Title Page

-

Business Unit:

-

Site/ Job No:

-

Site Manager:

-

Prepared by

-

Conducted on

SITE REVIEW

1. SABRE H&S SYSTEM

-

Relevant to this Site Review?

-

1.1 Is there an HSMP/ SSSP available on site?

-

1.2 Are there TAs in place for high-risk, non-routine, and notifiable work (communicated to all workers involved)?

-

1.3 Has a daily pre-start been undertaken?

-

1.4 Are weekly toolbox talks undertaken?

-

1.5 Are weekly site reviews undertaken?

-

1.6 Are SABRE staff, subcontractors and visitors signing into site?

-

1.7 Are site inductions being completed?

-

1.8 Are all hazardous substances accounted for in the hazardous substances register?

-

1.9 Has WorkSafe been notified of hazardous works?

-

1.10 Have corrective actions been closed out from the previous Site Review?

-

1.11 Have all incidents been closed out?

2. SUBCONTRACTOR SSSP's

-

Relevant to this Site Review?

-

Subcontractors on site:

-

2.1 Have all Subcontractors on site been pre-qualified by SABRE?

-

2.2 Do all Subcontractors have an approved (reviewed by SABRE) SSSP available on site?

-

2.3 Have Subcontractors notified WorkSafe where required?

-

2.4 Have Subcontractors completed a Task Analysis for Notifiable Works, high/ critical risk works or one-off works and is there an emergency response/ rescue plan?

-

2.5 Are Subcontractor's hazardous substances adequately recorded, controlled with SDS's readily available?

-

2.6 Do Subcontractors have evidence of training & competency for their staff and Subcontractors that are on site?

-

2.7 Do Subcontractors have a Plant & Equipment register in place?

3. EMERGENCY PREPAREDNESS & RESPONSE

-

Relevant to this Site Review?

-

3.1 Are site emergency/ evacuation procedures displayed?

-

3.2 Rescue plan available for scenario specific response i.e., rescue from nets; confined space rescue?

-

3.3 Is the emergency assembly point identified & sign posted?

-

3.4 Fire Extinguisher readily available, charged and serviced within the last 12 months?

-

3.5 First Aid kit in place and adequately stocked?

-

3.6 Are evacuation drills undertaken every 6 months?

4. FACILITIES & SIGNAGE

-

Relevant to this Site Review?

-

4.1 Warning signage posted where required?

-

4.2 Hazard board displayed near access point and up to date?

-

4.3 Contact details displayed for key personnel (incl. First Aider)?

-

4.4 Are minimum PPE requirements displayed?

-

4.5 Appropriate number of toilets onsite (male/ female), clean and hygienic?

-

4.6 Clean, potable water readily available onsite?

-

4.7 Smoko shed available for use?

-

4.8 Are all facilities (lunchroom, toilets) adequate, clean, tidy with soap etc. provided?

5. SITE SAFETY (GENERAL)

-

Relevant to this Site Review?

-

5.1 Is the worksite clean and tidy - housekeeping acceptable (slips/ trips controlled)?

-

5.2 Are access ways kept clear?

-

5.3 Are materials stacked safely?

-

5.4 Sufficient waste bins/ skips provided?

-

5.5 Waratah's/ protruding reinforcing capped?

-

5.6 Nails in timber made safe (no protruding nails)?

-

5.7 Adequate lighting/ task lighting available for workers?

-

5.8 Is site security/ access controlled (public protected from working areas)?

-

5.9 PPE requirements being followed - minimum and task specific?

6. TRAFFIC MANAGEMENT (TMP)

-

Relevant to this Site Review?

-

6.1 Is a TMP in place, current and approved by Road Corridor Authority?

-

6.2 Is the TMP being followed?

7. WORKING AT HEIGHTS

-

Relevant to this Site Review?

-

7.1 Workers use safe means of access i.e., ladder, EWP, scaffold etc.

-

7.2 Is there a risk of falling to a lower level?

-

7.3 Static lines and anchor points installed by a competent person?

-

7.4 Safety harness worn and used correctly where required? i.e., appropriate lanyard lengths, anchor points.

8. SCAFFOLDING

-

Relevant to this Site Review?

