Fire Suppression Systems–Level 1 Service

-

VDAS Loss Of Pressure (LOP) Fire Suppression System Doc No: QWI11.02

-

Maintenance Service Record in accordance with AS5062-2022

Customer Details:

-

Customer:

-

Location

-

Date:

-

Machine ID No:

-

Machine Type

-

Machine Model

-

Purchase Order No:

-

Work Order No:

6-Monthly Service Sheet

Fire System Information

-

Cylinder Size

- 12L

- 23L

- 25L

- 35L

- 45L

- 65L

- 88L

- 106L

-

Portable Water QTY 18.4 Lt. / F3 Foam Qty .6 Lt.

-

Portable Water QTY 25 Lt. / F3 Foam Qty 1 Lt.

-

Portable Water QTY 32.9 Lt. / F3 Foam Qty 1.1 Lt.

-

Portable Water QTY 48.5 Lt. / F3 Foam Qty 1.5 Lt.

-

Portable Water QTY 64 Lt. / F3 Foam Qty 2 Lt.

-

Portable Water QTY 77.5 Lt. / F3 Foam Qty 2.5 Lt.

-

Verify and record the cylinder(s) manufacture date. If this exceeds five years old then the cylinder will require an inspection and hydrostatic test in accordance with AS2030.5 and AS2337.1.

-

Confirm and ensure all cylinder(s) bracket bolts are tight and bracket(s) are in a serviceable condition.

-

Check all fire suppression labels are installed and legible

-

Number of 12L Cylinders?

-

Verify and record the cylinder(s) manufacture date. If this exceeds five years old then the cylinder will require an inspection and hydrostatic test in accordance with AS2030.5 and AS2337.1.

-

Nozzle Quality

-

Check nozzles for correct alignment and ensure each nozzle is pointing at per- determined aiming points free of obstructions.

-

Alarm Panel

Service Information

-

Is the Equipment Serviceable?

- Compliant

- Non-Compliant

- N/A

-

Can the Issue be rectified?

-

Parts used to Rectify issue

-

Check safety pins & anti-tamper ties are fitted on the remote actuators & ensure remote actuators are free of<br>damage.

-

Check all fire suppression labels are installed and legible (Remote actuators,<br>system warning etc).

-

Identify and record the type of foam installed in service as per the cylinder label (F3 Foam, C6 type foam). Foam Type?

-

Check that the alarm panel is functional (if fitted.)

-

Flush water (or blow compressed air/nitrogen, using extreme care) through the ring main to make sure there are no obstructions in the circuit and the dust caps blow off freely.

-

Lubricate nozzle O-rings with Molykote 111 O-ring grease and re-fit dust caps onto the<br>nozzles.

-

Inspect all hose and tube work for signs of damage (mechanical or abrasive) and ensure all hoses/hose ends and tube are tight, secured and in place.

-

Replace any worn or damaged parts.

-

Parts Replaced

-

Ensure system is at correct operating pressure. Record Cylinder(s) and Remote actuator(s) pressure<br>reading

After Maintenance Activities

-

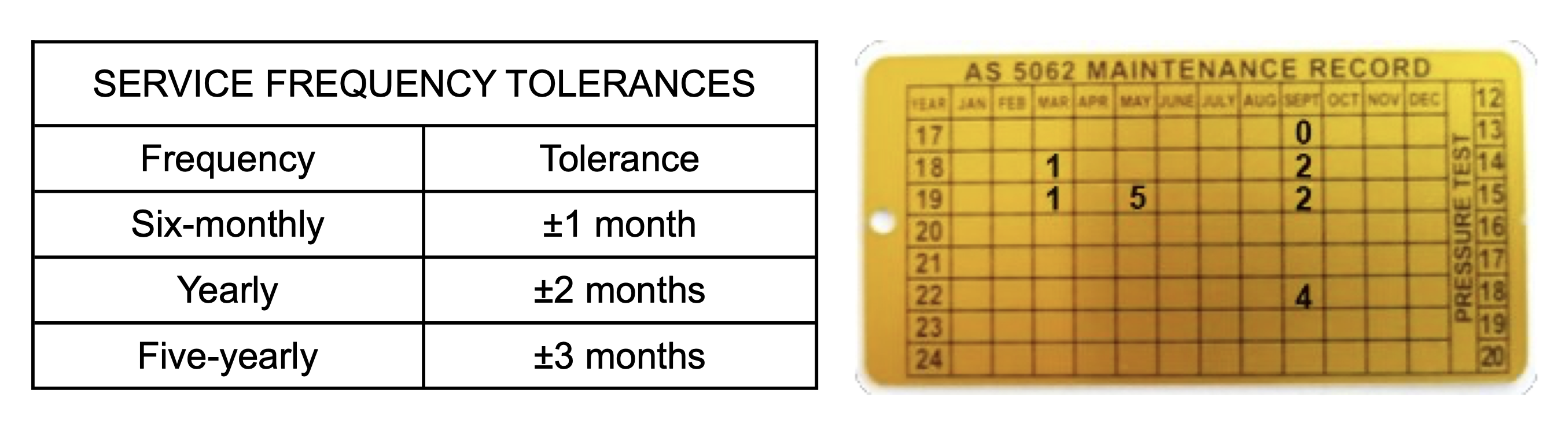

Install As 5062 service tag if missing. Stamp service tag #1 at the current month and year.

-

On completion of the service the LOCKOUT officer / staff member, needs to do a finalwalk around and check off all connections, hoses and service points for a final check before the reinstating of the system serviceability.

-

Update service records on the Pirtek Fire Suppression database.

Further Repairs Required:

-

Comment:

Labour Time:

-

Labour

Sign Off

-

I Hear by certify that the above system has been in accordance with AS5062-2022 and the information on this service record is true and correct

From PIRTEK

-

Pirtek Centre Name:

-

Technician Name:

- Ashley Lawson

- Chris Paton

- Peter Eversham

- Tim Eversham

- Nick Stallard

- Coedy Kleinig

-

Cert No: L1083

-

Email: Ashley@pirtekeme.com.au

-

Position: Service Technician

-

Cert No: L1084

-

Email: Chris@pirtekeme.com.au

-

Position: Service Technician

-

Cert No: E-086

-

Email: Peversham@pirtek.com.au

-

Position: Service Technician

-

Cert No: E-0146

-

Email: Teversham@pirtek.com.au

-

Position: Service Technician

-

Cert No: L-0963

-

Email: Nick@pirtekeme.com.au

-

Position: Service Technician

-

Cert No: L0958

-

Email: Coedy@pirtekeme.com.au

-

Position: Service Technician

-

Signature:

From Customer/End User

-

Name

-

Signature: