Title Page

-

Site conducted

-

Owner’s Plant No.:

-

Inspection Date

-

Inspector

-

Design Approval:

-

Location of Design Approval:

-

Vessel Serial No.:

-

Manufacturer:

-

Manufacture Date:

-

Owner:

-

Site Contact:

-

Vessel Location:

-

Type / Description:

-

Design Pressure (P): kPa

-

Volume (V) in LTS :

-

PV in MPaL:

-

Hazard Level:

EXTERNAL INSPECTION

-

Mechanical Damage

-

Protective Coating

-

Vessel Supports

-

Welded Seams & HAZ

-

Inspection Opening & Door

-

Branches & Nozzles

-

Connected Pipe Work

-

Drain System

PRESSURE GAUGE

-

Pressure Gauge Range (Working pressure of vessel should read in middle 1/3 of gauge range)

INTERNAL INSPECTION

-

Top/End

-

Shell

-

Bottom/End

-

Welded Seams & HAZ

-

Protective Coating

SAFETY/RELIEF VALVE

-

Relief Valve Setting (kpa)

-

Working Pressure (kpa)

-

Relief Valve Size

-

Relief Valve Flow

-

Manufacture

-

Serial#

-

Model#

-

Part#

-

Test Date

THICKNESS TESTS (mm)

-

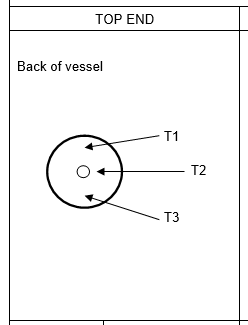

TOP END THICKNESS

-

T1 Thickness (mm)

-

T2 Thickness (mm)

-

T3 Thickness (mm)

-

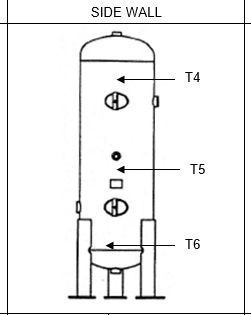

SIDE WALL THICKNESS

-

T4 Thickness (mm)

-

T5 Thickness (mm)

-

T6 Thickness (mm)

-

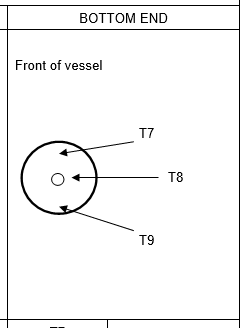

BOTTOM END THICKNESS

-

T7 Thickness (mm)

-

T8 Thickness (mm)

-

T9 Thickness (mm)

SIGN OFF

-

I have inspected the Pressure Vessel in accordance with AS/NZS 3788:2006 and assessed that it is/not suitable for continued operation subject to the following Non-Compliance(s) being rectified: - (Tick means in it is suitable for continued service)

-

Non-Compliance(s):

-

Inspector’s Signature:

-

Next Statutory Inspection Due: