Title Page

-

Conducted on

-

Prepared by

-

Location

Plant or Equipment Details

-

Name of Plant or Equipment

-

Where and how is the Plant or Equipment used?

-

Does the Plant or Equipment require registration with the regulator?

-

Describe the layout and physical conditions of areas of operation (including access and egress).

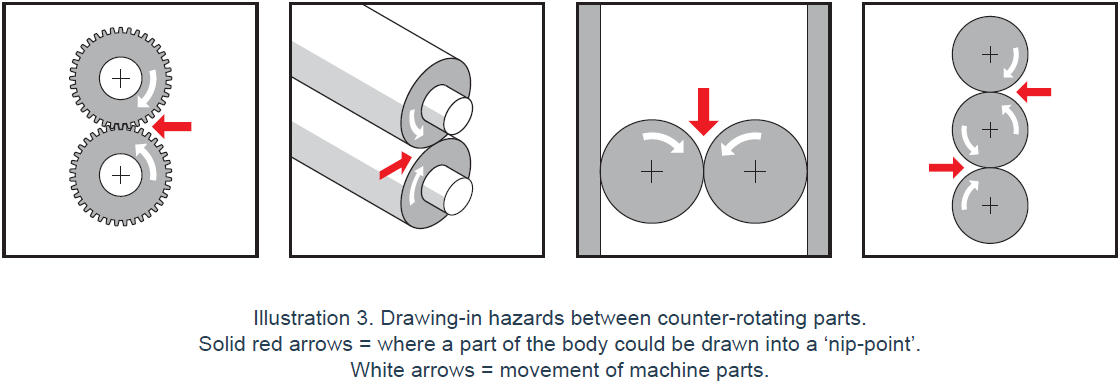

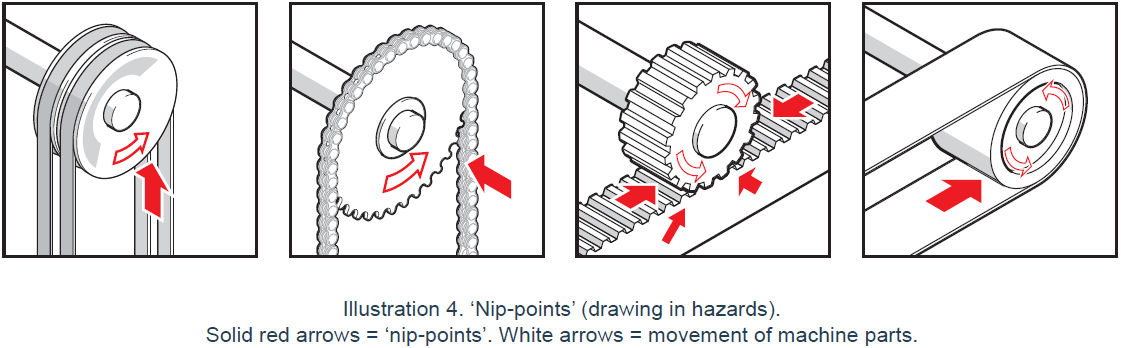

Drawing In / Trapping

-

Can a part of the body be drawn into or trapped in a 'nip-point’?

-

-

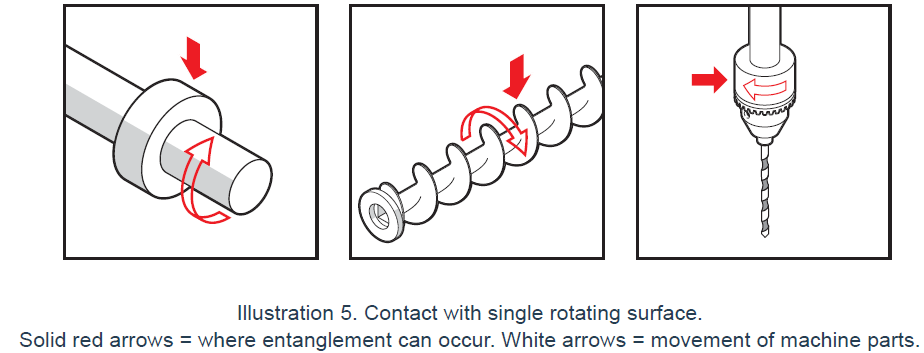

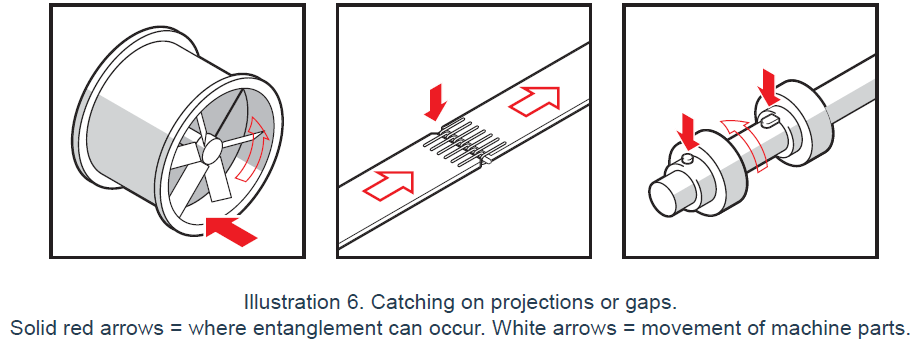

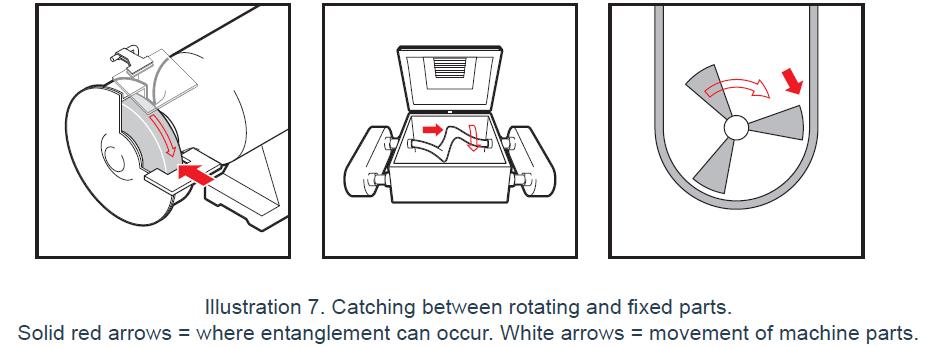

Entanglement

-

Can anyone’s hair, clothing, gloves, necktie, jewellery, cleaning brushes, rags or other materials become entangled with moving parts of the plant, or materials in motion?

