Information

-

Customers Name:

-

Client / Site:

-

Commissioners name:

-

Name of commissioner:

-

Conducted on

-

Location

Transtank Commissioning Document CR1/1.0 iPhone version

1.0 - Customer Information

-

Sales Order Number:

-

Customer Name:

-

Tank type and serial numbers:

-

Location/Mine name:

2.0 - Tanks (Before Commissioning)

-

This applies to all tanks being commissioned, only complete when all tanks have been checked:

-

2.1 - Tanks in good condition?<br>Check over condition and note any damage caused during transportation and unloading.

-

2.1.1 - Are tanks level and on a correctly prepared base/site?

-

2.2 - Tank clean and dry, water completely drained.

-

2.3 - External coating/paint in good condition, touch up damaged areas if present.

-

2.4 - Tanks properly identified with correct number stuck on the tanks.<br>

-

2.5 - Are doors, ladders, stairs, bridge ways, protective rails and awnings installed correctly and operational? Check all bolts are tighten correctly. Each row of tanks must have at least 2 entry/exit ladders at each end.

-

2.6 - Correct dip stick for the tank size, check SFL, does it match the SFL decal and ID plate.

-

2.7 - Does tank contain a interstitial dip?

-

2.8 - Are all the caps/plugs on the roof thread taped, tight and labeled correctly?

-

2.9 - Interstitial vent (TIV) is present and all bolts are secured. Bolts securing the vent cap must allow for vent to move, ensure bolts are not tightened completely, Bolts must contain springs to ensure vent doesn't move during heavy winds.

-

2.10 - Manway/s contain gasket and all nuts are secured correctly?

-

2.11 - Check for loose bolts, studs, fittings, hoses etc. Ensure all studs, bolts etc are marked with paint pen, this is a must!

-

2.12 - Correct vent pipe supplied, fit and ensure vent cap is secured and is not obstructed

-

2.13 - Scamp fitted, tested, set and secured correctly (Internal measurement - 150mm for T & P series, 80 mm for T10's)

-

2.14 - Flexible pipe between tanks fitted correctly and so no sign of stress or leakage.

-

2.15,- Check condition of hoses, ensure they are not damaged and are correct type, length and diameter.

-

2.16 - Check operation of ball valves, gate valves and triple action valves before delivery of product.

3.0 - Pipework

-

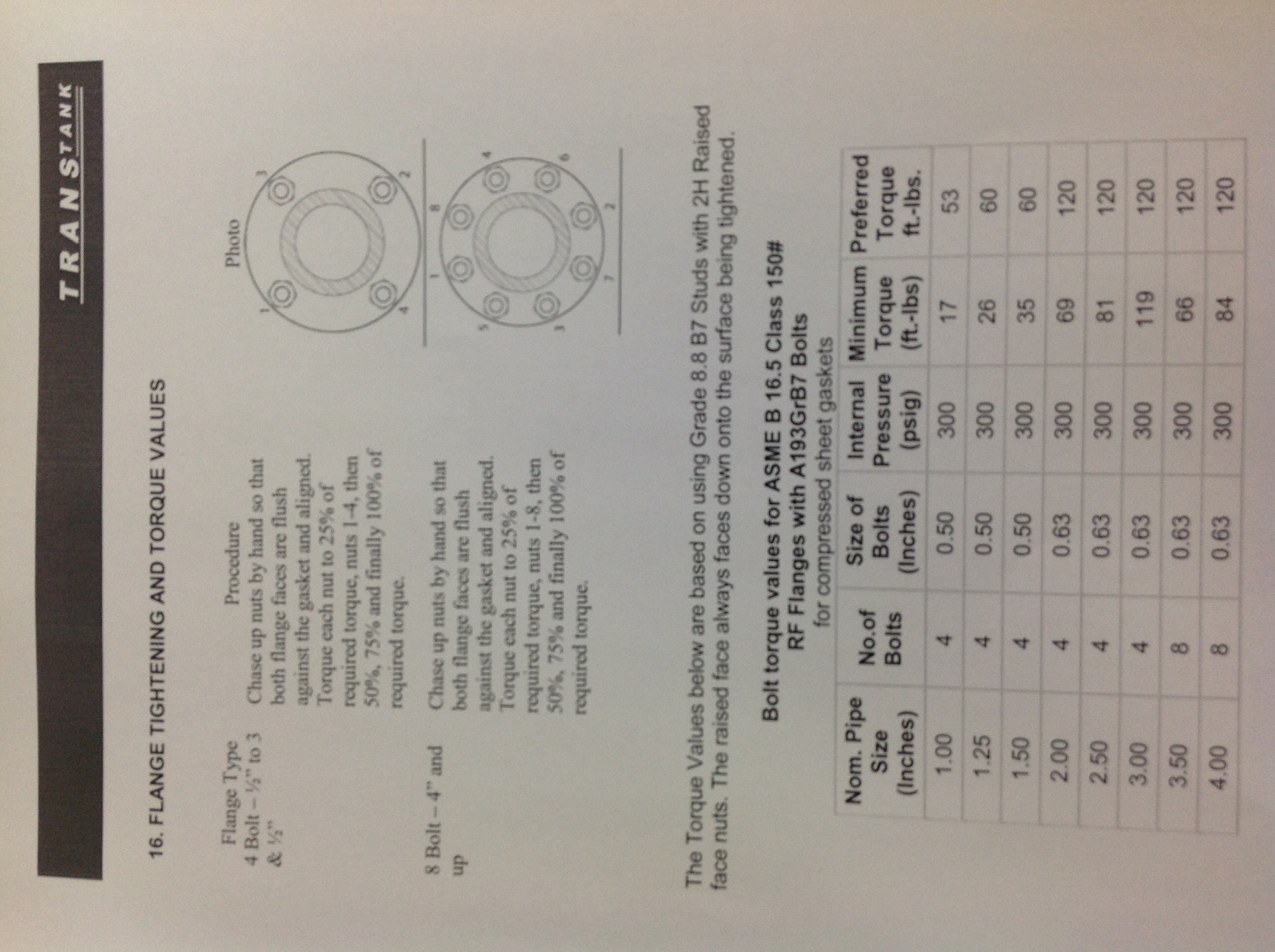

Please ensure all flanges are tightened to the correct torque valves.

-

All flanges have been tightened to correct torque settings?

-

3.1 - All external pipe work connections completed, check all joints to ensure studs are tight and contain a gasket.

-

3.2 - All ball valves operational, duo check valves are in the correct way?

-

3.3 - Are all ball valves on drain points closed and have a plug fitted?

-

3.4 - Ensure pipe work contain vents on high points and drains on low points:

-

3.5 - Pipes and valves as per P & ID

-

3.6 - Submitted Final P & ID Drawing

4.0 - Electrical Connection from Genset (Power supply) to office - product pumps are in scope of Transtank

-

4.1 - Transtank to arrange electrical connection to power supply (Genset)?

-

4.2 - Electrical connection completed?

-

4.3 - Check operation of all switches.

-

4.4 - All electrical conduit secured, neat and sealed from the weather?

-

4.5 - E stop/s installed at loading gantry operate correctly?

-

4.6 - Overloads set to correct amps?

-

4.7 - Light/s fitted and working correctly?

-

4.8 - Earth/Grounding stake provided and working correctly:

5.0 - Tank Commissining

-

This applies to all tanks being commissioned, please apply the below procedure to all tanks.

-

5.1 - Tank fill/delivery isolation valve to be in the closed position

-

5.2 - Check tank dip, record contents of tank, work out amount of product to deliver to reach SFL.

6.0 - Flow tests - Product Pumps

-

Please record all flow tests completed, record flow rates per minute and pressures both positive and negative.

6.1 - Flow test - Product Pump No 1

-

Pump priming - Suction line has been primed via the prime point.

-

Check for leaks? If no leaks present commence flow test.

-

Nozzle type

-

Please state type of nozzle:

-

6.1.6 - Product Pump No 1 flow test complete.

-

6.1.7 - Product Pump No 1 flow rates are as per P & ID or as per customers request:

6.2 - Flow test - Product Pump No 2

-

Pump priming - Suction line has been primed via the prime point.

-

Check for leaks? If no leaks present commence flow test.

-

Nozzle type

-

Please state type of nozzle:

-

6.2.6 - Product Pump No 2 flow test complete.

-

6.2.7 - Product Pump No 2 flow rates are as per P & ID or as per customers request:

6.3 - Truck Loading Flow Meter No 1

-

Pump priming - Suction line has been primed via the prime point.

-

Check for leaks? If no leaks present commence flow test.

-

Nozzle type

-

Please state type of nozzle:

-

6.3.6 - Truck Loading Flow Meter No 1 flow test complete.

-

6.3.7 - Truck Loading Flow Meter Flow rates are as per P & ID or as per customers request:

6.4 - Flow test - Truck Loading Flow Meter No 2

-

Pump priming - Suction line has been primed via the prime point.

-

Check for leaks? If no leaks present commence flow test.

-

Nozzle type

-

Please state type of nozzle:

-

6.4.6 - Truck Loading Flow Meter No 2 flow test complete.

-

6.4.7 - Truck Loading Flow Meter No 2 flow rates are as per P & ID or as per customers request:

7.0 - Photo's of site

-

Please add photos of site here:

8.0 - Sign Off

-

Commissioning complete.

-

Signature of Transtank representative.

-

Please record any notes here:

-

Customer acceptance.

-

Was your Transtank product installed to your satisfaction?

-

Are all components and equipment functioning correctly?

-

Was the site left in a clean and tidy state and to your satisfaction?

-

Any comments you would like to add?

-

Signature of Customer Representative.

-

Select date