Fire Suppression Systems–Qtec Level 4 Service

-

VDAS Loss Of Pressure (LOP) Fire Suppression System Doc No: QWI11.14

-

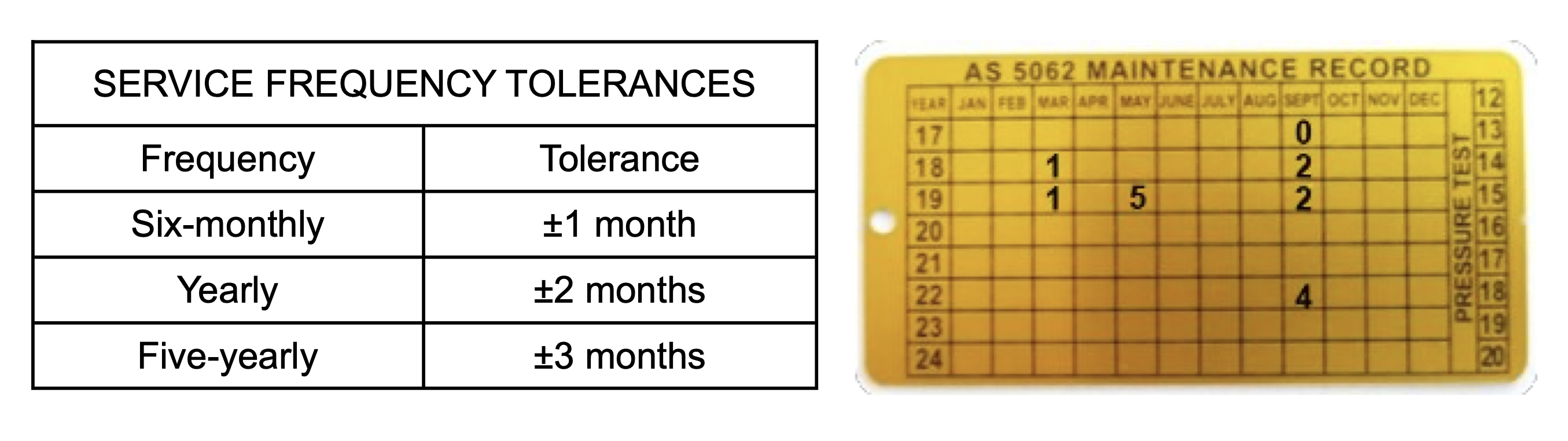

Maintenance Service Record in accordance with AS5062-2022

Customer Details:

-

Customer

-

Location:

-

Date:

-

Machine ID No:

-

Machine Type

-

Machine Model

-

Purchase Order No:

-

Work Order No:

Fire System Information

-

-

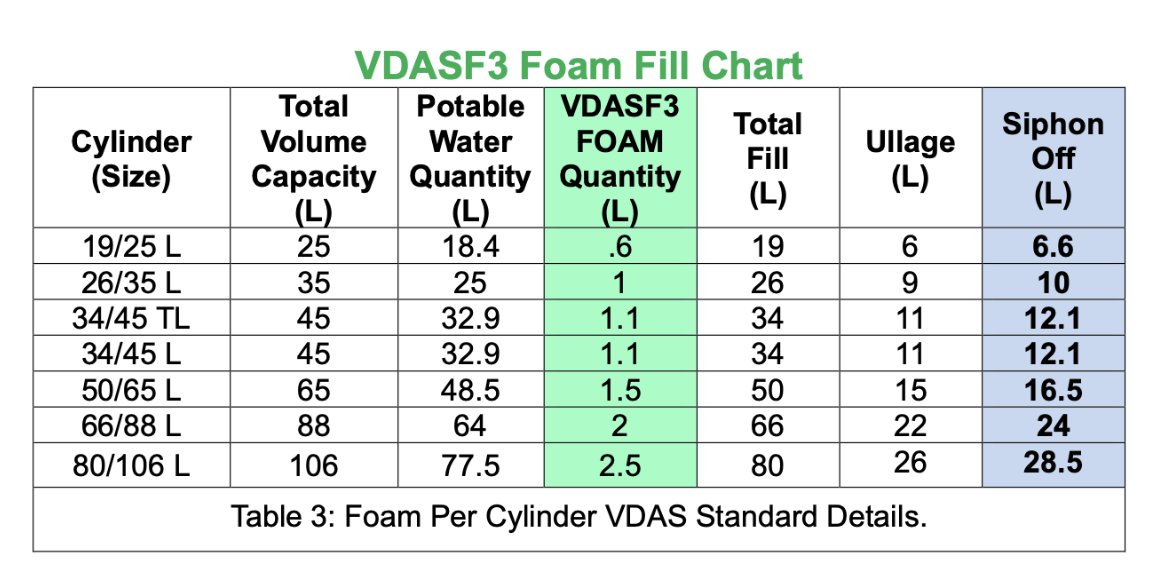

Cylinder Size

- 25L

- 35L

- 45L

- 65L

- 88L

- 106L

-

Portable Water QTY 18.4 Lt. / F3 Foam Qty .6 Lt.