-

8.1 Scaffold inspected by a competent person (competency of scaffold inspector verified)?

-

8.2 Has a handover certificate been issued for the scaffold?

-

8.3 Is the scaffold tagged and has it been inspected within the last 7 days?

-

8.4 Adequate base and sole plates?

-

8.5 Is the access point gated and is it self-closing?

-

8.6 Are there any scaffold components missing e.g. braces, hand rails, mid rails, toe boards etc.

-

8.7 Housekeeping maintained on scaffold platforms / landings (safe access and egress maintained - min 450mm)?

-

8.8 Are scaffold planks secured / tied down?

-

8.9 Scaffold planks/ components in good condition (pitting, excessive rust, splitting/ saw cuts in timber planks etc.)?

-

8.10 Gaps between scaffold platform and work face do not exceed 300 mm?

-

8.11 Gaps in work platform do not exceed 50mm?

-

8.12 Scrim in place where required and secured?

-

8.13 Shrink wrap - engineer report in place, no loose wrapping?

-

8.14 Mobile scaffold erected as per manufacturer's instructions?

9. SAFETY NETS

-

Relevant to this Site Review?

-

9.1 Safety nets installed where required and to standard?

-

9.2 Safety nets certificate available for inspection?

-

9.3 Safety nets in a good condition (visible signs of damage to the safety net system)?

-

9.4 Have the nets been installed as close as possible beneath the overhead work location?

-

9.5 Are gaps between net and structure less than 100 mm?

-

9.6 Is the net clear of debris?

10. EWP

-

Relevant to this Site Review?

-

10.1 EWP operator certified to operate equipment?

-

10.2 EWP inspected prior to use?

-

10.3 Exclusion zone established where required?

-

10.4 EWP maintenance intervals maintained (6-monthly)?

-

10.5 Safety harness used where required?

11. HYDRALADA

-

Relevant to this Site Review?

-

11.1 Hydralada operator trained and certified as competent to operate equipment?

-

11.2 Total weight (incl. body weight) is less than 175kg?

-

11.3 Hydralada operators manual available?

-

11.4 Logbook available and up to date?

-

11.5 EWP maintenance intervals maintained (6-monthly)?

-

11.6 Safety harness used and attached to the approved anchor point?

-

11.7 Overhead powerlines identified and exclusion zones established?

12. LADDERS

-

Relevant to this Site Review?

-

12.1 Ladders industrial rated?

-

12.2 Ladders used correctly i.e., 3-points contact; short duration; forward facing etc.?

13. CRANE/ LIFTING OPERATIONS

-

Relevant to this Site Review?

-

13.1 Is there a current test certificate?

-

13.2 Crane operator licensed / certified to operate crane?

-

13.3 Rigger / Dogman certified and competent to conduct crane lifts?

-

13.4 Is there a lift plan in place & has it been communicated all workers involved?

-

13.5 Rigging and lifting gear in good condition with current tags / certificates?

-

13.6 Lifting area flagged off/ exclusion zones established?

-

13.7 Crane established on firm solid ground, outriggers fully extended and outrigger pads in place?

-

13.8 Tag lines used to control the load (where required e.g., wind conditions)?

-

13.9 No overhead lifting?

14. MOBILE PLANT OPERATION

-

Relevant to this Site Review?

-

14.1 Pre-use operator checks completed?

-

14.2 Equipment servicing up to date?

-

14.3 Equipment operators licensed/ deemed competent to operate machinery?

-

14.4 ROP's in place and operators wearing seatbelts?

-

14.5 Spotters used where required during heavy machine operation?

15. EXCAVATIONS & TRENCHES

-

Relevant to this Site Review?

-

15.1 Safe access and egress provided into the excavation?

-

15.2 Guardrails in place for deep excavations/ trenches?

-

15.3 Shallow excavations/ trenches demarcated where required?

-

15.4 Shield protection or sides battered/ benched for excavations/ trenches >1.5m deep?

-

15.5 Excavated material/ spoil placed a safe distance from the excavation/ trench?

16. CONFINED SPACES

-

Relevant to this Site Review?

-

16.1 Confined space Risk Assessment undertaken?

-

16.2 Confined space isolated where required?

-

16.3 Confined spaces cleaned and purged if required?

-

16.4 Atmosphere testing conducted?

-

16.5 All workers trained (including stand-by person)?

-

16.6 Confined space rescue equipment in place and certified where required?

-

16.7 Emergency Response plan in place and communicated to all involved?

17. WORKING NEAR LIVE SERVICES

-

Relevant to this Site Review?

-

17.1. Before U Dig plans and supporting evidence of service locations provided (as-builds, site mark-up plans, GPR location, etc.) available on site?

-

17.2 Services marked and physically located/ verified (hand-dug potholes or hydro-vac'd)?

-

17.3 Service locations demarcated/ protected with barriers where required?

-

17.4 Minimum Approach Distance (M.A.D) Permit obtained and adhered to (where required)?

-

17.5 Services de-energised/ isolated where required?

-

17.6 Controls in place to prevent contact / damage? i.e., hydro-vac, spotter/ services stand-over, mud bucket etc.?

18. HOT WORK

-

Relevant to this Site Review?

-

18.1 Hot work permit in place?

-

18.2 Are hot work activities undertaken in line with hot work permit requirements?

19. ASBESTOS

-

Relevant to this Site Review?

-

19.1 Has ACM been considered as being present on the worksite and has a ACM survey been undertaken?

-

19.2 Is an ARCP in place?

-

19.3 Is the ACM plan being followed?

-

19.4 Have WorkSafe been notified of ACM? (>10sqm friable)

-

19.5 Are workers handling ACM competent?

20. ELECTRICAL

-

Relevant to this Site Review?

-

20.1 Lifeguard units and 63amp leads tagged 3 monthly?

-

20.2 All leads and tools tagged 3 monthly?

-

20.3 COC in place for builder's temporary power?

-

20.4 Leads protected, routed neatly and away from water sources?

-

20.5 RCD in place for all electricals, including internal power points?

21. TOOLS & EQUIPMENT

-

Relevant to this Site Review?

-

21.1 Tools set up properly with guards in place?

-

21.2 Are PATs used by competent operators?

-

21.2 Are exclusion zones and warning signs in place?

-

21.3 Are misfired charges secured and discarded correctly?

22. ENVIRONMENTAL

-

Relevant to this Site Review?

-

22.1 Are silt fences in place and in good working order?

-

22.2 Are silt socks/gutter bags in place at stormwater inlets and maintained?

-

22.3 Are accessways metaled?

-

22.4 Is sediment and run-off fully contained with the site boundary?

-

22.5 Are vehicles/ plant tracking mud into the road reserve?

-

22.6 Is dust being controlled on the worksite?

-

22.7 Is construction noise being controlled within resource consent conditions?

Observations

-

Any observations for items not covered in the Site Review?

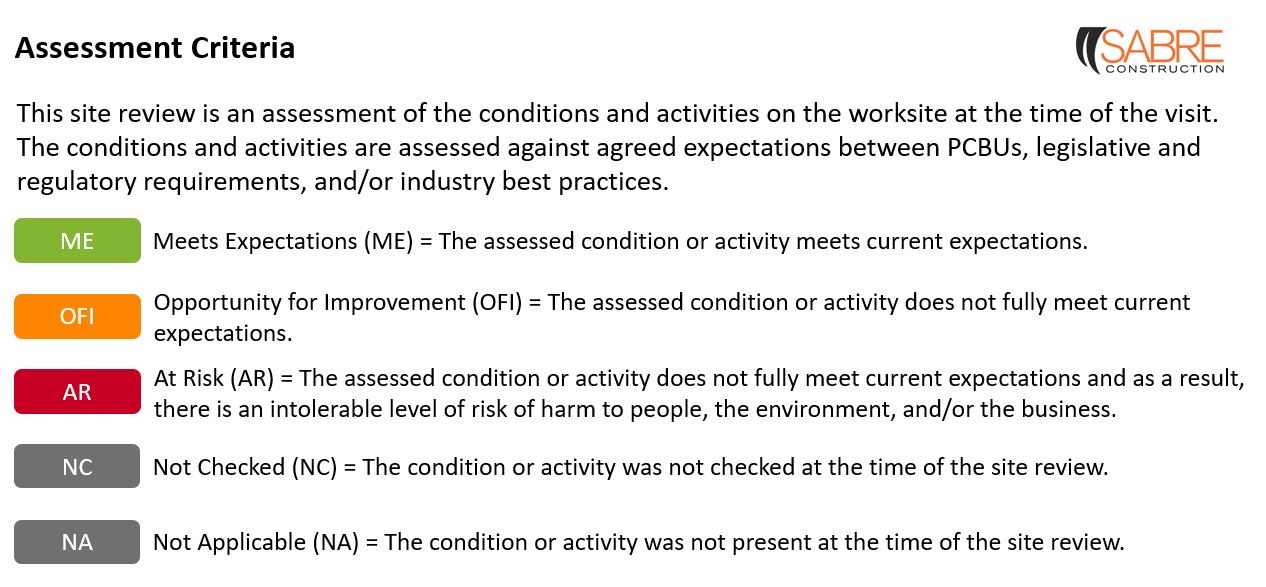

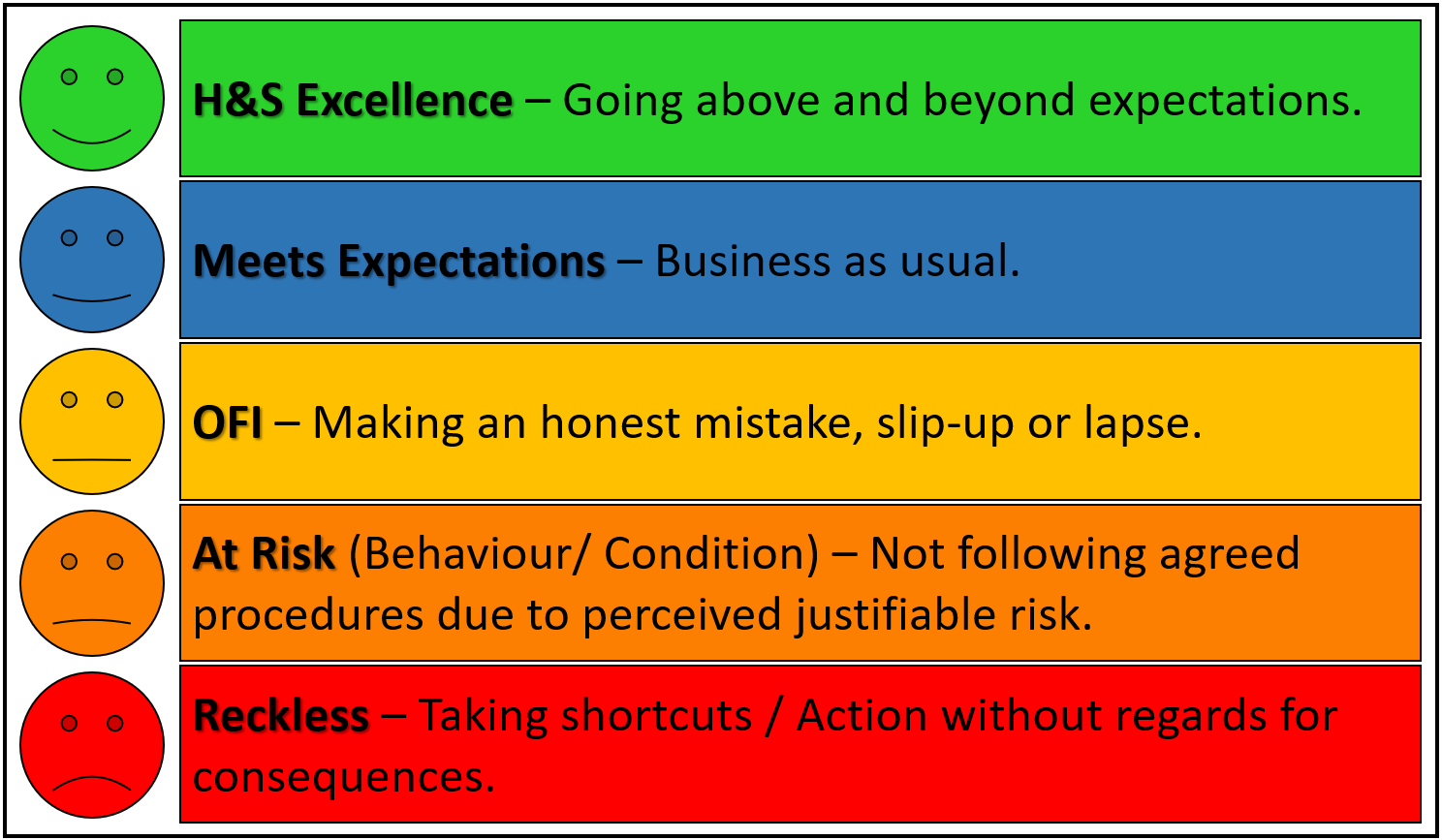

Observation Guidance - use the guide below in determining the observation criteria.

-

-

What was your Observation?

Click on the "+ button" over here ---->--->

Observation

-

What was your Observation?<br>(Select one of the following)