-

-

-

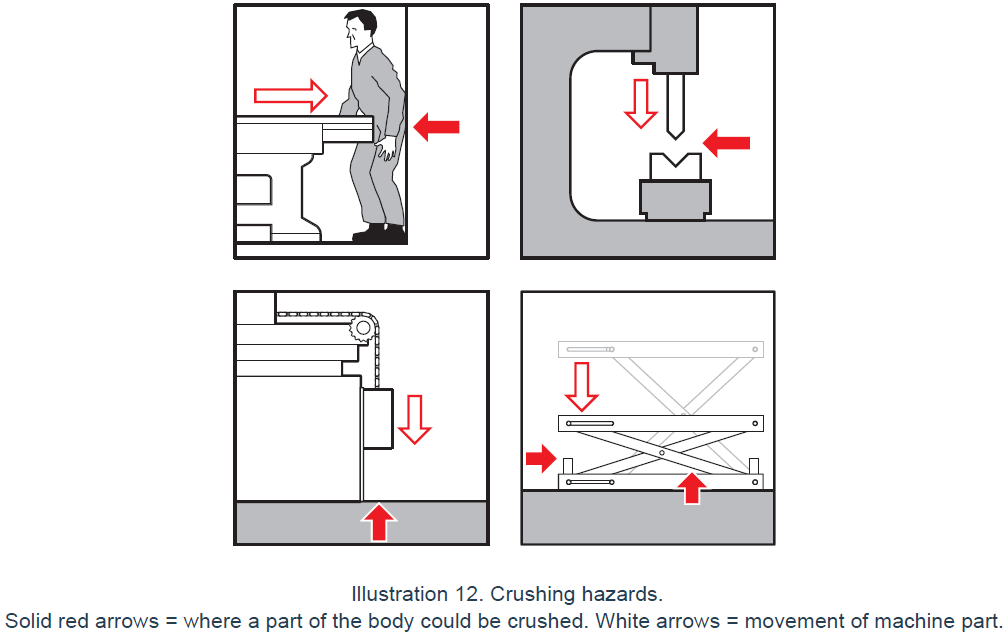

Crushing

-

Can anyone be crushed due to:<br>• material falling off the plant?<br>• uncontrolled or unexpected movement of the plant or its load?<br>• lack of capacity for the plant to be slowed, stopped or immobilised?<br>• the plant tipping or rolling over? <br>• parts of the plant collapsing?<br>• coming into contact with moving parts of the plant during testing, inspection, operation, maintenance, cleaning or repair?<br>• being thrown off or under the plant?<br>• being trapped between the plant and materials or fixed structures?

-

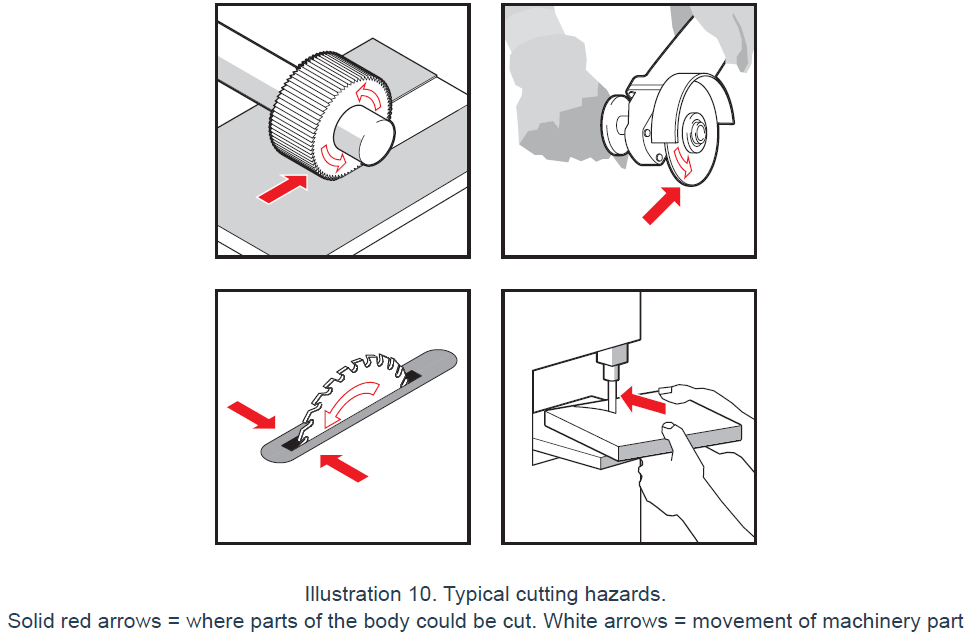

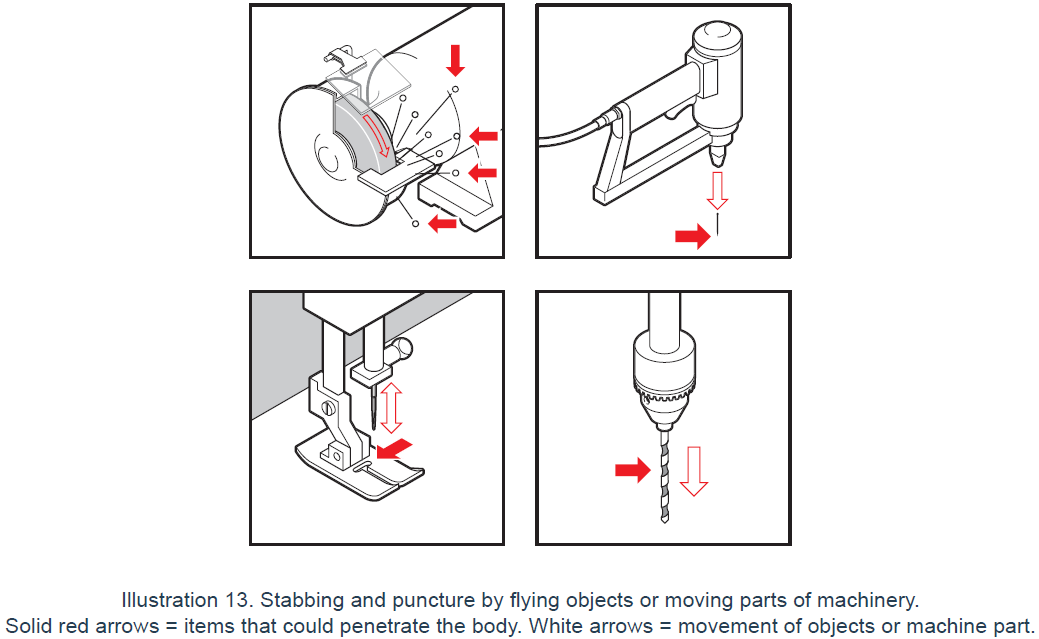

Cutting, stabbing and puncturing

-

Can anyone be cut, stabbed or punctured?

