Title Page

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

General

-

To complete this training you must read each section . There are eight sections and an assessment. You can access sections via tapping on the next section button on the bottom right.

There are three videos relevant to this SOP. -

General PPE required:

Hair Net

Beard Net

Safety Boots

Hearing protection

Safety Glasses

Vinyl or Nitrile Gloves

Apron -

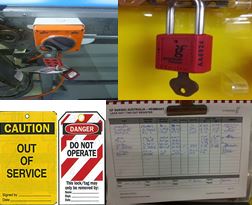

Lock Out Tag Out :

Lock out Tag out Padlock

Hasp

Out of Service Tag

Do not Operate Tag

Metal Detectable Ties

Loto Register -

Cleaning :

Hair Net

Beard Net

Safety Boots

Hearing Protection

Safety Glasses

Chemical Resistant Gloves

Heavy Duty Aprons -

The Following Training is required before undertaking these tasks:

Correct use of Personal Protective Equipment

Lock Out Tag Out

Manual Handling

Quality

-

Follow All GMP Requirements

Clean as you go. Ensure your hands are washed and sanitised before starting and during production.

Report any non Conformance of machinery, raw materials or product.

Safety/Emergency

-

There are no set emergency stops associated with this position. Ensure you know the location of any emergency stops on any equipment located and operated in the area.

Never point, brandish,wave,throw or jab/stab a knife toward yourself or another person at any time.

Never hold a knife by the blade as this can cause injury.

Never use a knife with butter on the handle as this is unsafe and can cause an injury. Wipe any butter off the handle and always wear a clean pair of gloves when using a knife.

Do not use a knife for any task that they are not approved for : eg: Opening packets

At all times use correct manual handling techniques when performing tasks. DO NOT OVER REACH OR TWIST YOUR BODY OR PARTS.

Position Requirements

-

Ensure you have washed and sanitised your hands and are wearing a clean set of gloves.

All knives used in hand buttering must be approved , marked and issued by the workplace.

Only use a clean, sanitised knife for hand buttering and ensure knife is not damaged or broken.

Report any damaged or broken knives to your line leader and/or QA immediately and do not use them.

Hand Butter

-

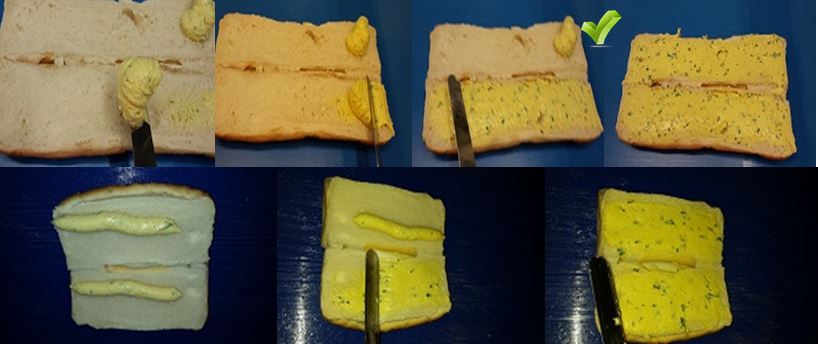

Butter is deposited onto the cut face of the roll either in two long deposits or two smaller rounder deposits. One on each face of the roll.

When hand buttering a bread roll, you are required to spread butter evenly across the open face of the roll making sure that butter is spread into the corners and up to the edge of the roll.

Hand buttering occurs in three movements, first is to remove the butter from the roll, second is to wipe the butter on the rear section of the roll and last is to spread the butter across the remainder of the roll. (See Pictures) -

Do not push the knife too hard into the roll as this can cause the knife to dig into the bread and damage the roll.

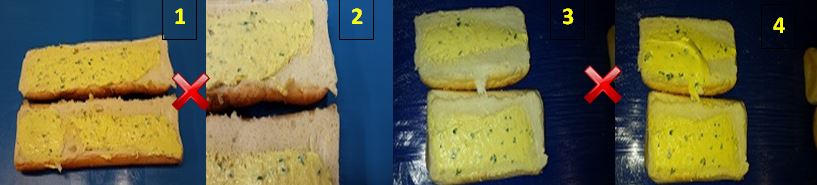

If you are hand buttering in first position you must remove any roll from the line that has not had butter deposited correctly or the butter deposit is missing completely.

