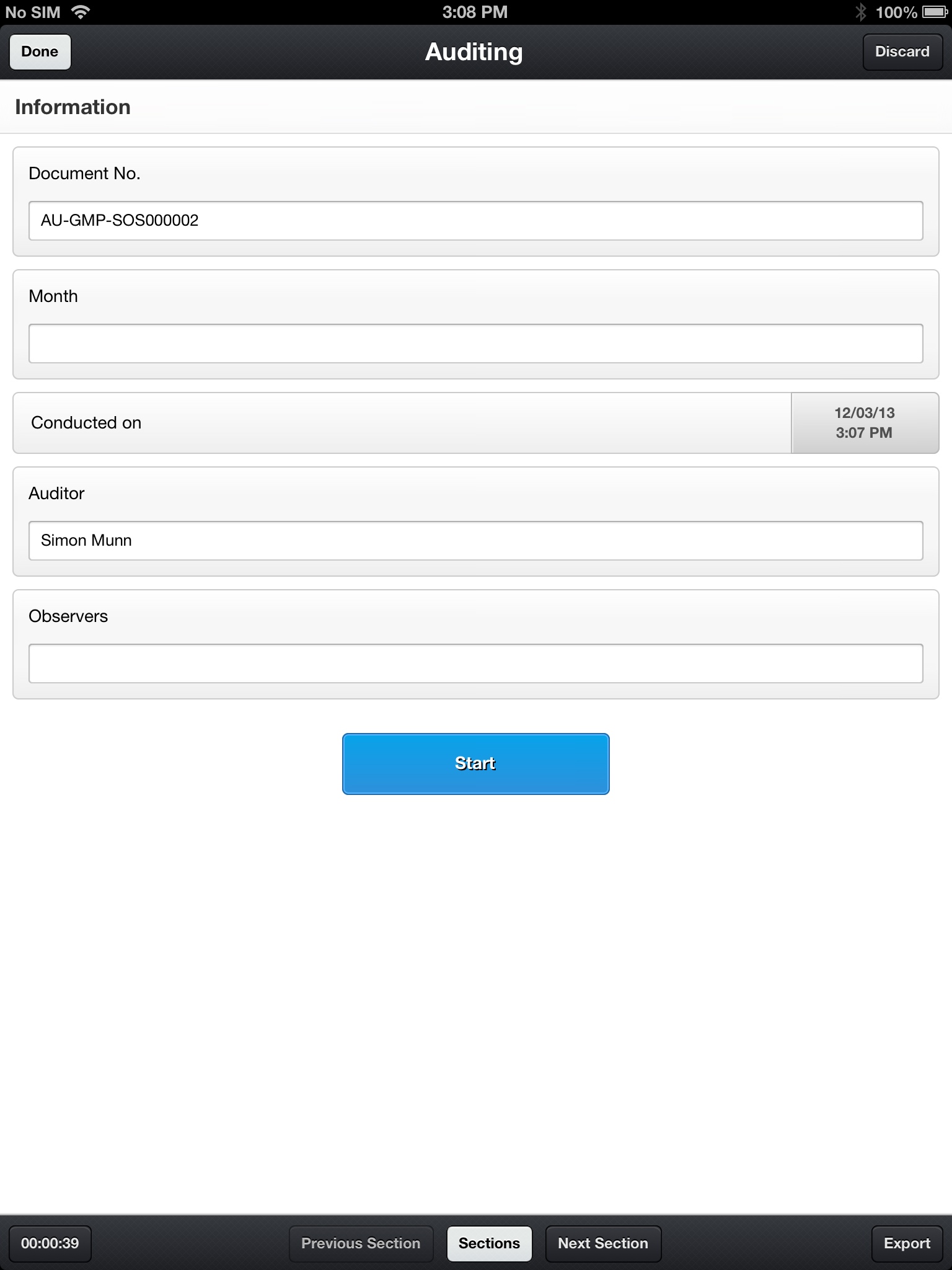

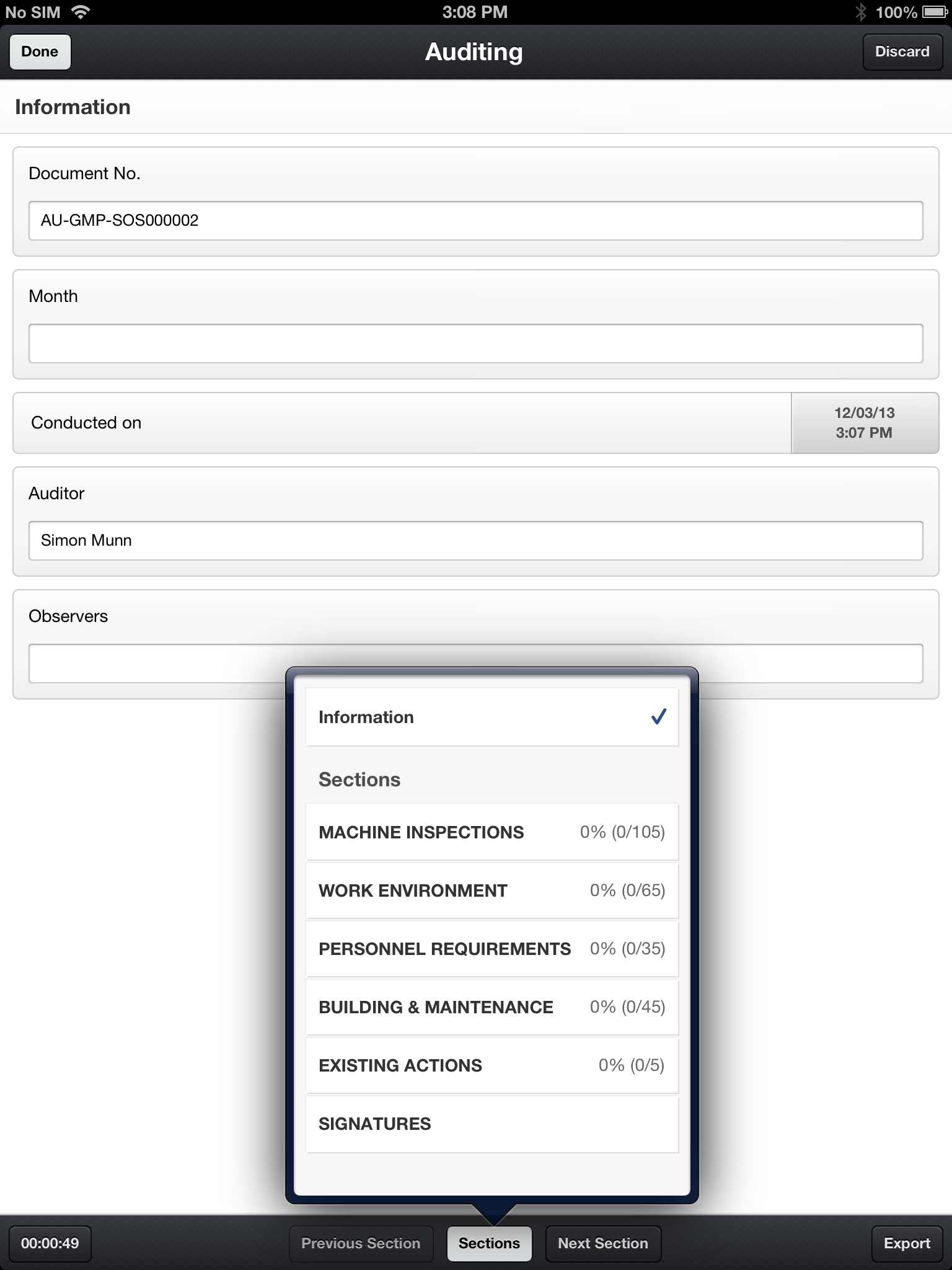

Information

-

Document No.

-

Month

-

Conducted on

-

Auditor

-

Observers

INSTRUCTIONS

Basic Use

-

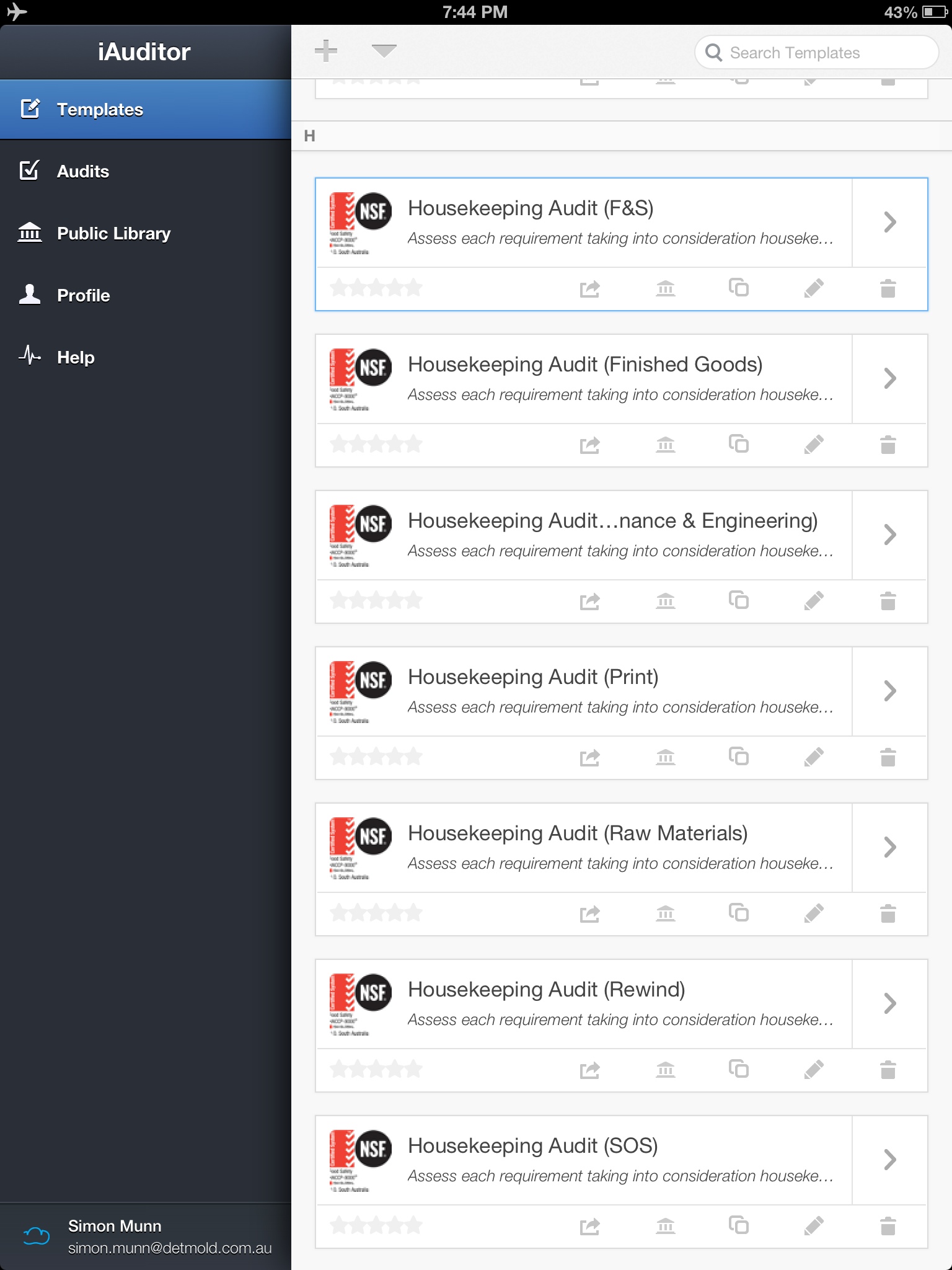

1. Open the iAuditor app. Now select the designated housekeeping audit you wish to complete by pushing on the main body of text. Do not select the pencil as this will edit the template.

-

2. Fill in basic information then click on "Start".

-

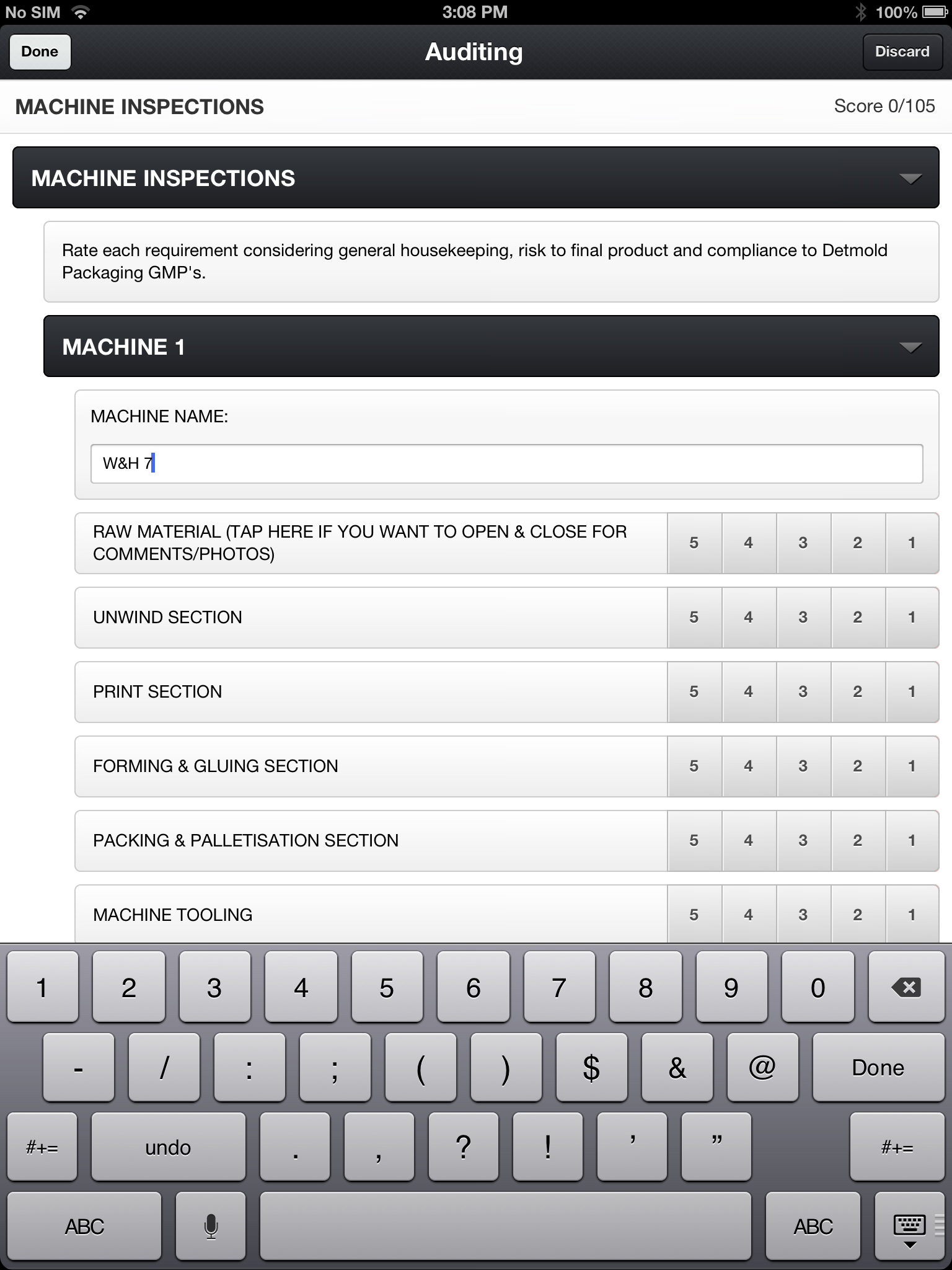

3. For machine audits, click on "Machine" text box which will bring up keyboard. Type in machine name. -

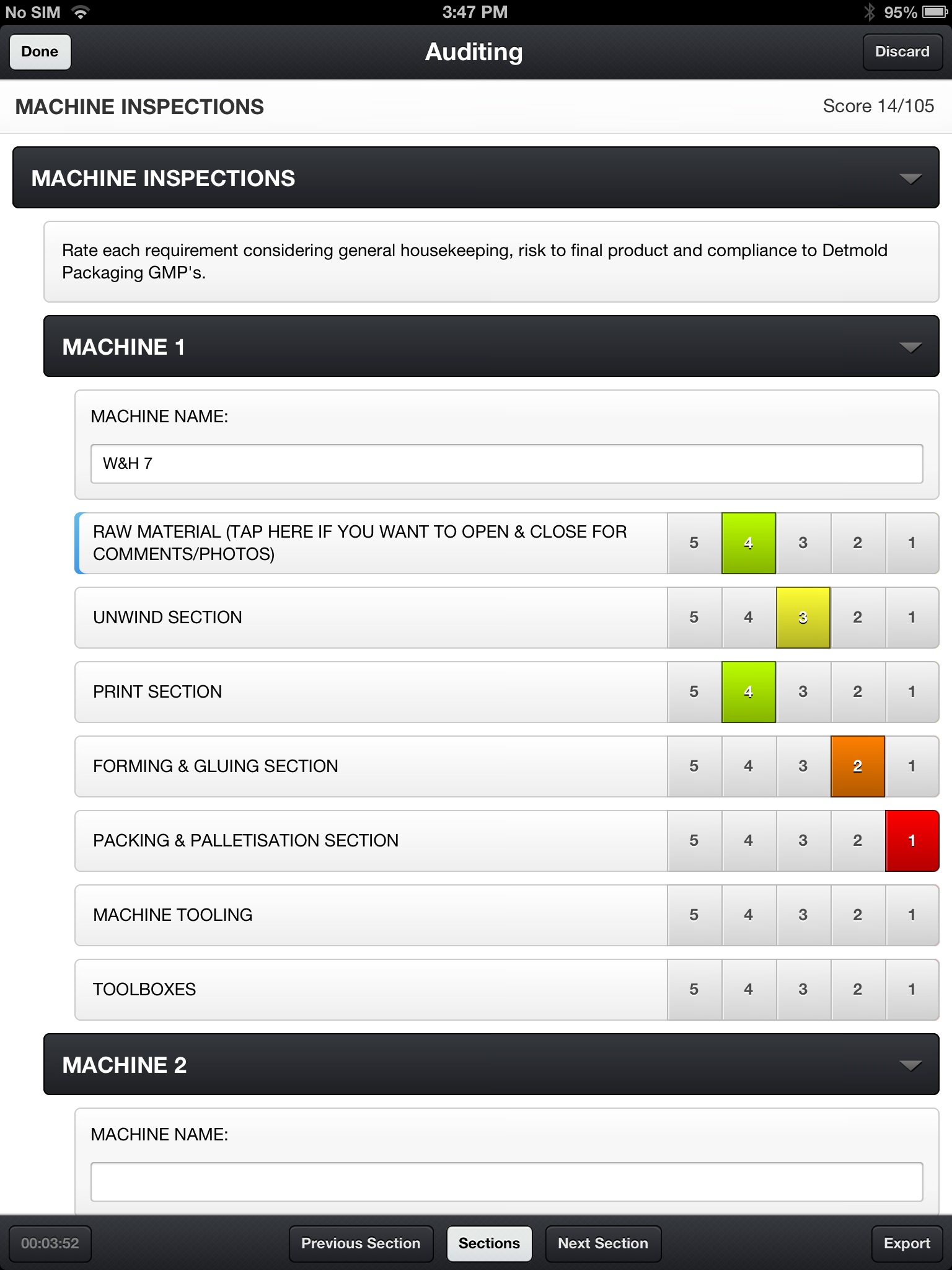

4. Score by clicking on the number.

-

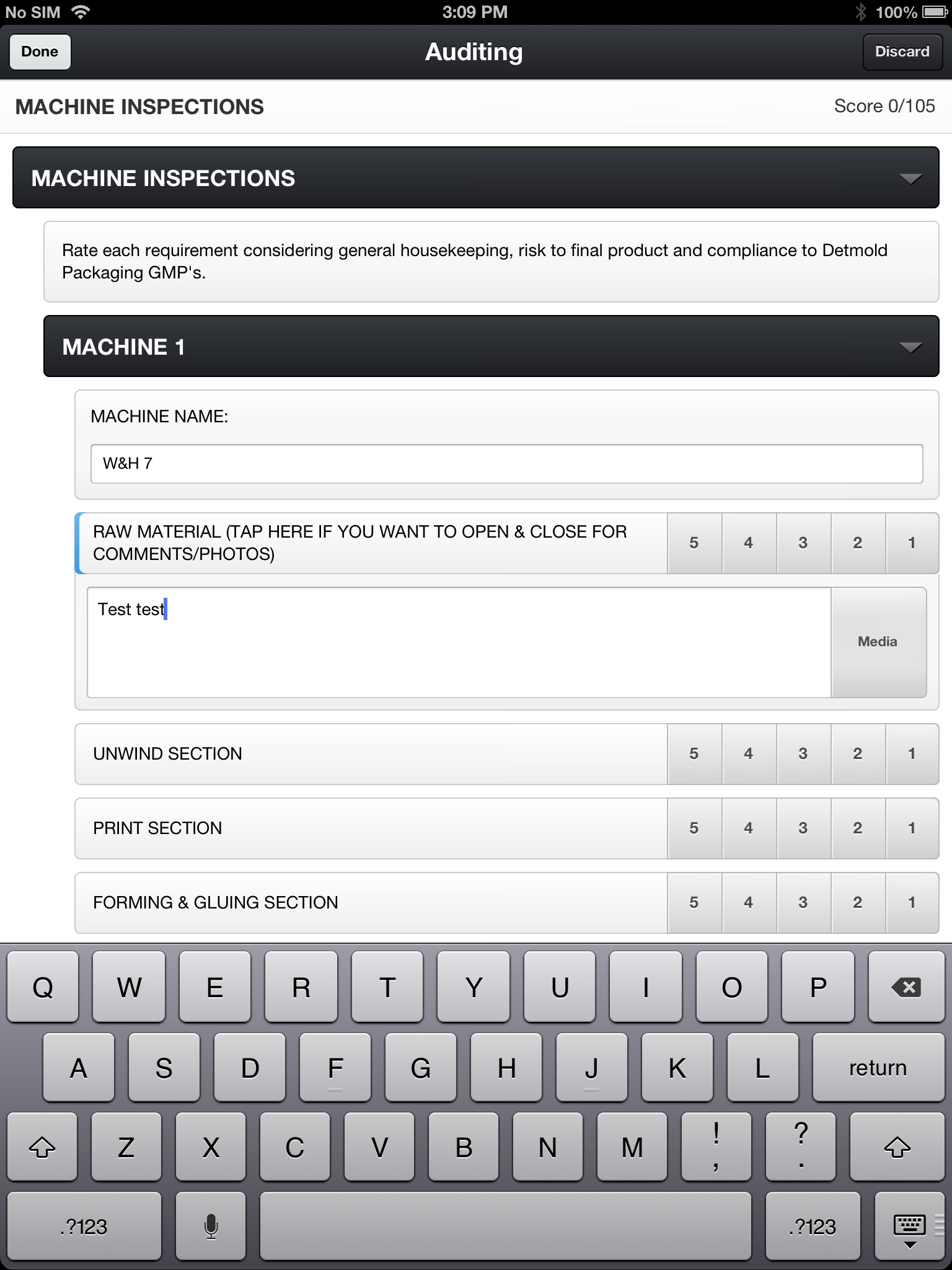

5. Add text to requirements by firstly pressing on requirement, then secondly clicking in text box (empty box next to "media").

-

6. Add photo by firstly clicking on requirement (e.g. Raw Material, Lights) which will open the media box. Then click on the "media" tab.

-

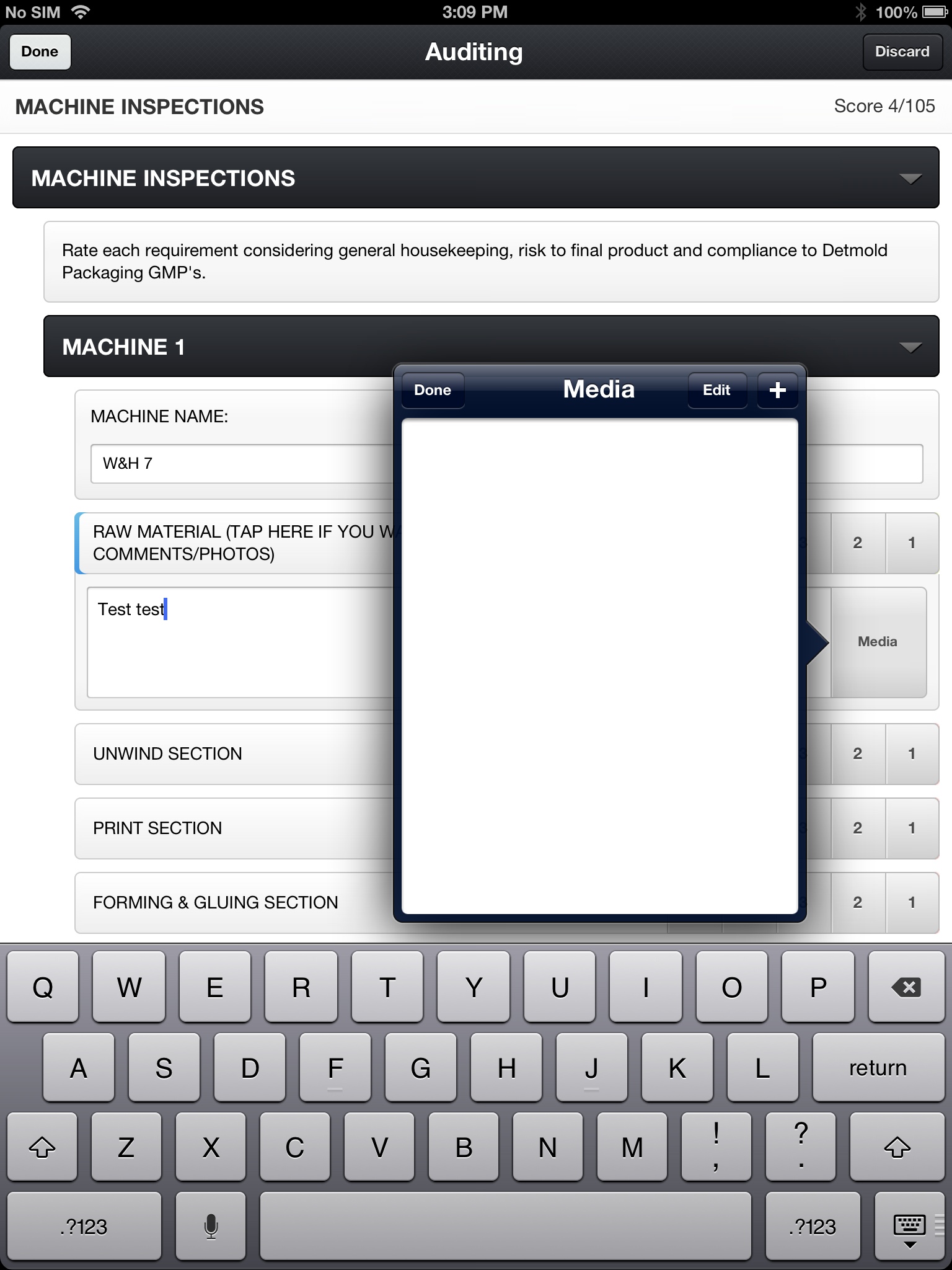

7. Then click on the + symbol to use camera.

-

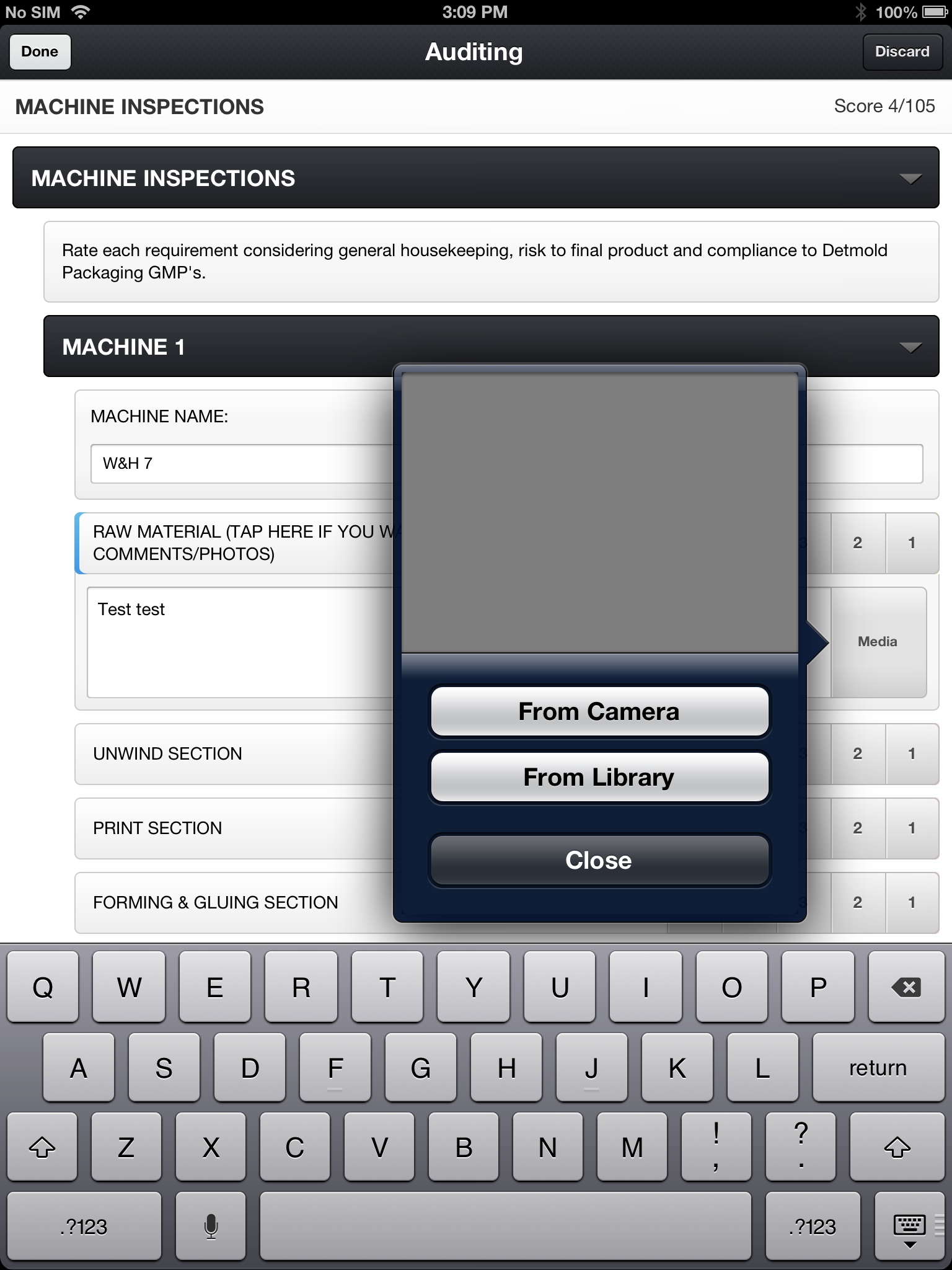

8. Then select "From Camera"

-

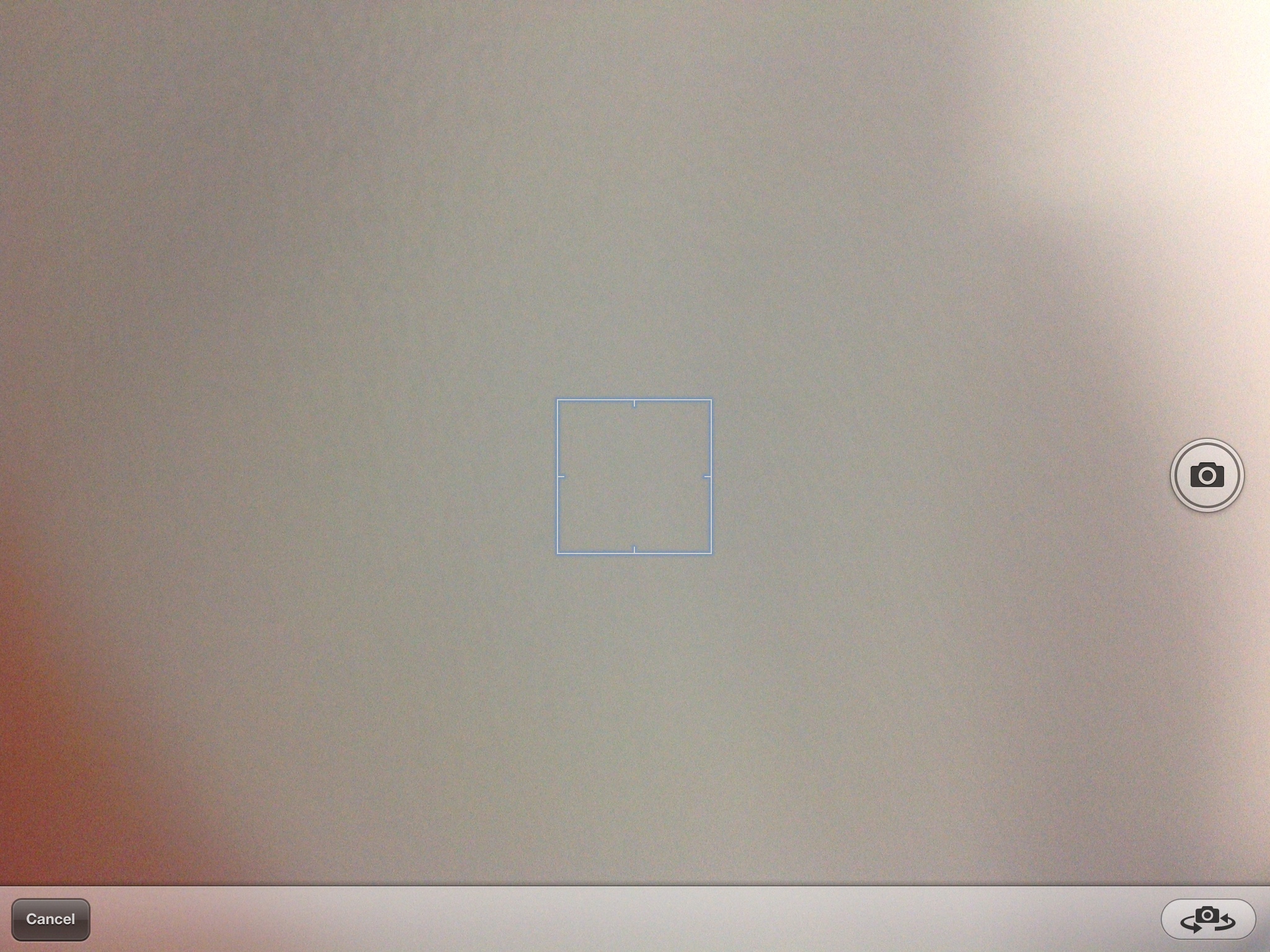

9. Take photo by clicking on the camera icon on the screen while pointing it at desired spot.

-

10. Flip through sections by clicking on the "Sections" button at the bottom of screen. Simply select the desired section.

-

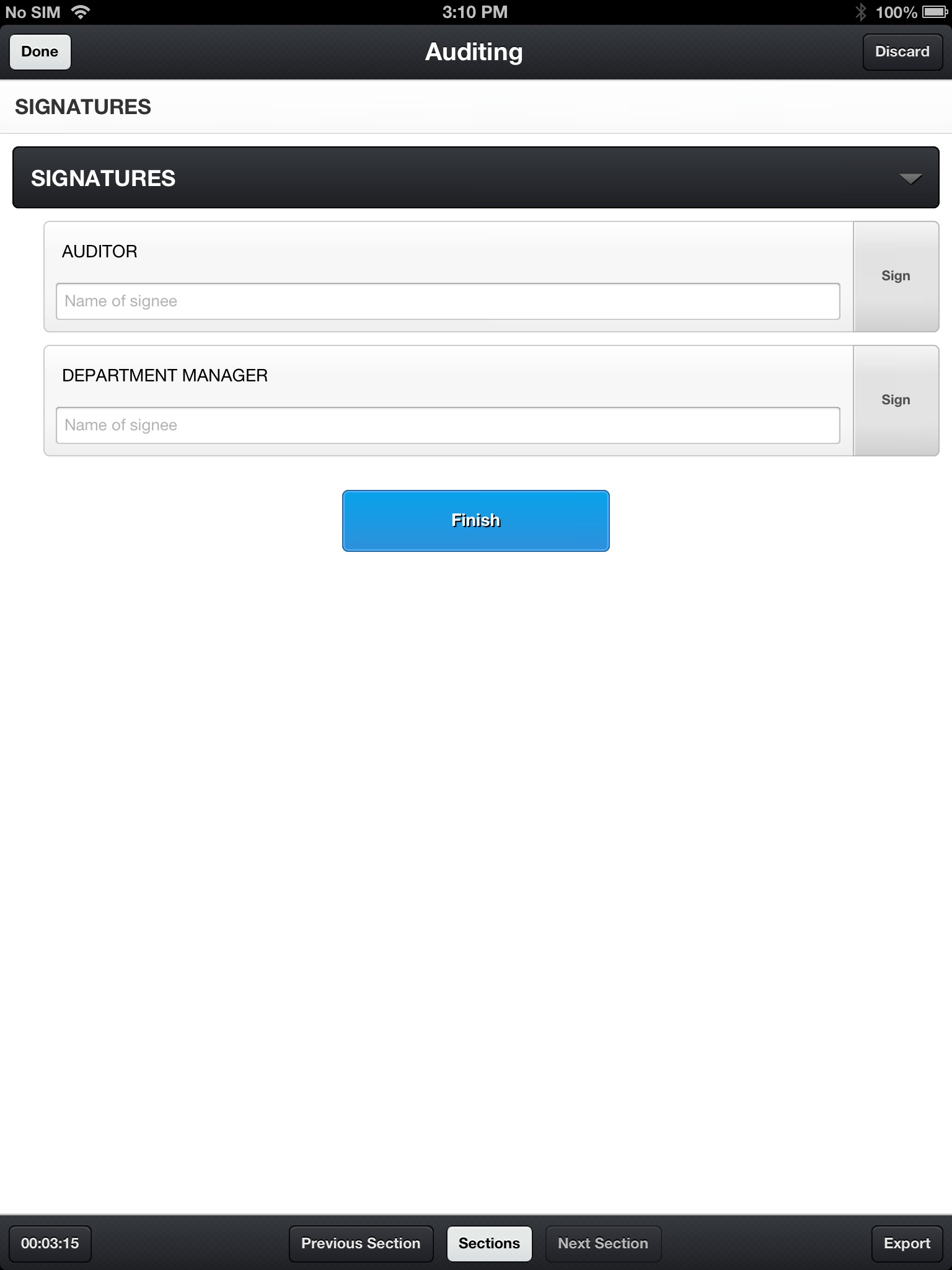

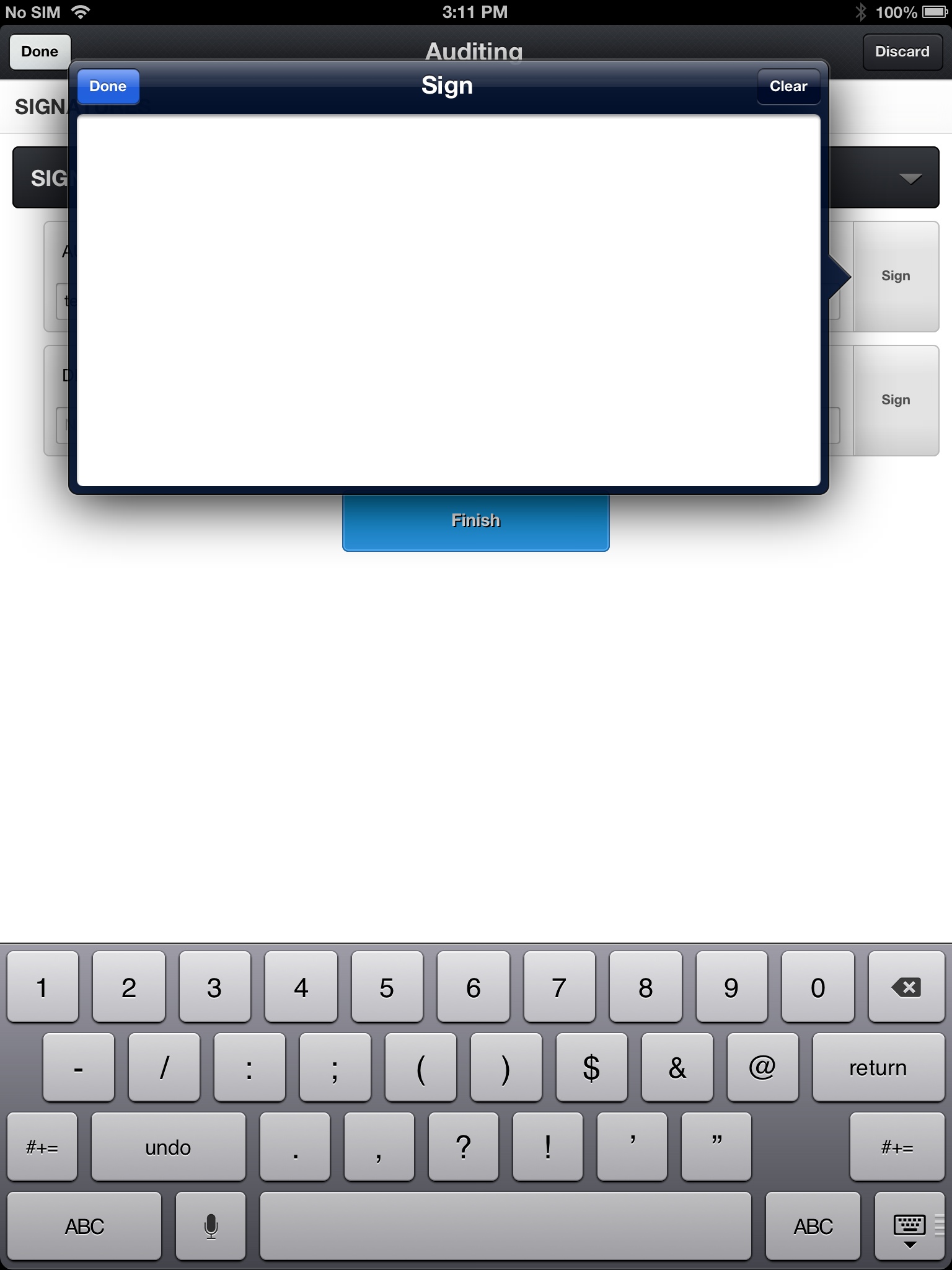

11. To complete "Signatures", select "Signatures" from Section menu. Then select "Sign".

-

12. With finger or Stylus Pen, sign drawing box

-

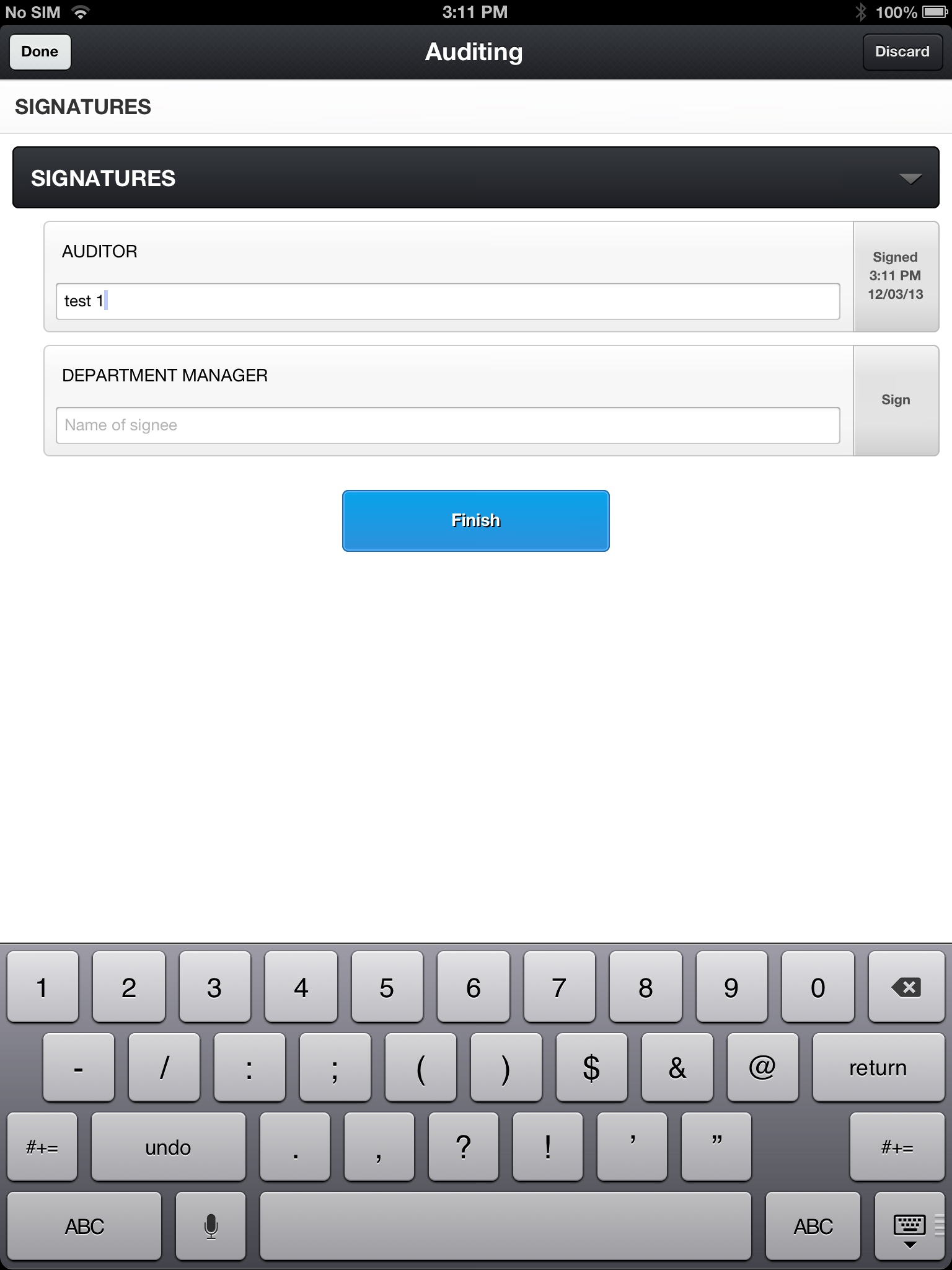

13. Put in name of Signee by selecting text box and typing in name. You will also see that the signature time and date has been auto-saved. Repeat for Department Manager.

-

14. Click on "Finish" to complete audit.

-

15. Return iPad to QA to upload audit. More to follow soon on this step....

MACHINE INSPECTIONS

1.0 MACHINE INSPECTIONS

-

Rate each requirement considering general housekeeping, risk to final product and compliance to Detmold Packaging GMP's.

MACHINE 1

-

MACHINE NAME:

-

RAW MATERIAL (TAP HERE IF YOU WANT TO OPEN & CLOSE FOR COMMENTS/PHOTOS)

-

UNWIND SECTION

-

PRINT SECTION

-

FORMING & GLUING SECTION

-

PACKING & PALLETISATION SECTION

-

MACHINE TOOLING

-

TOOLBOXES

MACHINE 2

-

MACHINE NAME:

-

RAW MATERIAL

-

UNWIND SECTION

-

PRINT SECTION

-

FORMING & GLUING SECTION

-

PACKING & PALLETISATION SECTION

-

MACHINE TOOLING

-

TOOLBOXES

MACHINE 3

-

MACHINE NAME:

-

RAW MATERIAL

-

UNWIND SECTION

-

PRINT SECTION

-

FORMING & GLUING SECTION

-

PACKING & PALLETISATION SECTION

-

MACHINE TOOLING

-

TOOLBOXES

WORK ENVIRONMENT

2.0 WORK ENVIRONMENT

-

Work environment is the general areas and sections within a department. Rate each requirement considering general housekeeping, risk to final product and compliance to Detmold Packaging GMP's.

-

PALLET AREA

-

LIGHT BOOTH

-

NOTICEBOARDS

-

SIGNAGE

-

TOOLING

-

BINS

-

CHEMICAL LABELLING & STORAGE

-

OIL & LUBE LABELLING & STORAGE

-

SAMPLE AREA

-

LOCKER AREA

-

CUPBOARDS & STORAGE

-

FLOOR CLEANLINESS ( NOT CONDITION)

-

REWORK AREA

BUILDING & MAINTENANCE

4.0 BUILDING & MAINTENANCE

-

Please rate each requirement in this section that are controlled by Building & Maintenance. This area is not considered for Gainshare.

-

AISLE DEMARCATION

-

CEILING & OVERHEAD FIXTURES

-

WALLS

-

FLOOR CONDITION (NOT CLEANLINESS)

-

LIGHTS

-

RAILS

-

HANDWASH STATIONS

-

TOILETS

-

ROLLERS DOORS

PERSONNEL REQUIREMENTS

3.0 PERSONNEL REQUIREMENTS

-

Personnel requirements relate to the plant rules. Rate each requirement considering general housekeeping, risk to final product and compliance to Detmold Packaging GMP's.

-

HAIRNETS

-

EAR PLUGS (CORDS MUST BE ATTACHED)

-

UNIFORMS

-

FOOD/DRINK

-

HANDWASHING

-

JEWELLERY

-

TOP POCKETS EMPTY

EXISTING ACTIONS

5.0 EXISTING CORRECTIVE ACTIONS

-

To continually improve or maintain housekeeping, it is important that existing corrective actions are completed. This section looks at the completion of corrective actions.

-

5 = 100% corrective actions completed, 1 = 0% corrective actions completed

SIGNATURES

SIGNATURES

-

AUDITOR

-

DEPARTMENT MANAGER