Title Page

-

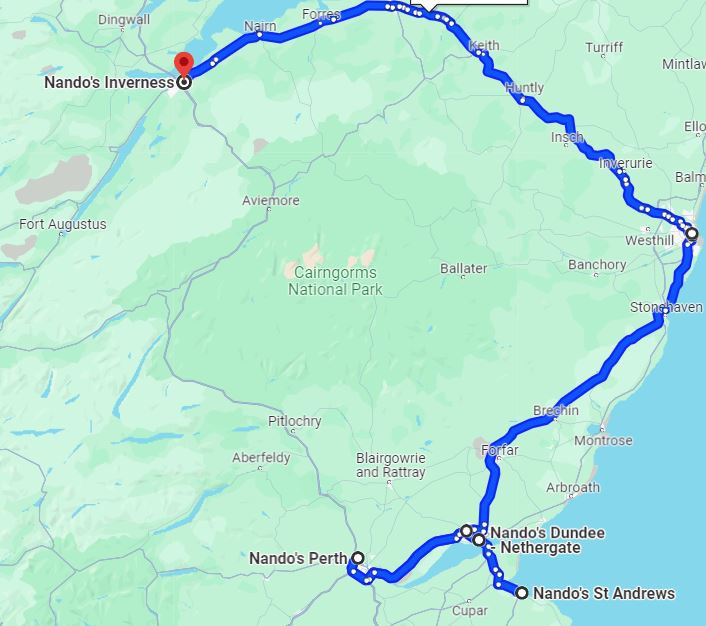

Site conducted

-

Conducted on

-

Prepared by

-

Location

Inspection Report

Compliance to Laws and Regulations

-

The registration of de-salination system is valid and up-to-date.

Personnel

-

Personnel with infections restricted

-

Outer garments suitable; clothing clean

-

Hands washed and clean; good hygiene practiced

-

Supervisory personnel competent, qualified

-

Handwashing facilities are adequate and up-to the standard requirement (With warm water/ handwashing soap/ hand sanitizer/ paper towel)

-

All the protective clothing required are supplied before entering to the plant

-

Visitor policy is implemented

Grounds

-

Premises free of litter and debris; potential pest harborage removed; grounds, roads, yards, parking lots free of dust, uncut weeds, grasses and unused equipment

-

Waste and disposal systems properly operated and maintained

Building and Facilities

-

Adequate washing, filtering, filling and storage rooms provided, used properly, contain only approved equipment, properly spaced

-

Floors of suitable construction, clean, good repair, properly sloped where required

-

Walls of suitable construction, clean and in good repair

-

Ceilings of suitable construction, clean and in good repair

-

Lighting adequate; adequate protection from glass breakage

-

Rooms and equipment vented as required; ventilation equipment properly located and filtered.

-

Outer openings into filling rooms protected against entry of dust and insects; RO and filling room doors open outwards.

Water Supply

-

Water supply must come from an approved source.

-

Water quality is inspected daily

-

Water purification systems approved and properly operated; water supply and temperature adequate; water piping approved and properly protected

-

Bulk water source approved, bulk water transported and handled in an approved manner

Disposal of Wastes

-

Liquid wastes disposed of in an approved manner

-

Solid waste properly handled, stored, and disposed

-

Broken glass policy is implemented

Plumbing

-

Plumbing properly maintained, meets code requirements

-

Floor drainage adequate

-

No cross connections, backflow

Toilet Facilities

-

Sewage must be disposed of in a sanitary manner.

-

Toilet facilities adequate, meet code requirements, properly designed and installed; ventilation adequate

-

Toilets equipped with self-closing doors; fixtures in good repair; clean; tissue, soap sanitary towels/hand-drying devices, waste receptacles, hand- washing sign provided.

Dressing Rooms and Locker Areas

-

Dressing rooms or areas provided when clothes changed at the plant, clean, good repair

-

Adequate lockers or suitable facilities provided and properly located for clothing and other personal belongings

Sanitary Operation

-

No substantial presence of rodents or insects may be allowed anywhere on the premises.

-

Building, fixtures and other facilities in good repair, sanitarily maintained, cleaning properly conducted; detergents, sanitizers, chemicals safe, effective, properly identified, used and stored

-

Insecticides and rodenticides properly labelled, used and stored

Equipment and Utensils

-

Equipment and utensils of easily cleanable construction, properly designed, kept clean and in good repair

-

Equipment properly installed and maintained

-

Storage tanks provided with tight – fitting covers; covers kept closed

-

Line covers provided, clean and in good repair

-

Bottle washing machine is operated by trained personnel

-

Records are implemented for temperature monitoring of the bottle washer

Process Controls

-

Bottled water properly protected during all steps of processing

-

Adequate supervision provided; all reasonable precautions taken to prevent product contamination

-

Chemical, microbiological and extraneous material testing adequate;

-

Raw materials properly handled, stored and labelled

-

Only product lines are used for manufacturing bottled water

Cleaning and Sanitizing

-

Food-contact surfaces clean

-

Non- food contact surfaces clean

-

Cleaning and sanitizing agents safe, adequate, properly labelled and stored

-

Cleaning and sanitizing equipment properly handled and stored above the floor

-

Food-contact surfaces properly sanitized

-

Container washers properly operated, equipped and maintained

-

Returnable containers properly washed, rinsed and sanitized by an approved method

-

Returnable container washer records properly maintained

Inspection of Returnable Containers

-

Returnable containers properly stored and inspected prior to filling

-

Defective returnable bottles destroyed; destruction of bottles conducted in an approved manner

-

Electronic inspectors operating properly

-

Inspectors periodically rotated to non-inspection work

-

Returnable bottles of proper design for easy inspection

Container Closures

-

Container closures safe, manufactured from food-grade materials, washed properly before using

-

Container closures properly packaged and stored prior to use

-

Contaminated container closures discarded

Filling and Sealing

-

Filling and sealing operations conducted in a sanitary manner

-

Containers adequately filled and sealed with approved mechanical equipment

-

Glass filling equipment provided with adequate shields

-

Satisfactory procedures followed for removing broken glass from filling equipment

-

Contents of imperfectly sealed containers discarded

Ingredients and Labelling

-

All ingredients from approved sources

-

All bottled water labelling in conformance with standard labelling requirements

Storage of the Ready-To-Use Bottles

-

Filled water bottles are stored above 8 inches from the floor

-

Used bottles are properly segregated and labelled to avoid cross contamination

-

RTS Water bottles are properly stored and handled in the house keeping pantries (Stored above 6 inches from the floor)

-

Water bottles are stored away from non-food grade chemicals