Title Page

-

Store

-

Location

-

Conducted on (Date and Time)

-

Inspected by

Risk, Evacuation and Fire.

Types of Risk

-

Fire🔥Evacuation ➡️Theft 💰 Accident🚑 <br>Operations manager understands types of risk?

-

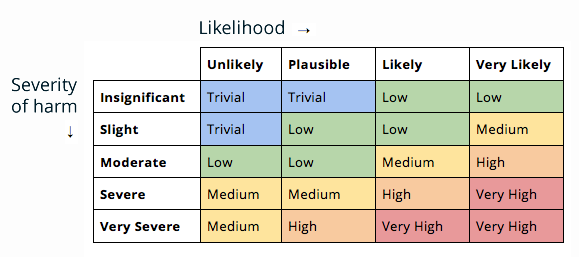

Risk Assessment & Probability.

-

Operations Manager understands risk assessment and probability?

Evacuation

-

Evacuation plan is known by all team mates?

-

Evacuation plan has been tested each quarter and record is kept of those tests?

-

Evacuation map is displayed on exit doors and internal rooms of our building?

-

Evacuation map and Emergency plan are reviewed as required and are kept up to date?

Fire Safety Equipment is fully functioning and tested regularly.

-

Are extinguishers are clear of obstruction?

-

Extinguisher layout matches that of the original extinguisher map?

-

Condition of extinguishers is reviewed monthly as part of monthly checks?

-

Are all emergency exits clear of blockage and the exit signs in good condition?

Power Shutdown

-

Emergency lighting is adequate should the store experience a power shutdown.

-

Front doors open in response to shutdown?

-

Emergency tannoy is available for use in event of a power shutdown?

-

Internal doors remain available to open in response to power shutdown?

-

Personal assistance alarms remain available in response to power shutdown?

-

Access out of lift is available in the event of a power shutdown?

Security

Intruder Alarm

-

Intruder alarm is fully functioning and protects entire site?

-

Alarm panel stores only up to date passwords. Old employee pins are removed?

-

All members of our team know what to do in the event of an armed robbery?

-

All members of our team know what to do in the event of a fire?

-

Are our technical rooms locked* and clear of obstruction/waste?

-

Chemicals are stored in locked units ,cossh files are available?

-

Mandatory signage and CCTV is available in our cash office?

-

Visitors to our store are signed in and out of our premise?

-

Clock in board is available to show employees on site at any given point of the day?

Department H&S checks

-

Department H&S checks are scheduled to take place after moves. Records are kept of checks.

-

Alongside standard H&S check, specific checks tailored to the needs of the department are considered during official check?

-

Test Zones are safe and checked regularly?

Workshop

-

PPE is available to all workshop technicians?

-

Chemicals are store in locked units. Cossh files are available?

-

Customer Details are not displayed in areas viewable by the general public?

-

Machines have operating procedures and personnel guidance available?

-

First aid kit is available in workshop?

Delivery Bay

-

Waste is controlled?

-

Fixtures are safe and tidy?

-

Machines have operating procedures and personnel guidance available?

-

Delivery Bay has PPE available for use to those working on delivery?

-

Manual handling poster is displayed in bay?

-

First aid kit is available in bay?

Car Park and Outside

-

Are test areas safe?

-

Are assembly points and routes clear?

-

Is shop front in good repair?

-

Are guidance lines for parking clear?

-

Are grounds in good repair?

Training & General Safety

Training and General Safety

-

Are all employees properly inducted and training and certification up to date? <br>

-

Are your employees actively and meaningfully involved in workplace safety programs? (i.e. participate in accident investigations, self inspection, committees, etc.)

-

Are accidents, near misses and injuries being investigated and are unsafe conditions being corrected, reported/documented in a timely manner?

Completion

Recommendation

-

Write recommendations here

Completion

-

Full Name and Signature of Inspector