-

-

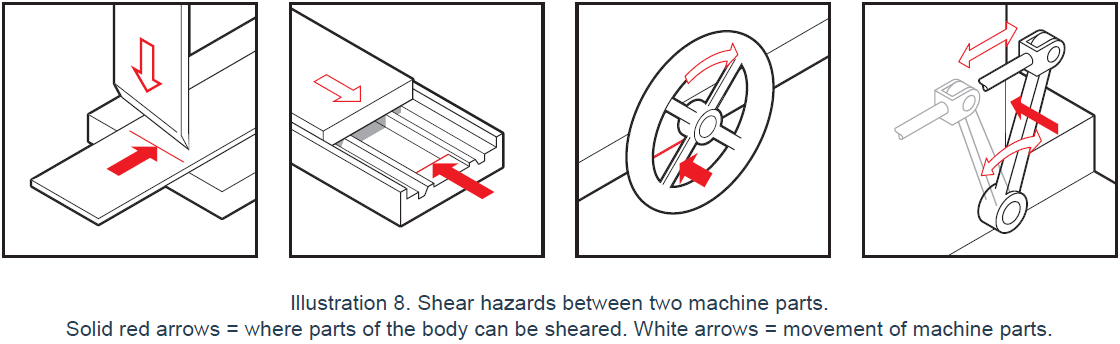

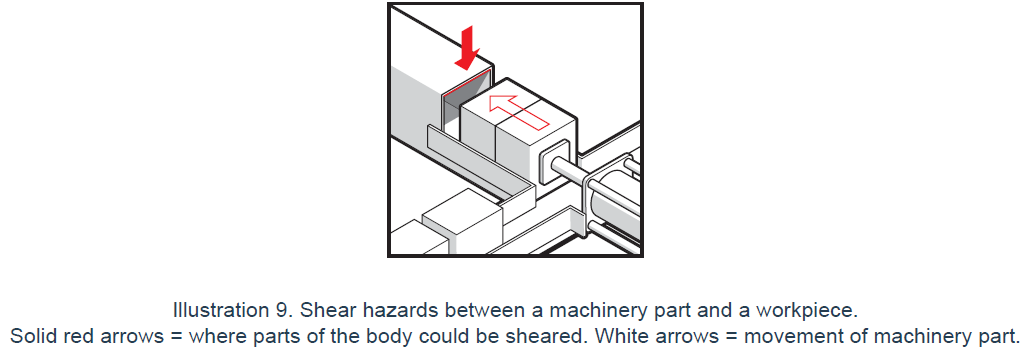

Shearing

-

Can anyone’s body parts be sheared between two parts of the plant or between a part of the plant and a work piece or structure?

-

-

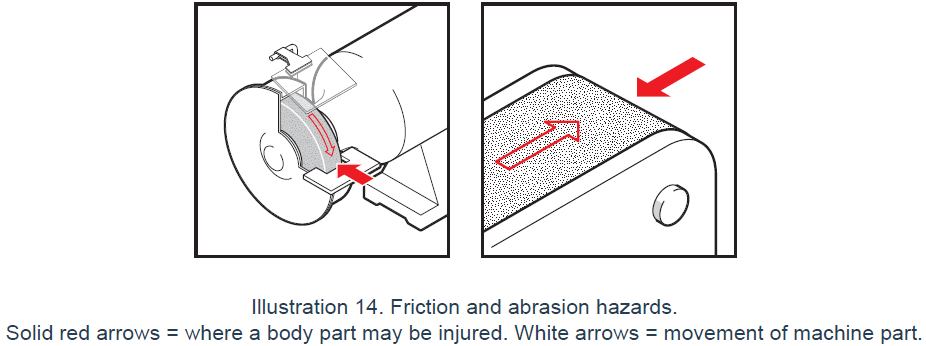

Friction

-

Can anyone be burnt due to contact with moving parts or surfaces of the plant, or material handled by the plant?

-

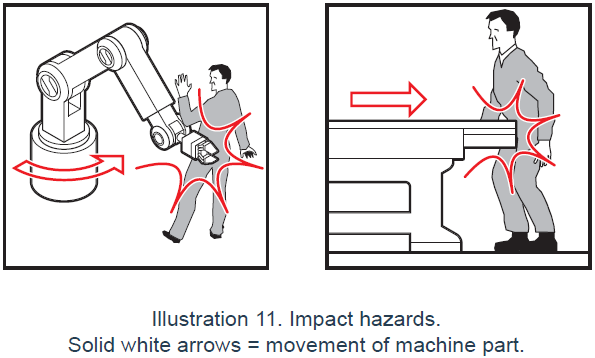

Striking / Impact

-

Can anyone be struck by moving objects due to:<br>• uncontrolled or unexpected movement of the plant or material handled by the plant? <br>• the plant, parts of the plant or work pieces disintegrating? <br>• work pieces being ejected? <br>• the mobility of the plant?<br>

-

Other Hazards

-

Can anyone come into contact with fluids under high pressure due to plant failure or misuse of the plant?

-

Can anyone be injured by electrical shock or burnt due to:<br>• the plant contacting live electrical conductors <br>• the plant working in close proximity to electrical conductors? <br>• overload of electrical circuits?<br>• damaged or poorly maintained electrical leads or cables? <br>• damaged electrical switches? <br>• water near electrical equipment?<br>• lack of isolation procedures?<br>

-

Can anyone be injured by explosion of gases, vapours, liquids, dusts or other substances triggered by the operation of the plant or by materials handled by the plant?

-

Can anyone using the plant, or in the vicinity of the plant, slip, trip or fall due to:<br>• uneven or slippery work surfaces?<br>• poor housekeeping?<br>• obstacles being placed in the vicinity of the plant?<br>

-

Can anyone fall from a height due to:<br>• lack of proper work platform?<br>• lack of proper stairs or ladders?<br>• lack of guardrails or other suitable edge protection?<br>• unprotected holes, penetrations or gaps?<br>• poor floor or walking surfaces such as the lack of slip resistant surface?<br>• steep walking surfaces?<br>• collapse of the supporting structure?<br>

-

Can anyone be injured due to:<br>• poorly designed seating?<br>• repetitive body movement?<br>• constrained body posture or the need for excessive effort?<br>• design deficiency causing mental or psychological stress?<br>• inadequate or poorly placed lighting?<br>• lack of consideration given to human error or human behaviour?<br>• mismatch of the plant with human traits and natural limitations?<br>

-

Can anyone be suffocated due to lack of oxygen or atmosphere contamination?

-

Can anyone be injured by fire or come into contact with objects at high temperature?<br>

-

Can anyone suffer ill-health due to exposure to high or low temperatures?

-

Can anyone be injured or suffer ill health from exposure to:<br>• chemicals<br>• toxic gases or vapours<br>• fumes<br>• dust<br>• noise<br>• vibration <br>• radiation

Current Controls

-

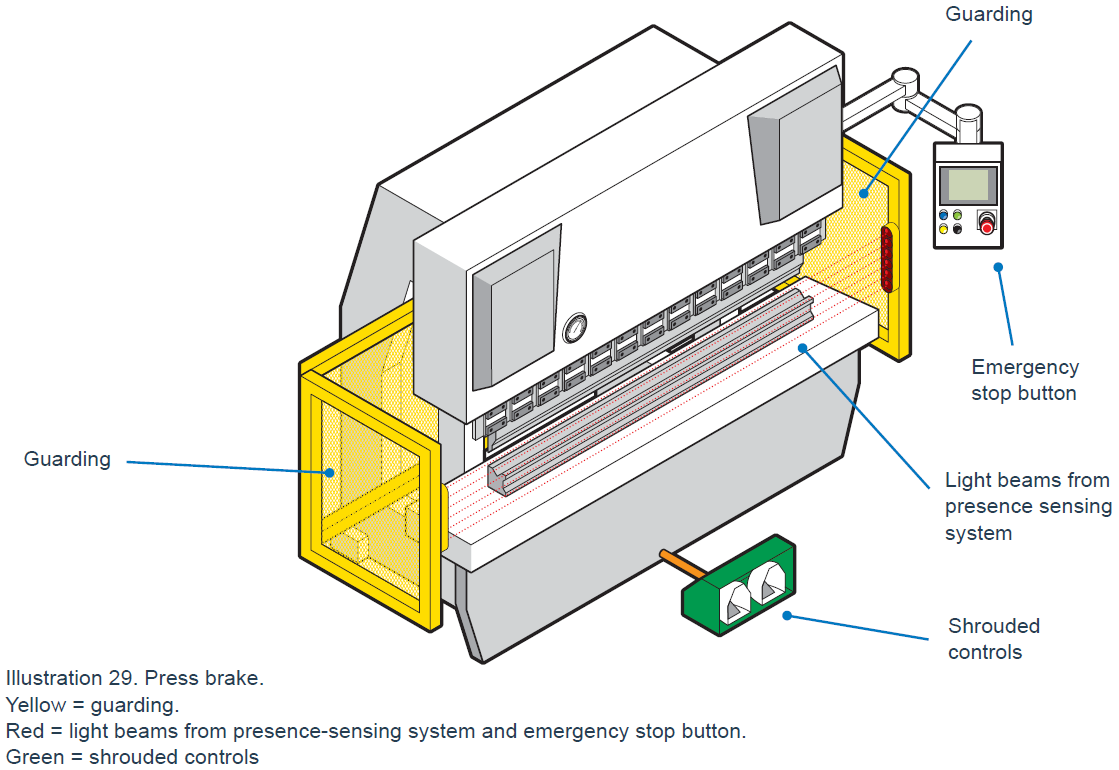

