Title Page

-

Site conducted in

-

Conducted on

-

Prepared by

-

Location

350R2 Uniloy Lubrication Instructions

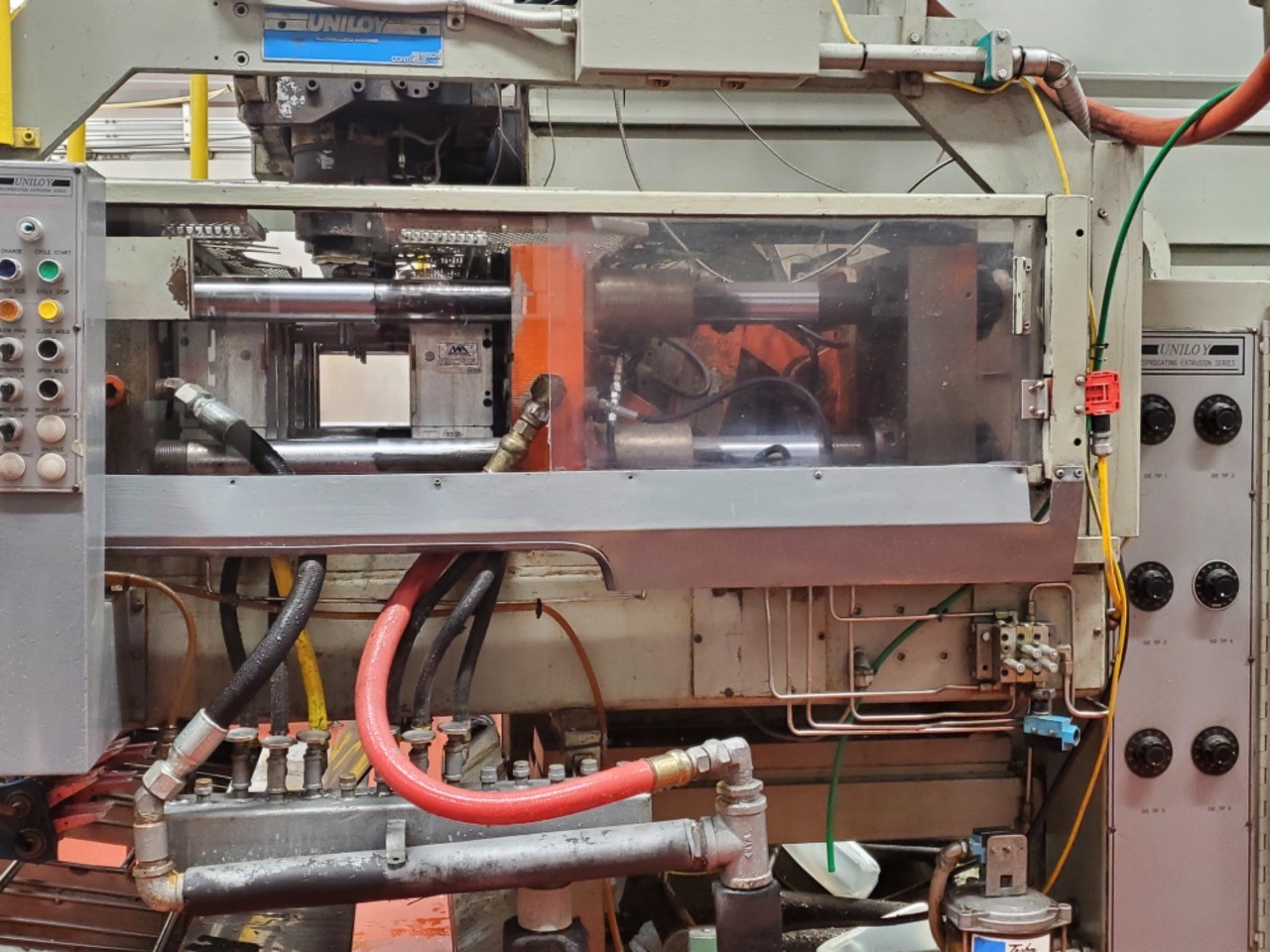

Blow Mold 1 Inspection

-

Air Lubrication Regulator is filled with Mineral Oil

-

Thrust Bearing - add 2 to 3 pumps of High Temp Grease NLGI Grade/No. 2

-

Ball Spline - add 10 to 20 pumps of grease - High Temp Grease NLGI Grade/No. 2

-

Reducer Gear Box - Do "Hand Test" if top is too hot to touch, shut machine down and check or add oil as needed - Mobil 220 Gear Oil

-

Barrel Cooling Unit - Adjust Water Flow to heat exchanger to maintain 150 to 200F temperature Refill with Multitherm IG-4, as needed

-

Clutch Cooling Unit - Maintain 90F Temp

-

Hydraulic Oil - Check to Maintain Proper Level, Use AW32 on all Machines except BM2. BM2 Uses AW68

-

Hydraulic Oil - Check water flow to Heat Exchanger to maintain 90 to 110F oil temp

-

Trimmer - 1 to 2 pumps of grease in each fitting on bucket guide chain, flange bearing, idler sprockets, platen time rod bearings, crank shaft pins, take up sprockets with High Temp Grease NLGI Grade/No. 2

-

Trimmer - Lightly oil S-Bar tie rod bearings with Mineral Oil or FG Silicon Spray

-

Trimmer - check fluid level, add Mobil 220 Gear Oil

-

Cooling Bed - 1 to 2 pumps of grease on both grease fittings of live roller and take up bearings with High Temp Grease NLGI Grade/No. 2 and check gearbox fluid level

-

Clamp - 2 to 3 pumps of grease in each grease fitting(if not an automatic lubrication system) on toggle pins, platen shoes, and tie bar bushings with High Temp Grease NLGI Grade/No. 2

Blow Mold 2 Inspection

-

Air Lubrication Oiled Lightly with Mineral Oil

-

Reducer Gear Box - Do "Hand Test" if top is too hot to touch, shut down machine or check and add oil as needed - Mobil 220 Gear Oil

-

Clutch Cooling Unit - Maintain 90F Temp

-

Hydraulic Oil - Check to Maintain oil at Bottom of Oil Filler Strainer when Machine is off (BM2 Uses AW68) Fill if needed

-

Hydraulic Oil - Check Water Flow to Heat Exchanger to maintain oil temperature between 90 - 120F

-