Scrape / Remove any butter off the roll and place in the bowl provided. Then place the roll onto the table to be run back under the depositor when able.

The person hand buttering in position number two can also fix any missed parts of the buttering before the roll has a paper applied. See pictures 1-4 for amount where it is applicable to fix the buttering on the roll. Any buttering where the butter has been applied less or requires more effort to correct is to be removed from the line by the second butterer or person applying the paper.

t no point are you to twist, rush or apply excessive effort to correct buttering on rolls. Remove the roll from the line. Ask the person applying the paper or the person flipping the rolls to remove the roll if required as well.

Do not twist whilst performing this task. Also do not reach for the bread on the belt.

Always ensure the floor and your surrounding area are clean and free from rubbish or hazards whilst performing this task. Clean up any dropped or spilt butter to minimise the chance of an incident or hazard occurring.

Papering

-

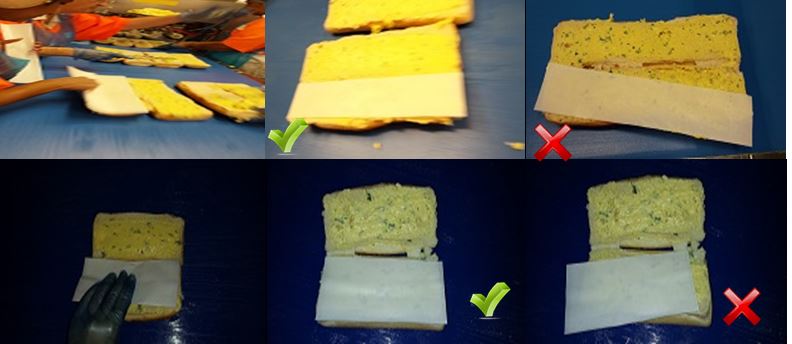

Ensure you are using the correct paper for the product.

Remove paper from plastic and stack neatly onto metal tray which is located on the table directly behind the operator applying the papers.

Do not use any papers that are marked or have butter on them. Dispose of any dirty papers and inform your line leader of any issues.

Paper is applied evenly on one side of the roll with the folded edge of the paper facing the centre of the sliced roll.

Do not apply paper so that over hangs the edge or side of the roll as this will cause the packet to not seal correctly.

Only apply one paper on each roll.

Pick up and dispose of any dropped papers.

Do not stand on dropped papers as they are a safety hazard and could result in a slip, trip or fall.

Always wash and sanitise your hands after picking up items from the floor.

Do not twist whilst performing this task. Ensure you move your feet when turning to take more papers from the stacks on the table.

Closing Rolls (Flipping)

-

Fix any papers that are not evenly or correctly placed as the open roll comes to you. Remove any excess papers that may be on the roll. Place excess papers onto the table located next to you.

Flip the top section closed onto the bottom section of the roll. Do not close two tops or two bottoms together.

Ensure the roll is closed and the top is not sitting uneven or crooked.

Ensure closed roll is placed correctly on conveyor so it can easily transition to the Fuji.

Remove from the line any roll that is not correctly buttered and place onto table to be fixed.

Do not twist whilst performing this task. Also do not reach for the bread on the belt.

GMP, Dry Cleaning and end of production.

-

When production has stopped for a break or a product change is occurring each operator performing the following tasks must:

BUTTERING:

Use a safty knife only, open all rewraps and return then through the Fuji to be packed.

Clean off all butter residues from tables and wipe over tables with paper towels.

Take the knives to the wash sinks and using hot water and detergent wash the knives until clean and no visible trace of butter or food stuff can be seen. Then sanitise the knife and return to clean table to air dry.

PAPERING:

Restock the papers on the metal tray ensuring they are facing the correct way in the tray. Usually folded side facing the operator.

FLIPPING:

Clean up all bread that is on the floor and dispose of into bread waste bins.

ALL OPERATORS:

Clean yo all rubbish from area and floor and dispose of into bins.

Empty all bins, placing rubbish into square bin for removal from production. -

END OF PRODUCTION

Take all knives to the wash sinks and place into container for cleaners to wash.

Place clean unused papers into a blue food quality bag and replace into carton. Seal carton and return carton of papers for warehouse to collect.

Clean up all bread that is on the floor and dispose of into bread waste bins.

Clean up all rubbish from area and floor and dispose of into bins.

Empty all bins, placing rubbish into square bin for removal from production.

Remove all catch trays from floor and dispose of contents into bin.(Butter from trays can be disposed of into bread bin but it must not contain rubbish or foreign matter.

LOTO

-

LOTO

You must perform and follow the Lock Out Tag Out Procedure for the following:

Interaction with machinery and equipment for cleaning and maintenance.

Interaction with machinery, equipment and parts for setup .

Interaction or assessing underneath conveyors and under belts.

Interaction with machinery , equipment and parts for product changover and/or allergen clean.

Follow LOTO procedure for breakdown or machine/equpment fault.

At any point where an injury could result due to accidental start up of machinery/equipment and connected parts.

If at any point you are unsure if LOTO is required ask your Supervisor before commencing the task.

Assessment

-

I have been trained and understand the requirements implemented by Goodman Fielder regarding this SOP. I also understand that this procedure must be adhered to at all times.

-

Read the following and then choose the correct answers.<br><br>When hand buttering on the production line you must:

-

Is the following True or False ?<br>You must never point, wave, throw or jab/stab a knife toward yourself or another person at any time.

-

What may be the result of using a knife that has butter on the handle or if you have butter on your hands ?

-

What is the correct process to follow to hand butter a roll ?

-

Read the following scenario and choose the correct answer. If the person who is buttering in position one(first butter) on the line is new to the task and not being able to consistently butter rolls to standard, what is the responsibility of the person buttering in second position ?

- Complain that the person is unable to do the job

- Assess whether the aount of butter that needs correcting is able to be done safely by them or if the roll is to be removed from the line for fixing later

- Reach sideways and fix the buttering

- Leave it for someone else to fix and say nothing

- All of the above

- B and C

-

Read the following statement and choose the correct answer Which of the following steps are to be followed when applying the paper to bread rolls ?

- Ensure you have the correct paper for the product

- Dispose of dirty or marked papers

- Papers that have been applied are not allowed to hang over the edge of the roll.

- Only the person applying the paper is reposnible for the quality of the paper

- Only apply one piece of paper to each roll

- All of the above

- A,B,D,E

- A,B,C,E

-

Which best describes the role of the person who is closing (Flipping) the rolls ?

-

Why is it important not to twist or to reach for product when performing any task in production ?

-

Read the following statement and choose the one correct answer ? Which of the following steps are to be performed when doing a dry clean or at end of production ?

- Only use a safety knife to open rewraps.

- Clean butter residue off all tables and wipe tables over with paper towel.

- Before going for a break wash and sanitise all knives.

- Papers must be bagged up in a blue food service bag, the carton sealed up and returned to the pallet for collection

- Clean up all bread that is on the floor and dispose of into bread waste bin.

- Clean up all rubbish and empty all bins.

- All of the above

-

Who do you inform when you have found a non conformance of a product or raw material ?

-

Name and Signature of person completing this training. Note: Now take this to a Supervisor to complete this assessment. Your Supervisor will now complete an assessment of you on the production line.

Supervisor Assessment

-

Can the employee demonstrate and explain why the wearing of the correct PPE for any task is important ?

-

Can the employee explain a scenario when you may have to apply LOTO when performing a task ?

-

Can the employee demonstrate and explain why we must use correct manual handling techniques at all times ?

-

Can the employee identify any hazards actual or possible that could occur whilst performing the line tasks ?

-

Can the employee demonstrate and explain the process to be followed whilst performing the line tasks ?

-

Can the employee explain the quality requirement for the line tasks they are performing and why ?

-

Can the employee explain why we are only allowed to use safety knives to open rewraps ?

-

Can the employee explain who they must report non conformance to and when they are to report it ?

-

Is the employee Competent ?

-

Name and signature of Supervisor. I have completed my assessment of the employee and provide feedback to them.

-

Name and signature of employee. I Confirm and agree with the record of training and have received feedback from the Supervisor.