Title Page

STARTERS

The Basics

-

Employee

- Alan

- Steven

- CK

- Bruce

- Monty

- Marcus

- Janai

- Hadyn

-

Date

-

Time Started

FIRST THINGS FIRST.

CO₂ SYSTEM (service light mounted on inside wall above access panel)

WORKING PRESSURE

-

WORKING PRESSURE INFO (check this box to open)

-

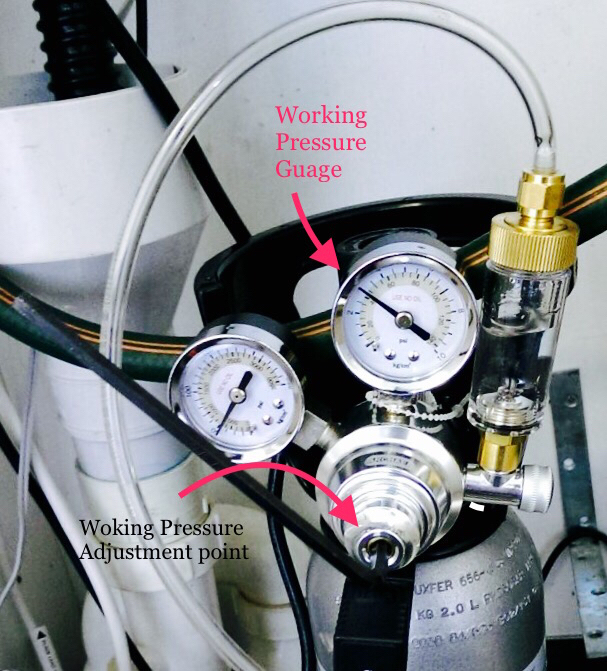

WORKING PRESSURE

This is the right hand gauge on the regulator assembly.

This helps stability in bubble rate and its flow through diffuser stone

Ideal around 4 Kg/cm²

Adjustment with Alan Key (on floor of cupboard) in centre of regulator.

NB: when turning on the CO2 Working pressure will initially drop, bubble rate will be quite rapid at first and then slow after about 10-20 seconds. This is because the hose line pressure will need to again build up after being emptied over night. The INLINE DIFFUSER will need about 2kg of pressure to start working. After about a minute or so of gas flowing through the bubble counter, you should see effervescence in the diffuser chamber. -

WORKING PRESSURE LEVELS OK? <br>(Ideal around 4kg/cm² on right hand gauge)

-

Gas bottle getting low?

-

If the WORKING PRESSURE is not high enough then opening up the the fine adjustment valve may not work to increase the bubble rate: use Alan Key to turn adjustment bolt clockwise.

-

If bottle is getting low and increasing working pressure was not possible then it's likely the bottle is actually too low and should be changed

-

Full 10 or 6 kg bottle in store below. Install and test WORKING PRESSURE. Adjust if necessary. Notify Bruce for refilling of main bottle needed.

-

If the WORKING PRESSURE is TOO HIGH use Alan Key to turn adjustment bolt anti-clockwise to reduce the working pressure to back within the desired range

BUBBLE RATE and INLINE DIFFUSER & REACTOR

-

NB wait 20 secs before assessment. For first 20 secs the bubble rate may be very fast. Then it will stop and resume at approximately 2 bubbles per second)<br><br>To manual override unplug solenoid power and plug into neighbouring power point.<br><br>How is BUBBLE RATE?

-

Bottle empty or getting low?

-

This most likely the reason and you have probably already noted a low working pressure. Full 10 or 6 kg bottle in store below. Install and check WP and bubble rate. Notify Bruce for refilling of main bottle needed. NB If this is unexpected (empty too fast) then contact Bruce now as we may have to check for leaks

-

If too slow then is it improved by a slight opening (anti-clockwise) of the FINE ADJUSTMENT on the regulator itself?

-

Still too slow? <br><br>May need to reduce flow through INLINE REGULATOR. <br>Note, this is counter intuitive setup: to INCREASE you turn the inner Phillips Head screw CLOCKWISE! <br>Also, move it only by the tiniest increments and test after each time.<br>Contact Bruce if you are also considering this.<br><br>Is it improved by a slight opening (use SCREWDRIVER to turn CLOCKWISE) of the INLINE REGULATOR?

-

Contact Bruce to discuss further.

-

Most likely the DIFFUSER STONE in the INLINE is blocked and needs cleaning. Check for any bubbles in diffuser chamber (left outlet rapped in aluminium foil- you'll need to shine your torch from behind) NB: this needs a min of 30mins. If you have no time then CONTACT BRUCE for alternative instructions.

-

Servicing the DIFFUSER STONE?

-

SERVICE THE DIFFUSER STONE: 1.Turn off pump and CO₂

-

2. Unscrew main locking nut of DIFFUSER CHAMBER and remove DIFFUSER STONE. Careful that o-rings at end of stone remain in place

-

3. Prepare two tablets of DENTURE CLEANER in a cup of warm water and drop in DIFFUSER STONE. Leave for as long as possible (2 hours ideal)

-

4. Discard solution and THOROUGHLY RINSE stone in tap water with toothbrush.

-

5. Replace stone into chamber and reassemble, making sure that: 1. O-rings in both seats for the stone are present and 2. the stone remains seated straight and not pushed out of alignment by the tightening up of the main locking nut.

-

6. Turn on pump and check for leaking of water from the chamber. Turn on CO₂ and check for improvements in bubble rate and subsequent diffusion in chamber.

-

Did cleaning the diffuser stone fix it?

-

Still too slow or nothing at all coming through?<br><br>Is it increased/started by a slight opening (use SCREWDRIVER to turn CLOCKWISE) of the INLINE REGULATOR?

-

Contact Bruce for further instructions

-

Getting better/some flow now? Be sure to thoroughly test the stability of the new position- we don't want to go the other way and have too much flowing. Contact Bruce if unsure.

-

Steady 2-3 bubbles per second? Great now check the INLINE DIFFUSER CHAMBER (left outlet rapped in aluminium foil- you'll need to shine your torch from behind)<br><br>Is there a strong flow of fine bubbles?

-

Have you waited long enough? If so then most likely the DIFFUSER STONE in the INLINE is blocked and needs cleaning. Check for any bubbles in diffuser chamber (left outlet rapped in aluminium foil- you'll need to shine your torch from behind) NB: this needs a min of 30mins. If you have no time then CONTACT BRUCE for alternative instructions.

-

Servicing the DIFFUSER STONE?

-

SERVICE THE DIFFUSER STONE: 1.Turn off pump and CO₂

-

2. Unscrew main locking nut of DIFFUSER CHAMBER and remove DIFFUSER STONE. Careful that o-rings at end of stone remain in place

-

3. Prepare two tablets of DENTURE CLEANER in a cup of warm water and drop in DIFFUSER STONE. Leave for as long as possible (2 hours ideal)

-

4. Discard solution and THOROUGHLY RINSE stone in tap water with toothbrush.

-

5. Replace stone into chamber and reassemble, making sure that: 1. O-rings in both seats for the stone are present and 2. the stone remains seated straight and not pushed out of alignment by the tightening up of the main locking nut.

-

6. Turn on pump and check for leaking of water from the chamber. Turn on CO₂ and check for improvements in bubble rate and subsequent diffusion in chamber.

-

Contact Bruce for further instructions

-

Did cleaning the diffuser stone fix it?

-

Still too slow or nothing at all coming through?<br><br>Is it increased/started by a slight opening (use SCREWDRIVER to turn CLOCKWISE) of the INLINE REGULATOR?

-

Contact Bruce for further instructions

-

Getting better/some flow now? Be sure to thoroughly test the stability of the new position- we don't want to go the other way and have too much flowing. Contact Bruce if unsure.

-

Turn FINE ADJUSTMENT dial in TINY INCREMENTS to reduce flow. Test stability by turning power to CO₂ solenoid off and on a few times and waiting to see where it settles. May need to reduce flow through INLINE REGULATOR. Note, this is counter intuitive setup: to REDUCE you turn the inner Phillips Head screw ANTI-clockwise! Also, move it only by the tiniest increments and test after each time. Contact Bruce if you are also considering this

-

Starts strong then drops off? <br>Is there a strong flow fine bubbles in INLINE DIFFUSER CHAMBER?

-

Most likely the DIFFUSER STONE is blocked and needs cleaning. Check this box for instructions. NB: this needs a min of 30mins. If you have no time then CONTACT BRUCE for alternative instructions.

-

Servicing the DIFFUSER STONE?

-

SERVICE THE DIFFUSER STONE: 1.Turn off pump and CO₂

-

2. Unscrew main locking nut of DIFFUSER CHAMBER and remove DIFFUSER STONE. Careful that o-rings at end of stone remain in place

-

3. Prepare two tablets of DENTURE CLEANER in a cup of warm water and drop in DIFFUSER STONE. Leave for as long as possible (2 hours ideal)

-

4. Discard solution and THOROUGHLY RINSE stone in tap water with toothbrush.

-

5. Replace stone into chamber and reassemble, making sure that: 1. O-rings in both seats for the stone are present and 2. the stone remains seated straight and not pushed out of alignment by the tightening up of the main locking nut.

-

6. Turn on pump and check for leaking of water from the chamber. Turn on CO₂ and check for improvements in bubble rate and subsequent diffusion in chamber.

-

Contact Bruce for further instructions

-

Did cleaning the diffuser stone fix it?

-

Still too slow or nothing at all coming through?<br><br>Is it increased/started by a slight opening (use SCREWDRIVER to turn CLOCKWISE) of the INLINE REGULATOR?

-

Contact Bruce for further instructions

-

Getting better/some flow now? Be sure to thoroughly test the stability of the new position- we don't want to go the other way and have too much flowing. Contact Bruce if unsure.

INLINE REACTOR (right outlet) This is really setup as a BACK-UP to the INLINE DIFFUSER and, as such, should engage more when the diffuser stone is blocked sending more pressure through to the right end

-

CO2 reactor Balls (on right end of return flow in tank) spinning?

-

Is there an excess of air in the reactor?

-

If this is happening in regular service times when the CO₂ is not on yet, then it is a mystery. Possibly due to pump being off now or recently for some reason. If it is noted in times when the CO₂ has been running for some time already, this would indicate that the gas has not been mixing in, possibly due to excess gas flow and/or mixing balls stuck and the gas has built up an air pocket. Flush through by turning up pump to full volume and closing off the valves of the middle outlets to force the air through the reactor.

-

When CO₂ is on, (and you've hopefully fixed the flow through the reactor) can you detect gas also flowing into the reactor? <br>You can usually hear it making a slight gurgle sound when mixing with the spinning balls.<br>If it's not flowing in there you should see a small amount of water in air line a couple of inches away from the reactor.

-

Again as this is designed as a back up for when the diffuser on the left side fails. If stone is blocked and therefore no fine effervescence is coming out of the diffuser and still nothing coming into this reactor then contact Bruce for further instructions.

-

Increase WAVELINE pump strength by one press and/or reduce flow from middle return outlets to send more flow to ends

-

Does this fix it?

-

Plan for FILTER clean next service. Make a FOLOWUP here in this field

-

Plan for a Service to REACTOR. Turn off PUMP and remove bottom section of reactor from head remove and rinse reactor balls Clean INSIDE WALL OF CYLINDER with paper towel. REASSEMBLE with out flow angle correctly aligned

-

When CO₂ is on, can you detect gas also flowing into the reactor? <br>You can usually hear it making a slight gurgle sound when mixing with the spinning balls.<br>If it's not flowing in there you should see a small amount of water in air line a couple of inches away from the reactor.

-

Again as this is designed as a back up for when the diffuser on the left side fails. If stone is blocked and therefore no fine effervescence is coming out of the diffuser and still nothing coming into this reactor then contact Bruce for further instructions.

-

When CO₂ is on, can you detect gas also flowing into the reactor? <br>You can usually hear it making a slight gurgle sound.<br>If it's not flowing in there you should see a small amount of water in air line a couple of inches away from the reactor.

-

Again as this is designed as a back up for when the diffuser on the left side fails. If stone is blocked and therefore no fine effervescence is coming out of the diffuser and still nothing coming into this reactor then contact Bruce for further instructions.

Setup

-

Tap here to open SETUP reminders

-

MOVE Dining Table chair at tank end to the side by the marble bench

-

Platform Ladder, hoses buckets and drop sheets downstairs. Normally unlocked but if needed green key in kitchen cabinet. Ask Liliana if unsure.

-

Need to override lights for working? Press here for instructions

-

Lights over-ride:

Dial on ends of the lights are also the enter button. Depress and hold until lights come on. This brings up the preset #1 which is bright. Hold again to get preset #2 which is dimmer.

Observations

-

Photos Before. 1-2 OVERALL. 2-3 CLOSEUPS on PLANTS

FISH

-

DISCUS and EMBER, WHITE-TIPPED TETRAS, PLATIES

- Great; vibrant, eager for food

- some individuals not right.

- sulky, sluggish, isolated from group

- dead fish, cloudy stinky water

-

Take photos of individuals and check for CAUSES. Questions: 1. Is it just an individual or are many affected? 2. Check for uneaten food, levels of ammonia or nitrite. 3. Filter or heater stopped or malfunctioning?

-

Anything on BODY? <br>WHITE SPOTS?<br>FUNGUS?<br>WOUNDS?

-

Take PHOTO of cases and NOTE down details.

-

Plan for LARGE WATER CHANGE (75-90%) with thorough GRAVEL VAC. Use STRESS COAT and BLUE SALTS to guard against chlorine and infection.

-

CONTACT BRUCE IMMEDIATELY

-

Take PHOTO where possible and NOTE down details.

-

Looking good? Place a couple of blocks of FROZEN FOOD in right hand end and observe how they eat.

The Workers: SUCKING CATS & FLYING FOXES

-

Show Siamese Flying Fox Photo====>

-

Siamese Flying Fox

-

Show Sucking Cat Photo====>

-

Sucking Cat (can be brown also)

-

SIAMESE FLYING FOX/es sighted? (5-7)

-

SUCKING CAT/s sighted? (1-2)

-

How's the algae levels on GLASS & PLANTS?

