Information

-

Document No.

-

Client / Site

-

Conducted On

-

Conducted By

ITEMS TO CHECK

-

WARNING:

* ONLY EXPERIENCED Operators to perform the following Checks.

* ALL REQUIRED PPE MUST BE WORN while performing these checks as the risk of injury from high pressure equipment is extremely dangerous.

* This form MUST be completed Every Month as part of the Preventative Maintenance Schedule (PM) inspections.

* FAULTS: MUST be reported to either the Operations Manager or SHEQ Department immediately.

* Once completed the form must be signed and dated. -

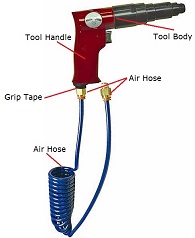

Parts of a Pneumatic Tool

PNEUMATIC TOOL CHECKS Pneumatic Tools are tool operated by air or gas under pressure, including Drill, Screw Guns, Angle Grinder, etc

-

Location of PNEUMATIC TOOL 01

-

Type of Pneumatic Tool

-

OTHER - Type of Pneumatic Tool:

-

1. Are all required Guards fitted, secure and undamaged

-

2. Do the bearings rotate smoothly on the tool without catching or making a screeching noise?

-

3. Is the Tool's body and handle in good condition with no cracks, damage or wear?

-

4. Is the Tool being oiled daily?

-

5. Is the Air Hose in good condition with no cracks, damage or wear?

-

6. Are the Air Hose Fittings in good condition with no cracks, damage, wear or evidence of leaking air?

-

7. Is the Grip Tape between Air Hose fittings to Tool, fitted and undamaged

-

Is there another Pneumatic Tool to be Inspected?

-

Location of PNEUMATIC TOOL 02

-

Type of Pneumatic Tool

-

OTHER - Type of Pneumatic Tool:

-

1. Are all required Guards fitted, secure and undamaged

-

2. Do the bearings rotate smoothly on the tool without catching or making a screeching noise?

-

3. Is the Tool's body and handle in good condition with no cracks, damage or wear?

-

4. Is the Tool being oiled daily?

-

5. Is the Air Hose in good condition with no cracks, damage or wear?

-

6. Are the Air Hose Fittings in good condition with no cracks, damage, wear or evidence of leaking air?

-

7. Is the Grip Tape between Air Hose fittings to Tool, fitted and undamaged

-

Is there another Pneumatic Tool to be Inspected?

-

Location of PNEUMATIC TOOL 03

-

Type of Pneumatic Tool

-

OTHER - Type of Pneumatic Tool:

-

1. Are all required Guards fitted, secure and undamaged

-

2. Do the bearings rotate smoothly on the tool without catching or making a screeching noise?

-

3. Is the Tool's body and handle in good condition with no cracks, damage or wear?

-

4. Is the Tool being oiled daily?

-

5. Is the Air Hose in good condition with no cracks, damage or wear?

-

6. Are the Air Hose Fittings in good condition with no cracks, damage, wear or evidence of leaking air?

-

7. Is the Grip Tape between Air Hose fittings to Tool, fitted and undamaged

-

Is there another Pneumatic Tool to be Inspected?

-

Location of PNEUMATIC TOOL 04

-

Type of Pneumatic Tool

-

OTHER - Type of Pneumatic Tool:

-

1. Are all required Guards fitted, secure and undamaged

-

2. Do the bearings rotate smoothly on the tool without catching or making a screeching noise?

-

3. Is the Tool's body and handle in good condition with no cracks, damage or wear?

-

4. Is the Tool being oiled daily?

-

5. Is the Air Hose in good condition with no cracks, damage or wear?

-

6. Are the Air Hose Fittings in good condition with no cracks, damage, wear or evidence of leaking air?

-

7. Is the Grip Tape between Air Hose fittings to Tool, fitted and undamaged

-

Is there another Pneumatic Tool to be Inspected?

-

Location of PNEUMATIC TOOL 05

-

Type of Pneumatic Tool

-

OTHER - Type of Pneumatic Tool:

-

1. Are all required Guards fitted, secure and undamaged

-

2. Do the bearings rotate smoothly on the tool without catching or making a screeching noise?

-

3. Is the Tool's body and handle in good condition with no cracks, damage or wear?

-

4. Is the Tool being oiled daily?

-

5. Is the Air Hose in good condition with no cracks, damage or wear?

-

6. Are the Air Hose Fittings in good condition with no cracks, damage, wear or evidence of leaking air?

-

7. Is the Grip Tape between Air Hose fittings to Tool, fitted and undamaged

-

Is there another Pneumatic Tool to be Inspected?

-

Location of PNEUMATIC TOOL 06

-

Type of Pneumatic Tool

-

OTHER - Type of Pneumatic Tool:

-

1. Are all required Guards fitted, secure and undamaged

-

2. Do the bearings rotate smoothly on the tool without catching or making a screeching noise?

-

3. Is the Tool's body and handle in good condition with no cracks, damage or wear?

-

4. Is the Tool being oiled daily?

-

5. Is the Air Hose in good condition with no cracks, damage or wear?

-

6. Are the Air Hose Fittings in good condition with no cracks, damage, wear or evidence of leaking air?

-

7. Is the Grip Tape between Air Hose fittings to Tool, fitted and undamaged

-

Is there another Pneumatic Tool to be Inspected?

-

Please Sign Off this Checklist and Start a New Audit Checklist.

COMMENTS / NOTES

-

Enter any Comments / Notes:

COMPLETED BY

-

Signature: