Title Page

-

Document No.

-

Audit Title

-

Location

-

Conducted on

-

Audit Conducted by:

- David Miller

- Roy Adams

- Ben Polk

- Jon Lollar

- Kasey Tviet

- Tyler Walker

- Bob Weis

- Bill McDowell

- Jim Odum

-

Personnel

Audit Overview

Audit Overview

-

Field Supervisor

Safety Related Questions

-

Safety Related Questions

Emergency Equipment

-

Emergency Equipment

-

Are fire extinguishers available as needed?

-

1926.150(a)(1)

The employer shall be responsible for the development of a fire protection program to be followed throughout all phases of the construction and demolition work, and he shall provide for the firefighting equipment as specified in this subpart. As fire hazards occur, there shall be no delay in providing the necessary equipment. -

Are fire extinguishers fully charged?

-

1910.157(c)(4)

The employer shall assure that portable fire extinguishers are maintained in a fully charged and operable condition and kept in their designated places at all times except during use. -

Are fire extinguishers inspected?

-

1910.157(e)(2)

Portable extinguishers or hose used in lieu thereof under paragraph (d)(3) of this section shall be visually inspected monthly. -

https://www.osha.gov/pls/oshaweb/owalink.query_links?src_doc_type=STANDARDS&src_unique_file=1910_0157&src_anchor_name=1910.157(e)(2) -

Are first aid kits available?

-

1910.269(b)(2)

First-aid supplies. First-aid supplies required by §1910.151(b) shall be placed in weatherproof containers if the supplies could be exposed to the weather. -

Are first aid kits inspected?

-

1910.269(b)(3)

First-aid kits. The employer shall maintain each first-aid kit, shall ensure that it is readily available for use, and shall inspect it frequently enough to ensure that expended items are replaced. The employer also shall inspect each first aid kit at least once per year. -

Are first aid kits fully stocked and out of date items removed?

-

1910.269(b)(3)

First-aid kits. The employer shall maintain each first-aid kit, shall ensure that it is readily available for use, and shall inspect it frequently enough to ensure that expended items are replaced. The employer also shall inspect each first aid kit at least once per year.

Job Briefing

-

Job Briefing

-

Is job briefing completed?

-

Has all signed on the job briefing?

-

Has all hazards been identified?

Materials Handling and Storage

-

Materials Handling and Storage

-

Are all materials being handled in a safe manner?

-

Are employees utilizing proper lifting techniques?

-

Are all materials on vehicles/trailers secure?

Housekeeping and Sanitation

-

Housekeeping and Sanitation

-

IS the working areas free from hazards and well maintained?

-

Is the laydown yard well maintained and free from trash?

-

Is the walkways unobstructed and free from wires, cords or hoses?

Personal Protective Equipment

-

Personal Protective Equipment

-

Are Safety Glasses being used?

-

Are Hard Hat being worn?

-

Is Arc Flash PPE needed and being worn properly?

-

Are safety vest being worn?

-

Are gloves being worn?

Hand & Power Tools

-

Hand & Power Tools

-

Are all tools storage neatly?

-

Are damaged tools repaired or replaced?

-

Are tools and cords in good condition?

-

All mechanical safeguards in use?

Ladders

-

Ladders

Compressed Gases

-

Compressed Gases

-

Compressed gas cylinders stored and upright?

-

1926.350(a)(4)

When cylinders are transported by powered vehicles, they shall be secured in a vertical position. -

https://www.osha.gov/pls/oshaweb/owalink.query_links?src_doc_type=STANDARDS&src_unique_file=1926_0350&src_anchor_name=1926.350(a)(4) -

Oxygen/acetylene torch units have flash back arrestors?

-

1910.253(c)(5)(iii)

When acetylene cylinders are coupled, approved flash arresters shall be installed between each cylinder and the coupler block. For outdoor use only, and when the number of cylinders coupled does not exceed three, one flash arrester installed between the coupler block and regulator is acceptable.

