Title Page

-

Job Name:

-

Job Number:

-

Installation Type:

- Traffic Signals

- Street lighting

- ITS/Comms

- LV / HV

-

ITP Lot Number

-

Site Location

-

Conducted on

-

Prepared by

Construction Proceedures & Materials

-

CB ENERGY ITP - CONDUIT & PIT INSTALLATION

-

Photo of construction drawing (title, page number, issue)

-

Risk assessment completed and construction drawings on site.

-

Conduit & Pit Installation type?

- Traffic Signals

- Street lighting

- ITS/Comms

- LV / HV

-

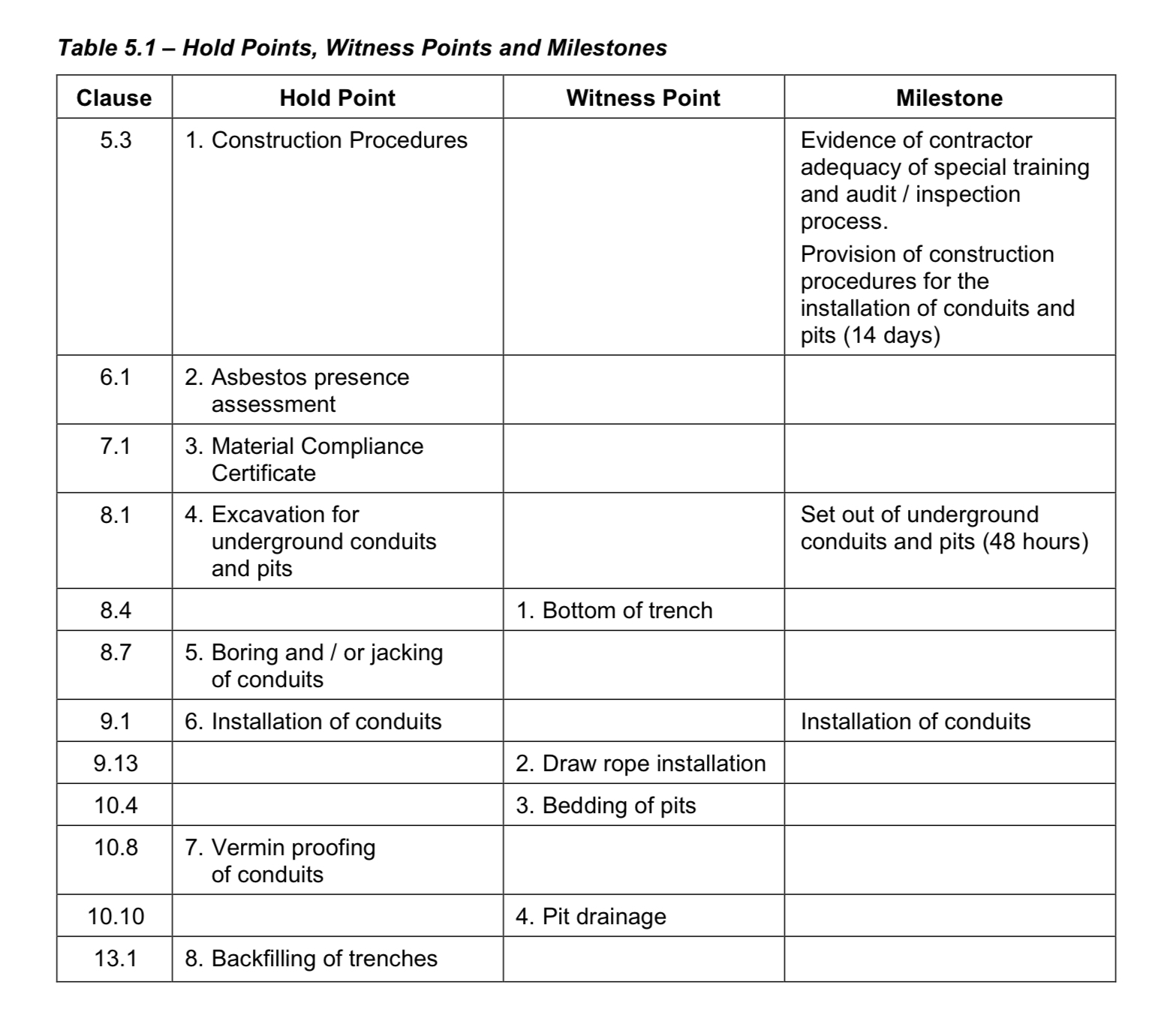

MILESTONE!<br>Has the construction procedure been submitted to the Administrator 14 days prior to commencement of installation?<br>(MRTS91, Table 5.1, Clause 5.3)<br>

-

HOLD POINT #1<br>Has the construction procedure reached its 14 day expiration period?<br>(MRTS91, Table 5.1, Clause 5.3)<br>

-

HOLD POINT #2<br>Has asbestos been found or suspected in existing installation?<br>If yes, work at this site must be stopped immediately, and the finding must be reported to the Principal immediately for their decision and instruction on the work to be carried out at the site.<br>Refer to MRTS96<br>(MRTS91, Table 5.1, Clause 6.1)<br>

-

HOLD POINT #3<br>Has a materials compliance certificate been provided and approved by the Administrator?<br>(MRTS91, Table 5.1, Clause 7.1)

Pre-construction

-

MILESTONE!<br>Notice of conduit and pit setout provided to Administrator at least 48 hours prior to commencement of construction <br>(MRTS91, Table 5.1, Clause 8.1)<br>

-

Has the conduit route and pit locations been pegged by the principle contractor?

-

HOLD POINT!<br>IF the conduit route or pit locations varies from the construction drawings, approval must be sought by the Administrator.

-

HOLD POINT #4<br>Has the Conduit & Pit setout reached its 48 hour expiration period? <br>(MRTS91, Table 5.1, Clause 8.1)<br>

-

Does the conduit alignment allow access to install footings in their surveyed and/ or appropriate locations, correct offset to carriageway and pits in correct location?

-

Does the conduit alignment ensure the pits will not be located in pedestrian areas where possible?

-

Does the conduit alignment ensure that the conduit entries to pits are square and neat?

-

Have finished levels been provided and confirmed by the surveyor?

-

Have all know services been located (electronically, visually) as required before excavation commences?

-

Has the site been assessed for drainage as per MRTS91 section 10.9? <br>Do any of the pits require drainage and has the principal been notified of potential drainage issues?

-

HOLD POINT - Photographs of set out (locations, pegs, survey marks).

Excavation for Underground Conduits & Pits

-

Has a permit to excavate been issued by the principle contractor?

-

Has the excavation been completed to MRTS91 section 8.1 requirements?

-

Does the trench width & depth comply with the issued construction drawings, Energex, BCC, Main Roads requirements?

-

WITNESS POINT #1 Has the bottom of trench been witnessed by the superintendent on site? (MRTS91, Table 5.1, Clause 8.4)

- YES - Superintendent to sign

- NO - Not on site to inspect

- No additional onsite inspection required

-

Witnessed by:

-

- Pre-approval given to backfill

- Verbal approval received to backfill

- Approval for backfill not require

- Photos of installation taken

-

Photos of bottom of trench taken

-

Has bedding sand been installed as per Main Roads/Energex/BCC Specifications?

-

Does the conduit and pit size & type comply with issued construction drawings and relevant Main Roads/Energex/BCC standards?

-

Are conduits stamped for AS2053 part 2 or part 6 for Main Roads/Energex as applicable?

-

Have all conduit joints been cleaned primed and glued?

-

Conduit writing to be faced up in trench?

-

Have any bends been used along the conduit run for change of direction?

-

Have you refered to MRTS91 (Conduit & Pits), section 9.7 (Bends)?

-

Have exposed ends been plugged to prevent ingress of dirt & moisture?

Conduit Installation Details

- Conduit details

-

Conduit Asset Owner?

- Energex/Rate 2

- TMR/Rate 3

- BCC

- NBN

- TPG

- Optus

-

Conduit run station numbers

-

Conduits in Roadway or Footpath/verge

-

Conduit Run Length? (metres)

-

Conduit Size?

- 100mm HD

- 80mm HD

- 50mm HD

- 40mm HD

- 125mm LD

- 100mm LD

- 80mm LD

- 100mm Coms HD

- 50mm Coms HD

-

Attach photos of the conduit installation. (E.G. Setout, Excavation, Bottom of trench, Conduits, Backfill/completion)

Pit Installation

-

Has the pit location been checked for suitability?<br>- Not in pram ramps or wings<br>- Outside footpath if possible<br>- Within 3mtrs of footing for TMR & Energex pits<br>- within 5mtrs of footing for BCC pits

-

Has the excavation been completed to MRTS91 section 8.1 requirements?

-

WITNESS POINT #3 Has the bottom of the pit been compacted to at least 95% relative compaction in accordance with the requirements of MRTS04? (MRTS91, Table 5.1, Clause 10.4)

- YES - Superintendent to sign

- NO - Not on site to inspect

- No additional onsite inspection required

-

Superintendent to sign

-

- Pre-approval given to backfill

- Verbal approval received to backfill

- Approval for backfill not require

- Photos of installation taken

-

Has the pit been installed on aggregate bedding to aid in drainage?

-

Have pit drains been installed where instructed or at the low point on a straight conduit run to MRTS91 section 10.9 and SD1314?

-

Pit Installation (ref TMR SD1415, SD1314)<br>• Is the pit aligned correctly?<br>• Does the lid match the surrounding Finished Surface Level, survey pegs, back of kerb or applicable finished level as provided or specified by the principal contractor?

-

WITNESS POINT #4 Have pits been provided with drainage holes in the bottom of the pit? (MRTS91, Table 5.1, Clause 10.10)

- YES - Superintendent to sign

- NO - Not on site to inspect

- No additional onsite inspection required

-

Conduits shall enter the pit no lower than 1200mm in depth as per MRTS91section 10.7

-

Have the incoming conduit holes been cut neatly using the correct size hole saw and sealed at entry points into the pit using black polyurethane (where required)?

-

Have all incoming conduits been trimmed back to 50mm into MTR pits<br> (MRTS 91 section 9.9, Standard Drawings 1415 and 1630) <br>or minimum 40mm for Energex pits (UDC C5 sect 3.2 ) and sealed?

-

Have all pit and pit lids supports been fitted correctly – where necessary? <br>Have all bolts attaching the collar been installed for a round pit once F.S.L has been determined?

-

Has the lid been replaced with a temporary lid or covered with plastic or Geofab to prevent damage to the non-slip coating

Pit Installation Details

- Add pit

-

Pit Category

- Traffic Signals

- Street lighting

- ITS/Comms

- LV / HV

-

Pit type?

- Electrical

- Comms

- T60

- P3

- P4

- P5

- P6

- P7

- P9

-

Pit station number/s?

-

Photos of pits installation

Backfill and completion

-

HOLD POINT #8 Back filling shall not commence until all the conformance and As Constructed Survey Requirements been met as specified in Clause 11 and 12 and notice of such works provided to the administrator (MRTS91, Table 5.1, Clause 13.1)

- Conduit/s installed picked up by surveyor

- No surveyor available, conduit risers installed

- Approval to backfill received

-

Have conduits been backfilled in accordance with the details shown on SD1149 with all precautions been taken to prevent any damage or movement to conduits during backfilling?

-

Has marker tape/hard cover to AS2648 Part 1 and individual authority requirements been installed as applicable?

-

Does the trench compaction for existing pavement, new pavement & footpaths comply?

-

For trenches in existing roadway has the lean mix concrete been installed & compacted as per MRD standard drawing 1149, Energex 6229-A4 [C2-3.3] or BSD2042?

-

HOLD POINT #6<br>After installation and backfilling, has the conduit and conduit fittings been proved by a mandrel at least 95% of the diameter of the conduit? <br>(MRTS91, Table 5.1, Clause 9.1)

-

WITNESS POINT #2<br>All joints made in the draw rope are capable of resisting the same tensile load as the draw rope without such a joint. The joint does not appreciably increase the diameter of the rope (MRTS91, Table 5.1, Clause 9.13)<br>

-

Superintendent to witness any joins in the rope.

-

MILESTONE<br>Have all repairs and the conduit been re-tested should the mandrel have not pass unhindered through the conduit?<br> (MRTS91, Table 8.1, Clause 9.1)<br>

-

HOLD POINT #7<br>Unless approved, vermin proofing system is carried out as per clause 10.8? <br>(MRTS91, Table 5.1, Clause 10.8)<br>

-

Completion <br>• The pit lids are to be stamped as per MRTS91, Energex or BCC BSD 4032, 4033, 4035 requirements depending on pit type. <br>• All bolts attaching the collar must be installed for a round pit once F.S.L has been determined.

-

Is there any issues ?

MRTS-91 References