Information

-

Vehicle Type & Number:

-

Date:

-

Name:

-

Job Title & Division:

-

Signature:

-

Team No.:

-

Assessment criteria are aligned with criteria from Technician Performance Assessment (TPA)

OK/ Yes = 2 point,

Partial = 1 point,

No/ Faulty/ Missing/ Not Available = 0 point

Indicate NA if not applicable.

Except for Section B, Criteria 1 : Maximum 10 points and Section I, Criteria 1 : Maximum 5 points

NOTE :

(i) Section B - Criteria 1 : Maximum 10 points. Circle one of the score.

(ii) Section I - Criteria 1 : Maximum 5 points. Circle one of the score.

A ~ Legislation, In-house SHE Rules

-

1. Technician have:<br>• Valid Driving/ Motorbike Riding License? (if have to drive for work)<br>• Pest Control Technician License? (issued by relevant local authority)<br>

-

2. Technician knows what does SHE stand for?

-

3. Is technician carrying the S.I.N.A (Success is no accident) card?

-

4. Is technician able to explain what the card is about?

-

5. Is technician carrying the Roof Void SRA Card? <br> (for technician who has to be PC Roof Void & HY Scenting work)

-

6. And can explain 3 points about roof void safety requirements?

B ~ Zero Tolerance Policy

-

Please circle the point collected for criterion no. 1.

If all ZTP requirements are mentioned = maximum 10 points for this criterion. -

1. Technician knows about “Zero Tolerance” Policy? Name all 7 rules under the ZTP.

- 0

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

-

ZTP :

• Safety Shoes

• Respirator use

• Do SRA for all service sites

• Seat Belts by Driver & Passengers (2 points)

• No use of hand-held HP while driving/ riding

• No HP use while operating equipment/ tools/ machinery

• Wear motorbike helmet, jacket & gloves while riding.(3 points) -

2. Technician knows the disciplinary for violation of the ZTP?<br>(first , second time offense - warning letter, third time – dismissal)

C ~ SHE Golden Rules

-

1. Does Technician maintain the SHE Golden Rules Booklet with him/ in his vehicle/ service station?

-

2. Can Technician explain 5 Golden Rules from Start/ Stop, Driving at Work, Work at Height and Moving Vehicle categories?

-

3. Technician knows the possible disciplinary actions for offense of the SHE Golden Rules? <br>(warning letter, withdrawal of vehicle, dismissal, stop-work without pay, etc)

D ~ Driving

-

1. Does technician wear seat belt? (applies to passenger and driver)

-

2. No use of hand-held hand phone while driving and operating equipment/ tools/ machinery?

-

3. No smoking while in the service vehicle/ service station/ at work?

-

4. Is the service vehicle parked at proper parking lot or a safe park area?

-

5. Is the service vehicle in good, working condition? <br>If there are malfunctions or problems, have these been reported?<br>Look out for : dents on vehicle body, worn out tires, missing/ broken mirror, signal lights.<br>Note : any safety critical functions with problems must be reported and repair arranged immediately, including tires, brake, signal lights, mirrors.

E ~ Vehicle Handbook

-

1. Technician has the vehicle handbook inside the vehicle?

-

2. Technician able to name 3 safety requirements stated in the vehicle handbook?

-

3. Technician knows who and when to inform when a road incident occurred?

-

4. Technician knows the frequency of “walk-around” vehicle inspections to check for obvious signs of damage?

-

5. Technician knows where to retrieve information on the hazards, safe handling, storage and use of chemicals?

-

6. Technician can explain at least 2 work conditions where High Visibility Vest must be worn?

-

7. Technician can explain at least 2 work conditions where Safety Cones must be used?<br>E.g. when mixing chemicals near the vehicle by the road side, when vehicle breakdown to divert traffic safely away from Technician and the breakdown vehicle, when opening a manhole of a drain.

F ~ PPE

-

1. Are the basic PPE maintained and worn by technician?

-

1(a). Safety goggles

-

1(b). Half-faced Respirator / Fumigation Full-Faced Respirator <br>+ Suitable Cartridge for Toxic, Acidic, Organic Vapors

-

1(c). N95 Dust mask (handling dusty mats, dusty/ smelly sanitary bins, handling/ spraying grandules or powder pesticides)

-

1(d). Chemical Resistant Gloves (when spraying at above waist level, fogging, misting, pesticide dilution/ mixing, drainage vacuuming work, sanitary bin washing, loading/ unloading mats to/fro washing machines)

-

1(e). Disposable Chemical Resistant Gloves <br>(for baits, baits station handling,sanitizer dilution, air freshener mixing/ dilution)

-

1(f). Cotton work gloves (handling soiled dust mats)

-

1(g). Safety shoes (all service works)

-

1(h). Protective Clothing (Long Sleeve Shirt) (fogging)

-

1(i). Ear Muff (fogging, and at any noisy areas with hearing protection sign)

-

1(j). High Visibility Vest

-

2. For Technician who has to ride motorbike at work, does he maintain and use the company Motorbike Jacket, Helmet and Gloves?

-

3. Are the PPE in good condition and stored separately from chemical and equipment in sealable container/ bag?

G ~ Safe Working Practices

-

1. Sample check 2 chemical products in vehicle/ service station.

-

1(a). Are the 2 sampled chemicals from the APL / AHCL?

-

1(b). Is the technician able to explain the target pests and hazards for the 2 chemical products? (check answer on label or SDS)

-

1(c). Does the technician has the right PPE to handle these 2 products?

-

1(d). Technician has the valid and complete SDS inside the vehicle? Sample check against 2 chemicals in the vehicle/ service station.

-

2. Technician knows what SDS is and able to name 4 out of 16 items stated in the SDS?

-

3. Can technician explain what is SRA?

-

4. Is Technician able to identify 2 of the hazards on the site?

-

5. Does Technician has access to SRA information for this site? Has he read it and is aware of the hazards mentioned in the SRA?<br>(via docket or PDA or SRA Report)

-

6. Observe Technician at work.<br>• Does he use the right type of PPE when carrying out service? <br>• And taken other appropriate safety measures? <br>E.g. use of proper trolley to reduce manual handling, use equipment/ tool that is in safe working condition, avoid doing any electrical works, put up cones.

-

7. Does Technician wear high visibility vest while working in areas with moving vehicles? (e.g. outdoor fogging/ spraying/ baiting, loading/ unloading by the road side/ car park, working in a warehouse with forklift)

-

8. Can technician explain what is 3-point contact on a ladder?

-

9. Does technician use the right ladder and in the right way?<br>E.g. ladder of right type & height, top 2 steps shall not be used, front body facing ladder

H ~ Emergency Response

-

1. Are the emergency items available inside the vehicle?

-

1(a). 20-litre Empty PVC Receptacle

-

1(b). 10 litre Clean Water

-

1(c). Sawdust/ Absorbent Material (Rags)

-

1(d). Black Plastic Bags (2 pcs)

-

1(e). Fire Extinguisher

-

1(f). First Aid Kit

-

1(g). Spare Pair of Shirt and Trousers

-

1(h). Broom and Dustpan

-

1(i). Soap & Towel

-

1(j). Plastic Bucket

-

1(k). Spill Kit Container

-

1(l). Safety Cones (2 per service vehicle; 6 per drainage vehicle)

I ~ Safe Chemical, Equipment, Tool Storage and Waste Disposal

-

Please circle the point collected for criterion no. 1.

If all Chemicals and Water are properly labelled = maximum 5 points for this criterion.

Deduct 1 point for each Chemical / Water found without proper label or worn out/ unclear label. -

1. Are the chemicals (liquid, powder, granules, gas, aerosol) with proper, clear labels?

- 0

- 1

- 2

- 3

- 4

- 5

-

2. Is the good housekeeping and segregation of PPE/ equipment/ chemicals observed in the vehicle or service station?

-

3. Are all chemicals been securely enclosed and stored in proper containers in the vehicle/ service station? And under lock and key?

-

4. Is the ladder securely stored in the vehicle?

-

5. Is the ladder provided by the company, of suitable type and height?

-

6. Is the ladder without any damage or defect?

-

7. Has the equipment (e.g. B&G sprayer, air-freshener, sanitizer) been washed/ cleaned upon completion of the service?

-

8. Are Aerosol are stored in boxes and enclosed? <br>Kept in shade, away from direct sunlight and other heat / spark sources e.g. electrical points, open flames, window.

J ~ Fogging Operation and Storage

-

1. Thermal Fogger

-

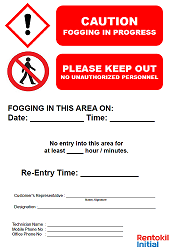

1(a). • Is the Thermal Fogger securely stored at rear of the vehicle? <br>• Does technician maintain the standard “Caution. Keep Out” sign in his vehicle/ service station? And use the sign?

-

Appendix for 1(a):

-

1(b). Is the technician aware of the standard minimum cooling time of a hot fogging machine after use? (min. 15 minutes)

-

1(c). Does technician shut down the engine and cool down the Fogger for at least 15minutes before refuelling, adjustment or transporting?

-

1(d). What is the minimum distance to maintain between a fogger nozzle and a wall/ other obstruction?<br>At least 60cm to prevent fire due to blocking of airflow that cools the machine

-

1(e). What is the maximum level that the fogger solution tank and fuel tank can be filled up? three-quarter (3/4) tank only.<br>Over-filling and spillage must be avoided to prevent fire !!

-

1(f). How much time must you give to ventilate an enclosed, restricted space before fogging e.g. rubbish chute? At least 5-10 minutes

K ~ Washroom Operation and Storage

-

1. Is the technician able to operate the following safely?

-

1(a). German crusher (Deep clean)

-

1(b). American super steam (Deep clean)

-

1(c). Hand drill (Technical team)

-

1(d). Vacuum cleaner (Deep clean)

-

1(e). Installation team installs Air Freshener unit at no more than 2m height from the ground floor, as per company WAH policy? <br>(this question is applicable to installation technician only during installation phase)

-

2. Air Freshener Services & Installation – does technician check if the unit is installed / glued securely to the wall?

-

3. Technician knows how to carry out manual handling job safely? (Pushing trolley along an elevated platform)?

-

4. Technician knows the preparations before starting work?<br>• Put up sign e.g. “Man at Work” sign at work areas to prevent unauthorized people from venturing near your work area?<br>• The need to tape up electrical cables to prevent trip and fall?

-

5. If laying wire, electrical connection work are to be done by RI instead of the customer, is this being done by RI Technician with valid electrician license? (e.g. Scenting PS1200 unit, hand dryer installation)

-

6. Technician knows the surrounding dangers depending on work site? i.e. slip on a wet floor or fall from ladder?

-

7. Is good housekeeping and segregation of items in the vehicle observed?

Assessed By

-

Name:

-

Job Title:

-

Signature:

-

Date: