Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Cooking, Heating & Holding Temperatures

-

1. Hot Dog internal temps for cooked and held products, 165*F or greater. Products cooked and held according to Sonic Procedures (CRITICAL).

-

2. Gravy internal temp must be 165*F or higher. Product must be cooked and held to Sonic standards. (CRITICAL)

-

3. Chili internal temps for cooked and held products, 165*F or greater. Products cooked and held according to Sonic Procedures (CRITICAL).

-

4. Fried product temperatures coming out of the fryer to be must be 165*F or higher. [CRITICAL] (Health Department)<br>

-

5. Onion Ring Batter temperature should be at 40*F or less.

-

6. Walk-in freezer temperature should be 0*F (+/- 10). Internal thermometer must be present and in good working condition. [CRITICAL] (Health Department)<br>

-

7. Walk-in cooler temperature must be 34*F to 38*F. Internal thermometer must be present and in good working condition. [CRITICAL] (Health Department)<br>

-

8. Swamp / Grill freezer temperature:

-

8aa. Swamp/Grill freezer temperature should be 0*F (+/- 10*F). Swamp/Grill freezer product temperature is 10 F or less. Internal thermometer must be present and in good working condition [CRITICAL] (Health Department)<br>

-

9. Swamp refrigerator temperature:

-

9aa. Swamp Refrigerator protein product temperature is 34*F to 40*F. Internal thermometer must be present and in good working condition. [CRITICAL] (Health Department)<br>

-

10. Dresser cabinet temperature:

-

10aa. Dresser product temperatures are 40*F or less. Internal thermometer is present and in good working condition. [CRITICAL] (Health Department)<br>

-

11. Fountainette cabinet temperature:

-

11aa. Fountainette temperature is 34*F to 38*F. Fountainette product temperatures are 40*F or less. Internal thermometer is present and in good working condition. [CRITICAL] (Health Department)<br>

-

12. Potentially Hazardous Foods (PHF) held in the Front Swamp must be held at 40F or below. Foods include sliced/diced tomatoes and Cole Slaw. [CRITICAL] (Health Department)<br>

-

13. APW, Round-up or like Cooker, Heat Wells, Warming Drawer, Hot Dog warming drawer, Prince Castle Holding and Heat Lamp product temperatures should be holding at 165 F or greater. [CRITICAL] (Health Department)<br>

-

14. Fryer temperature is 350*F (+/- 10*F)<br>

-

15. Grill temperature zones are 400*F (+/- 30*F), 350 F (+/- 30*F), and 200 F (200*F minimum, 230*F maximum), Garland Clamshell Top 425*F (+/- 15*F), Garland Clamshell Bottom 350*F (+/- 10*F).<br>

-

16. Internal Meat Temperature Log (monthly log) and Sonic Safe Log (daily log) completed per Sonic policy. Corrective actions documented. [CRITICAL]<br>

-

17. Ice Cream and Shake Machine cabinets are 34*F to 38*F, product temperature is 40*F or less. Thermometer must be present and in good working condition. [CRITICAL] (Health Department)<br>

-

18. Ice Cream and Shake Machine(s) must be clean, properly maintained and sanitized (Health Department).<br>

Operational Procedures

-

19. Correct grill procedures (including grill timers) for meat patties (4.0 & 2.0 oz.), bacon, ham, grilled chicken, eggs, sausage, burrito mix must be used. Mandatory done ness test performed. All products must be cooked to 165F or greater. [CRITICAL] (Health Department)<br>

-

20. Correct dresser station procedures must be used. [CRITICAL] (Health Department)<br>

-

21. Employees are following Sonic 20/20 Rule. Sonic, State or Local glove requirements are followed. [CRITICAL] (Health Department)<br>

-

22. Clean towels are being used, stored properly and in sanitizer. (Health Department)<br>

-

23. No cross-contamination is observed. [CRITICAL]<br>

-

24. Approved products used. [CRITICAL]:<br>

-

26. Food must be properly tempered (34-40*F) (chili, hot dogs, bacon, corn dogs, grilled chicken, eggs, strawberry topping, ham). [CRITICAL]<br>

-

27. Product stored in walk-in & reach-in coolers and freezers are properly covered and dated. This includes tempered items. (Health Department)<br>

General Food Safety

-

28. Sanitizer is present at the designated locations and in the correct concentration and temperature. Bucket locations: ice Cream, fountain / Carhop, dresser, front swamp, grill. Sanitizer test strips are present and in use. Chlorsan and Citrus Delimer present in drive-in. [CRITICAL] (Health Department)<br>

-

29. Digital thermometer kit and probes are present and properly calibrated. [CRITICAL]<br>

-

30. Dry food products are properly stored, dated and rotated (per FIFO). Dry paper products are properly stored. All food and packaging must be off the floor at least 6 inches. (Health Department)<br>

-

31. Use only approved chemical products at the drive-in (no Bleach, Comet, Brillo, Dawn, Pesticides, Herbicides, etc).<br>

-

32. All cleaning chemicals and equipment are properly identified and stored away from food and paper products. [CRITICAL] (Health Department)<br>

-

33. Floors, drains, and baseboards are clean and in good condition. All threaded water connections must have proper back flow device. (Health Department)<br>

-

34. Walls, doors, ceiling panels and vents are clean, in place, and in good repair. (Health Department)<br>

-

35. Restrooms are clean, properly stocked with soap, sanitizer, towels and a trashcan with lid. (Health Department)<br>

-

36. Trash cans and dumpster areas are clean, covered and free from debris. (Health Department)<br>

-

37. Light fixtures are shielded or covered. Coated bulbs may be used. (Health Department)<br>

-

38. Three compartment sinks are set up properly when being used: Wash, Rinse and Sanitizer. If approved mechanical dish machine is used, all temperatures and sanitizer concentrations, if applicable, meet requirements. Wash temperature must be above 110*. (Health Department)<br>

-

39. All food contact surfaces must be cleaned and sanitized at least every two hours. [CRITICAL] (Health Department)<br>

-

40. All equipment must be NSF certified/commercial grade, clean, in good condition, and properly maintained. (Health Department)<br>

-

41. All refrigeration/freezer units (including all shelving and light bulbs) are in good working condition and clean. (Health Department)<br>

-

42. Utensils and storage containers are cleaned, food grade, NSF certified, in good condition and stored properly: tomato slicer, can opener, onion ring machine, food bins, cutting boards, utensils, cutting gloves, malt collars etc. (Health Department)<br>

-

43. Soft drink, ice machine and ice bin are free of soil and in good working order. Ice Scoops must be properly stored. (Health Department)<br>

-

44. Ice bucket is NSF certified, clean, sanitized, in good condition, stored off the floor, and labeled as an “ice only” bucket. (Health Department)<br>

