Title Page

-

Document No.

-

Audit Title

-

Site

-

Location

-

Conducted on

-

Prepared by

-

Other Attendees

People

-

Compliance to uniform standards (uniform, hairnet, beard net, footwear). No unauthorised jewellery worn. Fingernails kept short, no false fingernails or polish in production areas. Band aids metal detectable and covered. No eating or drinking (water excepted) in production areas. Hands washed upon entry to facility. Contractors and visitors compliant to the above.

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

Pests

-

No evidence of pest activity (webbing, droppings, feathers, pests).

Pest control in place, stations clearly identified.

Pest reporting in place and signed off by Rentokil -

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (pests)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

Premises

-

Exterior of building in good repair (fences, walls, road ways, floors, ceilings); Gates in working order; Nil rubbish along fence line;Rubbish containers closed;Disused items stored in secure manner

Internal walls, floors, ceiling, flyovers in good condition -

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (premises)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

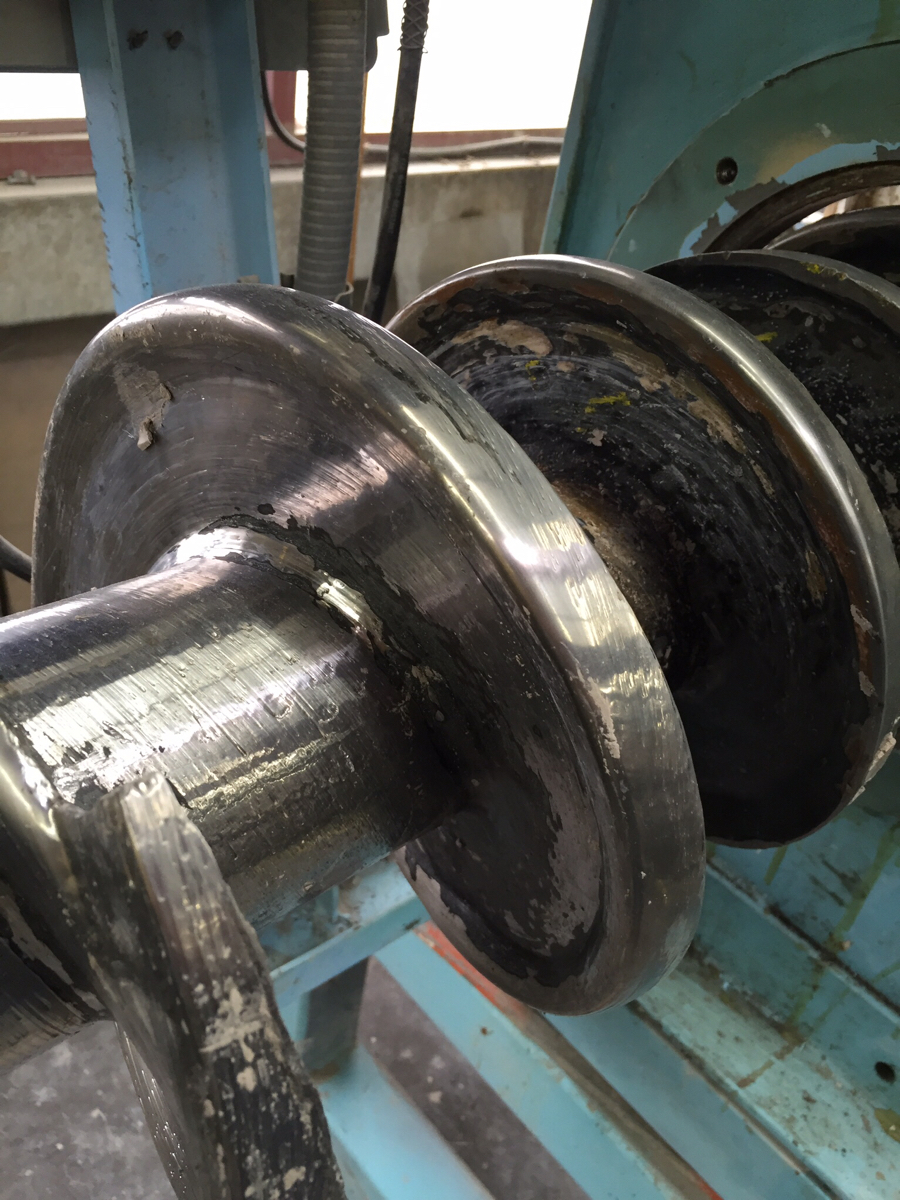

Plant

-

Production equipment in good repair.

Identified maintenance issues. Mobile plant in good condition -

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (plant)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

Process

-

Product protection in place. Traceability (raw materials and finished product) in place. Items stored in food safe manner. Nil cardboard present in factory. Loose item control. Nil foreign matter. WI; SO&Ps followed

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (process)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

Cleaning

-

Interior and exterior of premises in clean condition. Cleaning equipment in good condition. Cleaning equipment stored correctly. Cleaning schedules in place. Cleaning chemicals appropriately stored and labelled. Bins clean and emptied regularly.

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (cleaning)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

Allergen management

-

Allergens segregated.

Allergen cleans in place, no evidence of allergens after cleaning.

Designated cleaning equipment used for allergen cleaning.

Nil allergens spills present -

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (allergen management)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

Continuous Improvement

-

Gaps identified which require longer term improvement.

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (continuous improvement)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Non-Compliance Observed (people)

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Good Practice Observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

Brilliance

-

Brilliance noted during inspection (a brilliant job; a great idea)

-

Brilliance observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Brilliance observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Brilliance observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Brilliance observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Brilliance observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

-

Brilliance observed

- Bread Line

- Roll Line

- External

- Stores

- Distribution

- Maintenance

-

Add media

Summary and Close Out

-

Additional Comments

-

Next Scheduled Audit

-

Audit Completed by