Information

-

Audit Title

-

Conducted on

-

Prepared by

-

Location

-

Personnel

FLOOR

-

Are gangways clear of obstruction?

-

All items are removed from the floor (Everything on wheels or machines)?

-

Are the equipment/materials stored in the correct locations?

-

Are work areas clean and free of rubbish and dry? (no spillages)

-

Is the Fire Exits easy accessible?

-

Are pallets/ pallet trucks stored correctly?

EQUIPMENT/MACHINERY

-

Are guards in good condition and working or closed?

-

Are the cables, ancillary equipment & Hoovers stored correctly? Not posing any threat (Trips etc.)

-

Is machinery/equipment free from debris & obstructions?

-

Are machines free from damage?

-

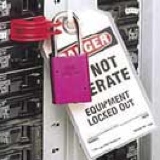

Is the fire equipment not obstructed & readily available?

-

Are ladders- serviceable/stored correctly?

-

Are tools & fixtures stored correctly/safely?

-

Ovens are clean inside (no debris or old tags on turntable or around)

SAFETY/GENERAL

-

Are scissors, knives and tools, stored correctly?

-

Are hazardous materials stored correctly?

-

Are contamination measures being adhered to?

-

Are lights clean & working?

-

Are all related documents filled properly (Pre start-up checks, Training)

-

Areas free from any broken glass or any broken hard plastics?

-

Safety Signage in place and in good condition

-

Areas are free from other observed issues?

BEHAVIOURAL

-

Is PPE being worn by workers?

-

Employee demonstrates general awareness of job hazards?

-

The employee is demonstrating safe work procedures (SSoW)?

-

Employee worksite is not causing environmental issues to building occupants?

-

The employee using available resources (tools, machines) as indented?

-

Employee is demonstrating proper ergonomic movements during activities? (Lifting, bending, twisting etc.)

-

The employee does not pose a threat with their behavior when using machines?

Summary

-

Have any close calls been raised from the audit

-

Have any improvement been identified

-

Auditor

-

Auditee