Title Page

-

Project or Site Name

-

Service or Construction Site/Project

-

Conducted on

-

Prepared by

-

Description of work being performed (i.e. Servicing unit, coil cleaning, installing duct, clean-up, etc.)

-

On-site Personnel

-

If, NO or AT RISK please use the ADD NOTES section to indicate action taken to correct.

Safety Program Components (5X5 / HAZCOM)

-

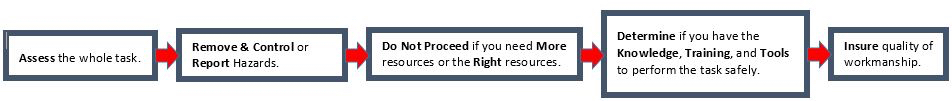

Employee(s) able to explain the 5X5 process and how they utilized prior to starting work task?

-

Click for more information on 5X5 process

-

-

Employee(s) have access to MSDSONLINE (HAZCOM) information?

-

In order to indicate yes employee(s) must demonstrate they have:

1-888 # programmed on company phone, and or

Have 1-888 decal displayed, and or

Have MSDSONLINE ASEI/MERIT homepage bookmarked on smart phone, iPad or laptop. -

ALL employees on-site participated in Stretch and Flex?

-

Site Specific Safety Plan (SSSP) on site? For construction and SPG projects only!

-

SSSP signed by all employees onsite?

Personal Protective Equipment (PPE)

-

Employee(s) observed where wearing all required PPE?

-

If AT RISK, please click on the RESPONSE button to indicate the PPE not being used and use the ADD NOTES section to indicate the corrective action taken.

-

An adequate supply of PPE is available on site for employees?

-

- NO OR INADEQUATE HEAD PROTECTION

- NO OR INADEQUATE HAND PROTECTION

- NO OR IMPROPER REFLECTIVE GEAR

- NO OR IMPROPER EYE PROTECTION

- NO OR INADEQUATE HEARING PROTECTION

- NO OR INADEQUATE RESPIRATORY PROTECTION

- NO OR INADEQUATE FOOT PROTECTION

- PPE DAMAGED OR IN POOR CONDITION

- OTHER

Power & Hand Tools

-

Employee(s) observed following proper Safe work practices when operating tool(s)

-

If AT RISK, please click on the RESPONSE button to indicate the at-risk behavior observed and use the ADD NOTES section to indicate the corrective action taken.

-

- IMPROPER PPE BEING USED FOR TOOL BEING OPERATED

- GUARD REMOVED

- IMPROPER TOOL BEING USED FOR WORK BEING PERFORMED

- TOOL IN POOR OPERATING CONDITION

- OTHER

-

Click on VISIT LINK to access LNI webpage

http://www.lni.wa.gov/Safety/Topics/AtoZ/HandPortablePowerTools/

Electrical Safety

-

Click on VISIT LINK to access LNI webpage

http://www.lni.wa.gov/Safety/Topics/AToZ/ppe/default.asp -

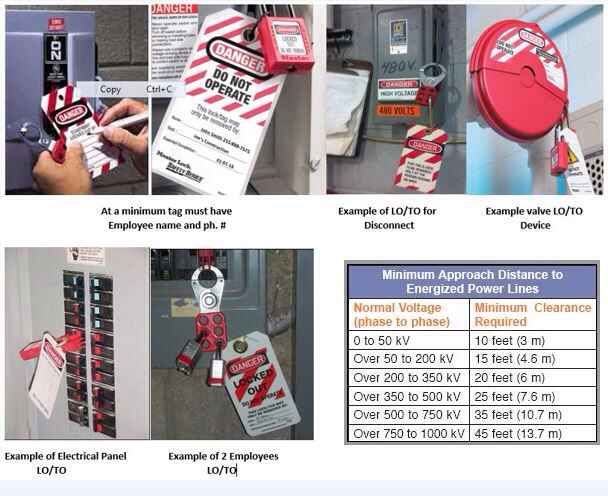

Employee(s) observed following proper safe work practices when working with electricity. Includes: <br>Following Lock-out / Tag-out procedure<br>Utilizing GFCI on all extension cords<br>Maintaining the minimum safe approached distance (MSAD) when working around power line.<br>Using non-conductive ladders when working around energized power lines<br>All power cords are in good condition

-

- Lock or / tag out be used

- GFCI being used

- Extension cords in good condition

- Other ( provide description in notes section)

-

If SAFE, please click on the RESPONSE button to indicate the SAFE behavior observed. Select all that apply

-

If AT RISK, please click on the RESPONSE button to indicate the at risk behavior observed and use the ADD NOTES section to indicate the corrective action taken.

-

- LO / TO NOT USED

- IMPROPER LOCK USED

- NO TAG USED

- EMP. INFO NOT WRITTEN ON TAG

- EMP. DID NOT VERIFY IF EQUIP. HAD BEEN DE-ENERGIZED

- MULTI EMP. LO/TO NOT USED

- FAILURE TO MAINTAIN PROPER DISTANCE FROM POWER LINES

- GFCI NOT BEING USED

- ELECTRICAL CORD(S) IN POOR CONDITION

-

For more information check box

-

-

Click on VISIT LINK to access LNI webpage

http://www.lni.wa.gov/Safety/Topics/AToZ/ElectricalHazards/default.asp

Ladder Safety

-

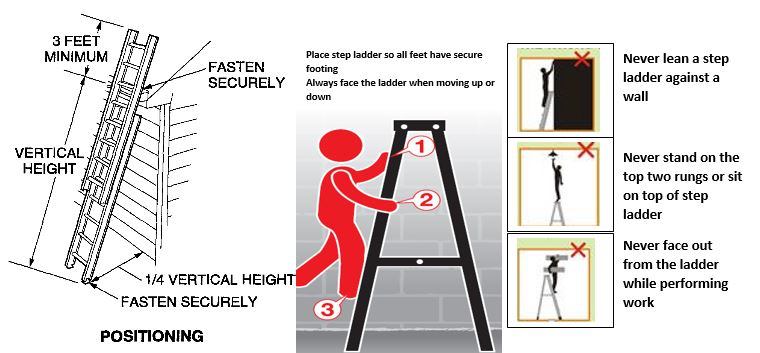

Employee(s) observed follow established safe work practices while using ladder(s)? Includes:<br>All ladders properly set-up (check box below for more information)<br>Employees have good body position while performing work<br>No one utilizing top two steps on step ladders

-

If AT RISK, please click on the RESPONSE button to indicate the at risk behavior observed and use the ADD NOTES section to indicate the corrective action taken.

-

- OVER - REACHING / LEANING PAST SIDE RAILS

- NOT MAINTAINING 3 POINTS OF CONTACT

- LADDER DOES NOT EXTEND 3' PAST ROOF EDGE FOR ACCESS

- STANDING ON TOP 2 STEPS OF STEP LADDER

- IMPROPER USE OF STEP LADDER

- FAILURE TO TIE-DOWN / SECURE EXTENSION LADDER AT TOP

- OTHER

-

For more information on Ladder Safety check box

-

-

Click on VISIT LINK to access LNI webpage

http://www.lni.wa.gov/Safety/Topics/AtoZ/LadderSafety/default.asp

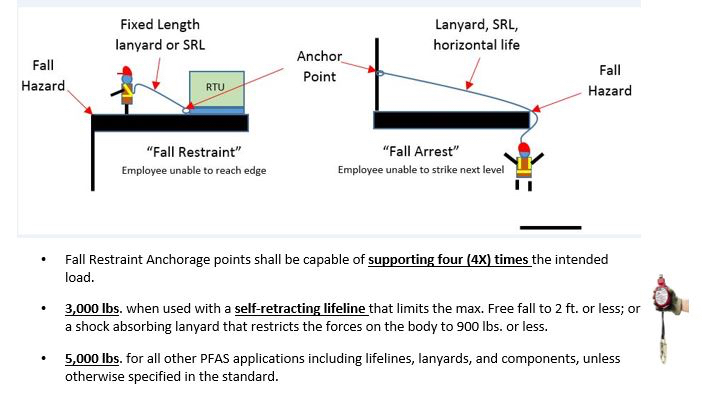

Fall Protection

-

Employee(s) observed using established safe work practices and procedures.<br>

Fall Protection Documentation

-

Fall Protection Work Plan (FPWP) created, on site, and signed by all employees exposed to the fall hazard?

-

If AT RISK, please click on the RESPONSE button to indicate the at-risk behavior observed and use the ADD NOTES section to indicate the corrective action taken.

-

- NO FALL PROTECTION IN PLACE

- NO WRITTEN FALL PROTECTION WORK PLAN

- INADEQUATE ANCHOR POINT USED

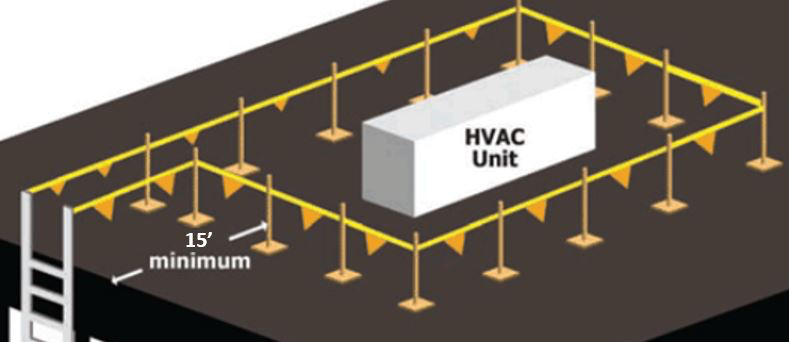

- IMPROPERLY USED WARNING LINE (<15' from edge)

- IMPROPERLY MAINTAINED WARNING LINE

- INSPECTION OF FP EQUIP. NOT PERFORMED

- FP EQUIP. DAMAGED OR IN POOR CONDITION

- FALL PROTECTION WORK PLAN NOT SIGNED BY ALL EMPLOYEES

- OTHER

-

For more information check box

-

-

-

Click on VISIT LINK to access LNI webpage

http://www.lni.wa.gov/Safety/Topics/AtoZ/fallprotect/

Scaffolding

-

Employee(s) observed are following safe work practices and procedures when utilizing scaffolding?

-

If AT RISK, please click on the RESPONSE button to indicate the at-risk behavior observed and use the ADD NOTES section to indicate the corrective action taken.

-

- Working from scaffolding during storms or high winds

- scaffolding covered in ice or snow

- tools, material, and or debris allowed to accumulate and cause a hazard

- working within 10' of energized powerlines

- scaffold wheels not locked to prevent movement

- overloaded scaffolding

- other

-

Click on VISIT LINK to access LNI webpage

http://www.lni.wa.gov/Safety/Topics/AtoZ/Scaffolds/Default.asp

Aerial Lifts (scissor / boom) Forklift

-

Employee(s) observed following established safe work practices while operating aerial lifts and/or forklifts

-

Employee(s) operating aerial and/or forklift(s) have been trained and authorized to do so?

-

Click on VISIT LINK to access LNI webpage - Aerial lifts

http://www.lni.wa.gov/Safety/Topics/AToZ/PersonHoistingPlatforms/default.asp -

If AT RISK, please click on the RESPONSE button to indicate the at risk behavior observed and use the ADD NOTES section to indicate the corrective action taken.

-

- STANDING ON MID-RAIL

- REAR MID-RAIL CHAIN NOT CLOSED

- WARNING LIGHTS/ALARMS NOT WORKING

- DECALS ELIGIBLE

- USING LADDER IN LIFT

- PRE-OPERATION INSPECTION NOT PERFORMED

- SEAT BELT NOT WORN (FORKLIFT)

- OVERLOADING

- OTHER

-

Click on VISIT LINK to access LNI webpage - Forklift

http://www.lni.wa.gov/Safety/Topics/AToZ/PoweredIndustrialTrucks/

Crane Pick

-

Is the crane Pick self performed or subcontracted?

-

Crane Pick Plan has been created and on-site

-

Pre-lift all hands meeting conducted?

Site Conditions

-

If NO, please use ADD NOTES section to indicate action taken to correct condition.

-

Adequate lighting provided?

-

Work area, walkways and stairs clear of debris and materials?

-

Materials being used stored neatly?

-

Tools (gang box) clean and organized?

-

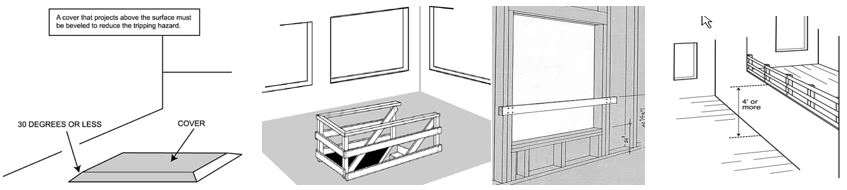

Floor and/ or wall opening appropriately guarded?

-

Click for more information on floor and wall openings.

-

-

Additional comments/observations

observation

-

Add comments/observations here.

Safety Recognition!

-

Check box for more information regarding the Safety Recognition Program

-

Catch someone doing the job right!

The goal of the recognition program is to acknowledge and reward outstanding individual and/or team contributions that promote stronger safety culture.

Contributions must positively impact the safety of an individual, team, department, or the company

Who can be recognized?

All employees all eligible to be recognized.

Who can submit a safety recognition?

All employees are strongly encouraged to submit safety recognitions

What is the criteria?

Employee(s) or Team must be performing an activity over and above performance goals and safety expectations. -

Person(s) being recognized?

-

Tap here to enter name(s)

Description of safe act or actions being recognized.

-

Tap here to enter description

Description of immediate action taken to recognize an individual or team.

-

Tap here to enter description

Safety Coaching Performed

-

Describing any safety coaching performed during the review.

Disciplinary Action.

-

Is disciplinary action required?

Provide name of employee(s)

Action taken or to be taken.

-

Verbal Warning Given

Provide description of infraction, and corrective action taken w/ employee(s)

-

Written Warning to be issued

-

Contact HR for process

signature of person(s) Completing this review.

-

Add signature

-

Add signature