Title Page

-

Conducted on

-

Prepared by

-

Location

Operators’ Daily Safety and Maintenance Checklist

-

Supplier:

-

Where is machine hired from?

-

Plant Id

-

Machine Model/type:

-

Model Number:

-

Serial No: HHKHZB05CF0000077

-

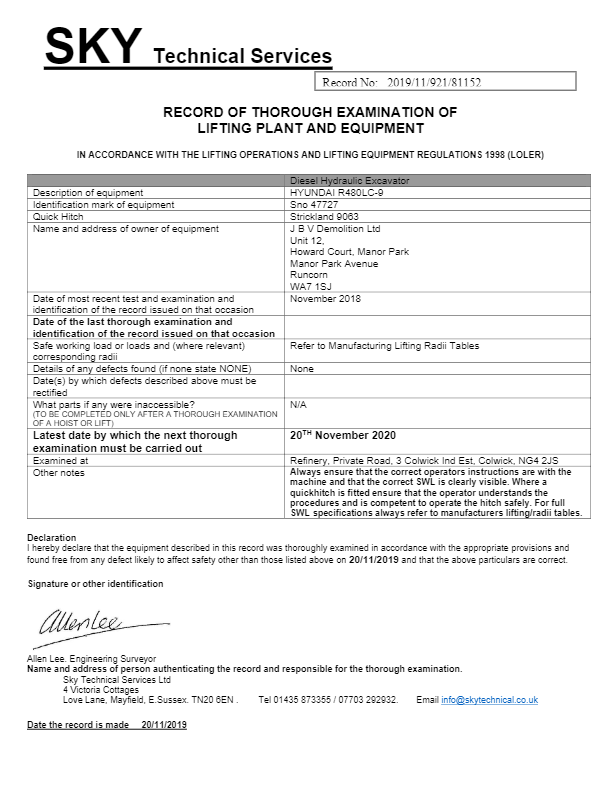

Loler Expiry: 20/11/2020

-

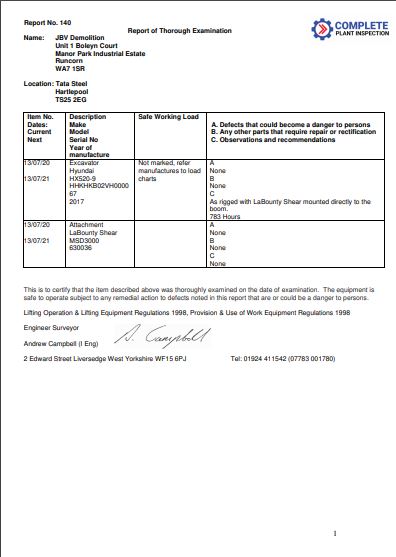

Serial No: HHKHKB02VH0000067

-

Loler Expiry: 13/07/2021

-

Model Number:

