Title Page

-

PSC Self-inspection

-

Name of the ship

-

Location

-

Voyage Number

-

Entry port

-

Port ETA

-

Confirmation by 1/E

-

Confirmation by C/O

-

Confirmation by C/E

-

Conducted on (Master's Name)

-

Master's Comment

1. ISPS Check (MST, Duty officer)

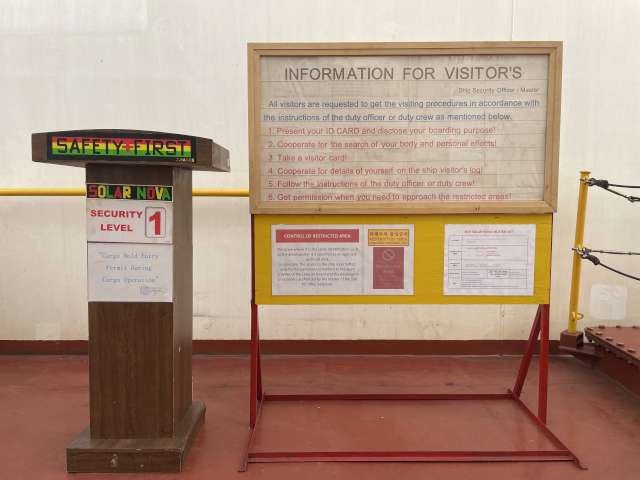

1.1 Security level display

Guide to inspection

-

instruction photo

Check Point

-

①(After arrival at port) Display Security level near Gangway

1.2 Gangway watch

Guide to Inspection

-

(ISPS, SOLAS CH-XI-2)

Watch man shall be engaged in day work for gangway watch.

Check Point

-

①Continuous strict gangway watch

-

②Prohibit standby ISPS stand under cargo loader & Crane

-

③Understand how to act when visitor entry

1.3 Visit Log

-

①Identification of visitors’ photo ID and visit log maintained, etc

1.4 Control of restricted areas

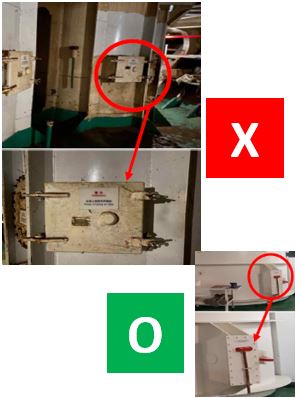

Guide to Inspection

-

- Check the condition on locks in Eng. Room and exit to S/G room related to ship’s security and safety.

- Check the control on the entrance to restricted area (Pad locks and Seals.)

Check Point

-

①Restricted areas controlled in accordance with levels set by SSP

-

②Restriction of access to prohibited areas<br>(with the entrances sealed and/or proper measures taken, sealing or pad lock)

2. Meeting Room (MST, C/E & C/O)

2.1 Certificates (HSSC)

Guide to Inspection

-

SOLAS CH-1, Appendix (Certificate)

①Class Certificates

②SOLAS Certificates (SC, SE, SR, ISM, ISPS Cert.)

③MARPOL Certificate (IOPP, IAPP, ISPP, IAFS)

④Load Line Certificate

⑤ Safety Manning Cert.

⑥ LC Certificate

- Officer & Crew Certificates (According to SMC, STCW)

- Listing the valid dates per each certificates.(Recommendation)

- Record on SE certificate (check with Form E)

Check Point

-

①Validity, Contents any defect see the [List of Certificate] [Status of Crew Qualification]

2.2. Stability booklet, grain loading manual

Guide to Inspection

-

SOLAS CH-VI CARRIAGE OF CARGOES AND OIL FUELS

cargo hold as specified in regulation 5.1 and the standards and criteria for side structures of bulk carriers of single-side skin construction, adopted by the Organization by resolution MSC.168(79), shall not sail with any hold loaded to less than 10% of the hold’s maximum allowable cargo weight

when in the full load condition, after reaching 10 years of age. The applicable full load condition for this regulation is a load equal to or greater than 90% of the ship’s deadweight at the relevant assigned freeboard.

(SOLAS 74, 2014)

Strength of the inner bottom plating could be deteriorated due to corrosion wastage. The operational parameters and tank top strength(T/m2) of the effected vessels may be updated by the classification society.

Check Point

-

①Original copy on board

-

②Loadcom annual test by Classification

-

②Loadcom annual test by Classification (Recorded the last date)

2.3 Survey report file (ESP only)

Guide to Inspection

-

SOLAS CH-I, Reg.10 Surveys of structure, machinery and equipment of cargo ships

(*ESP : Enhanced Survey Programme for bulk carriers, Crude oil tankers and chemical tankers. It belongs to the ships with certificate remarked ESP)

The latest version shall be downloaded through Class homepage.

Check Point

-

①Classification Report<br>(Tank Survey Report, EH/Executive Hull Summary)

-

②TM/Thickness measure report

-

③Survey Program(Until completion)

2.4 SOPEP

Guide to Inspection

-

MARPOL/ Annex I / Reg. 37, Shipboard oil pollution emergency plan

Every ship other than an oil tanker of 400 gross tonnage and above shall carry on board a shipboard oil-pollution emergency plan approved by the Administration.

Such a plan shall be prepared based on guidelines developed by the Organisation and written in the working language of the Master and officers. The plan shall consist at least of:

> The procedure to be followed by the Master or other persons having charge of the ship to report an oil pollution incident

> The list of authorities or persons to be contacted in the event of an oil pollution incident

> A detailed description of the action to be taken immediately by persons on board to reduce or control the discharge of oil following the incident

> The procedures and point of contact on the ship for coordinating shipboard action in combating the pollution with national and local authorities

> Description of equipment, its location, a plan for deployment and specific crewmember duties for handling small spills, and

> An up-to-date IMO Coastal Contact List.

Check Point

-

①Updated list of national operational contact list<br>ANNEX II: Every quarters (Date 1/31, 4/30, 7/31, 10/31) MSC-MEPC.6/Circ.22

-

②Oil spill kit update (Every Month)

-

③Flag Approval

2.5 Oil record book (ORB)

Guide to Inspection

-

MARPOL / Annex I / Reg.17, Oil Record Book, Part I - Machinery space operations MEPC1_Circ736/Rev.2]

(Especially, Comparison with Sound Log Book and ORB)

- IOPP Certificates, Tank names and Sizes

- Sludge incineration quantity (Quantity of Discharge ashore shore. / on board )

- Incinerator operation time record (Start / End)

Check Point

-

①Accurate entries

-

②Incinerated residue q’ty (to shore/on board)

-

③Bilge q’ty

-

④BDN

2.6 Garbage management plan (GMP) & Garbage record book (GRB)

Guide to Inspection

-

MARPOL / Annex V / Reg. 10 Placards, garbage management plans and garbage record-keeping

Check Point

-

①To be on board

-

②Accurate GRB, Kept a shore facility landing certificate

-

③Display the placards<br>W/H, Galley, A-DK(officer's mess RM, Crew's mess RM, Corridor), Uppder DK(P/S Entrance), Garbage store, Garbage collecting drum ECR, Incinerator

-

④Minimization, Segregation

2.7 Ballast water management plan &Ballast water record book

Guide to Inspection

-

BWM / ANNEX / Regulation B-1

Ballast Water Management Plan

B-2 Ballast Water Record Book

Mis-matching between BWRB, Ballast log

Miss the record the familarization

Check Point

-

①Approved BWMP & Certificate For Panama Flag : Classification annual endorsement

-

②Accurate BWRB

-

③Crew training & Familiarization

2.8 Rest Hours of Crew

Guide to Inspection

-

MLC Reg.2.3 Hours of work and hours of rest

- when ship arrival/departure procedures,

- transit of narrow channels

- crews’ drill and training

- bunker oil receiving operations

- Calling while off-duty due to UMA

** Minimum break time shall be more than 10 hours of 25 hrs, which shall not be divided more than twice and one of them shall be at least six hours.

- Exemption

① Calling while off-duty due to UMA cause interrupt normal break time

② Implementation of master’s instructions for instant of ship, life and cargo or saving life at distress.

Check Point

-

①Minimum rest hours properly provided to crews

2.9 MLC related matters

Guide to Inspection

-

MLC Reg.2.1 Seafarers' employment agreements

MLC Reg.5.1.5 – On-board complaint procedures

(full payment of wages and Medical care provided)

Check Point

-

①Seafarers' employment agreements

-

②Complaint Procedure onboard and provided to seafarers

2.10 Cargo information

Guide to Inspection

-

SOLAS / Chapter VI / Reg. 2 Cargo information

SOLAS / Chapter VI / Reg. 7 Loading, unloading and stowage of solid bulk cargoes

- MSDS/Material Safety Data Sheet

- BCI/Bulk Cargo Information(IMO's Bulk Cargo Shipping Name - BCSN).