Rubber Goods

-

Rubber Goods

-

Is any employee working with in the MAD distances listed below (consider tools and equipment that extend from the employee/work location in the MAD):<br> VECTREN<br>Minimum Approach Distance<br>300V and less Avoid Contact<br>Over 300V to 600V 1 Foot<br>Over 600V to 15KV 3 Feet<br>Over 16 kV to 69 KV 4 Feet<br>Over 70KV to 169KV 6 Feet<br>Over 170KV to 345kV 13 Feet<br>Over 500 KV to 800 KV 26 Feet<br>

-

1910.269(l)(3)(i)

The employer shall establish minimum approach distances no less than the distances computed by Table R-3 for ac systems or Table R-8 for dc systems. -

Are the rubber goods stored and handled properly?

-

1910.269(l)(3)(iii)

The employer shall ensure that no employee approaches or takes any conductive object closer to exposed energized parts than the employer's established minimum approach distance, unless:

1910.269(l)(3)(iii)(A)

The employee is insulated from the energized part (rubber insulating gloves or rubber insulating gloves and sleeves worn in accordance with paragraph (l)(4) of this section constitutes insulation of the employee from the energized part upon which the employee is working provided that the employee has control of the part in a manner sufficient to prevent exposure to uninsulated portions of the employee's body), or

1910.269(l)(3)(iii)(B)

The energized part is insulated from the employee and from any other conductive object at a different potential, or

1910.269(l)(3)(iii)(C)

The employee is insulated from any other exposed conductive object in accordance with the requirements for live-line barehand work in paragraph (q)(3) of this section. -

Are all second points of contact adequately covered by rubber goods?

-

1910.269(l)(3)(iii)

The employer shall ensure that no employee approaches or takes any conductive object closer to exposed energized parts than the employer's established minimum approach distance, unless:

1910.269(l)(3)(iii)(A)

The employee is insulated from the energized part (rubber insulating gloves or rubber insulating gloves and sleeves worn in accordance with paragraph (l)(4) of this section constitutes insulation of the employee from the energized part upon which the employee is working provided that the employee has control of the part in a manner sufficient to prevent exposure to uninsulated portions of the employee's body), or

1910.269(l)(3)(iii)(B)

The energized part is insulated from the employee and from any other conductive object at a different potential, or

1910.269(l)(3)(iii)(C)

The employee is insulated from any other exposed conductive object in accordance with the requirements for live-line barehand work in paragraph (q)(3) of this section. -

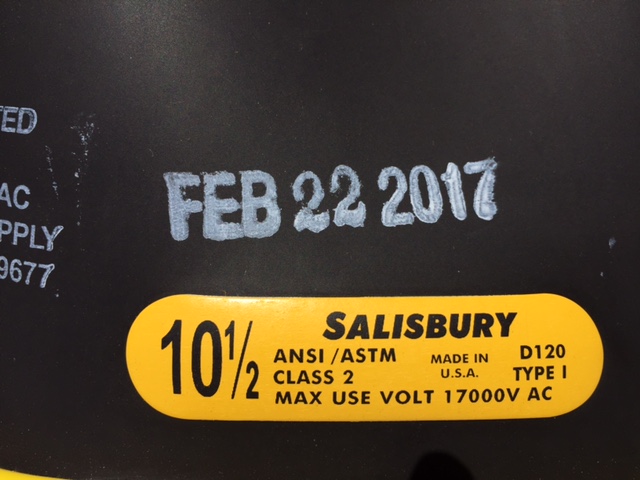

Have rubber gloves been inspected annually and stamped accordingly?

-

-

Were rubber gloves/sleeves/booties worn while setting a pole near energized primary?

Switching

-

Switching

-

Were lines or equipment switched out of service and visual opens established?

-

1910.269(m)(3)

Deenergizing lines and equipment.

1910.269(m)(3)(i)

The employee that the employer designates pursuant to paragraph (m)(2) of this section as being in charge of the clearance shall make a request of the system operator to deenergize the particular section of line or equipment. The designated employee becomes the employee in charge (as this term is used in paragraph (m)(3) of this section) and is responsible for the clearance.

1910.269(m)(3)(ii)

The employer shall ensure that all switches, disconnectors, jumpers, taps, and other means through which known sources of electric energy may be supplied to the particular lines and equipment to be deenergized are open. The employer shall render such means inoperable, unless its design does not so permit, and then ensure that such means are tagged to indicate that employees are at work.

1910.269(m)(3)(iii)

The employer shall ensure that automatically and remotely controlled switches that could cause the opened disconnecting means to close are also tagged at the points of control. The employer shall render the automatic or remote control feature inoperable, unless its design does not so permit.

1910.269(m)(3)(iv)

The employer need not use the tags mentioned in paragraphs (m)(3)(ii) and (m)(3)(iii) of this section on a network protector for work on the primary feeder for the network protector's associated network transformer when the employer can demonstrate all of the following conditions:

1910.269(m)(3)(iv)(A)

Every network protector is maintained so that it will immediately trip open if closed when a primary conductor is deenergized;

1910.269(m)(3)(iv)(B)

Employees cannot manually place any network protector in a closed position without the use of tools, and any manual override position is blocked, locked, or otherwise disabled; and

1910.269(m)(3)(iv)(C)

The employer has procedures for manually overriding any network protector that incorporate provisions for determining, before anyone places a network protector in a closed position, that: The line connected to the network protector is not deenergized for the protection of any employee working on the line; and (if the line connected to the network protector is not deenergized for the protection of any employee working on the line) the primary conductors for the network protector are energized.

1910.269(m)(3)(v)

Tags shall prohibit operation of the disconnecting means and shall indicate that employees are at work.

1910.269(m)(3)(vi)

After the applicable requirements in paragraphs (m)(3)(i) through (m)(3)(v) of this section have been followed and the system operator gives a clearance to the employee in charge, the employer shall ensure that the lines and equipment are deenergized by testing the lines and equipment to be worked with a device designed to detect voltage.

1910.269(m)(3)(vii)

The employer shall ensure the installation of protective grounds as required by paragraph (n) of this section.

1910.269(m)(3)(viii)

After the applicable requirements of paragraphs (m)(3)(i) through (m)(3)(vii) of this section have been followed, the lines and equipment involved may be considered deenergized. -

Were hold tags needed/placed?

-

1910.269(m)(3)(v)

Tags shall prohibit operation of the disconnecting means and shall indicate that employees are at work.

1910.269(m)(3)(vi)

After the applicable requirements in paragraphs (m)(3)(i) through (m)(3)(v) of this section have been followed and the system operator gives a clearance to the employee in charge, the employer shall ensure that the lines and equipment are deenergized by testing the lines and equipment to be worked with a device designed to detect voltage.

1910.269(m)(3)(vii)

The employer shall ensure the installation of protective grounds as required by paragraph (n) of this section.

1910.269(m)(3)(viii)

After the applicable requirements of paragraphs (m)(3)(i) through (m)(3)(vii) of this section have been followed, the lines and equipment involved may be considered deenergized. -

Are reclosing relays being utilized?

-

1910.269(m)(3)(iii)

The employer shall ensure that automatically and remotely controlled switches that could cause the opened disconnecting means to close are also tagged at the points of control. The employer shall render the automatic or remote control feature inoperable, unless its design does not so permit. -

Are clearance points known/communicated to the crew?

Grounding

-

Grounding

-

Have grounding jumpers been visually inspected before use?

-

Are grounds properly installed?

-

1) All OSHA 29 CFR 1910-269 N and Company rules for grounding shall apply in addition to these procedures.

2) At all times the conductor shall be verified open, tested de-energized with a hot line indicator (nominal voltage indicator) held with the proper authority before grounds are installed.

3) Each Grounding location will be flagged with the appropriate High Visibility Grounding Flag.

4) Only ASTM 855 compliant, properly fault current rated and annually tested grounding clamps and conductors will be used for grounding. Grounding Jumpers will be color coded by marking tape to ensure annual testing and will rotate Red, Yellow and Blue every three years

• End of year 2014 to End of year 2015 Red

• End of year 2015 to End of year 2016 Yellow

• End of year 2016 to End of year 2017 Blue

5) Single point “Equipotential” grounding will be used, whenever possible, to obtain the lowest difference in potential between the conductor and the employee and any second point of contact. The ground cluster bar shall be used on the pole. All phases, neutral, static wires, apparatus, structures and poles shall be bonded together to eliminate any hazardous difference in electrical potential.

6) In situations when single point grounding cannot be used, grounds shall be installed on both sides of the work area as close to the work area as possible. Ground cluster or other bonding jumpers are required at the work location to keep the pole, structures, equipment or apparatus in an equipotential zone.

7) Spacer cables shall be grounded at the closest bare spot on the conductor on each side of the work location. If the possibility of potential difference exists from any energy source (transformer, lateral, power bank, etc.) in the work area, then gloves, sleeves and di-electric boots shall be worn while working in the area.

8) Due to higher fault current on 4KV circuits, when grounding a 4kv circuit, the grounds shall be paralleled when using 1/0 (40KA at Deaconess) ground leads. The phases shall be grounded with paralleled ground leads, and paralleled long leads grounded to the system neutral.

Note: When working on circuits where bus ties exist, every attempt shall be made to separate the bus ties to reduce the fault current.

9) Underground cable shall be grounded on each side of the work location. The conductor shall be tested de-energized using a feed through, testing probe and a hotline indicator (nominal voltage indicator or “noisy tester”) or phasing transformer prior to grounding. Each work location must be properly checked open, tested de-energized, held, tagged and then grounded before work can be started.

10) To verify that an unidentified uncovered-grounded cable is de-energized, the cable shall be pierced with a grounded piercing clamp using a hot stick or cut with hydraulic cutters operated from a remote location.

11) The following are considered approved grounding sources and should be utilized in the order listed:

a) System neutral/substation grid system.

b) Pole ground attached to system neutral.

c) Driven ground rod.

d) Screw rod. -

1910.269(n)(6)

Connecting and removing grounds.

1910.269(n)(6)(i)

The employer shall ensure that, when an employee attaches a ground to a line or to equipment, the employee attaches the ground-end connection first and then attaches the other end by means of a live-line tool. For lines or equipment operating at 600 volts or less, the employer may permit the employee to use insulating equipment other than a live-line tool if the employer ensures that the line or equipment is not energized at the time the ground is connected or if the employer can demonstrate that each employee is protected from hazards that may develop if the line or equipment is energized.

1910.269(n)(6)(ii)

The employer shall ensure that, when an employee removes a ground, the employee removes the grounding device from the line or equipment using a live-line tool before he or she removes the ground-end connection. For lines or equipment operating at 600 volts or less, the employer may permit the employee to use insulating equipment other than a live-line tool if the employer ensures that the line or equipment is not energized at the time the ground is disconnected or if the employer can demonstrate that each employee is protected from hazards that may develop if the line or equipment is energized.

1910.269(n)(7)

Additional precautions. The employer shall ensure that, when an employee performs work on a cable at a location remote from the cable terminal, the cable is not grounded at the cable terminal if there is a possibility of hazardous transfer of potential should a fault occur. -

Are grounding flags utilized?

-

3) Each Grounding location will be flagged with the appropriate High Visibility Grounding Flag.

-

Was the digger derrick truck grounded or barricaded while working around energized primary? Including setting poles?