-

Portable Water QTY 25 Lt. / F3 Foam Qty 1 Lt.

-

Portable Water QTY 32.9 Lt. / F3 Foam Qty 1.1 Lt.

-

Portable Water QTY 48.5 Lt. / F3 Foam Qty 1.5 Lt.

-

Portable Water QTY 64 Lt. / F3 Foam Qty 2 Lt.

-

Portable Water QTY 77.5 Lt. / F3 Foam Qty 2.5 Lt.

-

Verify and record the cylinder(s) manufacture date. If this exceeds five years old then the cylinder will require an inspection and hydrostatic test in accordance with AS2030.5 and AS2337.1.

-

Confirm and ensure all cylinder(s) bracket bolts are tight and bracket(s) are in a serviceable condition.

-

Nozzle Quality

-

Alarm Panel

LOP 5 Yearly Service Sheet

-

Is the Equipment Serviceable?

- Compliant

- Non-Compliant

- N/A

-

Can the system be repaired

-

Parts used to repair

Discharge Test

-

Perform a discharge test by activating the system via a remote actuation point. Please follow local/state government<br>and site specific requirements and procedures - Refer to the foam change out procedure if required.

-

Record discharge time and observe nozzle area coverage (seconds)

-

Ensure that all dust caps blow off all nozzles.

-

Engine shutdown delay test completed, Record shutdown delay (seconds)

-

Inspect the spray pattern to ensure it has appropriate coverage in the hazard areas identified (based on nozzle<br>placement and general risk area locations - Video recording is recommended to identify and verify nozzle spray pattern<br>and discharge time).

-

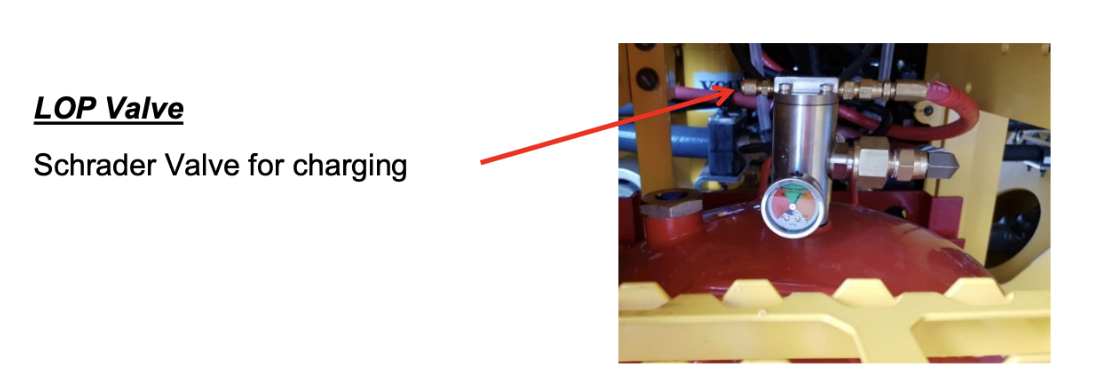

After discharge test has been performed ensure that the system is fully degassed. Degas the circuit by depressing the core of Schradder Valve.

-

Flush fresh water through the nozzles to remove all traces of foam agent. Once the the<br>discharge lines are free of foam agent use extreme care to ensure the lines are free of moisture using air/nitrogen. Clean the machine free of foam.

Storage containers

-

Remove discharge hose from cylinder valve. Remove actuation hose from top of cylinder valve.Remove filler port assembly Remove foam solution from the cylinder. Visually inspect exterior of all installed cylinders. Where a cylinder is dented, scored, pitted or otherwise damaged by corrosion and it cannot be determined if the damage is within the limits as detailed in AS 2337.1, then the cylinder shall be condemned. Visually inspect interior of all installed cylinders. Where a cylinder is damaged by corrosion and it cannot be determined if the damage is within the limits as detailed in AS 2337.1, then the cylinder shall be condemned.