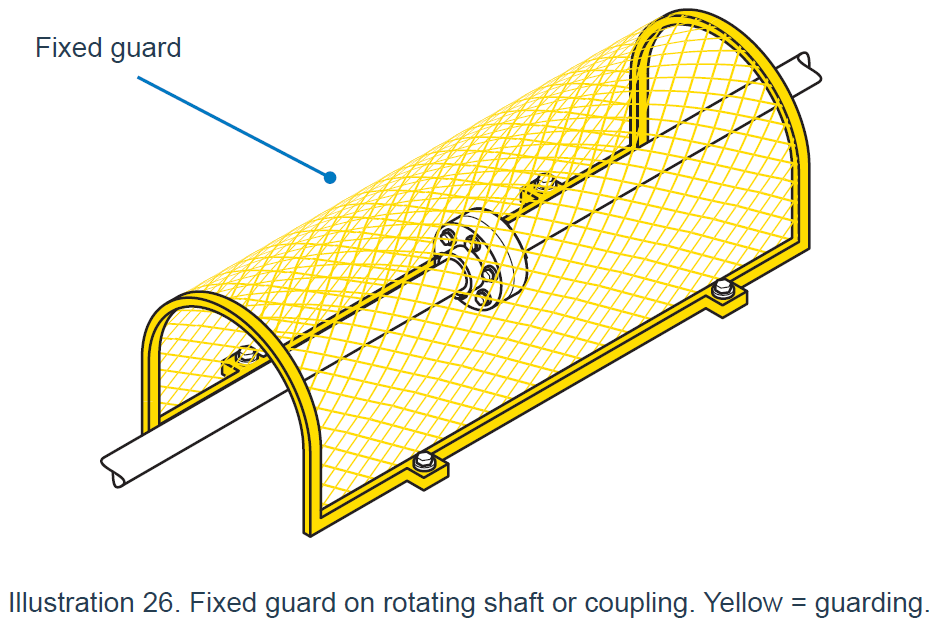

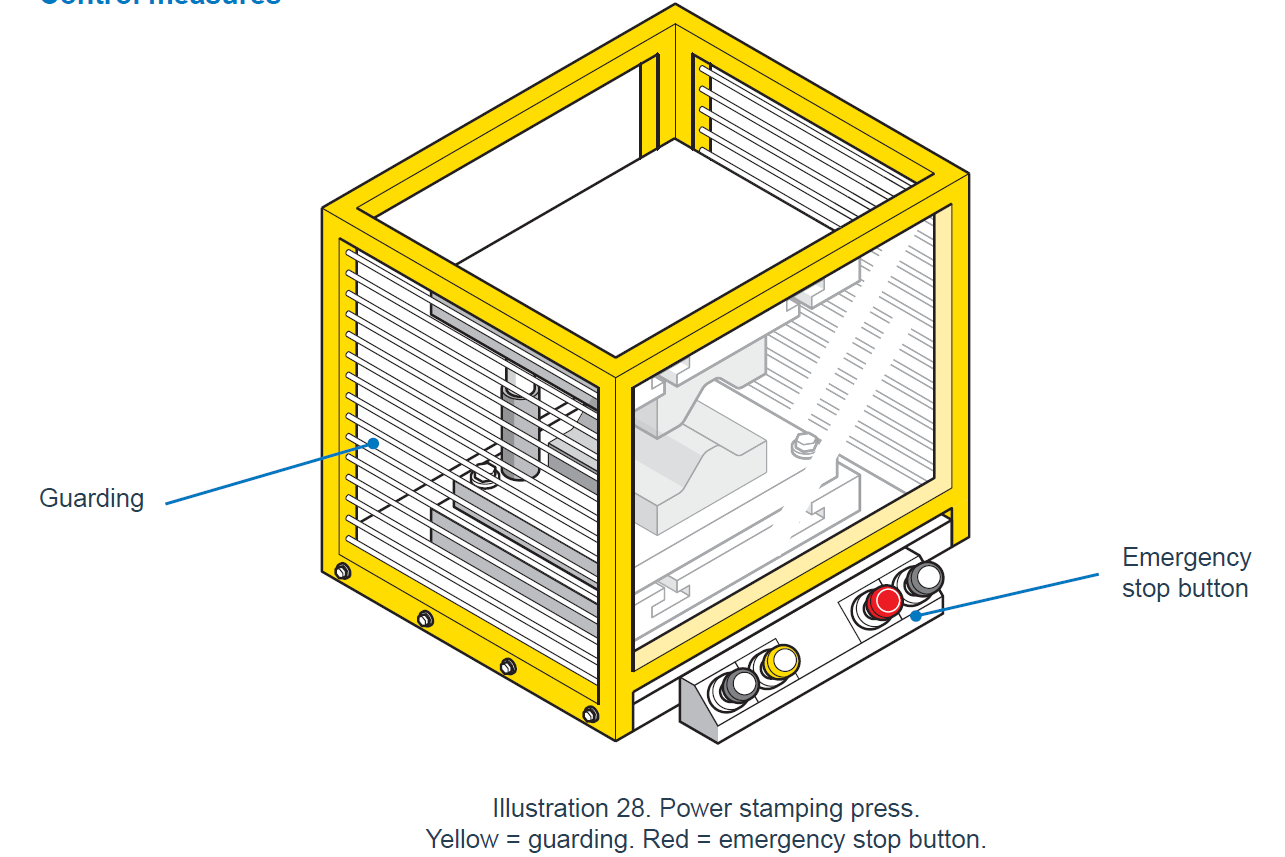

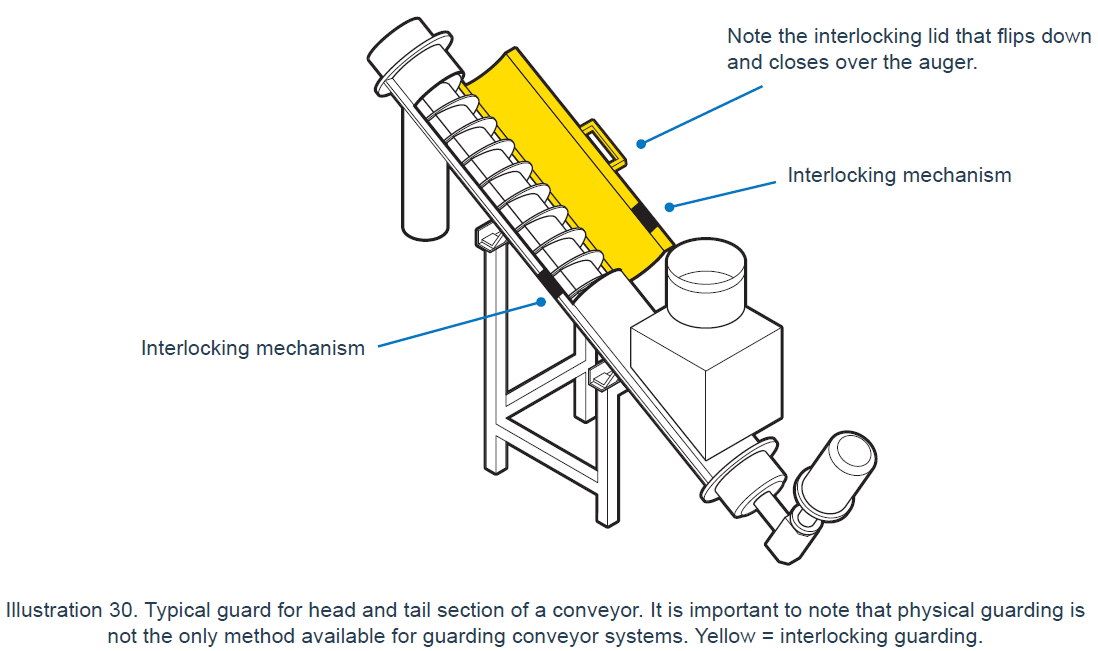

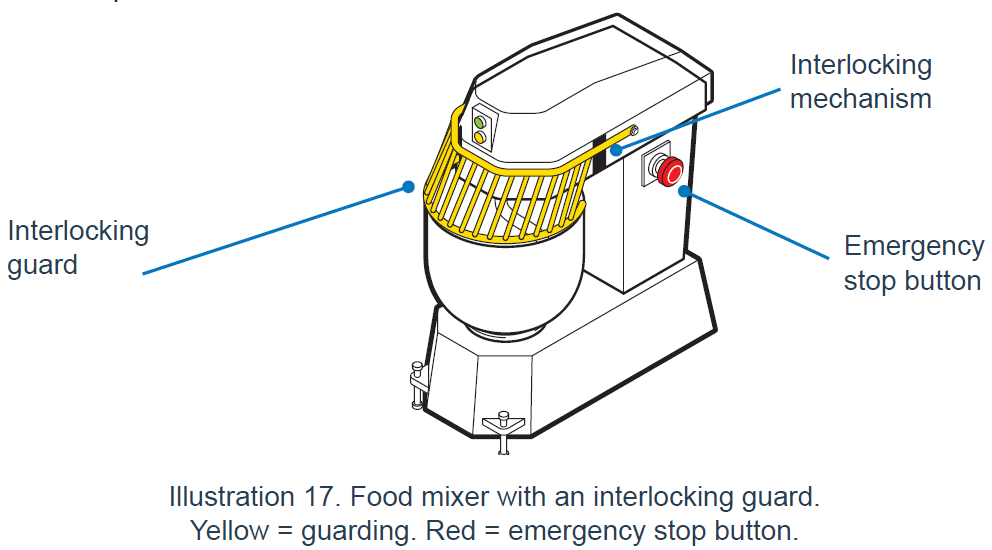

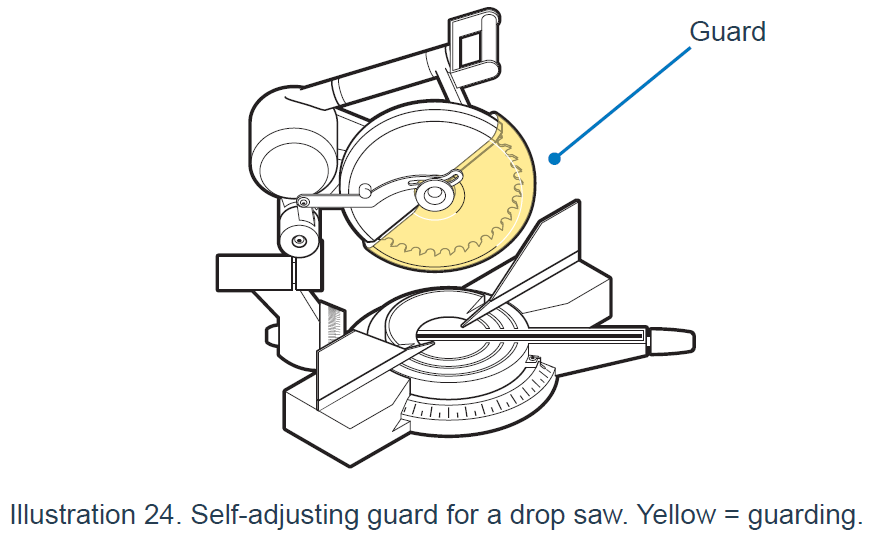

Is guarding installed?

-

Select guarding installed...

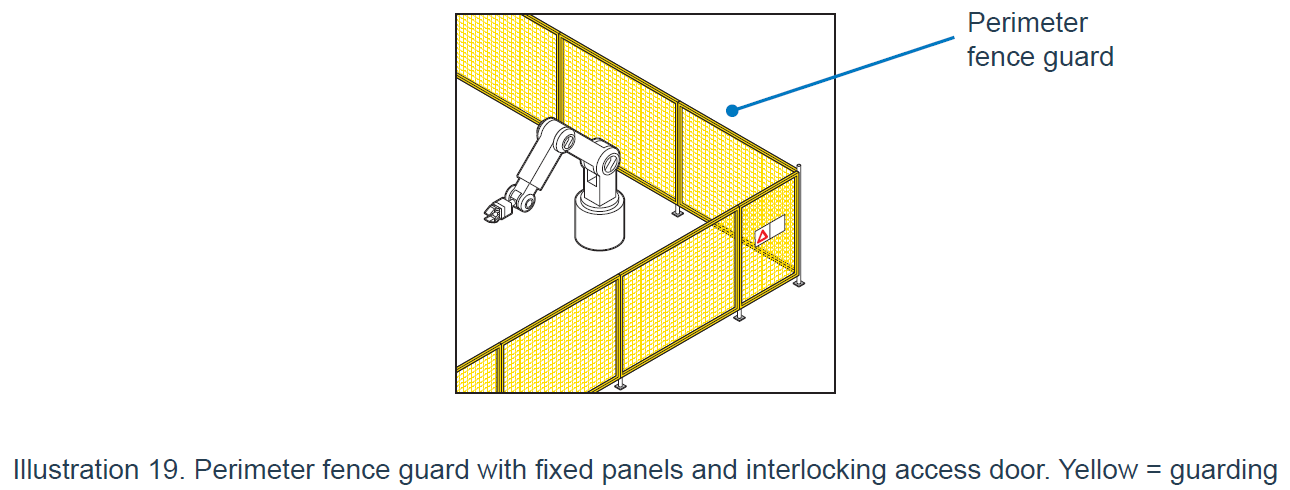

- Fixed Guards

- Interlocking Guards

- Fencing Guards

- Enclosure Guards

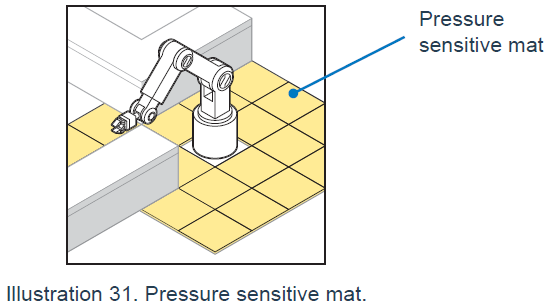

- Presence / Pressure Sensing Systems

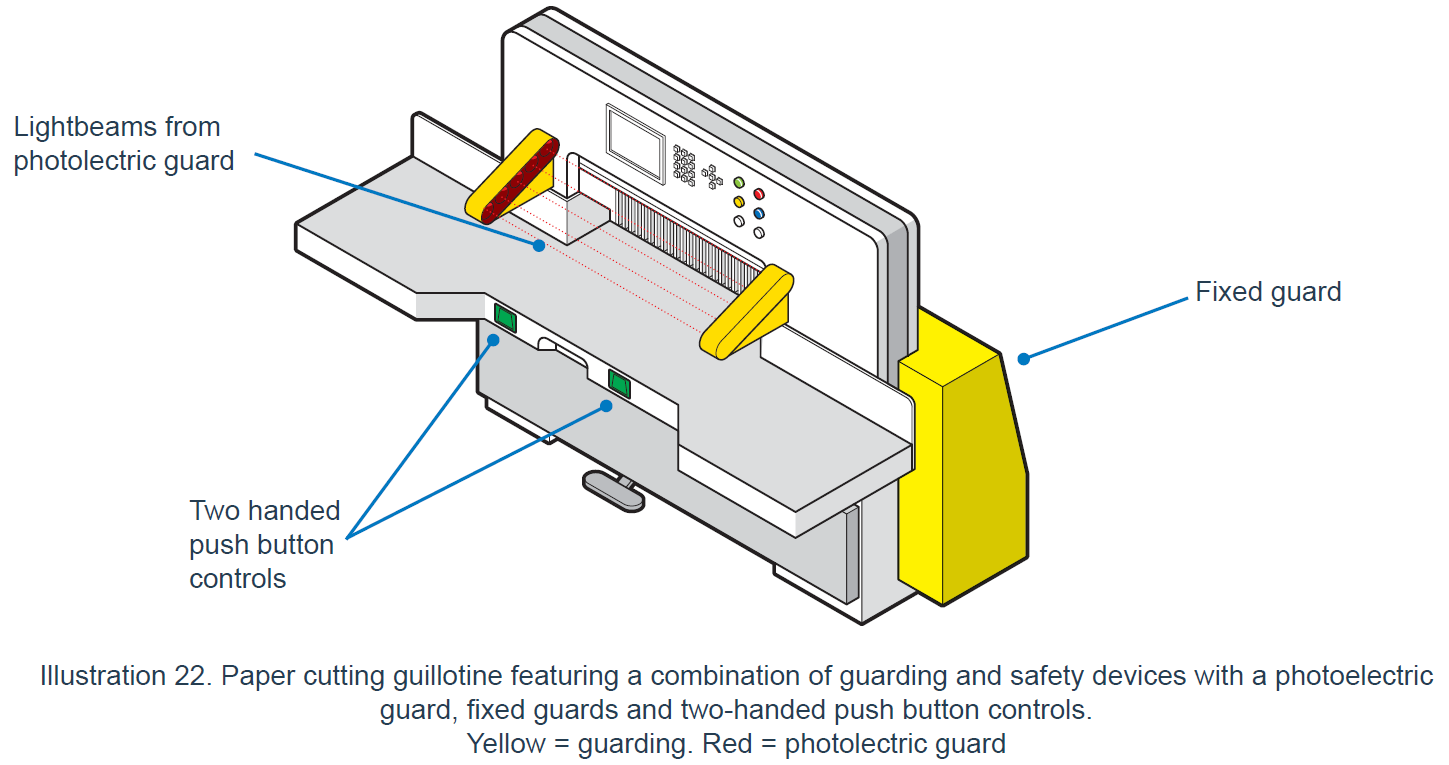

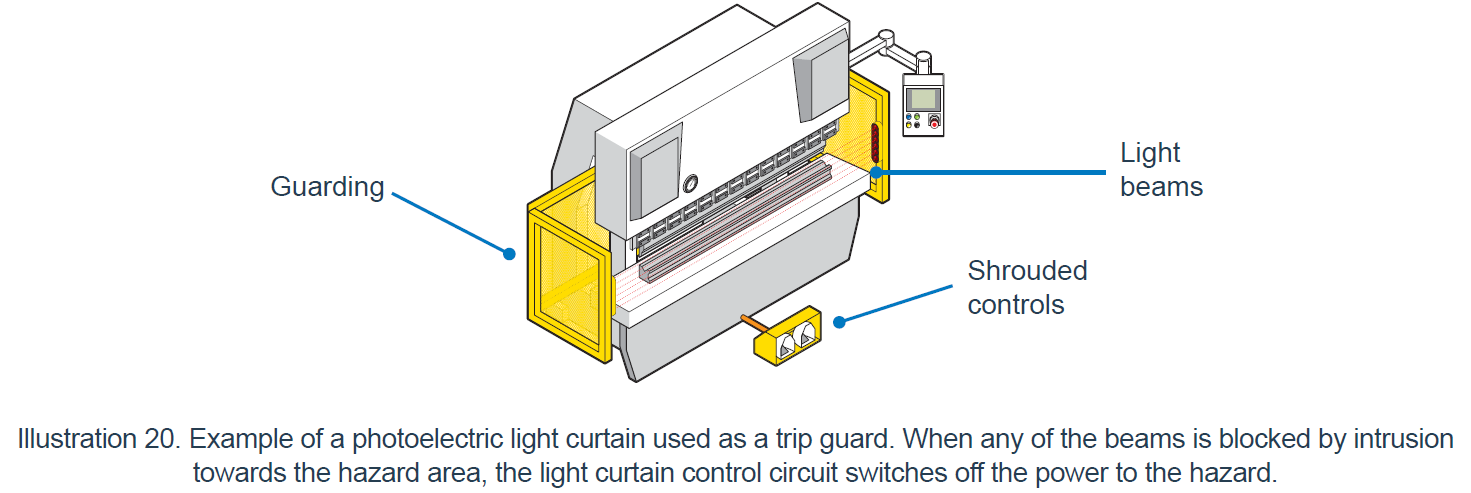

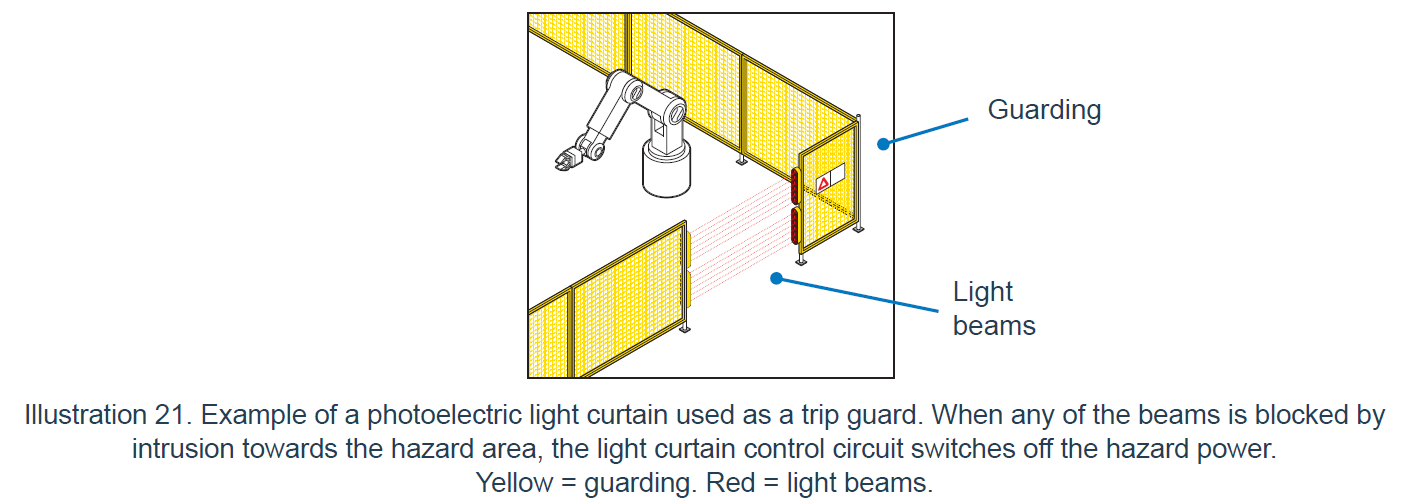

- Light Curtains

-

-

Are emergency stops installed at key areas of plant or equipment that are in reach of the operator?

-

-

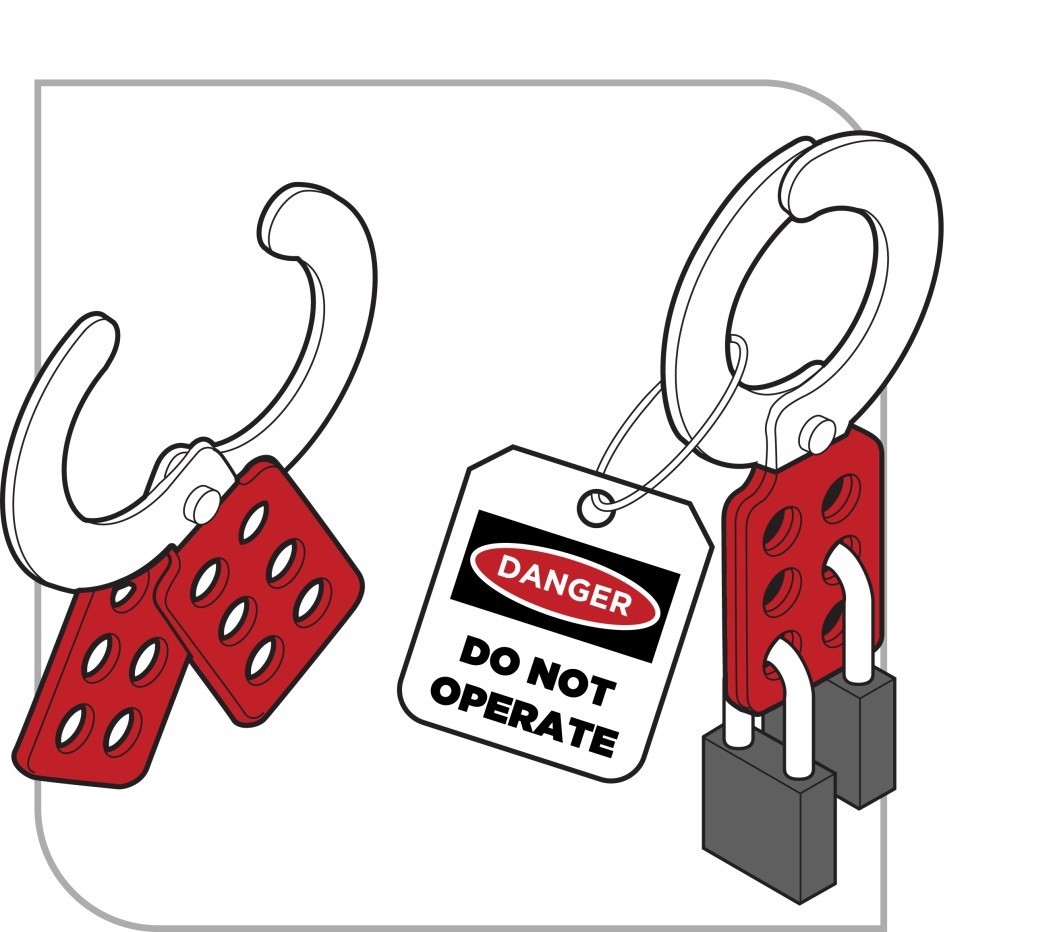

Is there a permit or isolation process implemented to ensure that plant and equipment cannot be energized in maintenance, cleaning or repair?

-

-

Is training provided for operation of the Plant or Equipment?

-

Is there signage and warning stickers on or near the Plant or Equipment?

-

Is the Original Equipment Manufacturer (OEM) booklets or information available?

-

Are there Safe Work Method Statements / Job Safety Analysis / Standard Operating Procedures / Safe Work Instructions completed?

-

Is the Plant or Equipment regularly inspected?

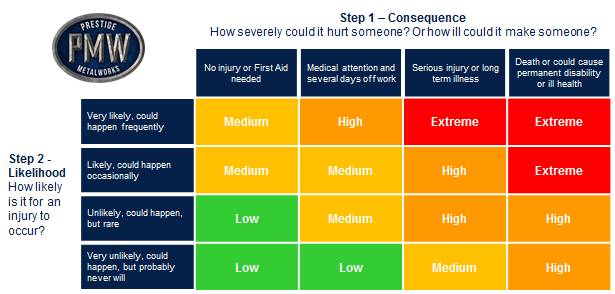

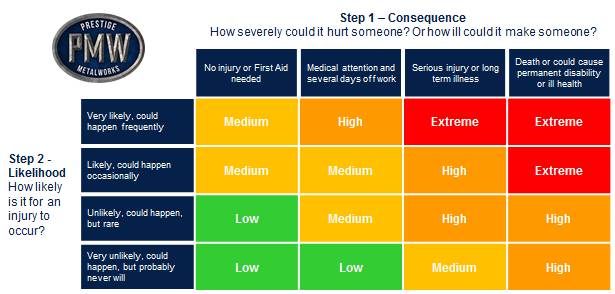

Risk Rating

-

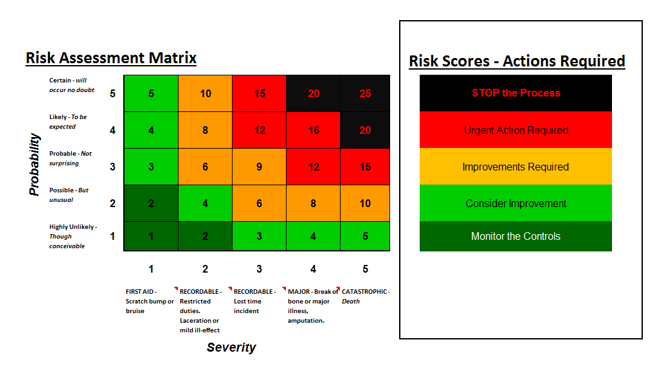

Based on the current risk controls implemented, what is the risk rating (align the likelihood and consequence on the risk matrix below to identify)?

-

Further Controls

-

Can hazards present be eliminated?

-

Can the Plant or Equipment be substituted for a safer alternative?

-

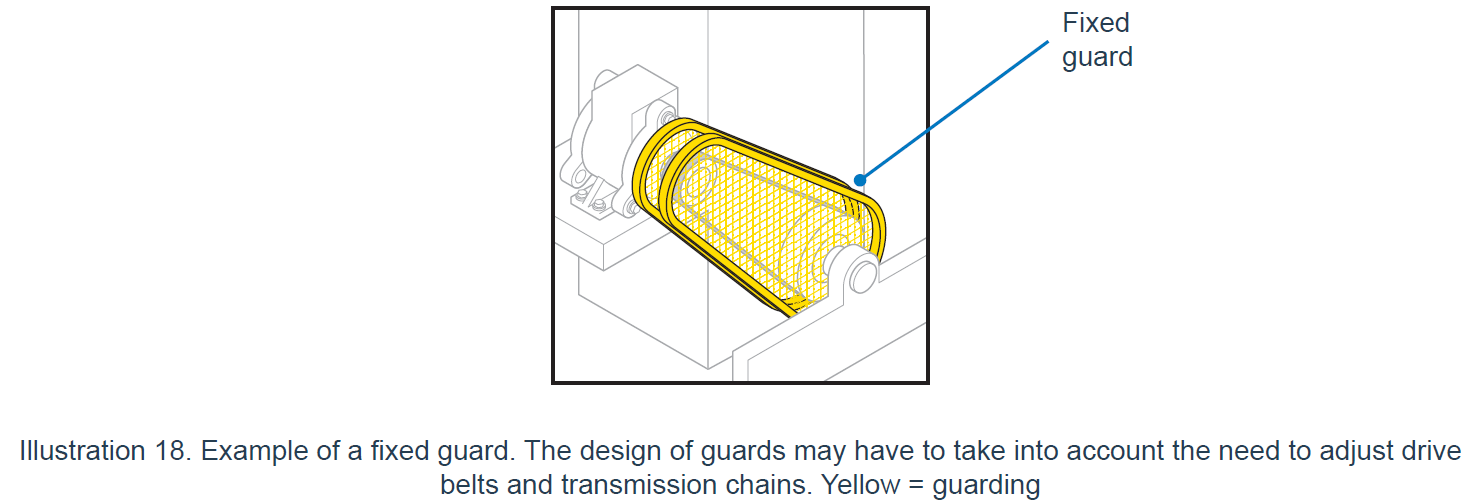

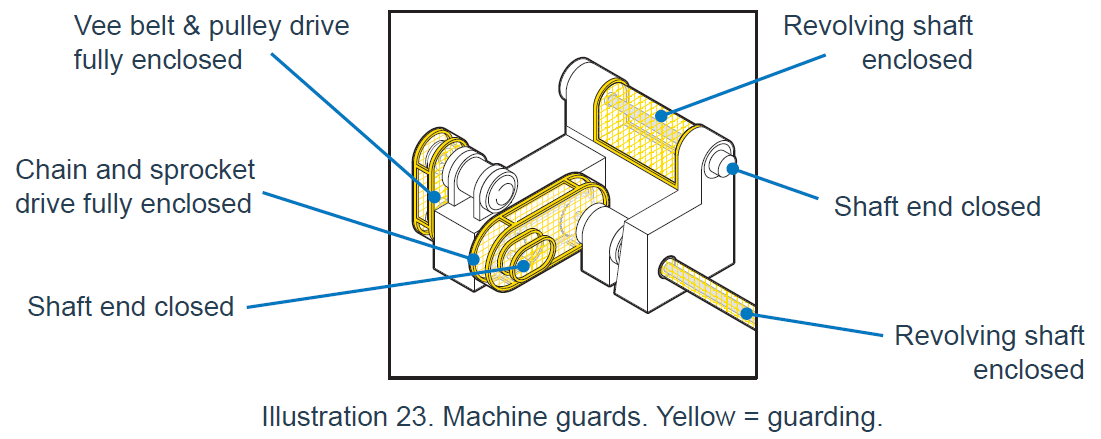

Can engineering controls be introduced to reduce the risk to workers (consider additional guarding examples below)?

-

Add actions above detailing what must be done and by who.

-

Examples of types of Guarding to consider if not already present:

-

-

-

-

-

-

-

-

-

-

-

-

Can administrative controls be added to reduce the risk to workers?

-

Can Personal Protective Equipment be provided?

Final Risk Rating (based on new controls being added)

-

Based on the new risk controls implemented, what is the risk rating (align the likelihood and consequence on the risk matrix below to identify)?

-