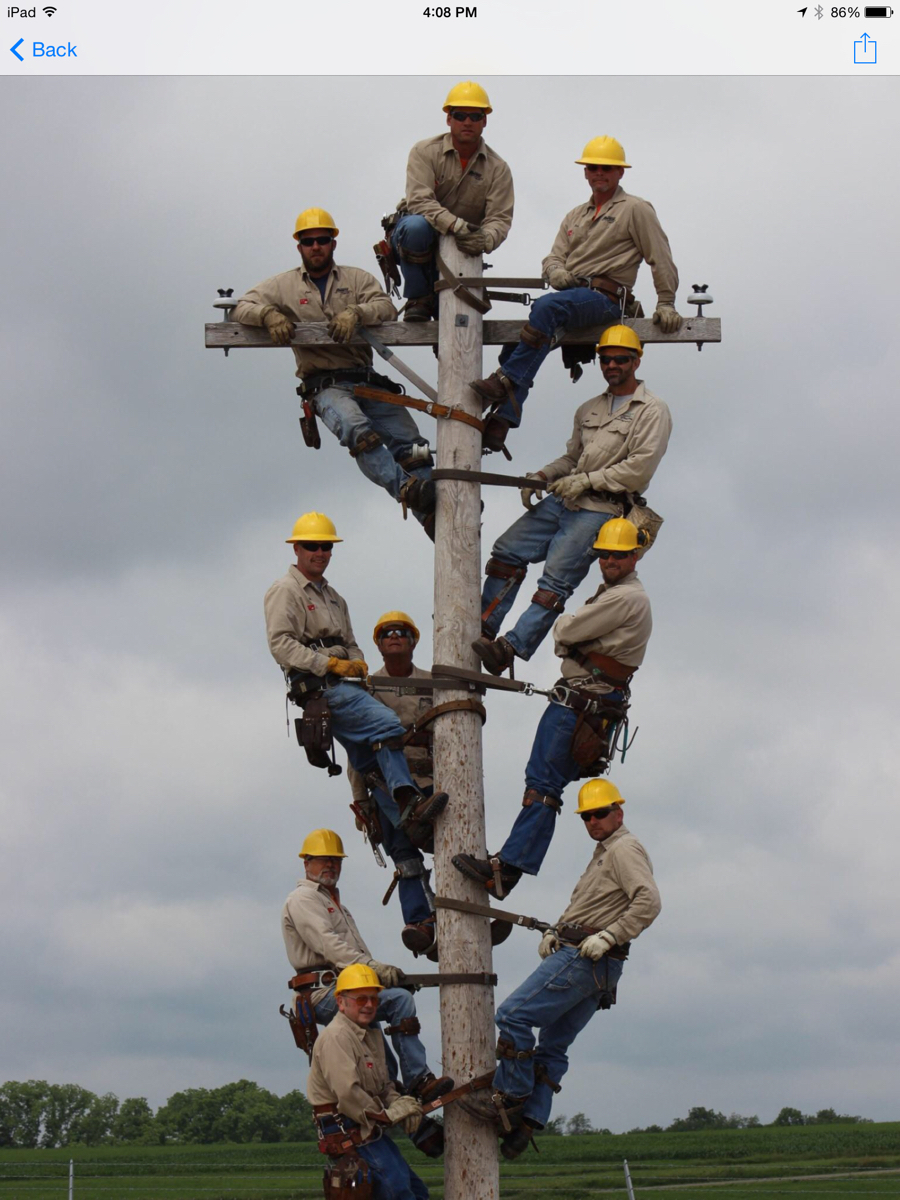

Climbing

-

Climbing

Fall Protection

-

Fall Protection

-

Fall protection inspected before each use

-

1910.269(g)(2)(iv)

The following requirements apply to the care and use of personal fall protection equipment.

1910.269(g)(2)(iv)(A)

Work-positioning equipment shall be inspected before use each day to determine that the equipment is in safe working condition. Work-positioning equipment that is not in safe working condition may not be used. -

Is fall protection adequate for arc flash?

-

1910.269(g)(2)(ii)

Personal fall arrest equipment used by employees who are exposed to hazards from flames or electric arcs, as determined by the employer under paragraph (l)(8)(i) of this section, shall be capable of passing a drop test equivalent to that required by paragraph (g)(2)(iii)(L) of this section after exposure to an electric arc with a heat energy of 40±5 cal/cm2. -

Excavation

-

Excavation

Additional Remarks

-

Additional Remarks

General Questons

-

General Questions