Title Page

-

Production Room

-

Conducted on

-

Prepared by

SP1

-

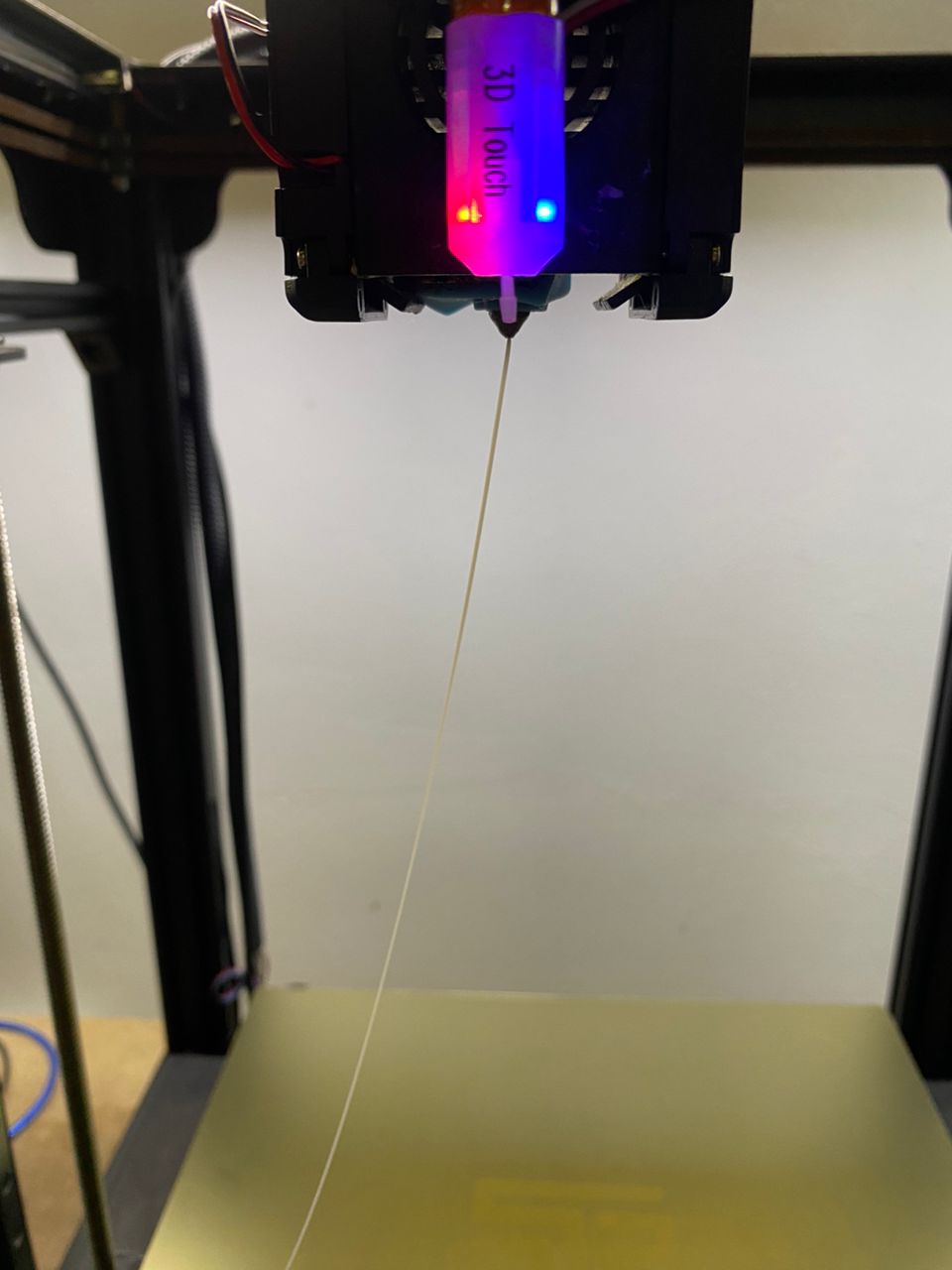

1. Check nozzle condition by extrude filament.

-

Nozzle

-

1.Heat the nozzle and clean with a needle

2.Remove the feeder tube and try pushing the filament through with another piece of filament

3.Dismantle the hot end and see if you can extract the filament blockage

4.Try an Atomic Pull (Cold Pull)

5.Please update on Asana Unserviceable printer overview, printer that got problem. -

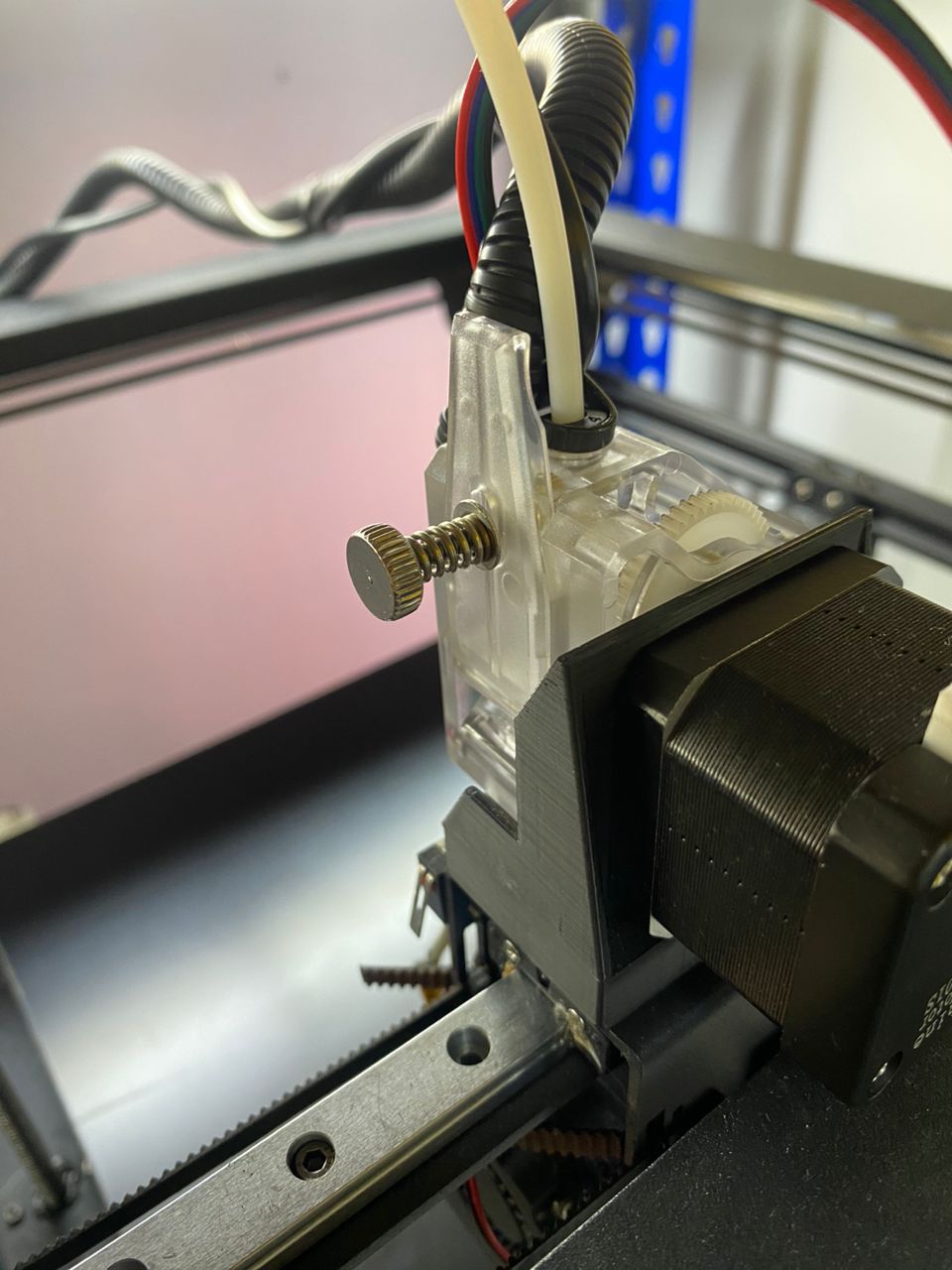

2. Try pull the filament at Extruder as hard as you can if filament doesn't move means extruder in normal condition.

-

Extruder

-

1. You can open the extruder and tighten the grub screw that lock the shaft. (if can't tighten it replace with the new one)

2. You can check the spring tension as well.

3. Check if there any broken parts in extruder.

4. Please update on Asana Unserviceable printer overview, printer that got problem. -

3. Check 3D touch pin condition by touching the pin.

-

3D touch pin

-

1. Get the spare parts and replace it.

2.Please update on Asana Unserviceable printer overview, printer that got problem. -

You can straighten back the pin back to normal .

-

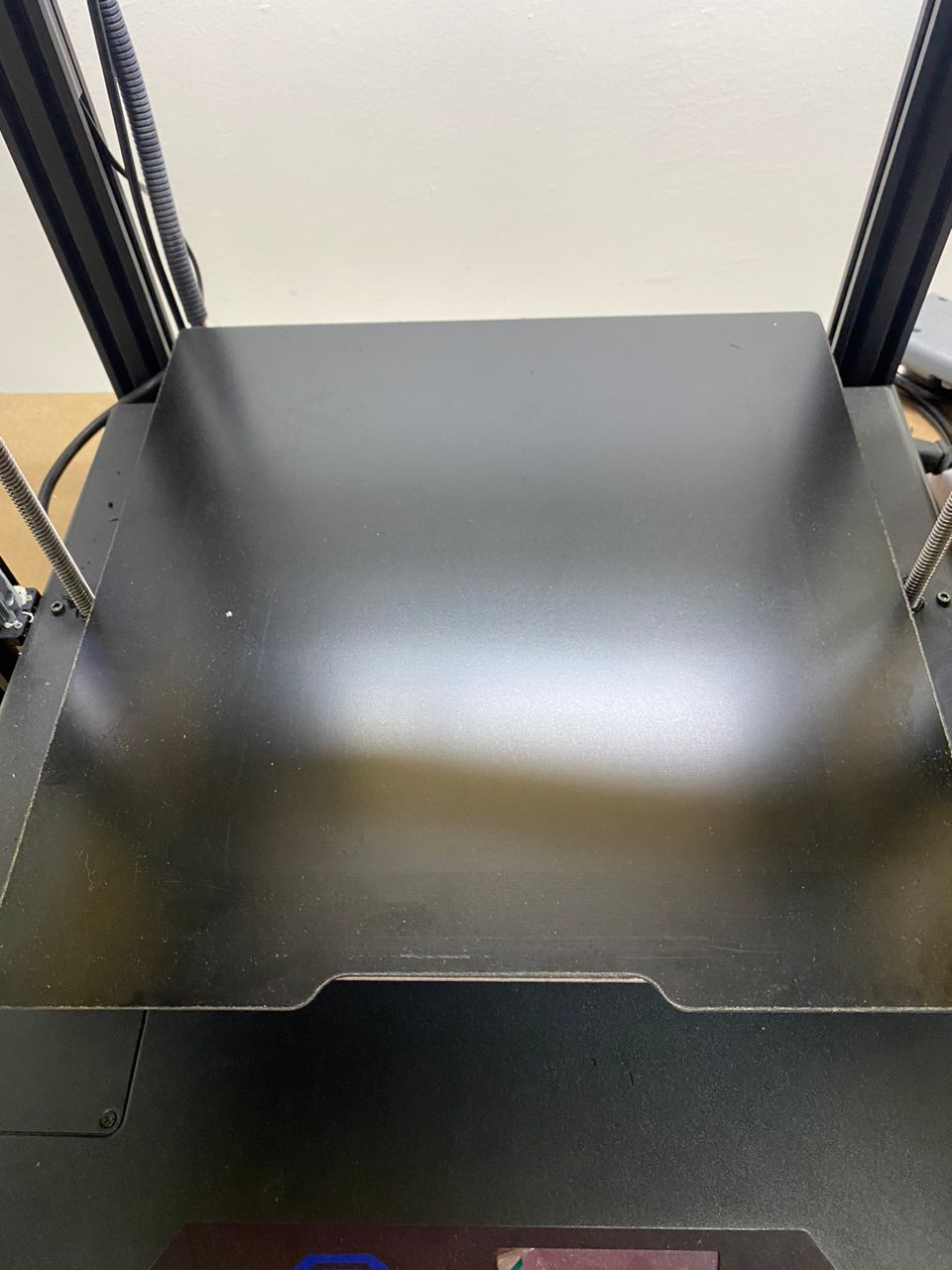

4. Check PEI/Fiber board place at right orientation and no damage on surface.

-

PEI build plate

-

1.Replace with new build plate.

2. Please update on Asana Unserviceable Printer overview. -

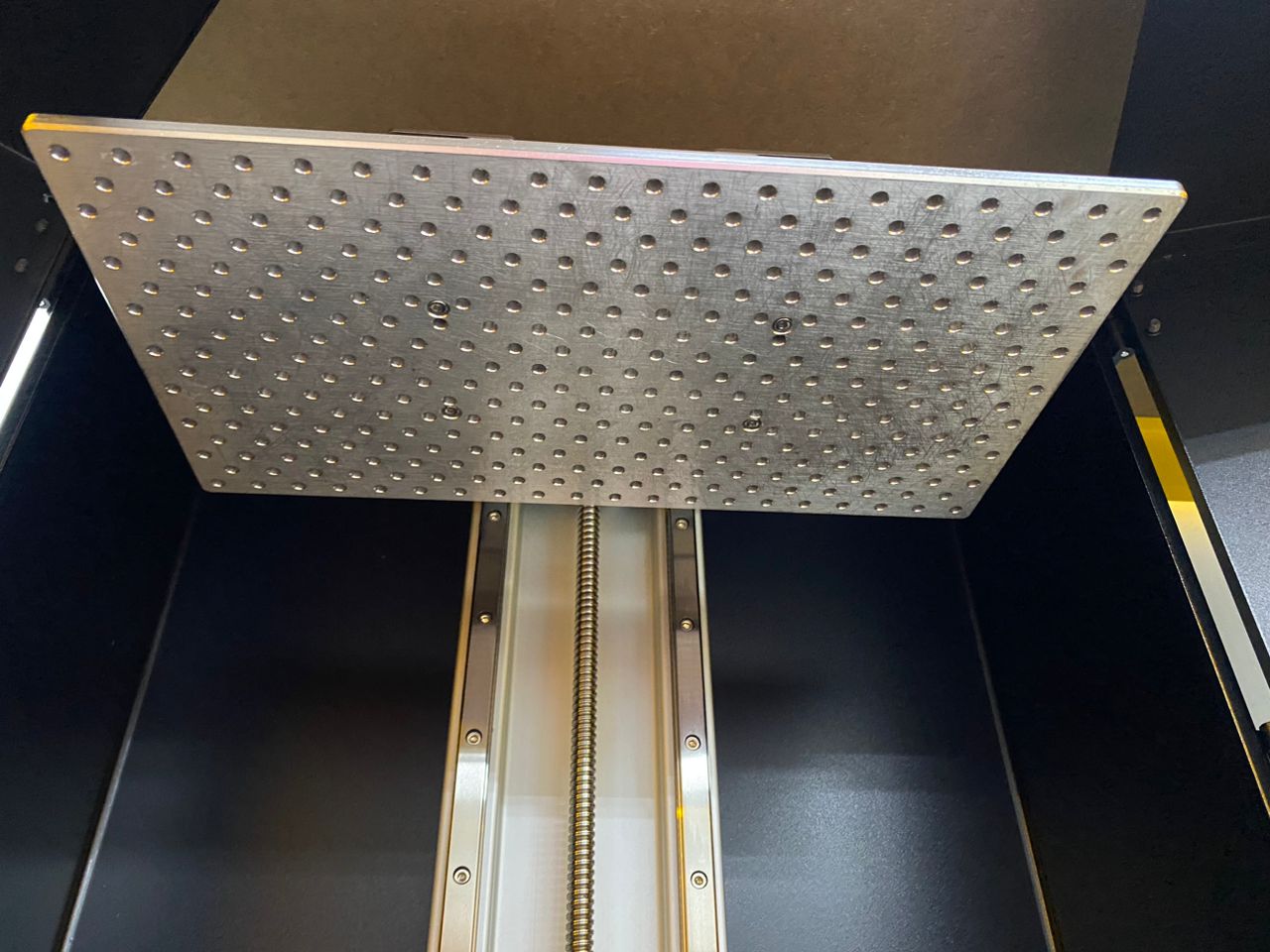

5. Check there is no dust or lubricant substance at Z-axis lead screw .

-

Z-axis Lead Screw

-

Please use paper towel to wipe down dust or lubricant substance that stuck at Z-axis lead screw.

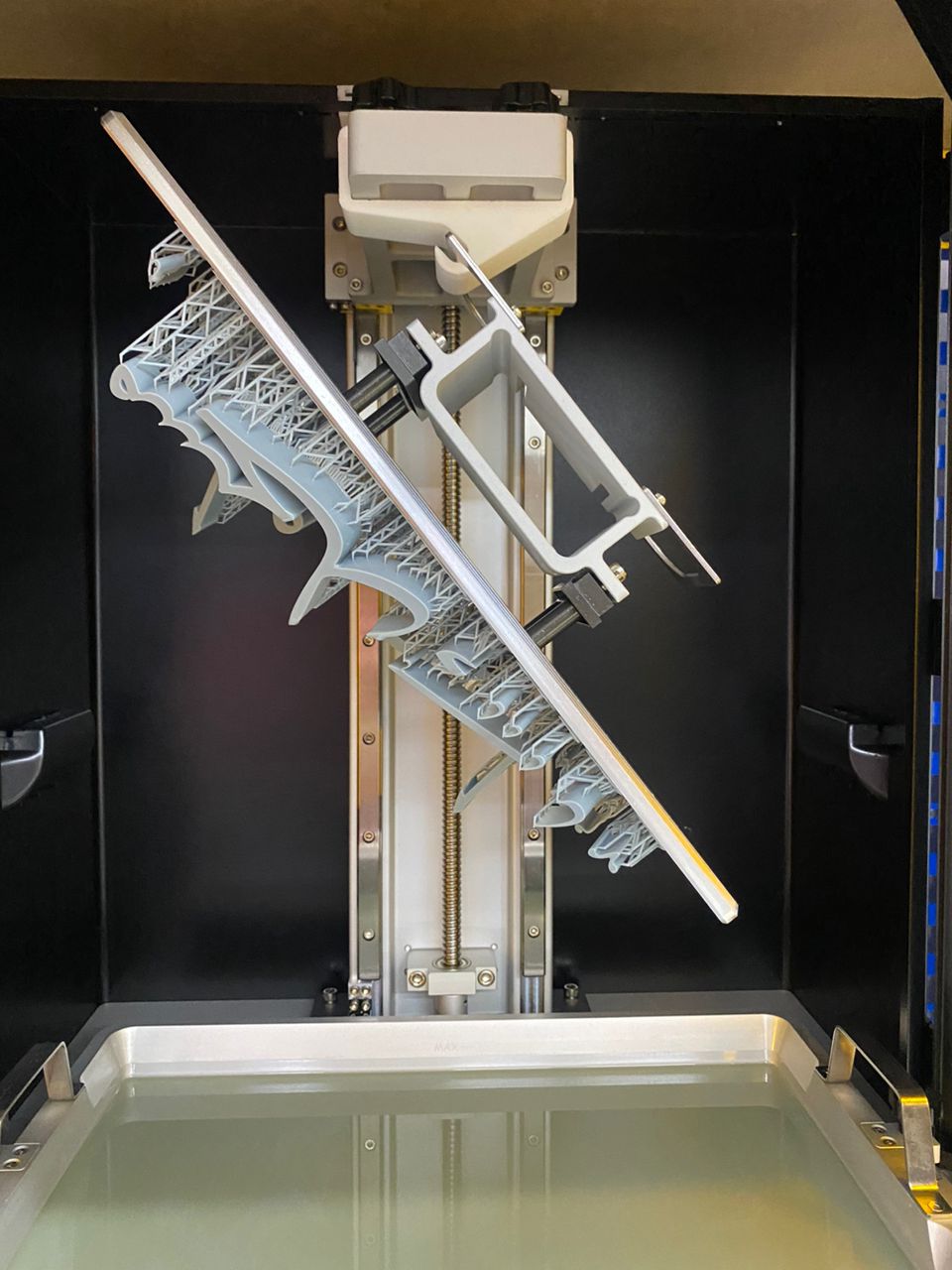

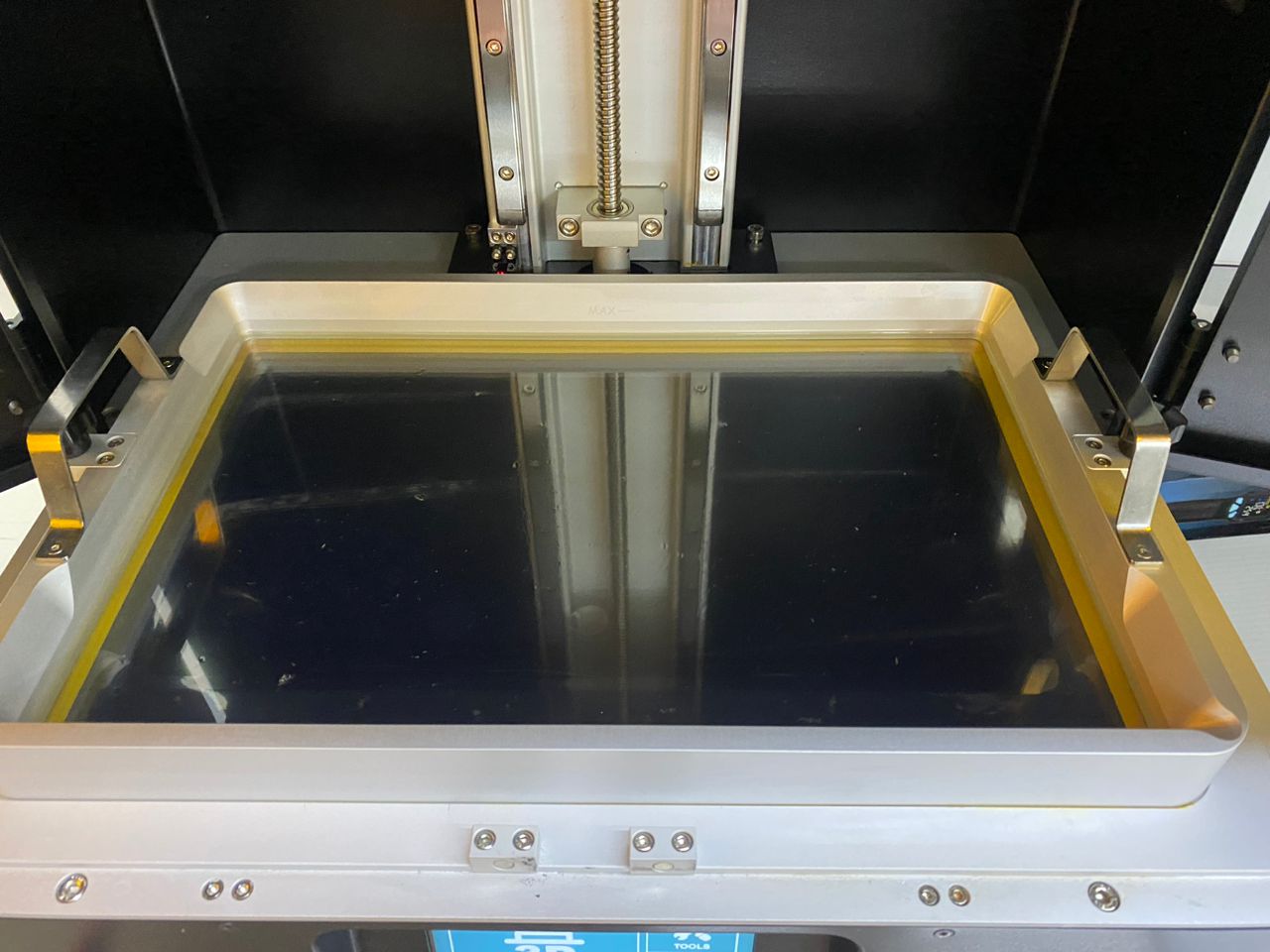

Mega 8K

-

1. Tilt the build plate if got print by using bracket provided. (refer picture below as a reference)

-

2. If there is no print, check build plate is clean from dust or any other dirt.

-

Build plate

-

3.Check there is no remnant of cured resin inside vat. You can check by using silicone spatula and stir all over.

-

VAT

-

1. You need to filter out the resin back into the bottle using metal funnel.

2.Use plastic spatula to remove hardened resin on nFEP film. Don't push too hard on nFEp film as it can damage the material and affect the quality of your prints future.

3. Take paper towel to absorb liquid resin out of the cat thoroughly. (gentle dabbing motion)

4. Refill back the resin if want to reprint.

5.Please update on Asana Unserviceable printer overview, printer that got problem.

Asana and Quotation

-

1. Reply all unreplied messages or message that mark unread in Whatsapp. Make sure you checked all the message started from the last day you worked.

-

2. Reply all unreplied messages or message that mark unread in Shopee Chat. Make sure you checked all the message started from the last day you worked. For Shopee chat, you need to be last message in conversation between you and your customer.

-

3. Reply all unreplied messages in email.

-

4. Transfer all order in Shopee to Asana. All the important information need to write down in the description. Don't forget to add note "Asana done" once done transferred.

-

5. Prioritize ready stock order (Coffee spare parts/filament/etc.) for on the particular day for shipping .

-

6. For quote purpose, please use Quotation profile in the Ultimaker Cura for FDM printing or Chitubox for SLA printing.

-

7. Quote customer with share link payment in Shopee.