- Moisture & TML(Transportable Moisture Limit) Certificate

Check Point

-

①Verified Cargo evidences <br><br>- MSDS/Material Safety Data Sheet<br>- BCI/Bulk Cargo Information(IMO's Bulk Cargo Shipping Name - BCSN). <br>- Moisture & TML(Transportable Moisture Limit) Certificate

-

②Loading/Unloading plan (monitoring, Signature)

2.11 Emergency Towing Arrangement

Guide to Inspection

-

SOLAS / Chapter II-1 / Reg. 3-4.1, MSC.1/Circ.1255

Matching with ship's particular (GMDSS Equipment, Mooring equipment & etc)

Check Point

-

①Updated ETA (Bridge, F’cle, Office or CCR)

2.12 PSC report

Guide to Inspection

-

IMO Res.A. PROCEDURES FOR PORT STATE CONTROL

Check Point

-

①Outstanding Deficiencies on the last report

2.13 Drills

Guide to Inspection

-

SOLAS CH-II-1,Reg.3-4

SOLAS CH-III Reg.19

SOLAS CH-III,Reg.17-1

SOLAS CH-V,Reg.26

MARPOL Ann I Reg.37

ISM

Check Point

-

①Drill conduct and recording <br> - SMS [Annual plan for Drill & Training] (ISM, ISPS)

-

②Content of training <br> - PSCO may be pointed out if not recorded convention's requirement<br> - Record log book, Training record

3. Bridge (Deck Officer)

3.1 Chart(ENC) & Notice to Mariner

Guide to Inspection

-

SOLAS CH-V,Reg.19.2.1.4

.4 nautical charts and nautical publications to plan and display the ship's route for the intended voyage and to plot and monitor positions throughout the voyage. An electronic chart display and information system (ECDIS) is also accepted as meeting the chart carriage requirements of this subparagraph. Ships to which paragraph 2.10 applies shall comply with the carriage requirements for ECDIS detailed therein; (Replaced by Res.MSC.282(86))

SOLAS CH-V,Reg.24

Nautical charts and nautical publications, such as sailing directions, lists of lights, notices to mariners, tide tables and all other nautical publications necessary for the intended voyage, shall be adequate and up to date. -

①Charts

-

②Latest edition & small correction

-

③AIO, T&P

3.2 Publication(E-Publication)

Guide to Inspection

-

** SOLAS Ch.V Regulation 27 “Nautical charts and nautical publications, such as

sailing directions, lists of lights, notices to mariners, tide tables and all other

nautical publications necessary for the intended voyage, shall be adequate and up

to date.”. Refer to MSC-MEPC.2/Circ.2 -

①Lights list, Tide table, Sail. Dir. Latest edition & Small corr.

-

②IAMSAR Manu.(Every 3years), International Code of Signals (Hard Copy)

3.3 Deck log book/Training Record

Guide to Inspection

-

SOLAS CH-III, Reg.19

SOLAS CH-V,Reg.26

** Fire Fighting/Abandon Ship: Once a month (SOLAS 2006 Amend Reg.III/19)

** Passenger ship : once a week회

Lifeboat launching drill : every three months

Rescue boat launching drill : once a month

Free-fall lifeboat launching drill : every six month

Entering enclosed area drill: once per two month (1 / two month)

Em’cy Steering drill : every three months (SOLAS 1999/2000 Amend / Ch.V/26)

Oil pollution response drill: once a month.

** Emergency Drills are required at least once a year according to KR rule Part2

Drills belonging to the convention are subject to SOLAS convention.

Fire/Explosion/Collision/Aground/Flood/Life -saving/Pollution/Steering Failure

/Loss of propulsion /Injuries/

Abandon Ship/Entering enclosed area and rescue/Ship-shore joint drills

** In case of 25% of crew change, concerned drills up to each type of ships are

distinguished. -

①Drill records (To be recorded last date of drills) <br>- Abandon ship/Fire drill-1M<br>- Lifeboat launching, maneuvering -3M (Rescue boat 1M)<br>- Em’cy steering drill-3M<br>- Entering to enclosed spaces-2M & etc.)

-

②Confirmation that drill details in deck log book is in accord with training records files

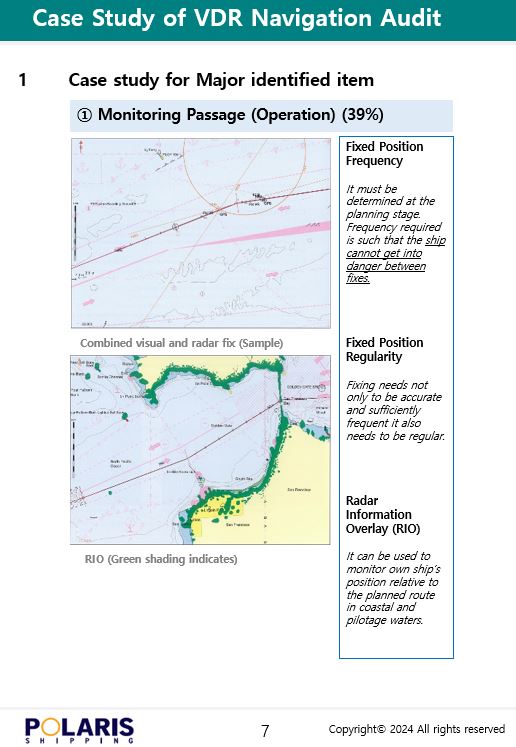

3.4. Passage Plan

Guide to Inspection

-

SOLAS / Chapter V / Reg. 34

Safe navigation and avoidance of dangerous situations

1 Prior to proceeding to sea, the master shall ensure that the intended voyage has been planned using the appropriate nautical charts and nautical publications for the area concerned, taking into account the guidelines and recommendations developed by the Organization* .

2 The voyage plan shall identify a route which:

.1 takes into account any relevant ships' routeing systems;

.2 ensures sufficient sea room for the safe passage of the ship throughout the voyage;

.3 anticipates all known navigational hazards and adverse weather conditions; and

.4 takes into account the marine environmental protection measures that apply, and avoids as far as possible actions and activities which could cause damage to the environment.

STCW Code Part A / Part 2, Res.A.893(21) -

①Berth to Berth

-

②Port Regulation(Environment, Traffic, UKC, etc)

-

③Monitoring of Passage plan(P.I., Position fixing)

-

④Evaluation of Passage plan after completion

-

⑤Proper Recording chronological

3.5 Standard magnetic compass

Guide to Inspection

-

SOLAS / Chapter V / Reg. 19.2.1

2.1 All ships irrespective of size shall have:

.1 a properly adjusted standard magnetic compass, or other means, independent of any power supply to determine the ship's heading and display the reading at the main steering position;

.2 a pelorus or compass bearing device, or other means, independent of any power supply to take bearings over an arc of the horizon of 360 degrees -

①Lighting

-

②No bubble

-

③Deviation table (Last date)

-

④Spare magnetic compass (if,fitted)

3.6 VHF, MF/HF radio

Guide to Inspection

-

SOLAS / Ch-IV / Reg. 12 Watches

- Shore Based Maintenance Company Guide - At the China Area

1) Select SSB (or J3E, TELEPHONE) in MF/HF and select CHANNEL 1225.

2) Afterwards, press ANT TUNE and when tuning is complete, press MIC (or HANDSET) KEY and call Guangzhou RADIO.

3) When Guangzhou RADIO responds, they conclude by saying that they are testing the equipment.

Note) CHANNEL frequency 1225 (If you select CHANNEL, the frequency appears automatically.)

Tx: 12,302KHz Rx: 13,149KHz -

①BQ/RQ test in Em’cy/Reserve of power & report - BQ (ACK Back quest), RQ (ACK Request)

-

②Familiarization

-

③MF/HF SSB(Single Side Band Radio) Test call

-

④VHF DSC TEST CALL

-

⑤Two-way VHF test call & Battery expire date

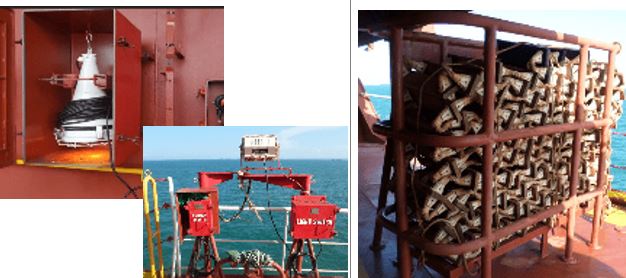

3.7 EPIRB

Guide to Inspection

-

SOLAS / Ch- IV / Reg. 7.1.5

.5 an EPIRB14 which shall be:

14 Refer to Search and rescue homing capability (resolution A.616(15)).

.1 installed in an easily accessible position;

.2 ready to be manually released and capable of being carried by one person into a survival craft;

.3 capable of floating free if the ship sinks and of being automatically activated when afloat; and

.4 capable of being activated manually; and

** Issued by EPIRB Shore-Based Maintenance Provider (MSC Circ.1039) -

①Test

-

②Valid date of HRU & Battery expire date

-

③Location (Resetting Condition)

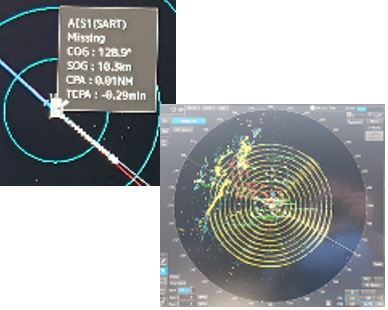

3.8 SART

Guide to Inspection

-

SOLAS / Ch IV / Reg. 7.1.3

-

①Test (Caution near ship's density)

-

②Battery expire date

3.9 AIS

Guide to Inspection

-

SOLAS / Ch V / Reg. 18.9

9 The automatic identification system (AIS) shall be subjected to an annual test. The test shall be conducted by an approved surveyor or an approved testing or servicing facility. The test shall verify the correct programming of the ship static information, correct data exchange with connected sensors as well as verifying the radio performance by radio frequency measurement and on-air test using, e.g., a Vessel Traffic Service (VTS). A copy of the test report shall be retained on board the ship.

MSC.1/Circ.1252 -

①Check the ship's information and status

3.10 Echo Sounder

Guide to Inspection

-

SOLAS / Ch V / Reg. 19.2.3 RESOLUTIONs / MSC Resolutions / Res.MSC.74(69)

5.2 Accuracy

5.2.1 Accuracy of measurement

Based on a sound speed in water of 1,500 m/s, the tolerance of the indicated depth should be either:

- +/- 0.5 m on the 20 m range scale, respectively +/- 5 m on the 200 m range scale; or

- +/- 2.5% of the indicated depth, whichever is greater. -

①Alarm set

-

②Verify the error

3.11 (S)VDR

Guide to Inspection

-

SOLAS / Ch V / Reg.18.8

8 The voyage data recorder system, including, all sensors, shall be subjected to an annual performance test. The test shall be conducted by an approved testing or servicing facility to verify the accuracy, duration and recoverability of the recorded data. In addition, tests and inspections shall be conducted to determine the serviceability of all protective enclosures and devices fitted to aid location. A copy of the certificate of compliance issued by the testing facility, stating the date of compliance and the applicable performance standards, shall be retained on board the ship. -

①Familiarization(VDR Back-up each case)

-

②Any defect alarm

-

③Control and management by Master

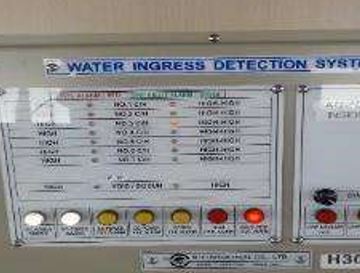

3.12 Water Ingress System

Guide to Inspection

-

SOLAS / Ch XII / Reg. 12.

SOLAS / Ch II-1 / Reg.25.

** This regulation is subject to the Bulk Carriers such as Ore carriers specified on SOLAS XII.

Single hold cargo ships other than bulk carriers shall be fitted water level detectors according to SOLAS II-1/25 -

①Any abnormal alarm - Sound, buzzer, indicator

-

②Any abnormal alarm tested date - Sound, buzzer, indicator

3.13 Daylight signal lamp

Guide to Inspection

-

SOLAS / Ch V / Reg. 19.2.2

All ships of 150 gross tonnage and upwards shall be fitted with a signalling daylight lamp, or other means to communicate by light during day and night using an energy source of electrical power not solely dependent upon the ship’s power supply (Reg.V/19.2.2 in SOLAS 2000 amendments ) -

①Operation by Em’cy power (Battery)

-

②Operation at both ship sides

-

③Portable battery and at least 3 spare illuminants

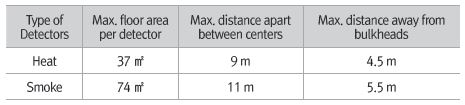

3.14 Fire alarm & fire detection system

Guide to Inspection

-

SOLAS CH-II-2, Reg.13.

** FSS code Chapter .9 /2.5

The activation of any detector or manually operated call point shall initiate a visual and audible fire detection alarm signal at the control panel and indicating units.

If the signals have not been acknowledged within 2 min, an audible fire alarm shall be automatically sounded throughout the crew accommodation and service spaces, control stations and machinery spaces of category A. This alarm sounder system need not be an integral part of the detection system ** Manually operated call points shall be installed throughout the accommodation spaces, service spaces and control stations. One manually operated call point shall be located at each exit. Manually operated call points shall be readily accessible in the corridors of each deck such that no part of the corridor is more than 20 m from a manually operated call point. (SOLAS 1983 Amend/ II-2, Reg.13.2) -

①Any abnormal alarm

-

②Test by Em’cy power

-

②Test by Em’cy power

-

③Alarm (Visual, audible acknowledge 2 min & relay)

-

④MCP’s Distance (Not exceed 20m)

-

⑤Detector’s distance (Max. Heat 9m / Smoke 11m)<br>- Bulkhead away : Heat 4.5m, Smoke 5.5m

-

⑥Check for control fault alarm cleared

-

⑦Test (as planned schedule)

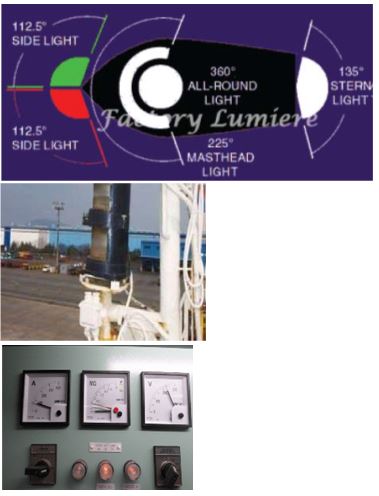

3.15 Navigation light & Signal light

Guide to Inspection

-

COLREG / Part C / Part D

In case of loss of main source, emergency source shall be provided to navigation lights as quickly as is safe and practicable.

Unless emergency generator starts supplying the required load within 45 sec, the ship shall be provided with a transitional source of emergency electrical power

NAVIGATION LIGHT PANEL (SOLAS Ch.II-1, Reg.43. 3, 4) -

①Light on/off test, Alarm test

-

②Any Covered by painting or damage/broken

-

③By Em’cy power

-

④Light angle

-

⑤Christmas light

3.16 Emergency lighting

Guide to Inspection

-

SOLAS / Ch II-1 / Reg. 43

2.3 For a period of 18 h :

.1 the navigation lights and other lights required by the International Regulations for Preventing Collisions at Sea in force ;

.2 on ships constructed on or after 1 February 1995 the VHF radio installation required by regulation IV/7.1.1 and IV/7.1.2 ;and if applicable :

.1 the MF radio installation required by regulations IV/9.1.1,IV/9.1.2,IV/10.1.2 and,IV/10.1.3 ;

.2 the ship earth station required by regulation IV/10.1.1 ;and

.3 the MF/HF radio installation required by regulations IV/11.1.1 and IV/11.1.2. ( -

①Functioning, No damage

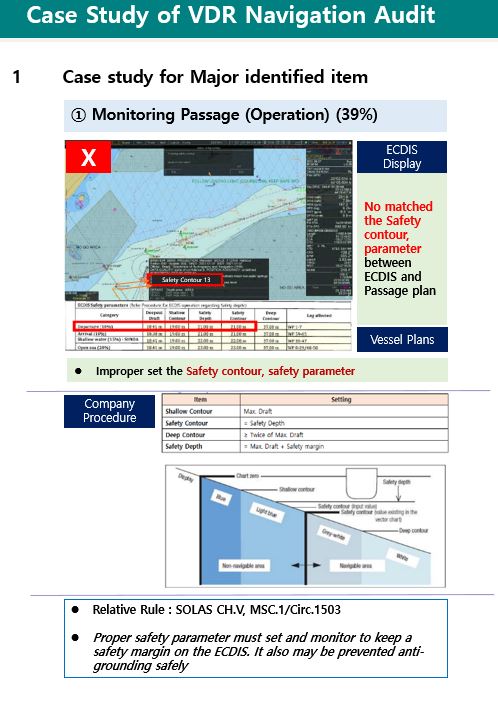

3.17 ECDIS

Guide to Inspection

-

SOLAS / Ch V / Reg. 19.2.1, STCW CH VIII, STANDARDS REGARDING WATCHKEEPING

1. Officer education: Division between Generic and Familiarization (TypeSpecification).

2. Generic education by training center - Module training (Certificate on board)

: According to STCW convention, the officers of the vessels fitted with ECDIS shall be required to be certified according to STCW Table A-II/1.

3. Familiarization training shall be carried out with the materials provided by maker and Record the education/training and result. -

① ENC License expire & Version of ENCs

-

②Proper setting <br>- Safety Depth, contour <br>- Safety detection <br>- Cross track distance <br>- Shade <br>- AIO<br>- Route display <br>- Radar, AIS Overlay

-

③Familiarization of Deck Officers & training record<br>[Familiarization with ECDIS]

-

④Familiarization of Emergency Response for ECDIS<br>- Sensor failure cases<br>- ECDIS failure case

-

⑤Operation under both main and emergency source of power, etc.

-

⑥Periodical backup (3M)

3.18 BNWAS

Guide to Inspection

-

SOLAS / Ch V / Reg. 19.1.2, Res.MSC.128(75)

The BNWAS must be operational whenever the ship is underway and should be used at anchor. Use of Bridge Navigational Watch Alarm System (BNWAS) modes (automatic, manual, on and off) and procedures for ensuring correct operation should be incorporated in the company navigation procedure.

The peration of the BNWAS should be part of the departure checklist and a key,if supplied, should be kept with the Master when switched on.

(Bridge Procedure Guide, 2022) If a failure (e.g., internal communication failure) of, or power supply failure to, the BNWAS is detected, it is to be indicated by visual and audible alarms. Means are to be provided to allow the repeat of this indication on a central alarm panel, if fitted.

The means of selecting the Operational Mode and the duration of the Dormant Period should be security protected so that access to these controls should be restricted to the master only. The BNWAS should be powered from the ship’s main power supply. The malfunction indication, and all elements of the Emergency Call facility, if incorporated, should be powered from a battery-maintained supply.

If a malfunction of, or power supply failure to, the BNWAS is detected, this should b -

①Proper set

-

②Keeping the Password, controlled by Master

-

③Alarm

3.19 Watch keeping schedules(for ship underway or at port)/Muster list

Guide to Inspction

-

MLC Reg.2.3.

① Duty Table shall be Displayed

② Minimum break time shall be observed -

①Watch keeping schedules(procedures) and muster list are established and posted on the bridge

-

②The number of personnel on board is considered in such lists.

3.20 Bridge Visibility

Guide to Inspection

-

SOLAS / Ch V / Reg.22

2 No blind sector caused by cargo, cargo gear or other obstructions outside of the wheelhouse forward of the beam which obstructs the view of the sea surface as seen from the conning position, shall exceed 10 degrees. The total arc of blind sectors shall not exceed 20 degrees. The clear sectors between blind sectors shall be at least 5 degrees. However, in the view described in .1, each individual blind sector shall not exceed 5 degrees;

.9.4 A clear view through at least two of the navigation bridge front windows and, depending on the bridge configuration, an additional number of clear-view windows shall be provided at all times, regardless of weather conditions. -

①Bridge window wiper & Clear view screen

-

②Operation of Heater

3.21 Deck officers familiarization with navigation equipment

Guide to Inspection

-

Deck officer familiarization with navigation equipment should be delivered one-on-one using a common language using the Bridge Procedure Guide’s (BPG) checklist C2.3 and C2.4. Familiarization should include all bridge equipment and procedures relevant to the roles and responsibilities of each bridge team member. (Bridge Procedure Guide, 2022)

-

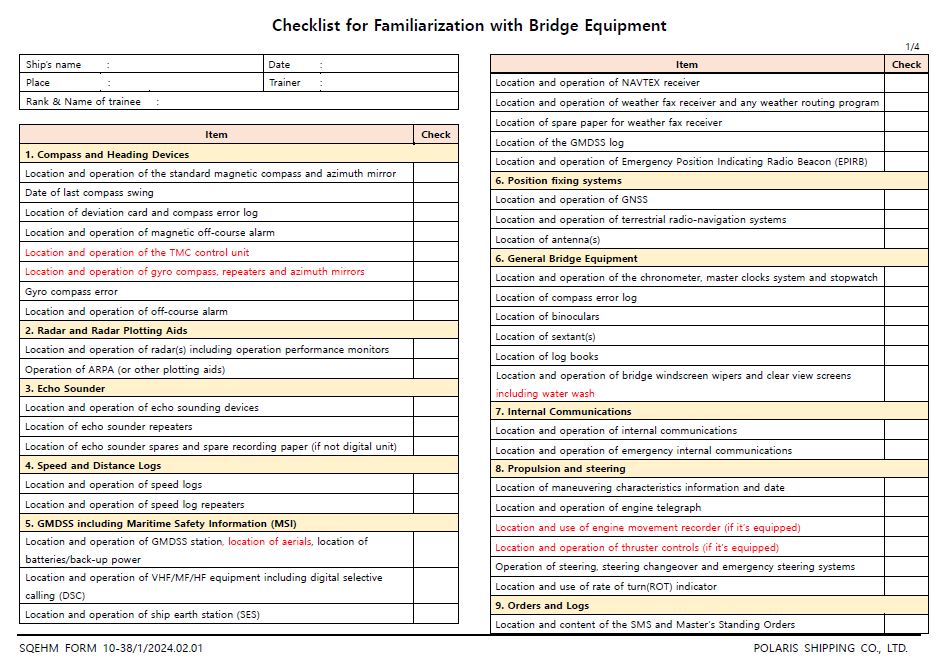

①Familiarization of Deck officers with navigational equipment operating and maintenance [Familiarization with Bridge equipment] - STCW CH VIII

4. Outside of Accommodation (C/O, Engineers)

4.1 Battery room

Guide to Inspection

-

SOLAS / CH-IV / Reg.13

SOLAS CH-II-2/Reg.5.2.1.1. / IACS UI SC 240

Battery room marking

“The main inlets and outlets of all ventilation systems shall be capable of being closed from outside the spaces being ventilated. The means of closing shall be easily accessible as well as prominently and permanently marked and shall indicate whether the shut-off is open or closed. “

Marking the following phrase around the Batter RM vent (or similar phrase)

- This closing device is to be kept open and only closed in the event of fire or other emergency – Explosive gas -

①Reserve cond. for GMDSS & Battery on/off load test

-

①Reserve cond. for GMDSS & Battery on/off load test

-

②Recharging

-

③Connecting cable

-

④Explosion-proof lamp

-

⑤Battery expired date

-

⑥Proper PPE standby (avoid possible contamination)

4.2 Em’cy generator room

Guide to Inspection

-

SOLAS / CH II-1 / Reg. 44

.3 all of these starting, charging and energy storing devices shall be located in the emergency generator space; these devices are not to be used for any purpose other than the operation of the emergency generating set. This does not preclude the supply to the air receiver of the emergency generating set from the main or auxiliary compressed air system through the non-return valve fitted in the emergency generator space.

If the vessel is trading in area with sub-zero temperature, the fuel tank of the emergency generator should be charged with fuel designed for use in sub-zero temperatures.

> The generator should be capable of providing full load requirements for at least 18 hours.

> Every oil fuel pipe (which, if damaged, would allow oil to escape from a storage, settling or daily service tank situated above the double bottom) shall be fitted with a cock or valve directly on the tank capable of being closed from a safe position, outside the space concerned, in the event of a fire occurring in the space in which such tanks are situated.

> Oil fuel pipes (which, if damaged, would allow oil to escape from a storage, settling or daily service tank having a capacity of 500 litres and above situated above the double bottom) shall be fitted with a cock or valve directly on the tank capable of being closed from a safe position, outside the space concerned, in the event of a fire occurring in the space in which such the tanks are situated.

> The controls for the remote operation of the valve for the emergency generator fuel tank shall be in a separate location from the controls for the remote operation of other valves for tanks located in machinery spaces. -

①Functioning

-

②Gauges, indicators

-

③Fuel oil tank quick closing valve condition

-

④Fuel q’ty (To be operated for 18 hours)

-

⑤Blackout test(test mode) ACB testing

-

⑤Blackout test(test mode) ACB testing (Date)

-

⑥Check Earth (During turn of deck light)

4.3 E/R ventilator & E/R funnel flap (damper)

Guide to Inspection

-

SOLAS / CH II-2 / Reg.9

SOLAS Reg. II-2/5.2.2.1 "means of control are to be provided for closure of openings in funnels which normally allow exhaust ventilation and closure of ventilation dampers".

There are NO requirements for the dampers located in the engine room funnels to be of the gastight or watertight type (normally these dampers are located higher than 2.3 m above position 2 and accordingly they are not required to be watertight in accordance with Load Line requirements).