System Service

-

Inspect detection tube and replace as required or at the 24 month period, whichever comes first.

-

Remove, service and reinstall the main cylinder valve(s) as per the LOP Service and Maintenance Manual.

-

Inspect siphon tube(s). Replace if collapsed, bulges, kinked, incorrect length, has holes, or is loose on the hose barb.

-

Seat piston manually prior to reinstalling LOP valve, to make sure it is seated fully.

-

Remove, service and reinstall remote actuator/s as per the LOP Service and Maintenance Manual.

-

Lubricate silicon nozzle dust caps (replace if damaged) or nozzle O-rings (for brass caps) with Molykote 111 O-ring grease and re-fit dust caps onto the nozzles.

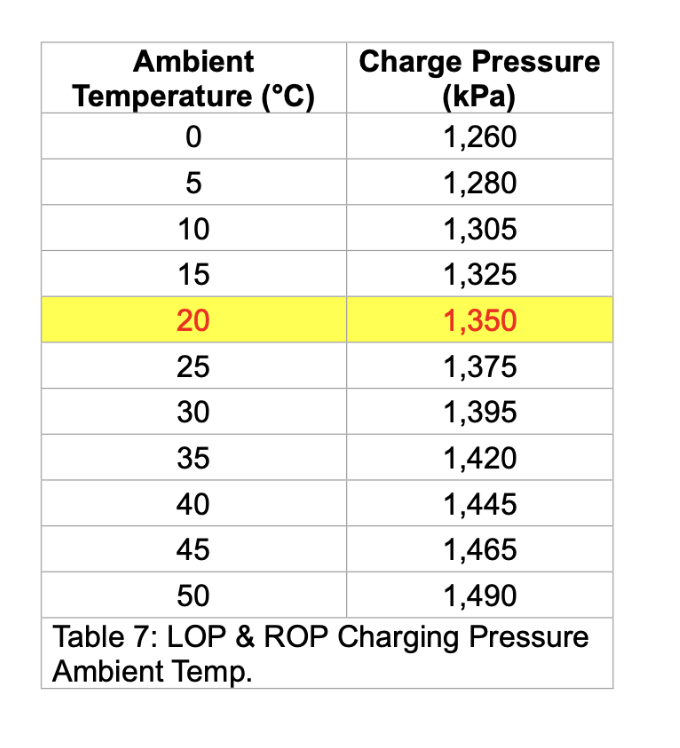

System Pressurising

-

-

Fill and charge the system to manufacturers specifications. If previously installed with a non-Fluorine free agent remove old label and replace with correct fluorine free label as per cylinder size and manufacturer of agent.

-

Carry out a leak test using the pressure gauges as a visual and utilise a leak detector spray on all possible leak points in the system.

-

Recorded pressure on all remote actuator(s) and cylinder(s):

-

Check that the relief valve fitted to the cylinder fill plug moves freely.

After Maintenance Activities

-

-

Install AS 5062 service tag if missing. Stamp service tag #2 (Yearly) at the current date

-

On completion of the service the LOCKOUT officer / staff member needs to conduct a final walk around to check all connections, hoses and service points for a final inspection before reinstating of the system serviceability.

-

Fit anti-tamper ties to remote actuator/s.

-

Update service record on the Fire Suppression Database.

Labour time:

-

Labour

Further repairs required:

-

Comment:

Sign Off

-

I Hear by certify that the above system has been in accordance with AS5062-2022 and the information on this service record is true and correct

From PIRTEK

-

Pirtek Centre Name:

-

Technician Name:

- Ashley Lawson

- Chris Paton

- Peter Eversham

- Tim Eversham

- Nick Stallard

- Coedy Kleinig

-

Cert Number: QTEC L1083

-

Email: Ashley@pirtekeme.com.au

-

Position: Service Technician

-

Cert No: L1084

-

Email: Chris@pirtekeme.com.au

-

Position: Service Technician

-

Cert No: E-086

-

Email: Peversham@pirtek.com.au

-

Position: Service Technician

-

Cert No: E-0146

-

Email: Teversham@pirtek.com.au

-

Position: Service Technician

-

Cert No: L0963

-

Email: Nick@pirtekeme.com.au

-

Position: Service Technician

-

Cert No: L0958

-

Email: Coedy@pirtekeme.com.au

-

Position: Service Technician

-

Signature:

From Customer/End User

-

Name

-

Signature: