations?

General House Keeping

-

Has the area around the machine been fully cleaned?

-

Are the cleaning shadow boards populated?

Spares & Consumables

-

If spares & Consumables have been used, have you emailed stores with a complete list for replenishment?

Finalisation

-

Has the service been completed?

Comments

-

Anything else to report?

-

Note