Employee Hygiene

-

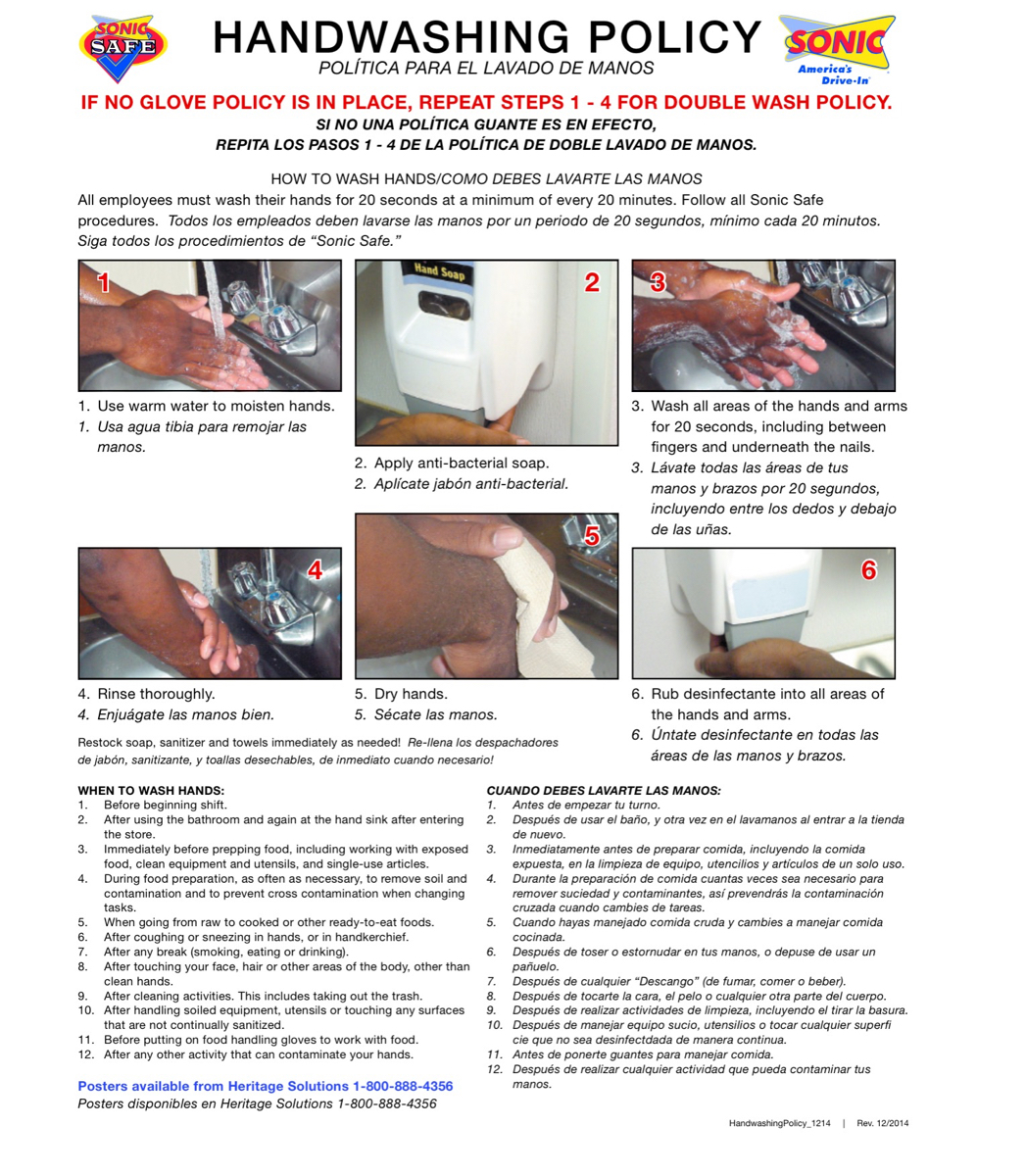

46. Hand sinks in kitchen (1) and front (1) area are properly stocked with hot water, soap, sanitizer, towels and waste receptacles and the handwashing signs pictured below. Hand sinks and drains are in good working order. [CRITICAL] (Health Department)<br>

-

-

48. Employees wearing clean uniforms and hair is restrained. Needs Improvement if only 1 or 2 violations. (Health Department)<br>

-

49. No nail polish and/or jewelry, including watches, worn by food handlers. No fingernails over ¼” in length. Bandages must be colored and covered. No jewels or stones allowed! (Health Department)<br>

-

50. Employee personal items, including food and drinks are properly stored. (Health Department)<br>

Pest Control

-

51. No visible signs of infestation. Outside doors should be sealed and remain closed. [CRITICAL] (Health Department)<br>

-

52. All pest control paperwork must be present in drive-in. Service contract, pest control reports, pest control applicator licenses, and certificate of insurance are on file.<br>

Information

-

55. Managers, Assistant Managers, or Person In Charge (PIC) are ServSafe Certified. [CRITICAL] (Health Department)<br>

-

56. Current Sonic Operations Manual is present.

-

56a. Current Food Safety Audit Packet must be present (may be saved on computer desktop and / or hard copy printed).

-

57. Star training documentation is present in drive-in. Check 2-3 employees training records. Must have Proficiency Checklist and Training Tracking Report. All employees must be re-certified since the beginning of the calendar year.

-

58. Historical temperature logs, (Internal Meat, and Sonic Safe) are recorded and corrective actions documented. [CRITICAL]<br>

-

59. SDS sheets must be available for all chemicals including pesticides and sanitizer.<br>

-

60. Bloodborne Pathogen and First Aid Kits must be present and properly stocked.<br>

-

62. Current State / Local Health Permit is posted. Health inspections should be maintained on file in the drive-in for a period of at least one year.<br>

-

63. Outside sewage and/or grease trap manhole covers are properly secured. (NO POINTS DEDUCTED)<br>

-

64. Manager and Assistant Manager Food Safety E-Learning course.<br>

-

Manager on Duty

-

Supervisor (Auditor)