Title Page

-

Documnet no

-

Description

-

Site conducted

-

Manager

-

Conducted on

-

Location

-

Handover Evidence and Description

-

Drawing Details

-

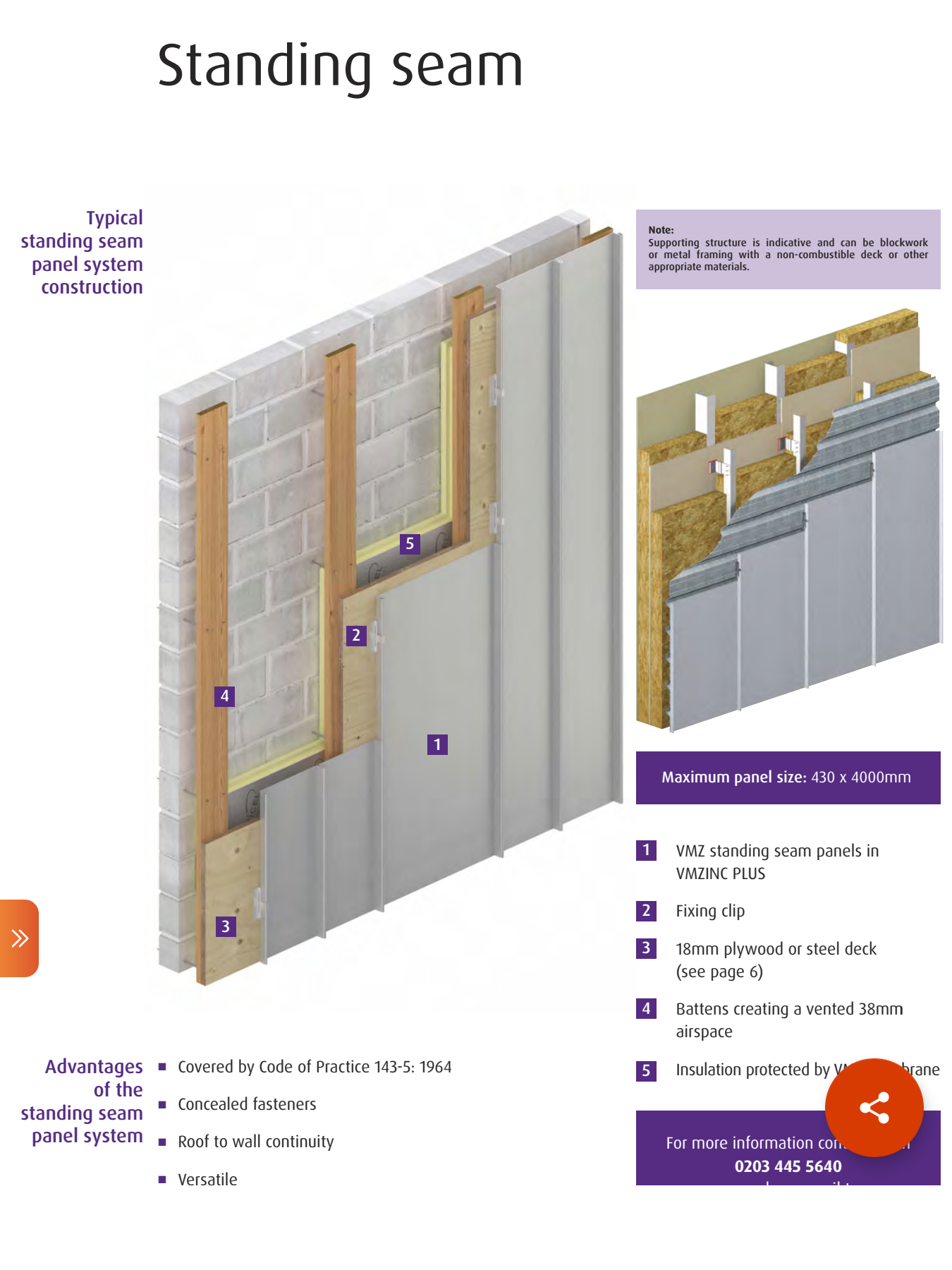

Sub-Frame Support : Insulation, Brackets, Rails, Tophats & Fixings

-

Sub-Frame Support :Board & Ywall & Fixings

-

Fixings Clips : Sliding clip & Fixed Clip

-

Sliding clip & Fix :Centre to centre distance between clips:<br>n 330mm on the main part of the facade<br>n 200mm on perimeter of the facade <br>(at least 1100mm from building corner)<br>n 150mm in corner are

Membrane

-

VMZINC Membrane is a breather layer that allows water vapour to pass through it but is water proof to liquid water (up to a column of 2m). VMZINC Membrane should be used to protect the internal leaf of the rainscreen wall which is often the insulation

Zinc Cladding

-

Instalation :The panels are installed in a sequential order from either left to right or right to left for vertical panels. Horizontal panels must be installed from bottom up. For panels less than 2m in length fixed clips can be used. For longer panels sliding clips must be used towards the bottom on vertical panels and to the left and right of the centre for horizontal panels. When using single lock all clips can be fixed. ZINC clips are made from 304 stainless steel and each<br>clip must resist a pull-out force of 50 daN. It is recommended that screws be used to secure the clips with three being used per sliding clip. The use of nails offers significantly less resistance, but in the event of using nails, contractors are advised to use ring shank nails.<br>The panels should be installed with the protective film in place.

-

Zinc anesthetics :Zinc is a material that requires almost no maintenance as the rinsing effect of rainwater performs this task naturally. However when zinc is used on a non rinsed surface such as a protected facade or soffit it is possible that the zinc may exhibit some superficial stains. These stains<br>will not affect the integrity of the zinc itself. It is for this reason that the very dark grey ANTHRA-ZINC should be carefully considered before being designed on a non rinsed facade or soffit. In marine locations the risk of superficial staining in these areas increases. Whilst stains are<br>possible on QUARTZ-ZINC and the PIGMENTO range the visual effect is greatly reduced and therefore these finishes may be more appropriate for some specific locations, however in a severe non-rinsed marine environment (1km from the sea), staining is still possible and therefore<br>PIGMENTO should not be used in this application.<br>Zinc can be installed adjacent to limestone. The run off from<br>limestone onto zinc material is acceptable. However, limestone dust and gypsum dust generated during cutting operations can react with zinc in the presence of water and form a superficial layer of white rust. No dust should be in contact with unprotected zinc. To prevent white rust, good construction practices should be used to limit the<br>amount of dust that comes in contact with the zinc.<br>VMZINC manufacturing uses a colour management system based on the Y-Factor. The Y-factor ranges from 0 to 100: 0 is black and 100 is white. The range for ANTHRA-ZINC is 5 to 7 and the range for QUARTZ-ZINC is 22 to 25. Variations are possible within this range when different production batches are used.

-

Fire Protection :Whilst zinc has a fire performance rating ‘AA’ - BS 476: Part 3 (`low vulnerability` class in Scotland) and has a fire classification of A1 or A2-s1,d0 when used on a vented wall it may be necessary to address fire risks created by the vented cavity. This can be dealt with by creating flashings that compartmentalise the vented cavity or by using<br>intumescent fire barriers that maintain the ventilated cavity in normal conditions, leaving the 38mm continuous free air space, but, in the event of fire, the intumescent ventilated fire barriers quickly expand to seal off the cavity to prevent fire spread. Not all fire retardant materials are compatible with zinc, therefore please contact us shoul you require project-specific information.

-

Interface Details

-

Commnets

-

Signature

-

Signature MC