Information

-

Maintenance ID

-

Site

-

Conducted on

-

Make

-

Model

-

Serial No.

-

Prepared by

-

Location

-

Main Entrance (Avon RB780CR Road Blocker)

Personal Hazard Assessment

-

1. Stop and Look

-

Observe Work and Surrounding

-

2. Think Through the Task

-

Work scope/procedures/JHA understood and in use

-

Correct Permit obtained and in use

-

Correct PPE obtained and in use

-

Correct Tools/Equipment available and in good order

-

3. Hazard Identification & Controls

-

Hazards Identified

- Traffic

- Electrical

- Mechanical

-

Traffic

-

Hazard Control Details

-

Electrical

-

Hazard Control Details

-

Mechanical

-

Hazard Control Details

-

Do the Task Safely

-

Can the job be done safely? (If No, STOP and contact your Supervisor)<br>

-

General Instructions:

• The following listed tasks are indicative only. All works shall be carried out in accordance to the agreed maintenance scope in the contract and shall be relevant to the Australian Standard.

• All work is to be undertaken in accordance with AS 3000-2000, relevant statutory and legislative policies/procedures.

• All Electrical equipment shall be maintained to meet with the requirements of AS 3000-2000.

• Tag-off all associated circuits when working on electrical equipment.

• Any abnormal conditions shall be noted in the Log Book, and reported to the Facility Manager.

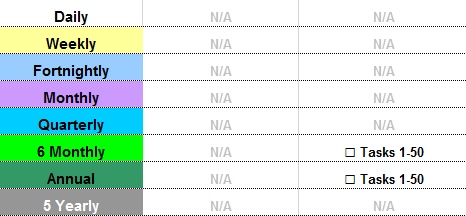

Tasks 1 - 10

-

1. Ensure safety signs are in place and warn people of gate testing.

-

2. Raise and lower Blocker (run through full cycle) and observe any abnormalities

-

3. Check and test operation of all inputs (push buttons, card readers, traffic lights etc.)

-

4. Check and tighten all fasteners and fixings if required

-

5. Isolate power to Road Blocker to perform visual and mechanical checks

-

6. Check that inside of Road Blocker is free of water/oil/dirt or debris

-

7. Check hydraulic hoses are tight and free of oil leaks

-

8. Check the ram piston and ensure it is free of oil leaks

-

9. Check the top and bottom ram pins are secure and retaining clips are correctly located.

-

10. Grease the top and bottom ram pins

Tasks 11 - 20

-

11. Remove Road Blocker wedge, replace and grease bearings. (Only if required)

-

12. Grease and tighten pivot bearing block retaining bolts

-

13. Check blocker wedge for detectable side movement

-

14. Check limit switch cable in not damaged and junction box is watertight

-

15. Clean and tighten limit switches and adjust if required

-

16. Record pressure settings during raise. (Psi)

-

17. Record pressure settings during lower.

-

18. Record pressure relief valve settings. (Psi)

-

19. Check hose connections are tight and free of oil leaks

-

20. Check HPU interior and exterior is clean and free of oil leaks

Tasks 21- 30

-

21. Check fasteners for motor/tank lid/oil filler etc are secure.

-

22. Check Road Blockers raise and lower smoothly and evenly

-

23. Check oil level through spy glass and top up with suitable oil if required.

-

24. Ensure oil cap is clean and secure

-

25. Ensure hand pump bolts are secure

-

26. Check hand pump operates correctly

-

27. Test hydraulic accumulator and make sure it operates correctly

-

28. Bleed air from hydraulic hoses if required

-

29. Check and record voltage between all phases, phases to earth and phases to neutral. (All recordings in Volts)

Tasks 31 - 40

-

30. Check and record voltage on both sides of transformer (All recordings in Volts)

-

31. Check and record voltage between earth and neutral. (Must be below 5 volts.)

-

32. Check and record earth impedance to frame. (Must be less than 1 ohm.)

-

33. Check and tighten electrical connections and terminations

-

34. Conduct a visual check on electrical components for signs of burning or overheating

-

35. Check that all cables are in good condition and undamaged

-

36. Test and ensure UPS operates correctly

-

37. Record UPS Battery Test

-

38. Check operation of circuit breakers and RCD's

-

39. Check functions of all installed inductive loops and make sure they operate correctly

-

40. Check and record brand and model number of detector unit.

-

Make

-

Model

Tasks 41 - 50

-

41. Check and record resistance of inductive loop. (Loop tail to loop tail.) Must be less than 5 ohms

-

42. Conduct an insulation resistance test on inductive loop (at 500v.) Minimum 100 Meg Ohm

-

43. Record Model number of PLC

-

44. Record model number of Loop Detectors.

-

Add media

-

45. Describe overall Blocker condition

-

46. Record all repairs by LES Contractors

-

47. Compile Report

-

48. Remove road warning signs.

-

49. Inform Site Security that task has been completed.

-

50. Inform Facilies Manager that task has been completed

Other

-

Comments

-

Add media

-

Complete Time

-

Technician

-

Add signature

-

Facilities Manager

-

Add signature

-

Client

-

Add signature