-

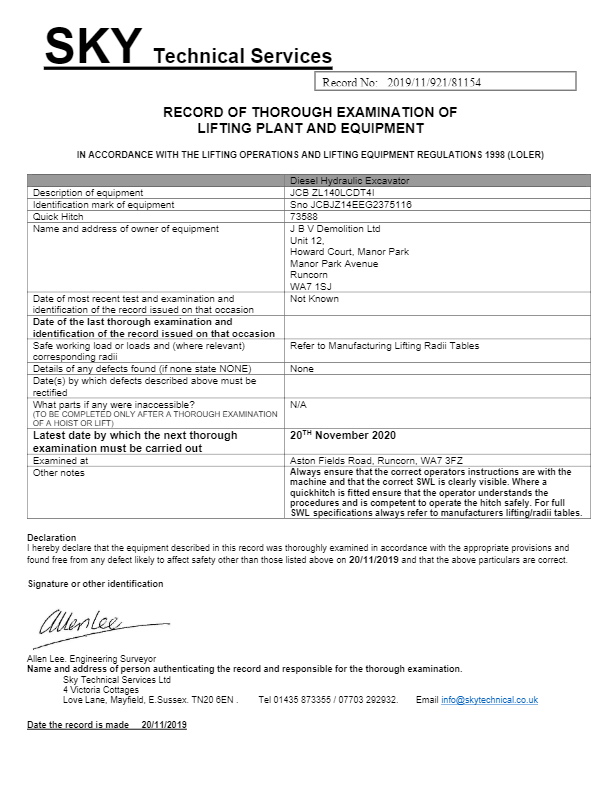

Serial No: JCBJZ14EEG2375116-SEE

-

Loler Expiry: 20/11/2020

-

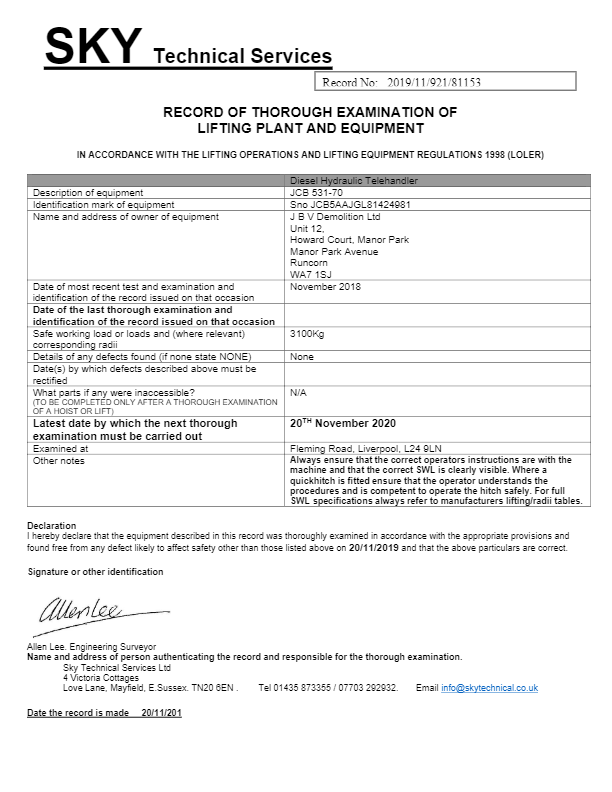

Serial No: JCB5AAJGL81424981

-

Loler Expiry: 20/11/2020

-

Plant Number:

