Information

-

Audit Title

-

Document No.

-

Conducted on

-

Prepared by

-

Personnel

-

Have all corrective actions been completed from previous audit

-

1. Are IBC's cleaned and sanitised before entering the product transition area ?<br>

-

IBC'S to be scraped clean around slide and blown down with air line(SOP#1) (form 35)

-

2. Is there appropriate PPE for the operators ?<br>

-

3. Are operators wearing PPE provided ?

-

4. Is their a sanitised fork lift that remains in the cleanroom production area ?

-

Form 2a/FSM/cleaning records/cleanroom

-

5. Are the products in this area stored correctly ?

-

6. Are the products adequately labelled and are stocks rotated (FIFO) ?<br>

-

All pallets to have lot # and Mars barcode/Lowest lot # used first

-

7. Is there a process flow for this area and does it accurately reflect the procedure ?<br>

-

Paradigm/documentation/HACCP/current plans.

-

8. Have operators been trained for this area ?

-

Paradigm/training/completed training

-

9. Are training records current and up to date ?

-

10. Are all critical control points correct ?

-

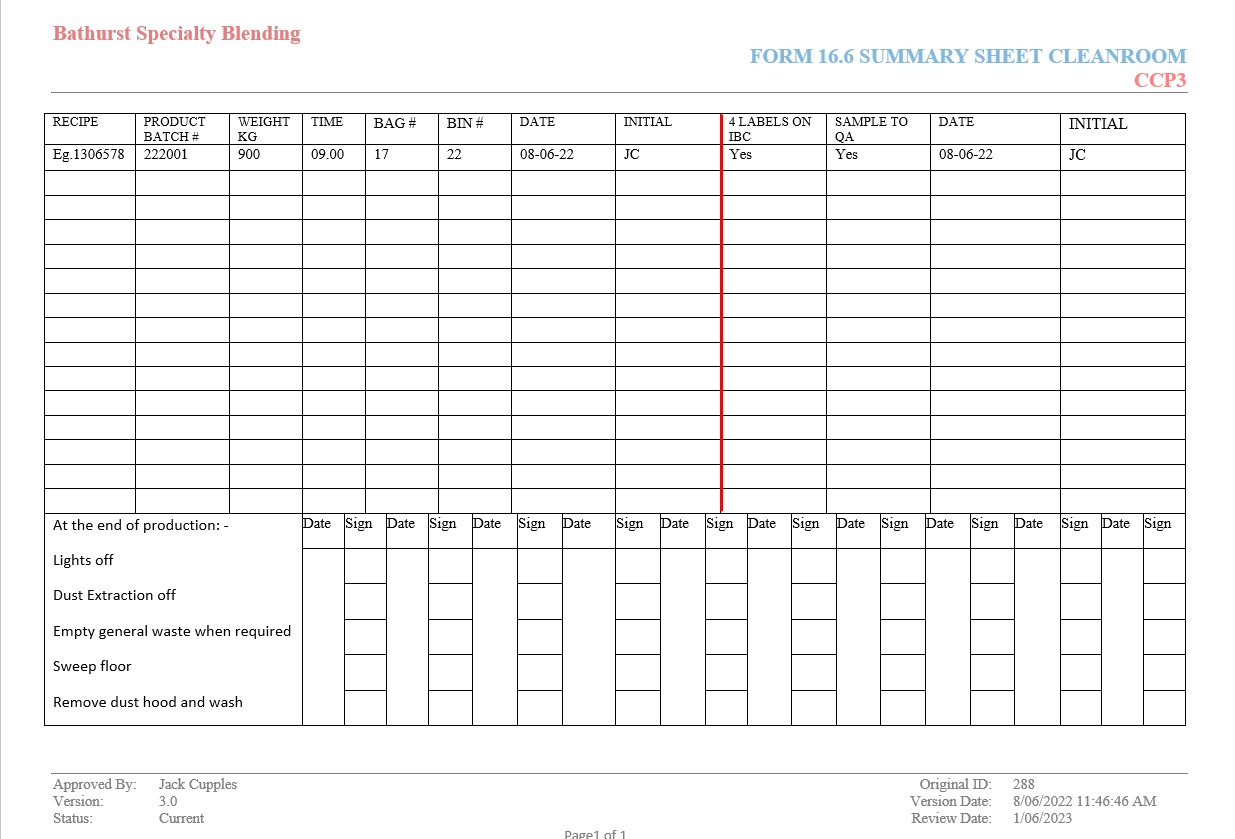

CCP3 form 16.6

-

11. When asked was the operator aware of the aseptic sampling process ?

-

SOP#107 aseptic sampling

-

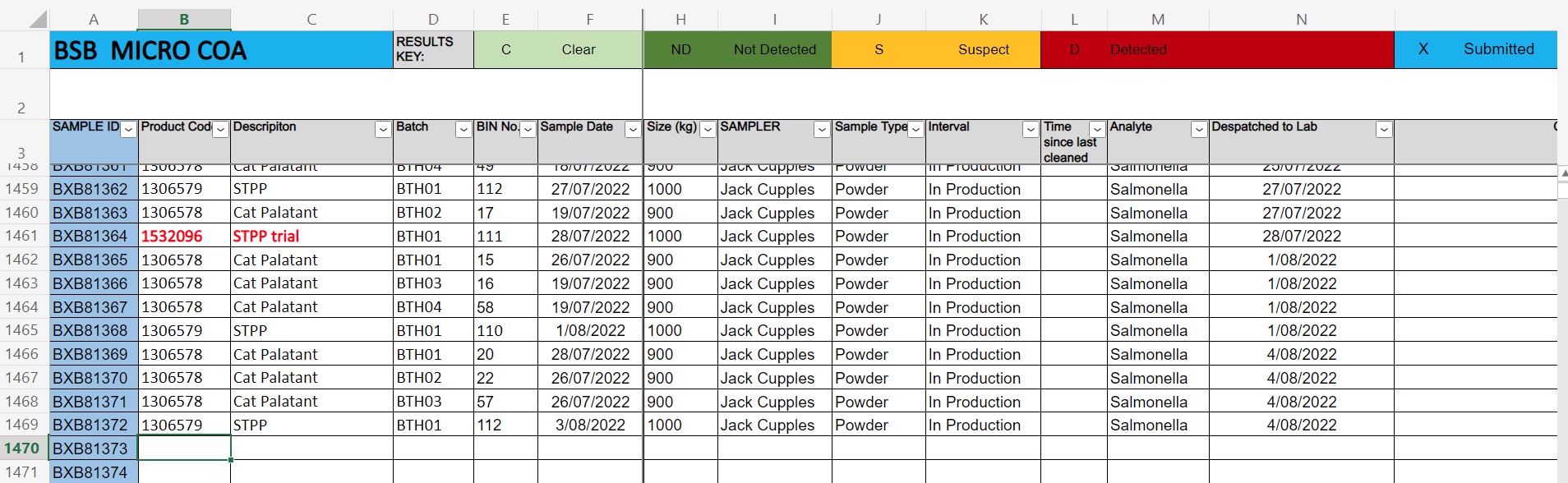

All samples are logged in the MARS TEAMS spread sheet before delivery

-

12. Are completed IBC'S labelled correctly ?<br>

-

13. Is all documentation complete and up to date ?

-

14. Is there a cleaning schedule in place and is it being followed ?<br>

-

form 16.6/front office

-

Form 2A eight weekly clean/FSM/cleaning records/cleanroom

-

15. Is the facility well maintained ?

-

16. Has the standard operating procedure been reviewed ?

-

SOP#1 review date on document

-

Corrective actions/notes

-

Corrective actions to be completed by:

-

General Manager