Title Page

-

Document No.

-

Audit Title - V1.

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Production Activities

-

If operating more than one shift, was the daily handover from the previous supervisor detailed and was the work area clean?<br>(Photos to be taken in support of statement. The handover is to cover WHSE, Operations and BAU details.

-

Have you reviewed the next day's waves, and or inbound register to determine staff level requirements?<br>(Staff levels vs output requirements should be measured. The measured process of outputs against a time parameter is referred to as TAKT time)

-

Has overtime been reviewed for accuracy and was it authorised?

-

Has the daily 'toolbox' been conducted?

-

Summarise the main points addressed.

-

Have you received an acceptable number of 5S checks today (Shine Plans) and are the safety 'flex' boards up to date?<br>

-

Summarise the main action points requiring follow up.

-

Have all staff time sheets been revised, staffs validated against the roster, and data entered into TMS?<br>(Detail any staff anomalies - eg. Unauthorised absence - to be completed and entered into TMS by 08:30am daily)

-

Do you have excess staff today? Can these excesses be used in other site BAU units?

-

Has the MHE requirements been matched to staff numbers?

-

Have the previous day's waves been finalised and completed?<br>(Has the corrective actions processes been initiated to rectify the outstanding items)

-

Have the goods returned been allocated to the correct inbound procedure and correctly located?<br>(Items will be pending a Werner response)

-

Have put away stocks been processed and correctly located?<br>(A visual and systems check should be carried out on each shift with attention placed on those items that have been carried over from previous shifts)

-

Do all outstanding operational and production issues have a 'history ' attached, of the corrective actions process employed in view of process finalisation?<br>(Provide a short description of the process engaged and expectant completion dates)

-

Has the MHE required for shift been checked for serviceability and charge levels?<br>(Supervisor to confirm prior to shift departure that the team has physically checked the MHE and scanners for functionality prior to shift changeover)

-

Have the RF Scanners been accounted for and can you confirm that the users have signed the register as the user?<br>(Are all RF scanners serviceable? Has a 'ticket been raised with IT for broken or faulty RF equipment)

Training

-

Has RF training been conducted within the last month?

-

Select date

-

If yes, take a photo of the training record and attach here

-

When was the last training date in the use of RF functions?

EOS (End of Shift) Process Requirements

-

Have all orders (Open Orders Report) that can be finalised, been processed?<br>(Physical inspection required by supervisor at EOS)

-

Have all pallet movements been recorded and accounted for?<br>(A visual inspection documentation is required by supervisor)

-

Have all transport documents been prepared, drafted , and or finalised?<br>(A visual inspection is required by the supervisor as confirmation)

-

Have all paradigm entry requirements been emailed to the designated WHSE site representative?

-

Summarise any events requiring paradigm entries that occurred during your shift.

-

Have you reviewed the outstanding paradigm entries log to determine if any outstanding items are able to be closed out?

-

Has the assigned work areas and functional spaces been inspected for cleanliness and potential obstructions and has the 5S process been applied to gauge compliance?<br>(Physical inspection required with correction actions identified and finalised before shift dismount)<br>(Bins and or items used as refuse receptacles are to be emptied daily and checked; empty pallets are to be consolidated and placed on the Werner/HP stacks)<br>

-

Has all MHE been put away in the correct location and placed on change?<br>(Visual inspection required for compliance)

-

Was any DBS equipment damaged during your shift? For MHE damages, if the damages were from labour hire, this is recoverable. Ensure this is detailed in the incident report)

-

Enter details of damages

-

Take photos of damages

-

Was any customer stock damaged during your shift?

-

Enter details of damages

-

Has the client been made aware of damages?

-

Insert photos of damages here

-

Was any pallet racking damaged during your shift?<br>( A visual inspection is required. Are the beams still within deflection tolerance? )

-

Has the racking been marked with an 'X' on the damaged beam with red spray ink to identify those beams that will require replacement due to defection specification failures?)

-

We're there any significant events during the shift that were considered noteworthy?<br>(This could be good or bad and morale affected or impacting)

-

What were the event details?

-

Have you prepared a detailed handover brief for the oncoming supervisor?<br>(Summary should include WHSE events, operations and production briefs, BAU planning)

-

Summarise the main points

Continuous Improvement

-

Did any 'POP' suggestions present themselves during the shift?<br>(Are they worthy of escalation - supportive photos and details required)

-

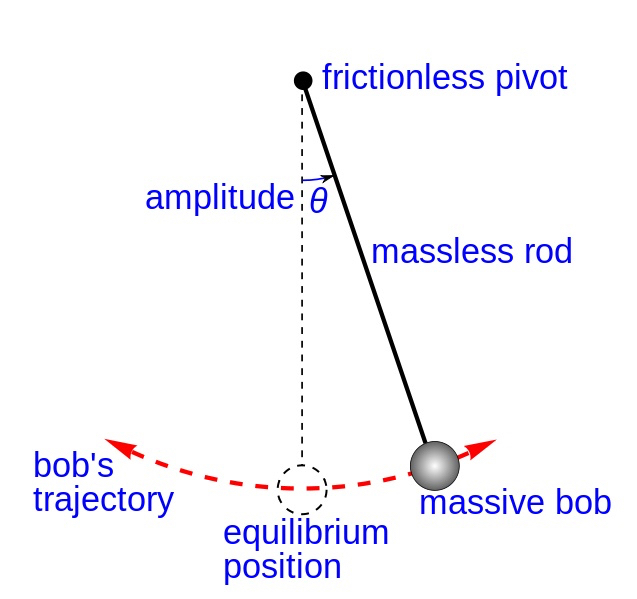

Graphic representation of suggestion if it can be drawn

-

Photo of improvement item if available

-

Supportive statement of POP suggestion with specific detail required.

-

Has anyone suggested a "better way" proposal for BAU processes? <br>( Supervisor to engage staffs on a regular basis as part of the shared learnings process)

-

Details of the 'Better Way' suggestion.

Safety additional items

-

Are emergency exits unobstructed, clearly marked and visible?

-

Are pallet stacked items positioned securely in racks and stretch wrapped?

-

Are bulk stack items secure and stacked IAW supplier recommendations?

-

You are required to print and sign this report for ownership of this process