-

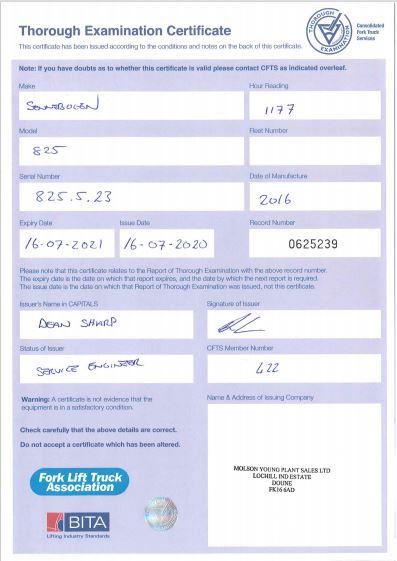

Serial Number: 825.5.23

-

Loler Expires - 16-07-21

-

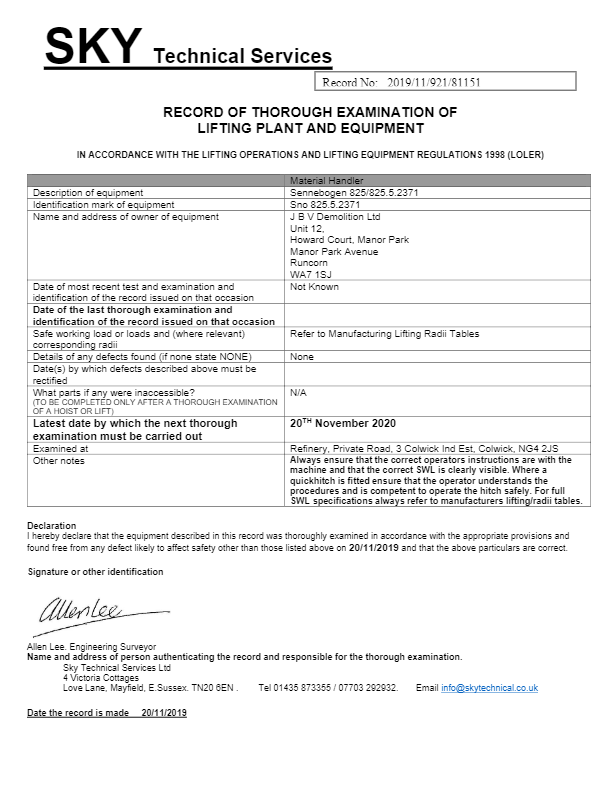

Serial Number - 825.5.2371

-

Loler Expires - 20/11/20

-

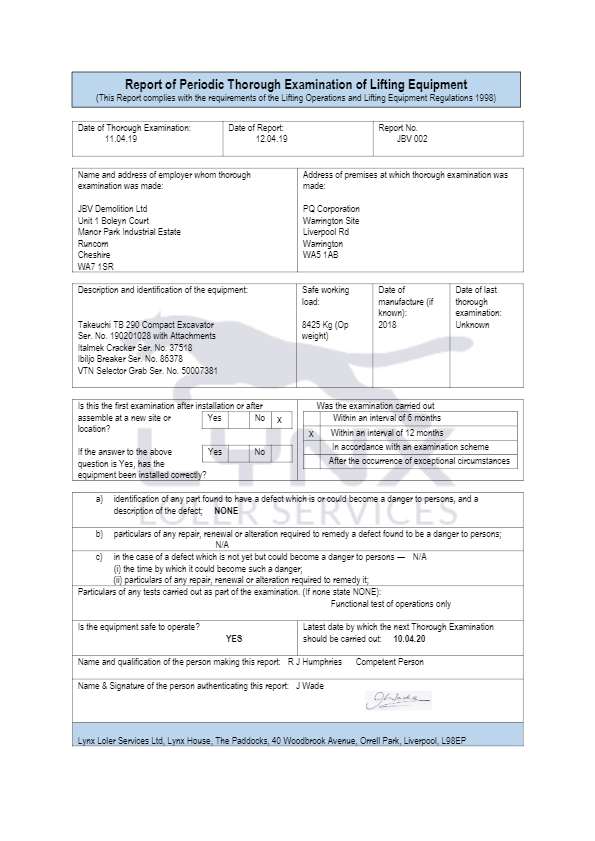

Model Number: TB290

-

Loler Expiry: 10/04/2020

-

Machine Hour Meter Reading

-

Operators Name:

Items to be Checked

Operators’ Daily Safety and Maintenance Checklist

-

If any of the below are answered NO, you must give a description of exactly what is wrong with that section. If it's something that can be resolved onsite (eg Oil level wants topping up/ Ad Blue wants topping up/ Bolts loose etc etc) these should be completed by the operator immediatley and marked as done.

-

I the operator have read and understood the above statement, I will keep on top of all maintenance on the machine wherever possible.

-

You must contact the Plant Manager/ Managing Director immediatley and explain why you won't keep on top of general maintenance.

Checklist

-

Yes = Satisfactory, No = defective and a comment must be added, N/A = Not applicable

-

Is the access and egress into the machine free from accumulation of debris.

-

Add Comment:

-

Take a photo

-

All engine oils, coolants and brake fluids are at correct operating levels

-

Add Comment:

-

Take a photo

-

Visual inspection of tyres and wheels. In good condition, inflated with all wheel nuts present

-

Add Comment:

-

Take a photo

-

Tracks in good condition – correct tension – no missing pads/grousers

-

Add Comment:

-

Take a photo

-

Operation of lights, horn, warning beacon and reversing alarm

-

Add Comment:

-

Take a photo

-

Windows and wipers

-

Add Comment:

-

Take a photo

-

All operating controls are clearly marked and function correctly

-

Add Comment:

-

Take a photo

-

Service and parking brakes operate and have been tested daily

-

Add Comment:

-

Take a photo

-

Seat belt present and operational. Flashing beacon working (if Present)

-

Add Comment:

-

Take a photo

-

All round vision - can you see anyone in your work zone including use of Visibility aids - mirrors and CCTV

-

Add Comment:

-

Take a photo

-

Steering operating correctly

-

Add Comment:

-

Take a photo

-

Quick hitch/coupler, hoses and attachments operating correctly and safety pin used where applicable

-

Add Comment:

-

Take a photo

-

Visual inspection for external damage to machine and ROPS/FOPS structure

-

Add Comment:

-

Take a photo

-

Access steps, handrails and footholds

-

Add Comment:

-

Take a photo

-

All guards are in position

-

Add Comment:

-

Take a photo

-

Ad Blue level checked

-

Add Comment:

-

Take a photo

-

Shut Off Lever/Dead Man (mobile plant) or emergency stop (fixed plant) operates correctly

-

Add Comment:

-

Take a photo

Sign Off

-

JBV operate a Zero Defects policy, if a defect arises stop work, report to the Plant Manager Immediately and do not start work again until rectified.

Operators Section

-

I confirm that all the above checks have been carried out thoroughly before the start off shift.

-

Operators Signature:

-

Machine operators to ignore the next section and complete the inspection.

Manager/Supervisor's Section

-

Title Onsite:

-

Full Name:

-

Signature:

-

Date & Time Checklist received:

-

If any failed items have been recorded on this sheet, they have automatically been sent to the Plant Manager via email.