- Lots of soft brown/green dust everywhere

- Very clear. A few spots on glass and old leaves

- Furry black algae growing on old leaves, pump, glass

- heavy with dark green spots on glass

- dark green algae all over rocks

-

FURRY BLACK ALGAE is an indication that there are no or low numbers of SIAMESE FLYING FOX. Mention in notes.

-

Remove as much as possible, prune old affected leaves off plants. Vacuum up loose pieces from after cleaning glass

-

Brown Dust and Fine Green Algae is possibly an indication that there are no SUCKING CATS. Mention in notes.

-

Check light TIMER and nitrate levels.

-

Plan for an "Adrian Special"; BEFORE draining, turn OFF pumps, scrape all of every glass surface and carefully brush clean all rocks Then drain 80% water.

PLANTS (responses can be more than one)

-

STAUROGYNE PORTO VELHO. (Tap for picture)

-

STAUROGYNE PORTO VELHO

-

How is the STAUROGYNE PORTO VELHO looking?

- good. healthy bright green star-shaped new growth

- new and old growth nibbled

- poor. old growth dark and nibbled and new growth small, slow, stunted

- curled/deformed new growth

-

Possibly low in NITRATE and/or POTASSIUM (K) CHECK levels. (Section 4). 10ppm or more with still poor growth possibly means therefore not enough K and thus they are being starved. Contact Bruce for further instructions.

-

CURLED & DEFORMED new leaves? May have to review K dosage levels. Possibly too much. Do tests & check with BRUCE by SMS.

-

Great. Prune any healthy taller stems and replant to improve coverage of ground.

-

STAUROGYNE REPENS. (Tap for picture)

-

STAUROGYNE REPENS

-

How is the STAUROGYNE REPENS looking?

- good. healthy bright green star-shaped new growth

- new and old growth nibbled

- poor. old growth dark and nibbled and new growth small, slow, stunted

- curled/deformed new growth

-

Possibly low in NITRATE and/or POTASSIUM (K) CHECK levels. (Section 4). 10ppm or more with still poor growth possibly means therefore not enough K and thus they are being starved. Contact Bruce for further instructions.

-

CURLED & DEFORMED new leaves? May have to review K dosage levels. Possibly too much. Do tests & check with BRUCE by SMS.

-

Great. Prune any healthy taller stems and replant to improve coverage of ground.

-

ALTERNANTHERA. (Tap for picture)

-

ALTERNANTHERA

-

How is the ALTERNANTHERA looking?

- healthy deep red new growth

- deformed new growth, leaves curled and/or stunted

- grown above 3 inches

- prematurely aged older leaves

- algae spots on older growth

-

Prematurely aging leaves usually refers to not enough phosphorus preset. Take closeup PHOTO.

-

Getting high? This is best as a mid to low ground cover. Cut off top 3 inches and replant. If HEADLESS STEMS are healthy and not too scrappy then leave for propagation of new growth, just make sure they are obscured by the the others

-

CURLED & DEFORMED new leaves? May have to review K dosage levels. Possibly too much. Do tests & check with BRUCE by SMS.

-

Great. Prune any healthy taller stems and replant to improve coverage of ground.

-

Water Hedge (Tap for picture)

-

Water Hedge (didiplus diandra)

-

How is the WATER HEDGE looking?

- great, health light feathery green new growth, pink in the growth head

- stems getting close to surface

- old leaves prematurely aging/falling off

- stunted or small new growth, old leaves look eaten

- twisted/malformed new growth

-

CUT approx in half and, If healthy, reduce HEADLESS STALK by a further 50% and replant heads on front to hide the stalk.

-

Possibly low in NITRATE and/or POTASSIUM (K) or CO2 not working CHECK levels. (Section 4). 10ppm or more with still poor growth possibly means therefore not enough K and thus they are being starved. Check CO2 functioning properly. Contact Bruce for further instructions.

-

Great. Be sure to SHORTEN DOWN any that are getting too close to the surface.

-

Premature ageing is possibly a deficiency in PHOS which is a mobile nutrient. (Here only available via the fish food) If phos levels sufficient then possibly not enough K. check with BRUCE by SMS.

-

CURLED & DEFORMED new leaves? May have to review K dosage levels. Possibly too much. Do tests & check with BRUCE by SMS.

-

LOBELIA (Tap for picture)

-

LOBELIA

-

How is the LOBELIA looking?

- new growth, large and healthy lustre

- new leaves smaller than previous.

- old growth remaining healthy, ageing slowly

- old leaves prematurely ageing, falling off, leaving bare base stalk

- algae spots on old leaves

- leaves deformed and twisted

- stems getting a little high

-

CUT approx in half and, If healthy, reduce HEADLESS STALK by a further 50% and replant heads on front to hide the stalk.

-

Possibly low in NITRATE and/or POTASSIUM (K) or CO2 not working CHECK levels. (Section 4). 10ppm or more with still poor growth possibly means therefore not enough K and thus they are being starved. Check CO2 functioning properly. Contact Bruce for further instructions.

-

Great. Be sure to SHORTEN DOWN any that are getting too close to the tall

-

Premature ageing is possibly a deficiency in PHOS which is a mobile nutrient. If phos levels sufficient then possibly not enough K. check with BRUCE by SMS.

-

CURLED & DEFORMED new leaves? May have to review K dosage levels. Possibly too much. Do tests & check with BRUCE by SMS.

-

VALLISNERIA (tap for picture)

-

VALLISNERIA

-

How is the VALLISNERIA looking?

- Healthy light green

- Ends reached and floating on surface

- Prematurely ageing leaves

- rotten ends and parts throughout

- deformed new growth

-

Give it a "haircut". Leaving an inch "overhang" on the surface is ideal

-

Possibly a deficiency in PHOS which is a mobile nutrient. If phos levels sufficient then possibly not enough K. check with BRUCE by SMS.

-

PEEL or SNIP any old and ageing leaves from base

-

Possibly low in NITRATE and/or POTASSIUM (K) or CO2 not working CHECK levels. (Section 4). 10ppm or more with still poor growth possibly means therefore not enough K and thus they are being starved. Contact Bruce for further instructions.

-

CURLED & DEFORMED new leaves? May have to review K dosage levels. Possibly too much. Do tests & check with BRUCE by SMS.

-

CRYPTS BALANSAE (tap for picture)

-

CRYPT BALANSAE

-

How are the CRYPTS BALANSAE looking?

- great. Healthy shiny lustre. new growth good size, slightly curved upwards

- prematurely aged older leaves (possibly with algae spots)

- pale, slightly yellow leaves

- many leaves curled downwards, not holding their own weight.

- curled or bumpy deformed leaves, possibly lots of dark spotted algae on leaves

- slow growth. new leaves remaining small, stunted.

- surface pads

-

Possibly a deficiency in PHOS which is a mobile nutrient. If phos levels sufficient then possibly not enough K. check with BRUCE by SMS.

-

PEEL AWAY any old and ageing leaves from base

-

Possibly low in NITRATE and/or POTASSIUM (K) or CO2 not working CHECK levels. (Section 4). 10ppm or more with still poor growth possibly means therefore not enough K and thus they are being starved. Contact Bruce for further instructions.

-

CURLED & DEFORMED new leaves? May have to review K dosage levels. Possibly too much. Do tests & check with BRUCE by SMS.

-

CRYPT PARVA (tap for picture)

-

CRYPTS PARVA

-

How are CRYPTS PARVA looking?

- shiny healthy deep green and strong new leaves,

- old leaves ageing well, minimum algae spots

- new leaves smaller than the older

- lots of algae spots on leaves

- deformed twisted leaves

- leaves weak and floppy, older leaves. spread out,

- prematurely aging, discoloured leaves

-

Possibly a deficiency in PHOS which is a mobile nutrient. If phos levels sufficient then possibly not enough K. check with BRUCE by SMS.

-

PEEL AWAY any old and ageing leaves from base

-

Possibly low in NITRATE and/or POTASSIUM (K) or CO2 not working CHECK levels. (Section 4). 10ppm or more with still poor growth possibly means therefore not enough K and thus they are being starved. Contact Bruce for further instructions.

-

CURLED & DEFORMED new leaves? May have to review K dosage levels. Possibly too much. Do tests & check with BRUCE by SMS.

-

Possibly a lack of K and/or CO2. Check nitrate and phos levels and check co2 system

-

Great. Peel away any old leaves that look on the way out

-

ANUBIAS (tap for picture)

-

ANUBIAS

-

How are the ANUBIAS looking?

- shiny and strong deep green new leaves

- older leaves pretty good, low algae

- new leaves small, twisted, algae spots on all leaves

- some dark, old and algae-covered leaves

-

PEEL AWAY any old and ageing leaves from base

-

CURLED & DEFORMED new leaves? May have to review K dosage levels. Possibly too much. Do tests & check with BRUCE by SMS. Perhaps too much light

-

Possibly a lack of K and/or CO2. Check nitrate and phos levels and check co2 system

-

Great. Peel away any old leaves that look on the way out

-

BLYXA

-

BLYXA

-

How is the BLYXA looking?

- great. large, light green new growth. old growth slightly darker but still intact

- OK. medium quality new growth. not spreading but each piece is well rooted and old growth hasn't prematurely fallen off

- old leaves prematurely old. (may be also eaten off)

- poor. new growth short, dark and slow. old leaves perhaps eaten away. roots week

-

Great. Manage any over-growth (pushing up to glass, swamping other smaller plants) by thinning out and replanting to any thinner areas.

-

Possibly low in NITRATE and/or POTASSIUM (K) CHECK levels. (Section 4). 10ppm or more with still poor growth possibly means therefore not enough K and thus they are being starved. Contact Bruce for further instructions.

-

Possibly a deficiency in PHOS which is a mobile nutrient. If phos levels sufficient then possibly not enough K. check with BRUCE by SMS.

-

Green Tiger Lotus

-

Green Tiger Lotus

-

How is the GREEN TIGER LOTUS looking?

- great. Healthy shiny lustre. new growth good size, slightly curved upwards

- prematurely aged older leaves (possibly with algae spots)

- pale, slightly yellow leaves

- many leaves curled downwards, not holding their own weight.

- curled or bumpy deformed leaves, possibly lots of dark spotted algae on leaves

- slow growth. new leaves remaining small, stunted.

- surface pads

-

Deformed new growth? May have to review K dosage levels. Check NITRATE and PHOS and check with BRUCE by SMS.

-

CUT all surface pads out from BASE. NB. Check for NEW SHOOTS. they are guaranteed to be also surface so be ruthless!

-

Great. Remove any old, ageing leaves from base. CAREFUL that you have the right one!

-

Possibly low in NITRATE and/or POTASSIUM (K) CHECK nitrate levels. (Section 4). 10ppm of nitrate or more with still poor growth possibly means therefore not enough K and thus they are being starved. Contact Bruce for further instructions.

-

Possibly a deficiency in PHOS which is a mobile nutrient. If phos levels sufficient then possibly not enough K. check with BRUCE by SMS.

-

Possibly low in IRON and/or NITRATES. Maybe cause for increase in fertilisers or ROOT TABLETS. Consult Bruce by SMS if no previous instructions.

-

BARCLAYA

-

BARCLAYA

-

How is the BARCLAYA looking?

- great. Healthy shiny lustre. new growth good size, slightly curved upwards

- prematurely aged older leaves (possibly with algae spots)

- pale, slightly yellow leaves

- many leaves curled downwards, not holding their own weight.

- curled or bumpy deformed leaves, possibly lots of dark spotted algae on leaves

- slow growth. new leaves remaining small, stunted.

- surface pads

-

Deformed new growth? May have to review K dosage levels. Check NITRATE and PHOS and check with BRUCE by SMS.

-

CUT all surface pads out from BASE. NB. Check for NEW SHOOTS. they are guaranteed to be also surface so be ruthless!

-

Great. Remove any old, ageing leaves from base. CAREFUL that you have the right one!

-

Possibly low in NITRATE and/or POTASSIUM (K) CHECK nitrate levels. (Section 4). 10ppm of nitrate or more with still poor growth possibly means therefore not enough K and thus they are being starved. Contact Bruce for further instructions.

-

Possibly a deficiency in PHOS which is a mobile nutrient. If phos levels sufficient then possibly not enough K. check with BRUCE by SMS.

-

Possibly low in IRON and/or NITRATES. Maybe cause for increase in fertilisers or ROOT TABLETS. Consult Bruce by SMS if no previous instructions.

Tests part 1

Tests part 1

-

TEMPERATURE test (ideal 28-29 C) Serviced by INLINE HEATER on right piping of filter return. Back up STANDARD ROD Mounted by filter intake should be set slightly lower to only come on during auto water changes and when main one fails

-

anything less than 25 degrees is cold for this tank. Is the INLINE HEATER plugged in/ functioning?<br>(Does the indicator light come on and off when you turn the thermostat setting up and down?)

-

Then plug in and confirm correct thermostat setting and check that indicator light comes on.

-

Is BACKUP heater functioning/plugged in? <br>(Does the indicator light come on and off when you turn the thermostat setting up and down?)

-

Then plug in and set thermostat of BACKUP at 27-28 degrees and check that indicator light comes on.

-

Notify Bruce to arrange replacement of INLINE HEATER Make a follow-up entry here

-

Then we may have a rare case of two heaters failing. This of course is highly unlikely so perform a double check. Perhaps the power board is faulty...?

-

Notify Bruce to arrange replacements ASAP. Make a follow-up entry here. Heat up tank with soup heater to 29 degrees to keep a buffer temp till replacements installed

-

Increase THERMOSTAT on BACKUP heater (clockwise) by the SUITABLE AMOUNT to bring it up within the range (see above) and make note of how much.

-

Increased THERMOSTAT by:

-

Notify Bruce to arrange replacement of INLINE HEATER Make a follow-up entry here

-

Increase THERMOSTAT (clockwise) by the SUITABLE AMOUNT to bring it up within the range (see above) and make note of how much.

-

Increased THERMOSTAT on BACK UP UNIT by:

-

Has the morning AUTO 10% water change happened recently?

-

Depending on how recent and how cool the temp is now, this is most likely the explanation for the temp drop. Is the indicator light of the INLINE HEATER on?

-

Is INLINE heater functioning/plugged in? <br>(Does the indicator light come on and off when you turn the thermostat setting up and down?)

