Information

-

Document No.

-

Month

-

Conducted on

-

Auditor

-

Observers

INSTRUCTIONS

Basic Use

-

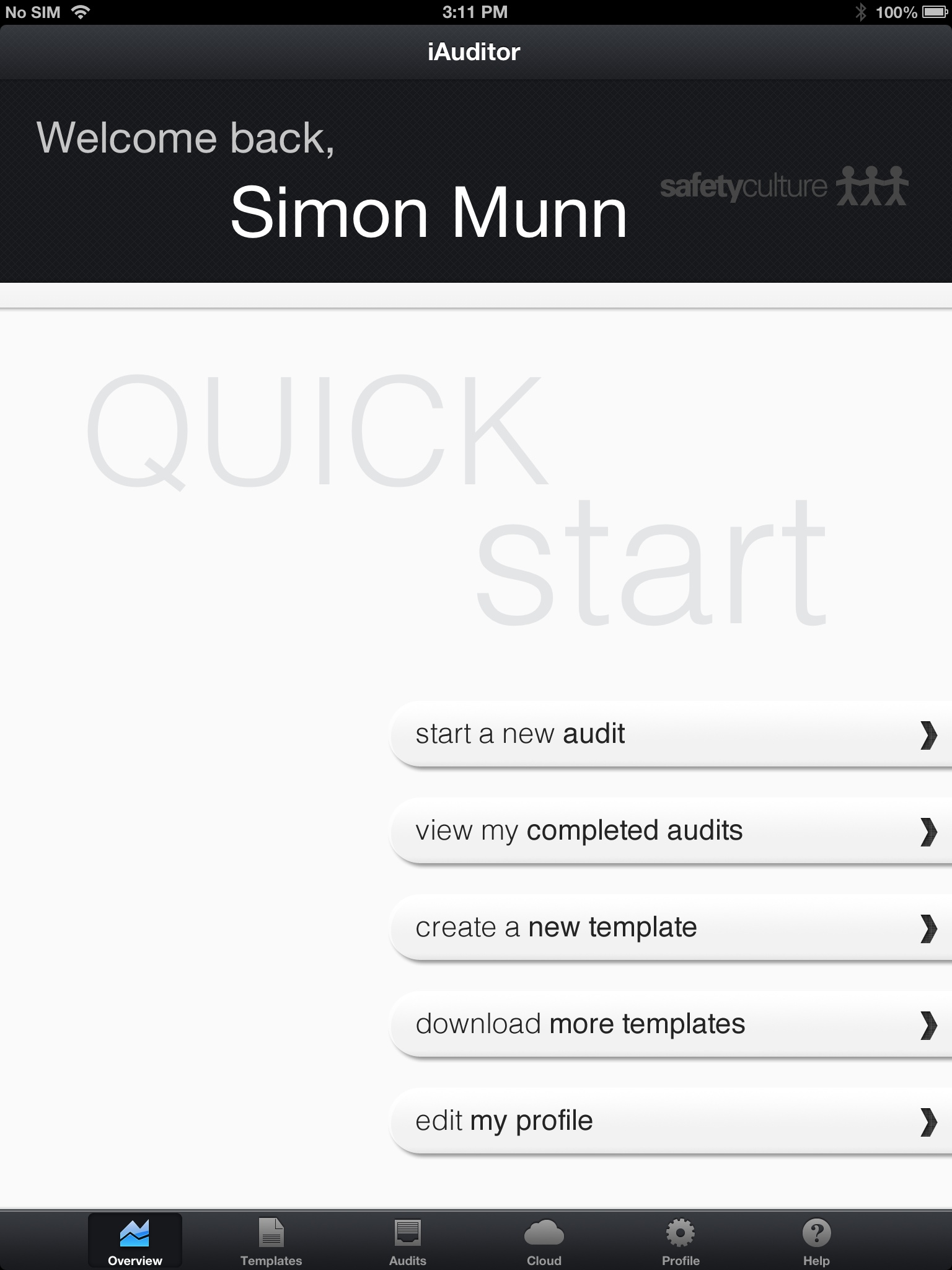

1. Select "Start a new audit".

-

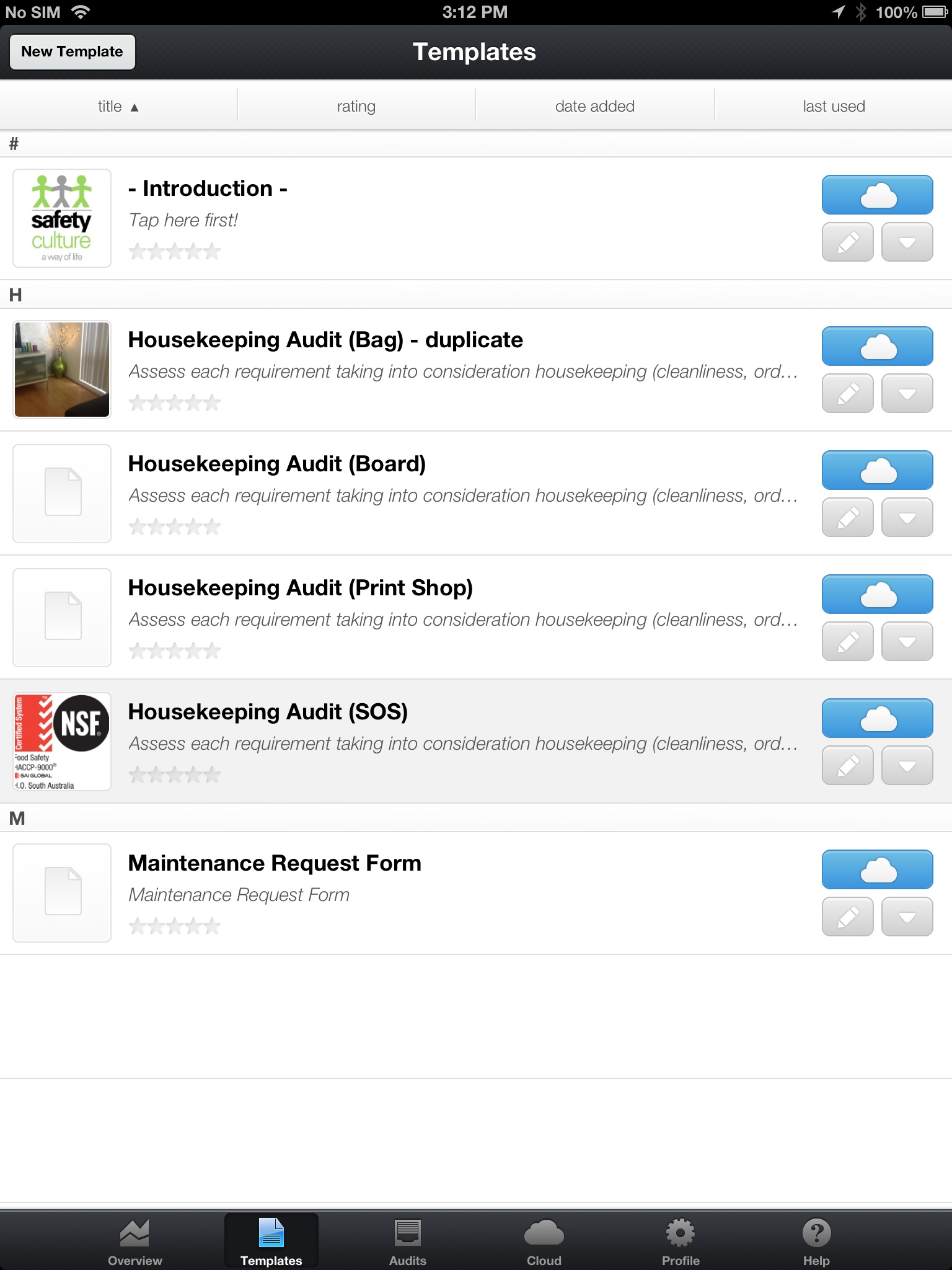

2. Select the housekeeping form for the designated department by simply press on the tab. Do not press on the pencil or cloud.

-

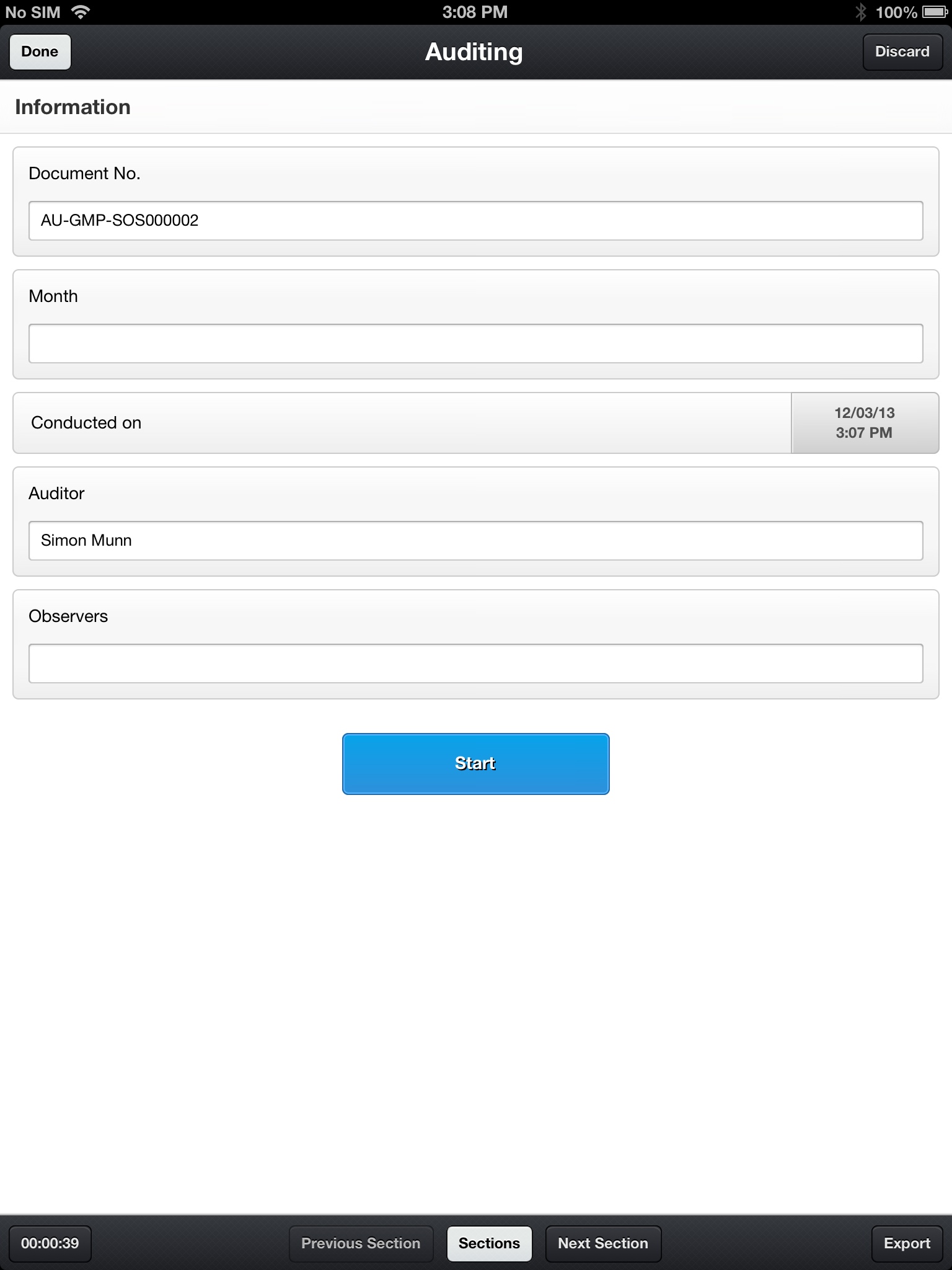

3. Fill in basic information then click on "Start".

-

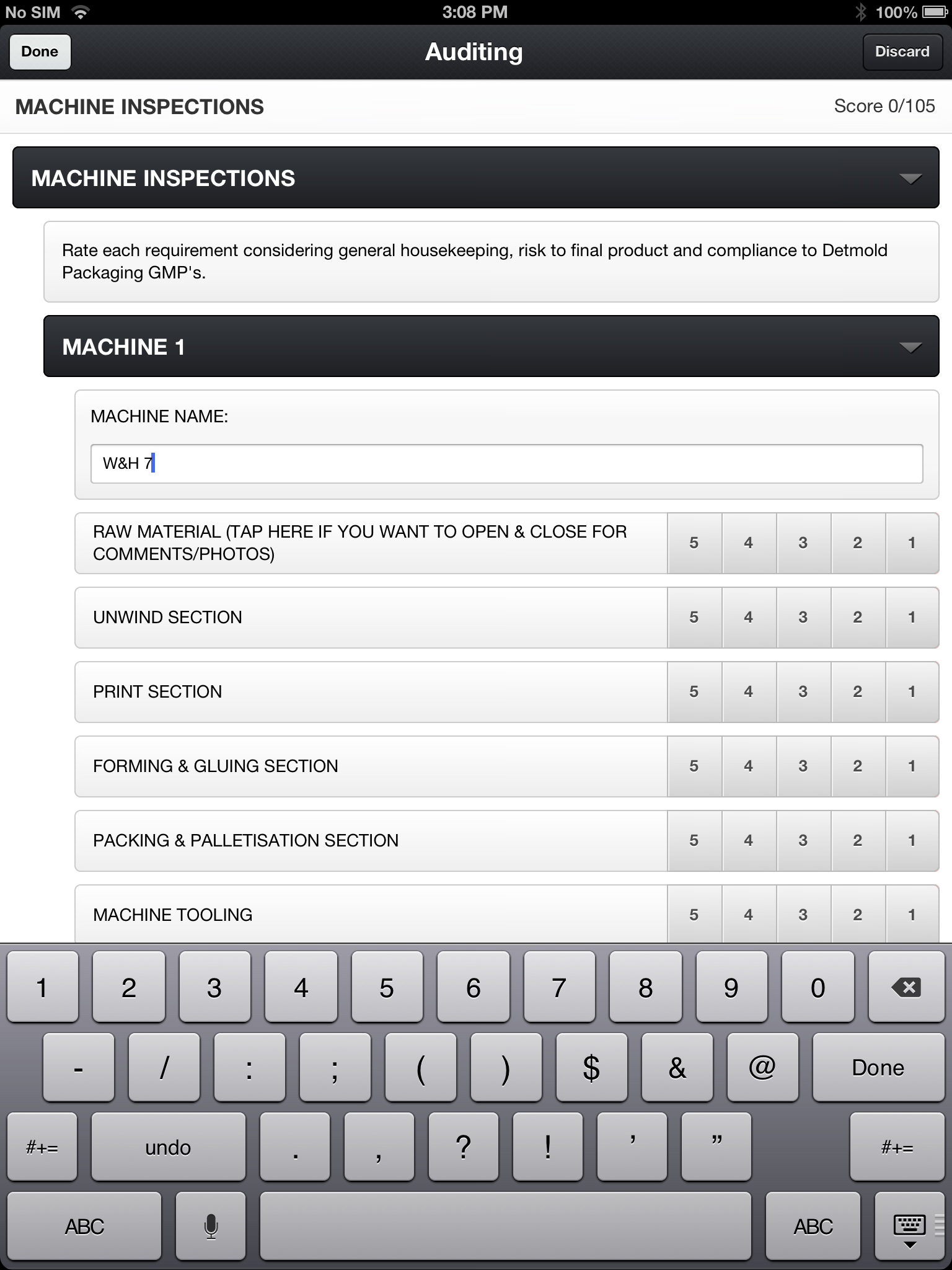

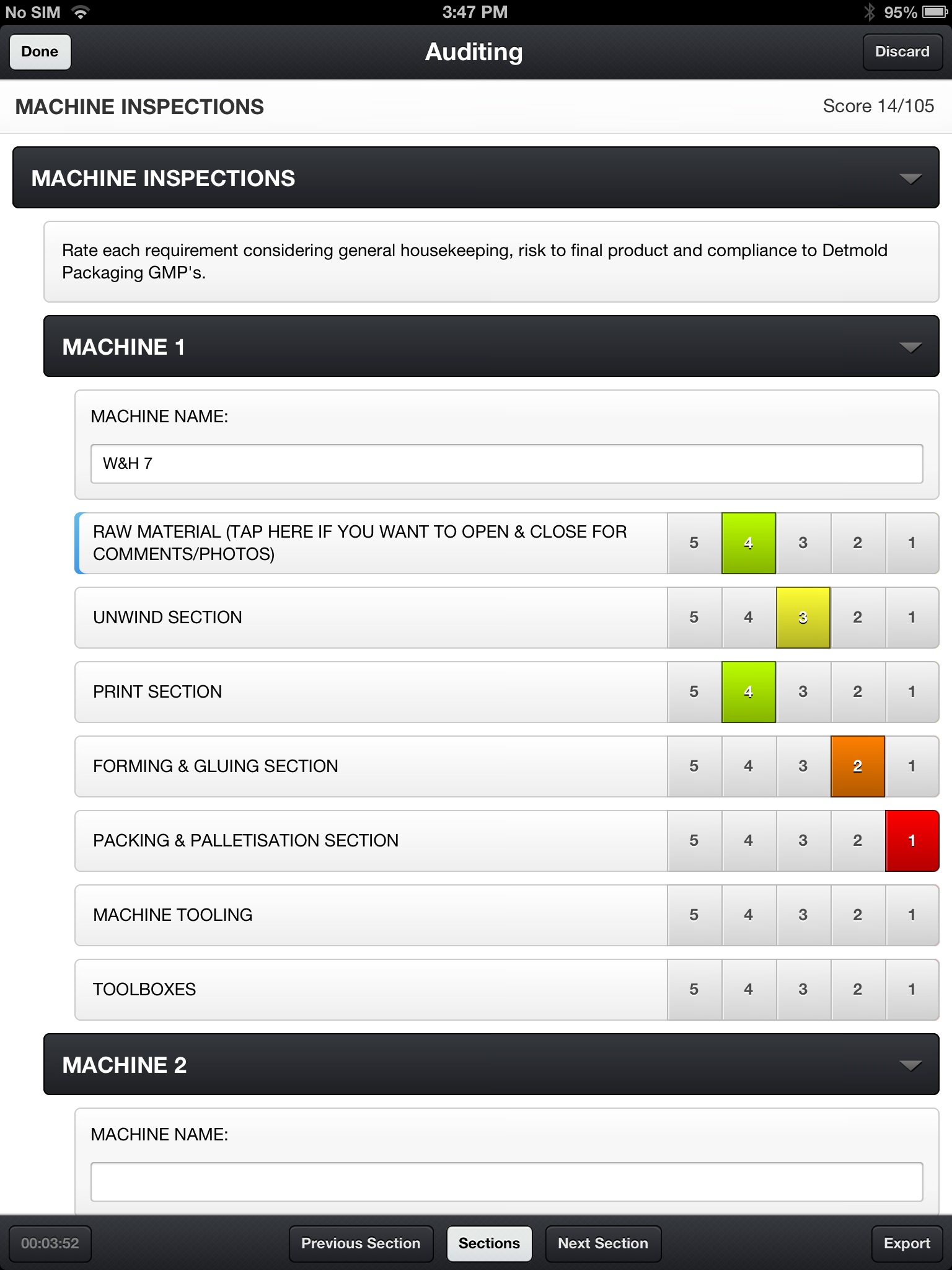

4. For machine audits, click on "Machine" text box which will bring up keyboard. Type in machine name.

-

5. Score by clicking on the number.

-

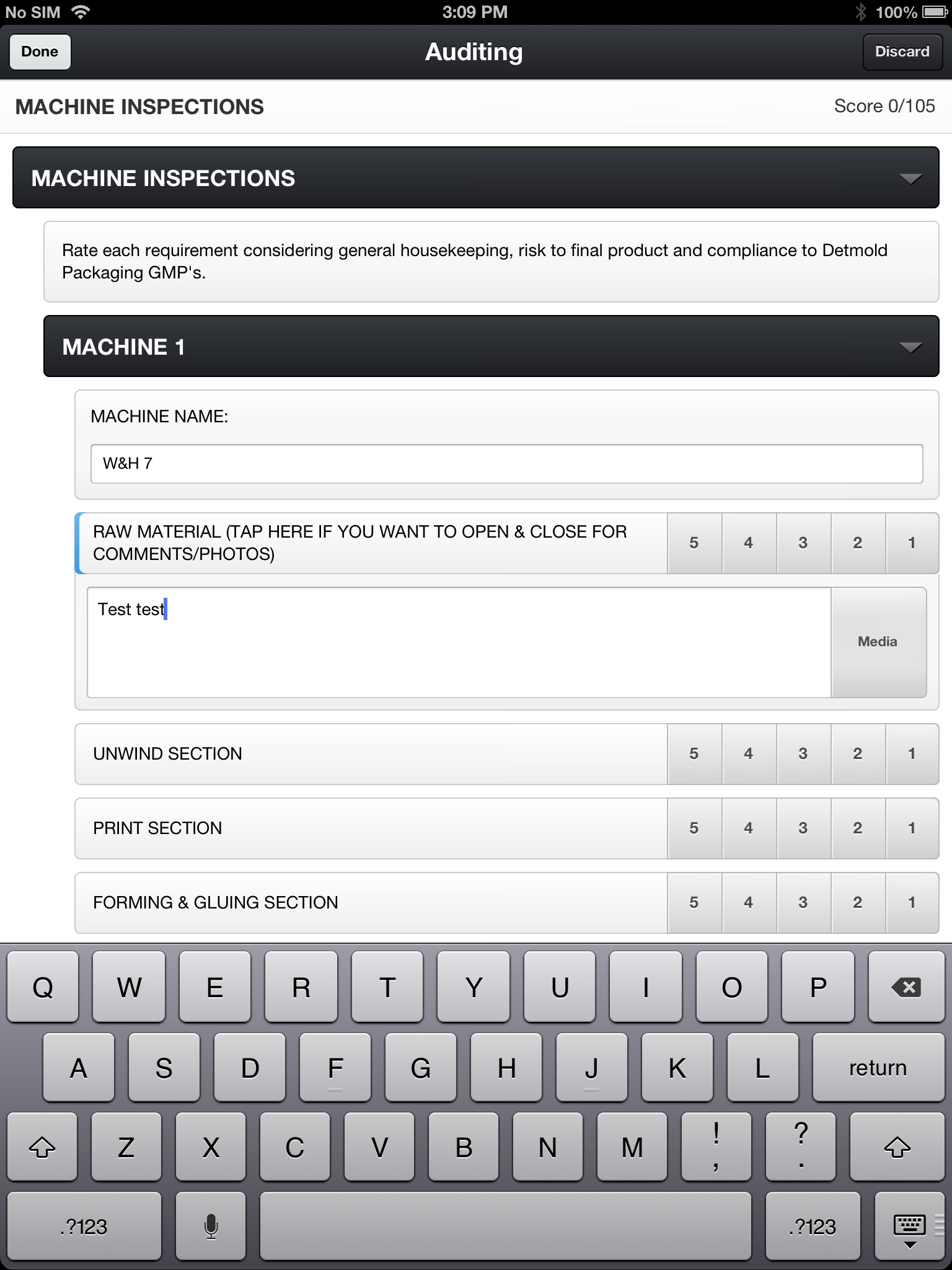

6. Add text to requirements by firstly pressing on requirement, then secondly clicking in text box (empty box next to "media").

-

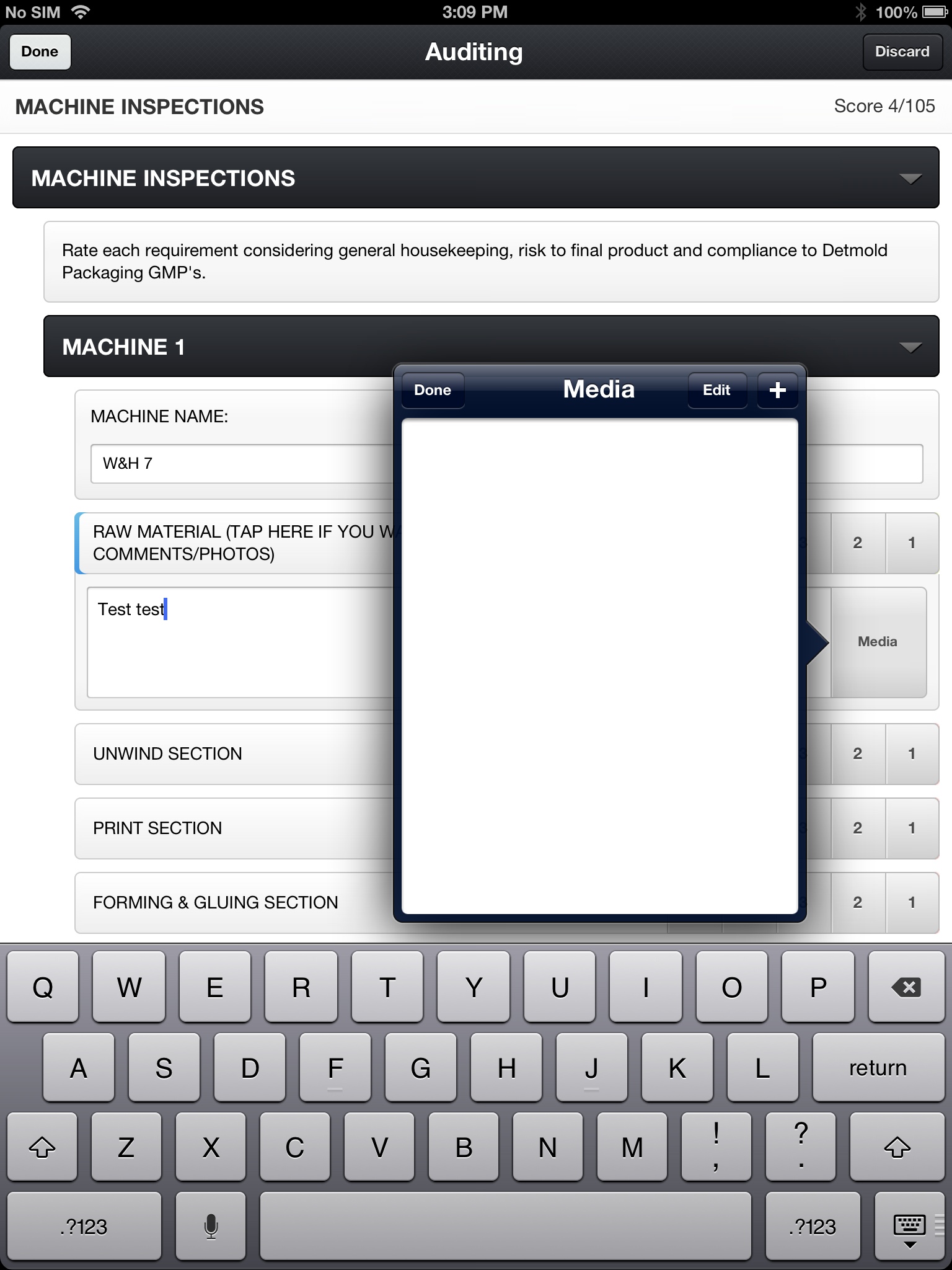

7. Add photo by firstly clicking on requirement (e.g. Raw Material, Lights) which will open the media box. Then click on the "media" tab.

-

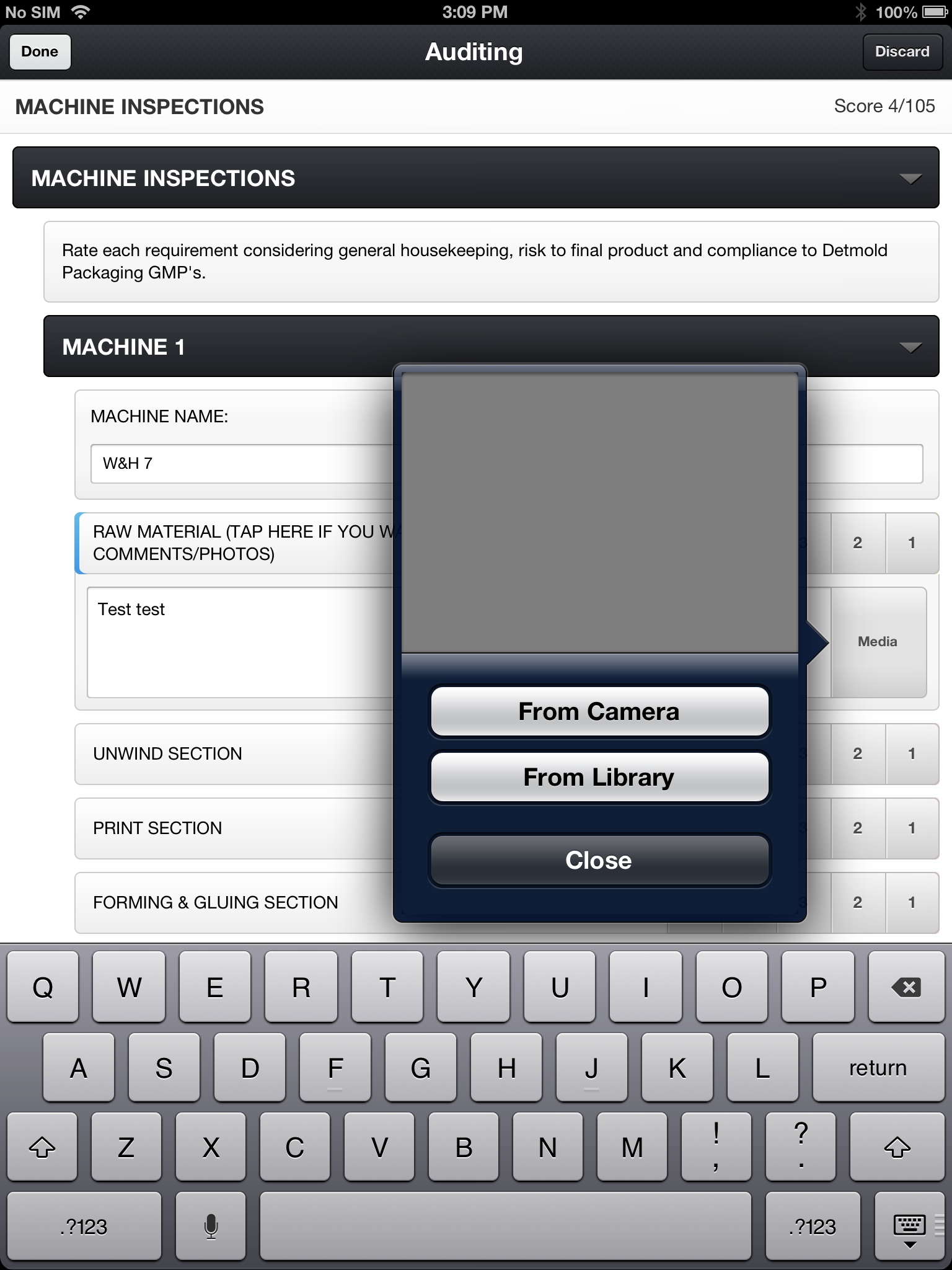

8. Then click on the + symbol to use camera.

-

9. Then select "From Camera"

-

10. Take photo by clicking on the camera icon on the screen while pointing it at desired spot.

-

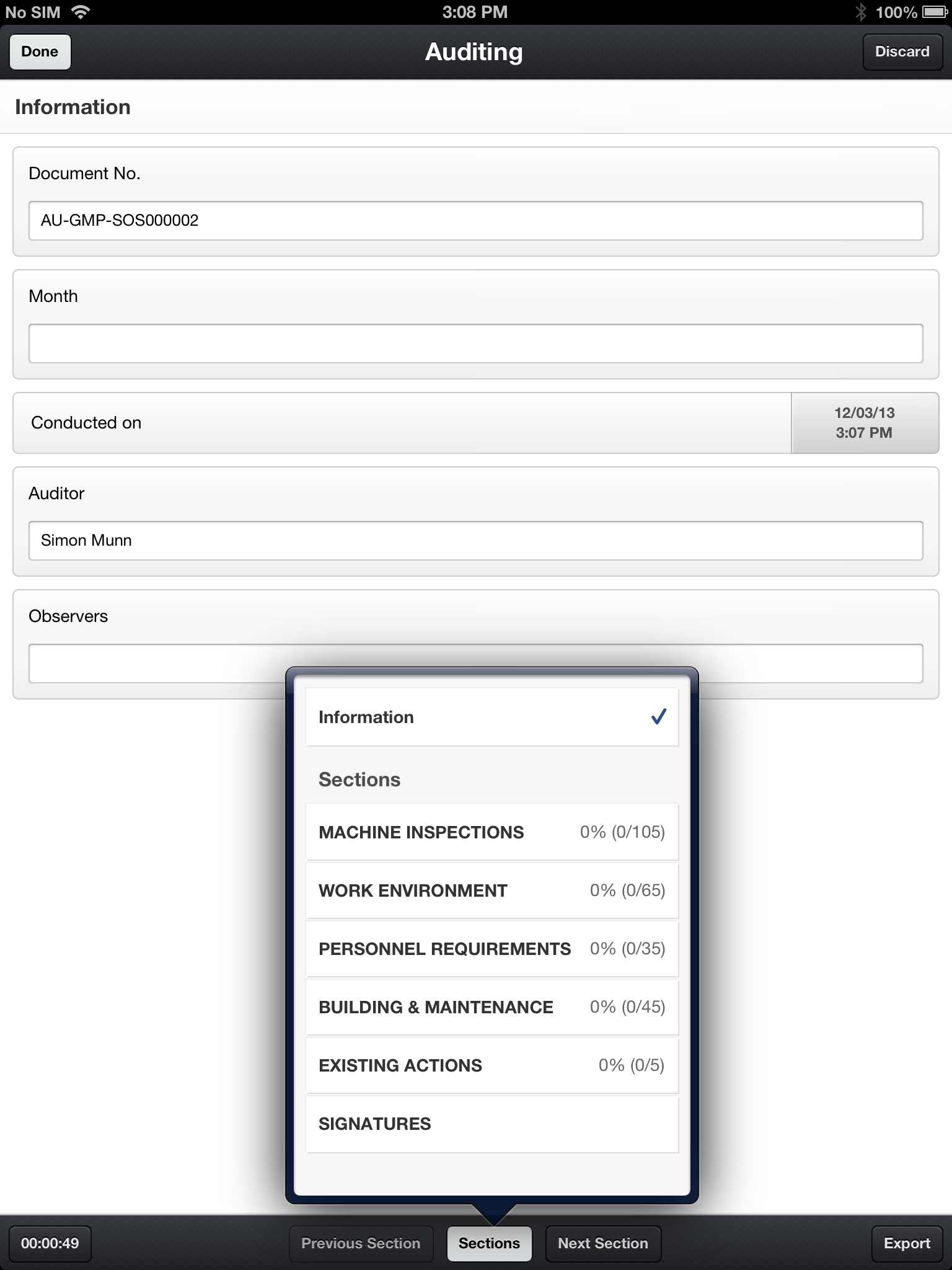

11. Flip through sections by clicking on the "Sections" button at the bottom of screen. Simply select the desired section.

-

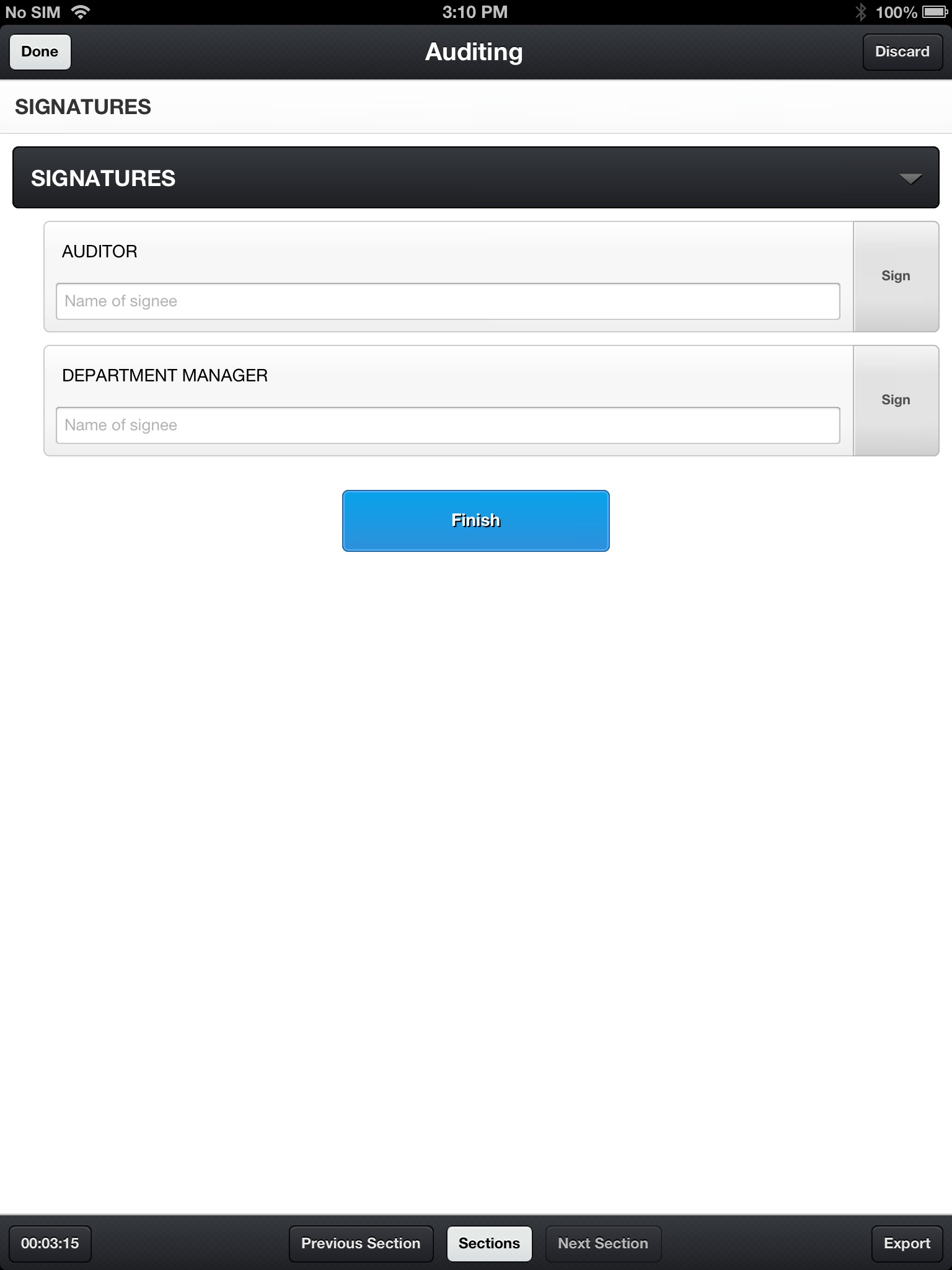

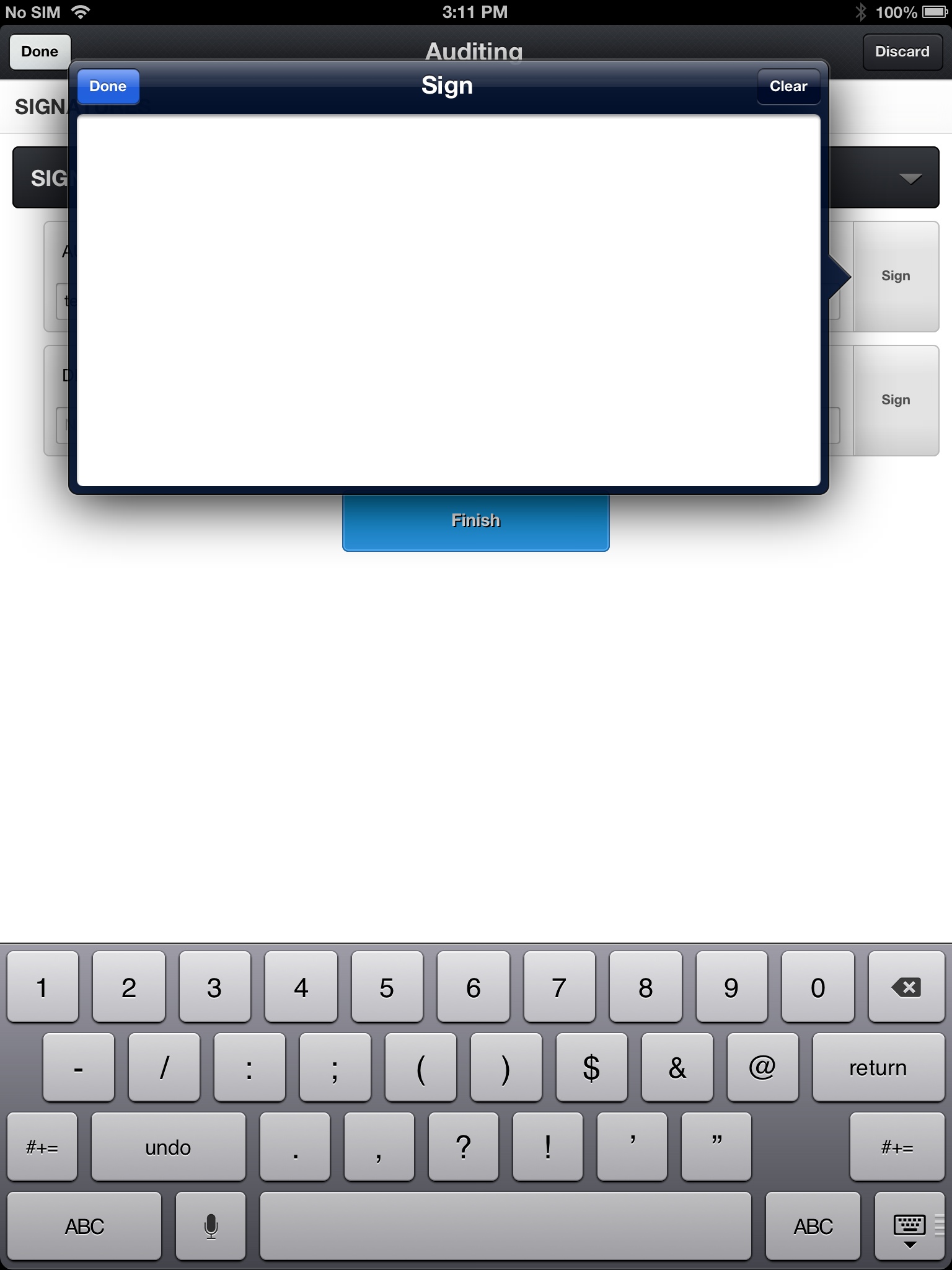

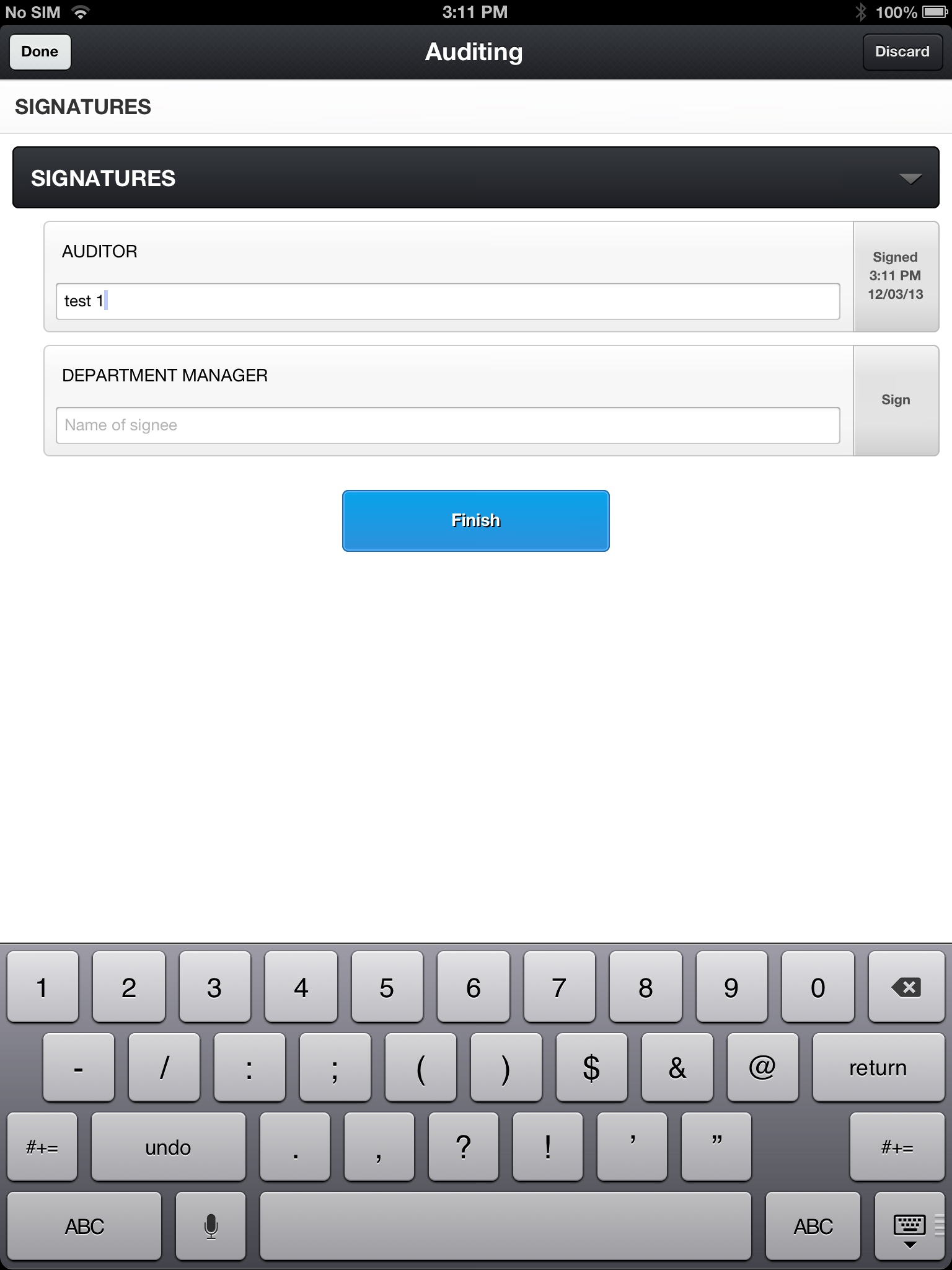

12. To complete "Signatures", select "Signatures" from Section menu. Then select "Sign".

-

13. With finger or Stylus Pen, sign drawing box

-

14. Put in name of Signee by selecting text box and typing in name. You will also see that the signature time and date has been auto-saved. Repeat for Department Manager.

-

15. Click on "Finish" to complete audit.

-

16. Return iPad to QA to upload audit. More to follow soon on this step....

WORK ENVIRONMENT

1.0 WORK ENVIRONMENT

-

Work environment is the general areas and sections within a department. Rate each requirement considering general housekeeping, risk to final product and compliance to Detmold Packaging GMP's.

-

PALLET AREA

-

COMPUTER BOOTHS

-

NOTICEBOARDS

-

SIGNAGE

-

EXTERNAL BINS AND COMPACTORS

-

LIQUID WASTE STORAGE

-

CHEMICAL, OIL & LUBE WASTE BUNDED AREA

-

SALES SAMPLE AREA

-

LOCKER AREA

-

CUPBOARDS & STORAGE

-

FLOOR CLEANLINESS ( NOT CONDITION)

PERSONNEL REQUIREMENTS

2.0 PERSONNEL REQUIREMENTS

-

Personnel requirements relate to the plant rules. Rate each requirement considering general housekeeping, risk to final product and compliance to Detmold Packaging GMP's.

-

HAIRNETS

-

EAR PLUGS (CORDS MUST BE ATTACHED)

-

UNIFORMS

-

FOOD/DRINK

-

HANDWASHING

-

JEWELLERY

-

TOP POCKETS EMPTY

BUILDING & MAINTENANCE

3.0 BUILDING & MAINTENANCE

-

Please rate each requirement in this section that are controlled by Building & Maintenance. This area is not considered for Gainshare.

-

AISLE DEMARCATION

-

CEILING & OVERHEAD FIXTURES

-

WALLS

-

FLOOR CONDITION (NOT CLEANLINESS)

-

LIGHTS

-

RAILS

-

HANDWASH STATIONS

-

TOILETS

-

ROLLERS DOORS

EXISTING ACTIONS

4.0 EXISTING CORRECTIVE ACTIONS

-

To continually improve or maintain housekeeping, it is important that existing corrective actions are completed. This section looks at the completion of corrective actions.

-

5 = 100% corrective actions completed, 1 = 0% corrective actions completed

SIGNATURES

SIGNATURES

-

AUDITOR

-

DEPARTMENT MANAGER