-

Increase THERMOSTAT on BACKUP heater (clockwise) by the SUITABLE AMOUNT to bring it up within the range (see above) and make note of how much.

-

Increased THERMOSTAT by:

-

Notify Bruce to arrange replacement of INLINE HEATER Make a follow-up entry here

-

Increase THERMOSTAT (clockwise) by the SUITABLE AMOUNT to bring it up within the range (see above) and make note of how much.

-

Increased THERMOSTAT by:

-

Then plug in and confirm correct thermostat setting and check that indicator light comes on.

-

Is the indicator light on the BACK UP STANDARD heater on?

-

Is BACKUP heater functioning/plugged in? <br>(Does the indicator light come on and off when you turn the thermostat setting up and down?)

-

Then we may have a rare case of two heaters failing. This of course is highly unlikely so perform a double check. Perhaps the power board is faulty...?

-

Notify Bruce to arrange replacements ASAP. Make a follow-up entry here. Heat up tank with soup heater to 29 degrees to keep a buffer temp till replacements installed

-

Increase THERMOSTAT on BACKUP heater (clockwise) by the SUITABLE AMOUNT to bring it up within the range (see above) and make note of how much.

-

Increased THERMOSTAT by:

-

Notify Bruce to arrange replacement of INLINE HEATER Make a follow-up entry here

-

Then plug in and confirm correct thermostat setting and check that indicator light comes on.

-

Then all should be normal. Leave all settings as they are.

-

If not performed the AUTO W/C then this is bit too cool. Is INLINE heater functioning/plugged in? <br>(Does the indicator light come on and off when you turn the thermostat setting up and down?)

-

Is BACKUP heater functioning/plugged in? <br>(Does the indicator light come on and off when you turn the thermostat setting up and down?)

-

Then plug in and confirm correct thermostat setting and check that indicator light comes on.

-

Increase THERMOSTAT on BACKUP heater (clockwise) by the SUITABLE AMOUNT to bring it up within the range (see above) and make note of how much.

-

Increased THERMOSTAT by:

-

Notify Bruce to arrange replacement of INLINE HEATER Make a follow-up entry here

-

Then we may have a rare case of two heaters failing. This of course is highly unlikely so perform a double check. Perhaps the power board is faulty...?

-

Notify Bruce to arrange replacements ASAP. Make a follow-up entry here. Heat up tank with soup heater to 29 degrees to keep a buffer temp till replacements installed

-

Increase THERMOSTAT on BACKUP heater (clockwise) by the SUITABLE AMOUNT to bring it up within the range (see above) and make note of how much.

-

Increased THERMOSTAT by:

-

Notify Bruce to arrange replacement of INLINE HEATER Make a follow-up entry here

-

Increase THERMOSTAT (clockwise) by the SUITABLE AMOUNT to bring it up within the range (see above) and make note of how much.

-

Increased THERMOSTAT on BACK UP UNIT by:

-

Then plug in and confirm correct thermostat setting and check that indicator light comes on.

-

A little too warm. Are the THERMOSTATS on both INLINE and backup STANDARD heaters functioning? <br>(Does the indicator light come on and off when you turn the thermostat setting up and down?)

-

Decrease THERMOSTAT (anticlockwise) by the SUITABLE AMOUNT to bring it down within the range (see above)and note by how much.

-

Decreased THERMOSTAT by:

-

HEATER Replaced?

-

if the THERMOSTAT doesn't respond to being turned down then better to have a cool tank than risking cooking the fish. Unplug faulty unit and plug in the SPARE HEATER that is already installed at receptionist end INSIDE THE TANK. Notify Bruce to arrange replacement.

-

Good. Refill with HEATER or KETTLES OF BOILED WATER in COLD months.

-

Rinse 4 TEST VIALS in tank water: MEASURE 5ml in each and SET ASIDE for later.

The Drain

The Drain (50%)

-

Turn off WATER WITCH

-

Turn off SURFACE SKIMMER FILTER

-

Turn off KORALIA PUMP mounted inside the tank, on back right corner

-

Turn off back up heater (situated next to filter intake)

GRAVEL VACUUM (only for special needs or emergencies. Light debris on surface perhaps.) NB: if plants are doing well, then leave. It's good food for them!

-

Gravel vacuum?

-

How dirty was it?

FAST DRAIN

-

Be sure to use BASKET STRAINER over end. Attach on inside with 2 functioning SUCTION CUPS. run HOSE out to back lawn. BE SURE TO CHECK IF any CATS ARE ON HOUSE ARREST!

The Refill

The Refill

-

Switch on WATER WITCH power. Water will flow in through OUTFLOW of filter system. Sensor is in pipe behind middle rocks by centre weir wall

-

SOUP HEATER in COLD months or in large water changes. Place in right end of the tank, away from plants. Plug into WALL OUTLET to the right by the floor. ALTERNATIVELY can plug into power points on back left wall and mount heater in the left

Things To Do During Refill

-

CLEAN GLASS; easiest at LOW WATER LEVELS. SOFT ALGAE lightly with sponge. DARK GREEN spots: best with SCRAPER. If using the Magnet Cleaner please use with caution near graveL!

-

Work on PLANTS

-

Water level high enough? Switch KORALIA PUMP back on and confirm is flowing

-

FILTER SERVICE?

-

Tap here for instructions ====>

-

INSTRUCTIONS: UNDER CONSTRUCTION.

Tests (continued)

-

NO TESTS LEFT ON BARE MARBLE TABLE TOPS! Use sink in second kitchen area opposite the island bench

-

pH Test? 3 drops in 5ml. (ideal range 6.5- 6.8)

-

ADD approx 1 tsp CORAL SAND.

-

ADD approx 2 tsp CORAL SAND

-

ADD approx 3 tsp CORAL SAND

-

Is this expected? Been a recent large dose of coral sand last time?

-

Rinse test tube thoroughly and retest. (Any traces of ammonia or GH tester solution will give a false alkaline reading)

-

WOAH! Unlikely! Rinse test tube thoroughly and retest. (Any traces of AMMONIA TEST or GH TEST solutions will give a false alkaline reading) If still high then we must assume that there has been an excess amount of coral sand and all we can do is water change. It will eventually come down as the coral sand dissolves.

-

GH TEST. number of drops to turn from ORANGE to GREEN

-

SIZE of water change:

-

ADD up to 3/4 Measure spoons GH POWDER

-

ADD up to 1 & 1/2 Measure spoons GH POWDER

-

Depending on SIZE of WATER CHANGE, add NO SALTS and let WC reduce the GH to within desired range

-

KH TEST. number of drops to turn from BLUE to YELLOW

-

NITRATE TEST

-

What day is it today?

- Monday

- Tuesday

- Wednesday

- Thursday

- Friday

- Saturday

- Sunday

-

Last Nitrogen dose was last night so: Depending on state of plants, this is POSSIBLY grounds for increase in NITROGEN dose. Contact Bruce for further instructions.

-

Next Nitrogen Dose is tonight so that should be fine.

-

GENERALLY this is the OPTIMUM RANGE.

-

High Nitrate reading? Has the NITROGEN PUMP dosed already today or just last night? (Doses at 8pm MON, WED, FRIDAY, SUNDAY)

-

This is the most likely cause of this reading and should drop once the plants start eating

-

Almost certainly and LACK of POTASSIUM. Perhaps K is underdosing and/or NITROGEN is overdosing. Be sure to check DOSING PUMPS for mechanical function. Are all primed and functioning properly?

-

Details

-

Does this issue provide plausible answer to the issue?

-

Done a calibration of the PUMPS recently? (In the last 3 months)

-

Look at INCREASING POTASSIUM dose. Consult Bruce

-

Do a NITROGEN PUMP CALIBRATION: <br>QUESTION: did it dose MORE or LESS than the volume displayed at the end of the calibration?

-

By how much?

- 1ml

- 2ml

- 3ml

- 4ml

- 5ml

- more than 5 ml

-

Input correct volume. This will effectively decrease the NITROGEN DOSE.

-

By how much?

- 1ml

- 2ml

- 3ml

- 4ml

- 5ml

- more than 5 ml

-

Input correct volume.

-

Look at INCREASING POTASSIUM dose. Consult Bruce

-

Done a calibration of the PUMPS recently? (In the last 3 months)

-

Look at INCREASING POTASSIUM dose. Consult Bruce

-

Do a NITROGEN PUMP CALIBRATION: <br>QUESTION: did it dose MORE or LESS than the volume displayed at the end of the calibration?

-

By how much?

- 1ml

- 2ml

- 3ml

- 4ml

- 5ml

- more than 5 ml

-

Input correct volume. This will effectively decrease the NITROGEN DOSE.

-

By how much?

- 1ml

- 2ml

- 3ml

- 4ml

- 5ml

- more than 5 ml

-

Input correct volume.

-

Look at INCREASING POTASSIUM dose. Consult Bruce

-

PHOSPHATE TEST

-

GENERALLY this is the OPTIMUM RANGE. Some say 1/10th of the nitrate level. HOWEVER if there is POOR PLANT GROWTH (premature aging leaves usually) observed then possibly means therefore not enough K and thus they are being starved. Contact Bruce for further instructions.

-

If algae issues this may be a contributing factor. Make note to Bruce

-

Is there premature aging/falling off of leaves on any of the plants?

-

Phosphorus here is supplied by the fish food In auto feeder. Cheek feeder's function. May need to supplement phosphorus. Make note for Bruce.

-

Then don't worry about it. Enjoy algae-free aquarium maintenance!

Additives

-

GH UP POWDER ADDED?

-

How many measured spoons?

-

Coral sand added? (Low pH)

-

How many teaspoons?

DOSING PUMP

TRACE & IRON

-

Any AIRLOCKS to bleed out?

TEST THE LINE

-

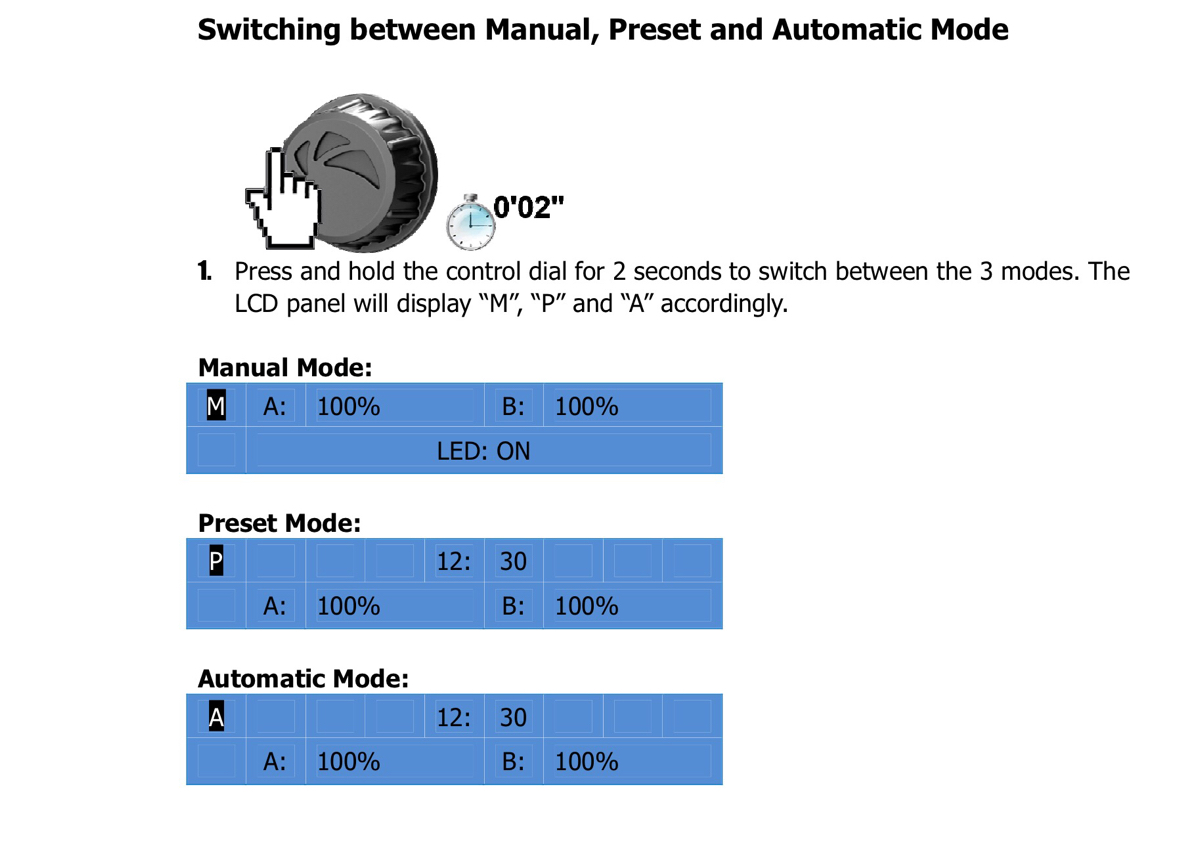

TEST LINES; "Manual Dose", scroll UP or DOWN to select pump and hold SET. Only do as much as a couple of drops.

-

Liquid moving through the line?

-

Make note and contact Bruce for further instruction

-

Is the SUCTION LINE immersed in the liquid?

-

Is it an OBSTRUCTION in the line caused by oxidised minerals from the liquid?

-

Remove SUCTION LINE from PUMP HEAD and WASH in hot water, massage or blow out the blockage and RE-ATTACH to PUMP HEAD.

-

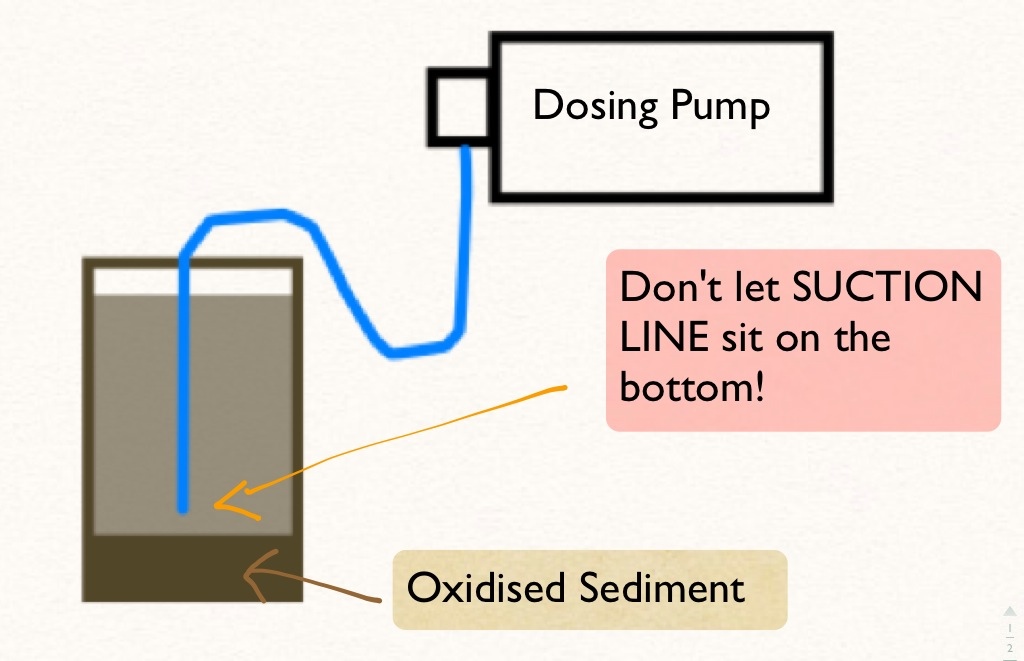

IMPORTANT: the SUCTION LINE must NOT be sitting on the bottom of the SUPPLY BOTTLE. The supply bottles here are deliberately NOT DIRECTLY BELOW THEIR RESPECTIVE PUMPS in order to allow ease of refilling and accessing the control panel so the SUCTION LINES are quite long.

If unsure, SIMULATE it's position outside, next to the supply container. -

WASH OUT the supply bottle. If there is reasonable amount of liquid still in it then gently DECANTER the clear liquid into a second container. As soon as it is no longer clear STOP (in the case of DAILY-GRO it goes from tea coloured to thick brown). WASH OUT SLUDGE and return the clear liquid to the bottle.

-

Where and how big was the airlock in the TRACE & IRON line?

PRIME/BLEED OUT AIRLOCKS OUT OF THE LINE

-

If substantial amount of liquid needs to be moved in order to release the airlock then use a CONTAINER (eg. test vial.) to catch the liquid while priming the line. We don't want to give unquantified extra doses!

-

BLEED THE LINE; Select "Manual Dose", scroll UP or DOWN to select pump and hold SET. Release to stop

-

Liquid moving through the line?

-

Make note and contact Bruce for further instruction

-

Is the SUCTION LINE immersed in the liquid?

-

Is it an OBSTRUCTION in the line caused by oxidised minerals from the liquid?

-

Remove SUCTION LINE from PUMP HEAD and WASH in hot water, massage or blow out the blockage and RE-ATTACH to PUMP HEAD.

-

IMPORTANT: the SUCTION LINE must NOT be sitting on the bottom of the SUPPLY BOTTLE. The supply bottles here are deliberately NOT DIRECTLY BELOW THEIR RESPECTIVE PUMPS in order to allow ease of refilling and accessing the control panel so the SUCTION LINES are quite long.

If unsure, SIMULATE it's position outside, next to the supply container. -

WASH OUT the supply bottle. If there is reasonable amount of liquid still in it then gently DECANTER the clear liquid into a second container. As soon as it is no longer clear STOP (in the case of DAILY-GRO it goes from tea coloured to thick brown). WASH OUT SLUDGE and return the clear liquid to the bottle.

-

Check that the CONNECTIONS between PUMP and FEEDER lines are well secure. If necessary, REMOVE feeder line, snip of tip with scissors and SOAK new tip in hot water to soften and REFIT.

-

Test CHECKVALVE. Blow air thru both ends. Should only let you in one direction. If it flows in both directions (or indeed none!) a paper clip wire or similar lightly poked into the rubber valve from both ends can fix this. Otherwise make note to replace valve.

-

Clean CHECK VALVES/ENDS OF LINES of dried/calcified buildup. They should be just hanging over the SUPPORT STRIP of glass and above the water line.

NITROGEN

-

Any AIRLOCKS to bleed out?

TEST THE LINE

-

TEST LINES; "Manual Dose", scroll UP or DOWN to select pump and hold SET. Only do as much as a couple of drops.

-

Liquid moving through the line?

-

Make note and contact Bruce for further instruction

-

Is the SUCTION LINE immersed in the liquid?

-

Is it an OBSTRUCTION in the line caused by oxidised minerals from the liquid?

-

Remove SUCTION LINE from PUMP HEAD and WASH in hot water, massage or blow out the blockage and RE-ATTACH to PUMP HEAD.

-

IMPORTANT: the SUCTION LINE must NOT be sitting on the bottom of the SUPPLY BOTTLE. The supply bottles here are deliberately NOT DIRECTLY BELOW THEIR RESPECTIVE PUMPS in order to allow ease of refilling and accessing the control panel so the SUCTION LINES are quite long.

If unsure, SIMULATE it's position outside, next to the supply container. -

WASH OUT the supply bottle. If there is reasonable amount of liquid still in it then gently DECANTER the clear liquid into a second container. As soon as it is no longer clear STOP (in the case of DAILY-GRO it goes from tea coloured to thick brown). WASH OUT SLUDGE and return the clear liquid to the bottle.

-

Where and how big was the airlock in the NITROGEN line?

PRIME/BLEED OUT AIRLOCKS OUT OF THE LINE

-

If substantial amount of liquid needs to be moved in order to release the airlock then use a CONTAINER (eg. test vial.) to catch the liquid while priming the line. We don't want to give unquantified extra doses!

-

BLEED THE LINE; Select "Manual Dose", scroll UP or DOWN to select pump and hold SET. Release to stop

-

Liquid moving through the line?

-

Make note and contact Bruce for further instruction

-

Is the SUCTION LINE immersed in the liquid?

-

Is it an OBSTRUCTION in the line caused by oxidised minerals from the liquid?

-

Remove SUCTION LINE from PUMP HEAD and WASH in hot water, massage or blow out the blockage and RE-ATTACH to PUMP HEAD.

-

IMPORTANT: the SUCTION LINE must NOT be sitting on the bottom of the SUPPLY BOTTLE. The supply bottles here are deliberately NOT DIRECTLY BELOW THEIR RESPECTIVE PUMPS in order to allow ease of refilling and accessing the control panel so the SUCTION LINES are quite long.

If unsure, SIMULATE it's position outside, next to the supply container. -

WASH OUT the supply bottle. If there is reasonable amount of liquid still in it then gently DECANTER the clear liquid into a second container. As soon as it is no longer clear STOP (in the case of DAILY-GRO it goes from tea coloured to thick brown). WASH OUT SLUDGE and return the clear liquid to the bottle.

-

Check that the CONNECTIONS between PUMP and FEEDER lines are well secure. If necessary, REMOVE feeder line, snip of tip with scissors and SOAK new tip in hot water to soften and REFIT.

-

Test CHECKVALVE. Blow air thru both ends. Should only let you in one direction. If it flows in both directions (or indeed none!) a paper clip wire or similar lightly poked into the rubber valve from both ends can fix this. Otherwise make note to replace valve.

-

ADJUSTMENT DOSE: Is today a Tuesday, Thursday or Saturday?

-

NITROGEN won't be dosing till tomorrow so let's make up for loss. Make MANUAL HALF-DOSE holding a measuring cap under hose at a % corresponding to size of water change. Eg. 50% water change = 50% of half a dose=1/4 of program. Add 10% if Auto Water Change had already happened before your arrival (10am - 10:30am) So full dose currently at 32ml. So add 8ml if you've got in before the auto change or 10 ml if afterwards

-

Programmed to dose tonight (mon, wed, fri, Sunday 8pm) so no need to dose now

-

Clean CHECK VALVES/ENDS OF LINES of dried/calcified buildup. They should be just hanging over the SUPPORT STRIP of glass and above the water line.

POTASSIUM

-

Any AIRLOCKS to bleed out?

TEST THE LINE

-

TEST LINES; "Manual Dose", scroll UP or DOWN to select pump and hold SET. Only do as much as a couple of drops.

-

Liquid moving through the line?

-

Make note and contact Bruce for further instruction

-

Is the SUCTION LINE immersed in the liquid?

-

Is it an OBSTRUCTION in the line caused by oxidised minerals from the liquid?

-

Remove SUCTION LINE from PUMP HEAD and WASH in hot water, massage or blow out the blockage and RE-ATTACH to PUMP HEAD.

-

IMPORTANT: the SUCTION LINE must NOT be sitting on the bottom of the SUPPLY BOTTLE. The supply bottles here are deliberately NOT DIRECTLY BELOW THEIR RESPECTIVE PUMPS in order to allow ease of refilling and accessing the control panel so the SUCTION LINES are quite long.

If unsure, SIMULATE it's position outside, next to the supply container. -

WASH OUT the supply bottle. If there is reasonable amount of liquid still in it then gently DECANTER the clear liquid into a second container. As soon as it is no longer clear STOP (in the case of DAILY-GRO it goes from tea coloured to thick brown). WASH OUT SLUDGE and return the clear liquid to the bottle.

-

Where and how big was the airlock in the POTASSIUM line?

PRIME/BLEED OUT AIRLOCKS OUT OF THE LINE

-

If substantial amount of liquid needs to be moved in order to release the airlock then use a CONTAINER (eg. test vial.) to catch the liquid while priming the line. We don't want to give unquantified extra doses!

-

BLEED THE LINE; Select "Manual Dose", scroll UP or DOWN to select pump and hold SET. Release to stop

-

Liquid moving through the line?

-

Make note and contact Bruce for further instruction

-

Is the SUCTION LINE immersed in the liquid?

-

Is it an OBSTRUCTION in the line caused by oxidised minerals from the liquid?

-

Remove SUCTION LINE from PUMP HEAD and WASH in hot water, massage or blow out the blockage and RE-ATTACH to PUMP HEAD.

-

IMPORTANT: the SUCTION LINE must NOT be sitting on the bottom of the SUPPLY BOTTLE. The supply bottles here are deliberately NOT DIRECTLY BELOW THEIR RESPECTIVE PUMPS in order to allow ease of refilling and accessing the control panel so the SUCTION LINES are quite long.

If unsure, SIMULATE it's position outside, next to the supply container. -

WASH OUT the supply bottle. If there is reasonable amount of liquid still in it then gently DECANTER the clear liquid into a second container. As soon as it is no longer clear STOP (in the case of DAILY-GRO it goes from tea coloured to thick brown). WASH OUT SLUDGE and return the clear liquid to the bottle.

-

Check that the CONNECTIONS between PUMP and FEEDER lines are well secure. If necessary, REMOVE feeder line, snip of tip with scissors and SOAK new tip in hot water to soften and REFIT.

-

Test CHECKVALVE. Blow air thru both ends. Should only let you in one direction. If it flows in both directions (or indeed none!) a paper clip wire or similar lightly poked into the rubber valve from both ends can fix this. Otherwise make note to replace valve.

-

Clean CHECK VALVES/ENDS OF LINES of dried/calcified buildup. They should be just hanging over the SUPPORT STRIP of glass and above the water line.

Packing up

SUPPLIES; ANY REFILLING TO BE DONE IN SINK OR OUTSIDE!

-

GH UP REPLACE?

-

DRYFOOD (TETRABITS) REPLACE?

-

Will any need replacing next month?

- TETRABITS

- SPIRULINA FLAKES

- SPIRULINA TABLETS

- DISCUS PELLETS

-

NITROGEN refill?

-

HOW MUCH IS LEFT?

-

THIS IS DEFINITELY NOT ENOUGH TO LAST! Refill within the week

-

Bring some next time as almost definitely will need some.

-

How much?

-

TRACE & IRON refill?

-

How much?

-

HOW MUCH IS LEFT?

-

THIS WON'T BE ENOUGH TO LAST. It uses 4 ml per week. Refill within 2 weeks

-

Bring some next time as almost definitely will need some.

-

POTASSIUM supply refill?

-

How much?

-

HOW MUCH IS LEFT?

-

THIS IS PROBABLY NOT ENOUGH TO LAST. Refill within the week

-

Auto feeder topped up? Tetrabits. NB. BE SURE THAT OPENING IS AT CORRECT LEVEL!! Can use test turn as departing treat and to make sure it is dumping in open area (preferably taken up by wave pump flow)

-

CO2 replaced?

-

What Size?

-

Refilled the old one?

Equipment Check

-

TIME on Lights correct?

-

CO2 TIMER on the correct time?

-

Replacement Installed?

-

IMPORTANT! Remove and notify Bruce They will have to go without CO2 until a new one is sourced. Plan for a replacement ASAP.

-

CO2: Are you leaving before programmed time to come on?

-

Return the timer to the setting: AUTO OFF!!

-

then confirm that the timer is set to: AUTO ON!!

-

"Galcon" auto water changer solenoid battery need replacing?

-

Replaced Battery?<br>(Should be spare batteries in store room, on shelf)

-

Make sure that a replacement is ready. If none on site then make follow up here to buy one

-

LIGHTS working ok?

-

Details

-

DOSING PUMP returned to operation display? Tip: press ESC until no more peeps sound.

-

Notes. Any extra work performed? Any additions of fish? Any questions...?

FINAL CHECKS

-

HEATERS (main one inline on way to the right CO2 reactor, backup second attached to right side of centre weir) and FILTER PUMP (including Wavemaker Pump) ON and functioning?

-

OUTSIDE GLASS, CABINETRY etc CLEAN & DRY?

-

WATER WITCH on? Remember, here it is constantly used to top up from evaporation. It must ALWAYS BE ON.

-

RETURN THE LIGHTS TO AUTO!! Press adjustment dials 2 seconds until it shows "A" (if you are leaving after the first programmed time then it will be probably go to a dim setting. Otherwise it will be completely dark again)

-

Got your: BASKET STRAINER? TOOTH BRUSH? TEASPOON?

-

Photos After. 1 x OVERALL. Both sides, 2 half shots CLOSEUPS of any REARRANGED PLANT.

-

Time Finished