The funnel flaps are not for forced ventilation they are a natural means of exhaust. Once they are closed and ER ventilation shutdown there is no air flow, and therefore no pressure differential across the dampers and if CO2 is released into the machinery space it flows to the lower levels as it is heavier than air. -

①Damper moving/corrosion

-

②Maintenance considering manufacturer’s gap standard

-

③Visual check the flap

-

④No Leakage from Control air line

4.4 Lighting (Emergency)

Guide to Inspection

-

SOLAS / CH II-1 / Reg. 41

-

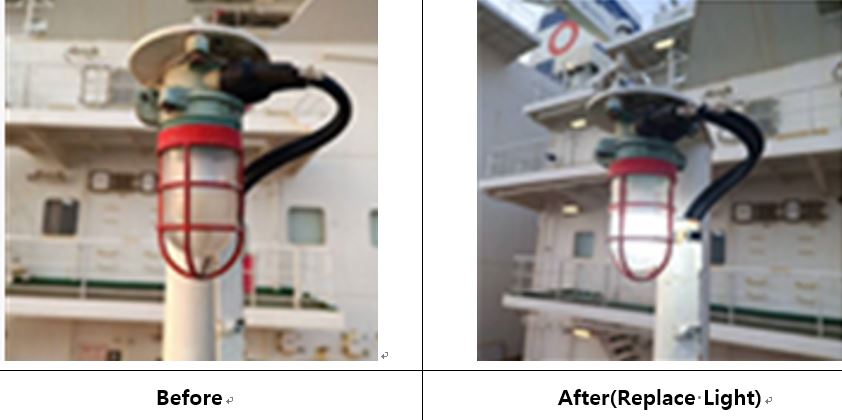

①Working condition

4.5 Air pipe & Sounding

Guide to Inspection

-

ICLL / Annex I / Chapter II / Reg. 20

Where air pipes to ballast and other tanks extend above the freeboard or superstructure decks, the exposed parts of the pipes shall be of substantial construction; the height from the deck to the point where water may have access below shall be at least 760 mm (30 inches) on the freeboard deck and 450 millimetres ( 17½ inches) on the superstructure deck. Where these heights may interfere with the working of the ship, a lower height may be approved, provided the Administration is satisfied that the closing arrangements and other circumstances justify a lower height. Satisfactory means permanently attached, shall be provided for closing the openings of the air pipes. -

①Marking

-

②Air pipe head, ball, floater damage

-

③Any missing of sounding cap

4.6 Garbage management & Garbage storage

Guide to Inspection

-

MARPOL / Annex V / Reg. 10

Garbage collected throughout the ship should be delivered to designated processing or storage locations. Cleaning and disinfecting of garbage storage location are both preventative and remedial pest control methods that should be applied regularly in garbage storage areas.

SOLAS CH II-2, Reg.4.4 / 4.2 Waste receptacles Go!IACS UI SC 166

Waste receptacles shall be constructed of non-combustible materials with no openings in the sides or bottom. -

①Garbage storage - If exessive of garbage, request to be landing to shore

-

②Segregation, Minimizing

-

③Proper marking & Display <br>- Category, Placard

5. Survival Craft & Launching arrangements (C/O, 2/O, 2/E & 3/E)

5.1 Inflatable liferaft

Guide to Inspection

-

SOLAS / CH-IV, 4.2.

Cargo ships shall carry one or more inflatable or rigid liferafts, stowed in a position providing for easy side-to-side transfer at a single open deck level and of such aggregate capacity as will accommodate the total number of persons on board. If not stowed in a position providing for easy side-to-side transfer at a single open deck level, the total capacity available on each

side shall be sufficient to accommodate the total number of persons on board.

If a free-fall lifeboat is fitted, cargo ships shall have one or more inflatable or rigid liferafts, on each side of the ship, of such aggregate capacity as will accommodate the total number of persons on board. The liferafts on at least one side of the ship shall be served by launching appliances.

For davit launched liferafts, the launching appliance shall include an automatic release hook arranged so as to prevent premature release during lowering and shall release the liferaft when waterborne. The release hook shall include a capability to release the hook under load. The on-load release control shall:

> Be clearly differentiated from the control which activates the automatic release function;

> Require at least two separate actions to operate;

> Be designed such that crew members on deck can clearly observe when the release mechanism is properly and completely set.

Every liferaft shall be stowed with its painter permanently attached to the ship.

Each liferaft or group of liferafts shall be stowed with a float-free arrangement so that each floats free and if inflatable, inflates automatically when the ship sinks.

Liferafts shall be so stowed as to permit manual release of one raft or container at a time from their securing arrangements.

Some hydrostatic release manufacturers recommend that each liferaft is fitted with its own individual hydrostatic release unit (HRU), to prevent the possibility, where more than one liferaft is utilising the same release, of one of the liferafts breaking the weak link before the second or subsequent liferafts have inflated.

When multiple liferafts are connected to a single HRU, each raft must be equipped with its own weak link. A HRU is not required for liferafts stored in the forward part of a vessel.

Check point

-

①HRU & Expired date

-

②Movable(if applicable)

-

③Weak Link connection

-

④Clear instruction

-

⑤Any obstruction above

-

⑥Drain hole condition (Position)

-

⑦Marking(Port of Registry, Ship Name)

5.2 Annual thorough exam. By shore technician

Guide to Inspection

-

SOLAS / CH 1

Check Point

-

①Report and filing<br> (clean without any recommendation or any remark)

5.3 Access (escape) route

Guide to Inspection

-

SOLAS / CH II-2 / Reg.13

Check Point

-

①No obstacle on the way

-

②Clear marking & symbol

5.4 Lifeboat (Freefall)

Guide to Inspection

-

LSA / CH IV/ Reg.4.7

Each survival craft shall be stowed in a state of continuous readiness so that two crew members can carry out preparations for embarkation and launching in less than five minutes.

Falls used in launching shall be inspected periodically with special regard for areas passing through sheaves and renewed when necessary due to deterioration of the falls or at intervals of not more than five years – whichever is the earlier.

Each free-fall lifeboat shall be fitted with a release system which shall be designed to test the release system without launching the lifeboat.

Each lifeboat shall be clearly marked with the number of persons for which the lifeboat is approved and the name and port of registry. Means of identifying the ship to which the lifeboat belongs, and the number of the lifeboat shall be marked in such a way that they are visible from above.

The release system of lifeboats, rescue boats, free-fall lifeboat including davit-launched life rafts shall be:

> Maintained in accordance with instructions for on-board maintenance as required by regulation 36.

> Subjected to a thorough examination and operational test during the annual surveys required by regulations I/7 and I/8 by properly trained personnel familiar with the system; and

> Operationally tested under a load of 1.1 times the total mass of the lifeboat when loaded with its full complement of person and equipment whenever the release gear is overhauled. Such over-hauling and testing shall be carried out at least once every five years.

Davit-launched life raft automatic release hooks shall be:

> Maintained in accordance with instructions for on-board maintenance as required by regulation 36.

> Subjected to a thorough examination and operational test during the annual surveys required by regulations I/7 and I/8 by properly trained personnel familiar with the system; and

> Operationally tested under a load of 1.1 times the total mass of the lifeboat when loaded with its full complement of person and equipment whenever the release gear is overhauled. Such over-hauling and test shall be carried out at least once every five years.

Check Point

-

①Hull condition(including Skate Pender, Bilge keel etc)

-

②Clear Hull Marking

-

③Retro taping

-

④Window sight

-

⑤Running(3 min.) & Propulsion(FWD/AFT, full speed)

-

⑥F.O level & Tk

-

⑦Battery recharged(if required)

-

⑧Two independent engine starting system

-

⑨Internal in L/boat

-

⑩Search light, nav. Light

-

⑪Fire extinguisher

-

⑫Expired date Food ration, drinking water, anti-seasickness pills & Other inventory

-

⑬Magnetic compass bubble & error

-

⑭Release hook Correct re-setting (according to instruction)

-

⑮Recovery condition

-

⑯Access (Clear without any obstruction, No locking)

5.5 Rescue boat

Guide to Inspection

-

LSA / CH V

5.1.2 Rescue boat equipment

5.1.2.1 All items of rescue boat equipment, with the exception of boat-hooks which shall be kept free for fending off purposes, shall be secured within the rescue boat by lashings, storage in lockers or compartments, storage in brackets or similar mounting arrangements, or other suitable means. The equipment shall be secured in such a manner as not to interfere with any launching or recovery procedures. All items of rescue boat equipment shall be as small and of as little mass as possible and shall be packed in suitable and compact form.

5.1.2.2 The normal equipment of every rescue boat shall consist of:

.1 sufficient buoyant oars or paddles to make headway in calm seas. Thole pins, crutches or equivalent arrangements shall be provided for each oar. Thole pins or crutches shall be attached to the boat by lanyards or chains;

.2 a buoyant bailer;

.3 a binnacle containing an efficient compass which is luminous or provided with suitable means of illumination;

.4 a sea-anchor and tripping line if fitted with a hawser of adequate strength not less than 10 m in length;

.5 a painter of sufficient length and strength, attached to the release device complying with the requirements of paragraph 4.4.7.7 and placed at the forward end of the rescue boat;

.6 one buoyant line, not less than 50 m in length, of sufficient strength to tow a liferaft as required by paragraph 5.1.1.7;

.7 one waterproof electric torch suitable for Morse signalling, together with one spare set of batteries and one spare bulb in a waterproof container;

Refer to MSC.1/Circ.1674 UNIFIED INTERPRETATION OF THE LSA CODE AND THE 1994 AND 2000 HSC CODES

.8 one whistle or equivalent sound signal;

.9 a first-aid outfit in a waterproof case capable of being closed tightly after use;

.10 two buoyant rescue quoits, attached to not less than 30 m of buoyant line;

.11 a searchlight with a horizontal and vertical sector of at least 6° and a measured luminous intensity of 2500 cd which can work continuously for not less than 3 h;

.12 an efficient radar reflector;

.13 thermal protective aids complying with the requirements of section 2.5 sufficient for 10% of the number of persons the rescue boat is permitted to accommodate or two, whichever is the greater; and

.14 portable fire-extinguishing equipment of an approved type suitable for extinguishing oil fires.*

*Refer to the Improved Guidelines for marine portable fire extinguishers, adopted by the Organization by resolution A.951(23).

5.1.2.3 In addition to the equipment required by paragraph 5.1.2.2, the normal equipment of every rigid rescue boat shall include:

.1 a boat-hook;

.2 a bucket; and

.3 a knife or hatchet.

5.1.2.4 In addition to the equipment required by paragraph 5.1.2.2, the normal equipment of every inflated rescue boat shall consist of:

.1 a buoyant safety knife;

.2 two sponges;

.3 an efficient manually operated bellows or pump;

.4 a repair kit in a suitable container for repairing punctures; and

.5 a safety boat-hook.

Check Point

-

①Hull condition

-

②Clear Hull Marking

-

③Retro taping

-

④Inventory (Any defect, expired, short of item)

-

⑤Running(3 min.) & Propulsion(FWD/AFT, full speed)

-

⑥F.O level & Tk

-

⑦Battery recharged(if required)

-

⑧Two independent engine starting system

-

⑨Any damage

-

⑩Light

-

⑪Fire extinguisher

5.6.1 Davit (lifeboat, rescue boat)

Guide to Inspection

-

LSA / CH IV/ Reg.4.7 & LSA / CH V

Check point

-

①Excessive corrosion

-

②Limit Switch

-

③Greasing for moving part

5.6.2 Davit (Davit-launched liferaft)-if fitted

Guide to Inspection

-

LSA / CH IV

Check Point

-

①Excessive corrosion

-

②Limit Switch

-

③Greasing for moving part

-

④Lifting Hook Assembly

-

⑤By 2nd means power (Accumulator, davit arm rotating angle for combined type)

-

⑤By 2nd means power (Accumulator, davit arm rotating angle for combined type)

5.7 Mainteance

Guide to Inspection

-

SOLAS / CH III / Reg.20

3 Maintenance

3.1 Maintenance, testing and inspections of life-saving appliances shall be carried out in a manner having due regard to ensuring reliability of such appliances.( Replaced by Res.MSC.404(96))

3.2 Instructions for on-board maintenance of life-saving appliances complying with regulation 36 shall be provided and maintenance shall be carried out accordingly.

3.3 The Administration may accept, in compliance with the requirements of paragraph 3.2, a shipboard planned maintenance programme, which includes the requirements of regulation 36.

4 Maintenance of falls

Falls used in launching shall be inspected periodically* with special regard for areas passing through sheaves, and renewed when necessary due to deterioration of the falls or at intervals of not more than 5 years, whichever is the earlier.

* Refer to Measures to prevent accidents with lifeboats (MSC.1/Circ.1206/Rev.1).

5 Spares and repair equipment

Spares and repair equipment shall be provided for life-saving appliances and their components which are subject to excessive wear or consumption and need to be replaced regularly.

6 Weekly inspection

The following tests and inspections shall be carried out weekly and a report of the inspection shall be entered in the log-book:

.1 all survival craft, rescue boats and launching appliances shall be visually inspected to ensure that they are ready for use. The inspection shall include, but is not limited to, the condition of hooks, their attachment to the lifeboat and the on-load release gear being properly and completely reset;

.2 all engines in lifeboats and rescue boats shall be run for a total period of not less than 3 min, provided the ambient temperature is above the minimum temperature required for starting and running the engine. During this period of time, it should be demonstrated that the gear box and gear box train are engaging satisfactorily. If the special characteristics of an outboard motor fitted to a rescue boat would not allow it to be run other than with its propeller submerged for a period of 3 min, a suitable water supply may be provided. In special cases, the Administration may waive this requirement for ships constructed before 1 July 1986;

.3 lifeboats, except free-fall lifeboats, on cargo ships shall be moved from their stowed position, without any persons on board, to the extent necessary to demonstrate satisfactory operation of launching appliances, if weather and sea conditions so allow; and

.4 the general emergency alarm shall be tested.

7 Monthly inspection

7.1 All lifeboats, except free-fall lifeboats, shall be turned out from their stowed position, without any persons on board if weather and sea conditions so allow.

7.2 Inspection of the life-saving appliances, including lifeboat equipment, shall be carried out monthly using the checklist required by regulation 36.1 to ensure that they are complete and in good order. A report of the inspection shall be entered in the log-book.

8 Servicing of inflatable liferafts, inflatable lifejackets, marine evacuation systems and maintenance and repair of inflated rescue boats

8.1 Every inflatable liferaft, inflatable lifejacket, and marine evacuation system shall be serviced:

.1 at intervals not exceeding 12 months, provided where in any case this is impracticable, the Administration may extend this period to 17 months;and

.2 at an approved servicing station which is competent to service them, maintains proper servicing facilities and used only properly trained personnel.*

* Refer to the Recommendation on Conditions for the Approval of Servicing Stations for Inflatable Liferafts adopted by the Organization by resolution A.761(18), as amended.

8.2 Rotational deployment of marine evacuation systems

In addition to or in conjunction with the servicing intervals of marine evacuation systems required by paragraph 8.1, each marine evacuation system should be deployed from the ship on a rotational basis at intervals to be agreed by the Administration provided that each system is to be deployed at least once every six years.

8.3 An Administration which approves new and novel inflatable liferaft arrangements pursuant to regulation 4 may allow for extended service intervals on the following conditions:

.1 The new and novel liferaft arrangement has proved to maintain the same standard, as required by testing procedure, during extended service intervals.

.2 The liferaft system shall be checked on board by certified personnel according to paragraph 8.1.1.

.3 Service at intervals not exceeding 5 years shall be carried out in accordance with the recommendations of the Organization.*

* Refer to the Recommendation on Conditions for the Approval of Servicing Stations for Inflatable Liferafts adopted by the Organization by resolution A.761(18), as amended.

8.4 All repairs and maintenance of inflated rescue boats shall be carried out in accordance with the manufacturer's instructions. Emergency repairs may be carried out on board the ship;however, permanent repairs shall be effected at an approved servicing station. -

①Working

-

②Hole/excessive corrosion for Davit

-

③Lower Bkts, Bolt/Nut for Davit, Winch & Foundation

-

④Fall renew(Every 5 yr)

-

⑤Winch Brake

-

⑥No oil / air leakage from winches and motors

5.8 Embarkation ladder

Guide to Inspection

-

LSA CODE / CH VI / 6.1.

6.1.6 Embarkation ladders

6.1.6.1 Handholds shall be provided to ensure a safe passage from the deck to the head of the ladder and vice versa.

6.1.6.2 The steps of the ladder shall be:

.1 made of hardwood, free from knots or other irregularities, smoothly machined and free from sharp edges and splinters, or of suitable material of equivalent properties;

.2 provided with an efficient nonslip surface either by longitudinal grooving or by the application of an approved nonslip coating;

.3 not less than 480 mm long, 115 mm wide and 25 mm in depth, excluding any nonslip surface or coating; and

.4 equally spaced not less than 300 mm or more than 380 mm apart and secured in such a manner that they will remain horizontal.

6.1.6.3 The side ropes of the ladder shall consist of two uncovered manila ropes not less than 65 mm in circumference on each side. Each rope shall be continuous with no joints below the top step. Other materials may be used provided the dimensions, breaking strain, weathering, stretching and gripping properties are at least equivalent to those of manila rope. All rope ends shall be secured to prevent unravelling.

Check point

-

①Condition<br> - Rope, Shackle, Ladder steps

5.9 Drill, abandon ship (Mandatory)

Guide to inspection

-

SOLAS CH-III

Check Point

-

①Crew familiarity <br>Launch of the survival craft within a required time period<br>* preparation for embarking and launching by 2 crews in less than 5 min. (SOLAS III/13.1.3)<br>* Cargo ship : 10 min. for lifeboats and davit-launched liferafts (SOLAS III/31.1.5)

-

②Familiarization of the survival craft launching procedure (Commander, Substitute for commander and Bos’n)

-

③Drill evidence

-

③Drill evidence

-

④Instruction displayed

-

⑤Substitute

-

⑤Record keeping (Minimum req. SOLAS CH III,Reg.19)

5.10 Fire drill

Guide to Inspection

-

SOLAS / CH-III / Reg.19

SOLAS / CH-II-2 / Reg.15.2

3.5 Fire drills

3.5.1 Fire drills should be planned in such a way that due consideration is given to regular practice in the various emergencies that may occur depending on the type of ships and the cargo.

3.5.2 Each fire drill shall include;

.1 reporting to stations and preparing for the duties described in the muster list required by regulation 8;

.2 starting of a fire pump, using at least the two required jets of water to show that the system is in proper working order;

.3 checking of fireman's outfit and other personal rescue equipment;

.4 checking of relevant communication equipment;

.5 checking the operation of watertight doors, fire doors, fire dampers and main inlets and outlets of ventilation systems in the drill area;and

.6 checking the necessary arrangements for subsequent abandoning of the ship.

3.5.3 The equipment used during drills shall immediately be brought back to its fully operational condition and any faults and defects discovered during the drills shall be remedied as soon as possible.

Check Point

-

①Crew familiarity & Record keeping <br> (Minimum req. SOLAS CH III, Reg.19)

6. Inside of Accommodation (C/O, 3/O, 1/E)

6.1 Door with self-closing device

Guide to inspection

-

SOLAS / CH II-2 / Reg. 9.4.

** Self Closing Door shall be indicated on Fire Control Plan as A-60 (Eng. room Entrance

Door, Eng. Room floor emergency escape door, Galley door)

Check Point

-

①No holding Back

-

②Working (Fully closed)

-

③Visual condition (any damaged or hole)

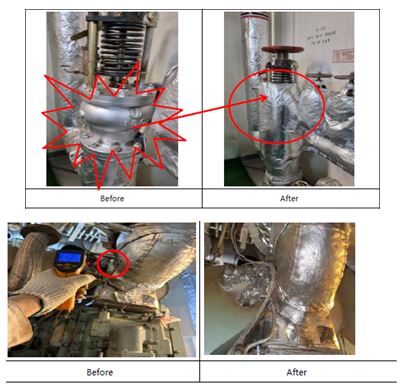

6.2 Insulation

Guide to Inspection

-

SOLAS / CH II-2 / Reg. 4.3

4.3 Insulation surfaces protected against oil penetration

In spaces where penetration of oil products is possible, the surface of insulation shall be impervious to oil or oil vapours.

Check Point

-

①No missing / omission

-

②No breakaway

6.3 Fixed extinguisher system-CO2 (Rm)

Guide to Inspection

-

FSS / CH 5

2.1.3 System control requirements

2.1.3.1 The necessary pipes for conveying fire-extinguishing medium into the protected spaces shall be provided with control valves so marked as to indicate clearly the spaces to which the pipes are led. Suitable provisions shall be made to prevent inadvertent release of the medium into the space. Where a cargo space fitted with a gas fire-extinguishing system is used as a passenger space, the gas connection shall be blanked during such use. The pipes may pass through accommodations providing that they are of substantial thickness and that their tightness is verified with a pressure test, after their installation, at a pressure head not less than 5 N/mm². In addition, pipes passing through accommodation areas shall be joined only by welding and shall not be fitted with drains or other openings within such spaces. The pipes shall not pass through refrigerated spaces.

2.1.3.2 Means shall be provided for automatically giving audible and visual warning of the release of fire-extinguishing medium into any ro-ro spaces, container holds equipped with integral reefer containers, spaces accessible by doors or hatches, and other spaces in which personnel normally work or to which they have access. (Replaced by Res.MSC.339(91)) The audible alarms shall be located so as to be audible throughout the protected space with all machinery operating, and the alarms should be distinguished from other audible alarms by adjustment of sound pressure or sound patterns. The pre-discharge alarm shall be automatically activated (e.g., by opening of the release cabinet door). The alarm shall operate for the length of time needed to evacuate the space, but in no case less than 20 s before the medium is released. Conventional cargo spaces and small spaces (such as compressor rooms, paint lockers, etc.) with only a local release need not be provided with such an alarm.

Check Point

-

①Bottle contents, q'ty as per manufacturer's standard

-

②Hydro Test date

-

③Crew familiarity

-

④Insulation

-

⑤Safety pin location (As per manufacturer’s standard)

-

⑥Weight scale & accessories

-

⑦Flexible Connecting hose

-

⑧(If,fitted) condition of Ventilator

-

⑨Safety sign before entry

6.4 Fire control station

Guide to Inspection

-

SOLAS / CH II-2 & CH II-2, Reg.7 Detection and alarm

Check Point

-

①Fire detector Audible/Visible alarm test

-

②Water mist buzzer & Alarm test (if fitted)

6.5 Isolating valve

Guide to Inspection

-

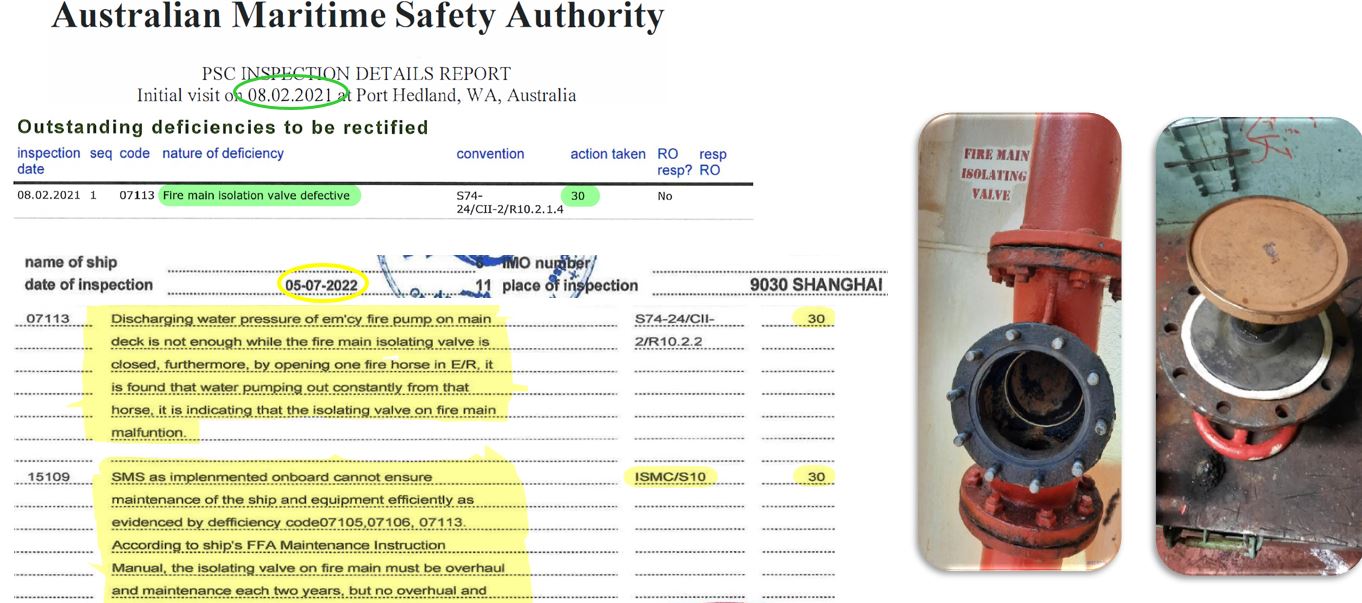

SOLAS / Ch II-2 / Reg. 10.2.1.1

Isolation valves shall be installed for all open deck fire main branches used for purposes other than fire fighting. In ships where deck cargo may be carried, the positions of the hydrants shall be such that they are always readily accessible and the pipes shall be arranged as far as practicable to avoid risk of damage by such cargo.

Check Point

-

①Location

-

②Condition of moving part

-

③Marking

6.6 Fire fighter's outfits

Guide to Inspection

-

FSS / CH 3 / 2.1

2.1 Fire-fighter's outfit

A fire-fighter's outfit shall consist of a set of personal equipment and a breathing apparatus.

2.1.1 Personal equipment

Personal equipment shall consist of the following:

.1 protective clothing of material to protect the skin from the heat radiating from the fire and from burns and scalding by steam. The outer surface shall be water-resistant;

.2 boots of rubber or other electrically non-conducting material;

.3 rigid helmet providing effective protection against impact;

.4 electric safety lamp (hand lantern) of an approved type with a minimum burning period of 3 hours. Electric safety lamps on tankers and those intended to be used in hazardous areas shall be of an explosion-proof type*; and

*Refer to the recommendations of International Electrotechnical Commission, in particular publication IEC 60079, Electrical Apparatus for Explosive Gas Atmosphere

.5 axe with a handle provided with high-voltage insulation.

2.1.2.1 Breathing apparatus shall be a self-contained compressed air breathing apparatus for which the volume of air contained in the cylinders shall be at least 1,200 l, or other self-contained breathing apparatus which shall be capable of functioning for at least 30 min. All air cylinders for breathing apparatus shall be interchangeable. (Replaced by Res.MSC.339(91))

2.1.2.2 Compressed air breathing apparatus shall be fitted with an audible alarm and a visual or other device which will alert the user before the volume of the air in the cylinder has been reduced to no less than 200 l.(Replaced by Res.MSC.339(91))

Refer to MSC.1/Circ.1499 UNIFIED INTERPRETATION OF CHAPTER 3 OF THE FSS CODE

2.1.3 Lifeline

For each breathing apparatus a fireproof lifeline of at least 30 m in length shall be provided. The lifeline shall successfully pass an approval test by statical load of 3.5 kN for 5 min without failure. The lifeline shall be capable of being attached by means of a snap-hook to the harness of the apparatus or to a separate belt in order to prevent the breathing apparatus becoming detached when the lifeline is operated.

Check Point

-

①Separate Stowage condition

-

②Bottle pressurized date & contents(incl. spare)

-

③Visual condition

-

④Belongings

-

⑤Emergency lights

-

⑥Two way VHF Communication

-

⑦B.A. Low pressure alarm

6.7 MLC-related matters

Check Point

-

①Clean and hygienic for Crew cabin

- bedding

- adequate artificial light

- hot and cold running water with showers -

②Clean and available for the suitable public toilet

-

③Display the MLC Related certificate <br>- [Form] Checklist Maritime Labour Convention

6.8 Symbol

Guide to Inspection

-

SOLAS / CH II-2 / Reg.15.2.4<br>Res.A.952(23)<br>SOLAS / CH III / Reg. 9 Res.A.760(18)

Check Point

-

①Clear and highlight attached as per [Safety plan]

6.9 Hospital

Guide to Inspection

-

MLC, Reg.4.1 Medical care on board ship and ashore

The ship’s hospital shall not use the hospital as a cabin or storage space.

3. Each Member shall adopt laws and regulations establishing requirements for on-board hospital and medical care facilities and equipment and training on ships that fly its flag.

Check Point

-

①Hospital call alarm (Sound, Visual)

-

②Medical log, Medicine list control

-

③Hygine condition

6.10 Ref.Chamber

Guide to Inspection

-

MLC, Reg.3.2 Food and catering

In accordance with the ongoing compliance procedures under Title 5, the competent authority shall require that frequent documented inspections be carried out on board ships, by or under the authority of the master, with respect to:

(a) supplies of food and drinking water in relation to their quantity, nutritional value, quality and variety;(Replaced by MLC 2022 Amendment)

(b) all spaces and equipment used for the storage and handling of food and drinking water; and

(c) galley and other equipment for the preparation and service of meals.

Check Point

-

①Ref.Chamber call alarm (Sound, Visual)

-

②Ref.Chamber Door frame(packing), door handle

-

③Temperature condition<br>- Chill 5°C & Freezer minus 18°C or colder"

-

④Exessive defrosting (Ice) on pipe

6.11 Cyber Security

Guide to Inspection

-

IMO Reg.MSC.428(98)

The cyber security management shall:

> Identify the roles and responsibilities of users, key personnel, and management both ashore and on board

> Identify the systems, assets, data and capabilities, which if disrupted, could pose risks to the ship’s operations and safety

> Implement technical measures to protect against a cyber-incident and ensure continuity of operations. This may include configuration of networks, access control to networks and systems, communication and boundary defence and the use of protection and detection software

> Implement activities and plans (procedural protection measures) to provide resilience against cyber incidents. This may include training and awareness, software maintenance, remote and local access, access privileges, use of removable media and equipment disposal

> Implement activities to prepare for and respond to cyber incidents.

Check Point

-

①Electric device security (Implement Procedure)

-

②Public PC Security(USB & Caution Sign)

-

③Cyber security training and drill implementation

7. Personal Life-saving appliances (C/O, 2/O)

7.1 Lifebuoys (Common)

Guide to Inspection

-

LSA / Ch 2.1

2.1.1 Lifebuoy specification

Every lifebuoy shall:

.1 have an outer diameter of not more than 800 mm and an inner diameter of not less than 400 mm;

.2 be constructed of inherently buoyant material; it shall not depend upon rushes, cork shavings or granulated cork, any other loose granulated material or any air compartment which depends on inflation for buoyancy;

.3 be capable of supporting not less than 14.5 kg of iron in fresh water for a period of 24 h;

.4 have a mass of not less than 2.5 kg;

.5 not sustain burning or continue melting after being totally enveloped in a fire for a period of 2 s;

.6 be constructed to withstand a drop into the water from the height at which it is stowed above the waterline in the lightest seagoing condition or 30 m, whichever is the greater, without impairing either its operating capability or that of its attached components;

.7 if it is intended to operate the quick release arrangement provided for the self-activated smoke signals and self-igniting lights, have a mass of not less than 4 kg (Amended by Res.MSC.207(81)); and

.8 be fitted with a grabline not less than 9.5 mm in diameter and not less than 4 times the outside diameter of the body of the buoy in length. The grabline shall be secured at four equidistant points around the circumference of the buoy to form four equal loops.

Check Point

-

①Weight <br>- Normal : not less than 2.5kg <br>- Self-activating smoke not more than 4kg

-

②Crack, Damage

-

③Marking (Ship name & Port of registry)

7.2 Quick release Life-buoy

Guide to Inspection

-

LSA / CH II / 2.1

.7 if it is intended to operate the quick release arrangement provided for the self-activated smoke signals and self-igniting lights, have a mass of not less than 4 kg (Amended by Res.MSC.207(81)); and

Check Point

-

①Quick Release

-

②Self-igniting light

-

③Expiration date

-

④Clear Marking

-

⑤Connection the link & Overall

7.3 Self-igniting light

Guide to Inspection

-

LSA / CH II / 2.1

2.1.2 Lifebuoy self-igniting lights

Self-igniting lights required by regulation III/7.1.3 shall:

.1 be such that they cannot be extinguished by water;

.2 be of white colour and capable of either burning continuously with a luminous intensity of not less than 2 cd in all directions of the upper hemisphere or flashing (discharge flashing) at a rate of not less than 50 flashes and not more than 70 flashes per min with at least the corresponding effective luminous intensity;

.3 be provided with a source of energy capable of meeting the requirement of paragraph 2.1.2.2 for a period of at least 2 h; and

.4 be capable of withstanding the drop test required by paragraph 2.1.1.6.

2.1.3 Lifebuoy self-activating smoke signals

Self-activating smoke signals required by regulation III/7.1.3 shall:

.1 emit smoke of a highly visible colour at a uniform rate for a period of at least 15 min when floating in calm water;

.2 not ignite explosively or emit any flame during the entire smoke emission time of the signal;

.3 not be swamped in a seaway;

.4 continue to emit smoke when fully submerged in water for a period of at least 10 s;

.5 be capable of withstanding the drop test required by paragraph 2.1.1.6; and

.6 be provided with a quick-release arrangement that will automatically release and activate the signal and associated self-igniting light connected to a lifebuoy having a mass of not more than 4 kg. ( Go! Added by Res.MSC.207(81))

Check Point

-

①Normal working & any damage (Bulb, Light cover)

-

②Battery expire date

7.4 Buoyant lifelines

Guide to Inspection

-

LSA / CH II / 2.1

2.1.4 Buoyant lifelines

Buoyant lifelines required by regulation III/7.1.2 shall:

.1 be non-kinking;

.2 have a diameter of not less than 8 mm; and

.3 have a breaking strength of not less than 5 kN.

Check Point

-

①Non-kinking.

-

②Not less than dia 8 mm dia & Strength 5 Kn

7.5 Lifejacket

Guide to Inspection

-

LSA / CH II / 2.2

2.2.1.5 An adult lifejacket shall be so constructed that:

.1 at least 75% of persons who are completely unfamiliar with the lifejacket can correctly don it within a period of 1 min without assistance, guidance or prior demonstration;

.2 after demonstration, all persons can correctly don it within a period of 1 min without assistance;

.3 it is clearly capable of being worn in only one way or inside-out and, if donned incorrectly, it is not injurious to the wearer;

.4 the method of securing the lifejacket to the wearer has quick and positive means of closure that do not require tying of knots;

.5 it is comfortable to wear; and

.6 it allows the wearer to jump into the water from a height of at least 4.5 m while holding on to the lifejacket, and from a height of at least 1m with arms held overhead, without injury and without dislodging or damaging the lifejacket or its attachments.

2.2.1.7 An adult lifejacket shall allow the person wearing it to swim a short distance and to board a survival craft.

2.2.1.11 A lifejacket shall have buoyancy which is not reduced by more than 5% after 24 h submersion in fresh water.

2.2.1.12 The buoyancy of a lifejacket shall not depend on the use of loose granulated materials.

2.2.1.13 Each lifejacket shall be provided with means of securing a lifejacket light as specified in paragraph 2.2.3 such that it shall be capable of complying with paragraphs 2.2.1.5.6 and 2.2.3.1.3.

2.2.1.14 Each lifejacket shall be fitted with a whistle firmly secured by a lanyard.

2.2.1.15 Lifejacket lights and whistles shall be selected and secured to the lifejacket in such a way that their performance in combination is not degraded.

2.2.1.16 A lifejacket shall be provided with a releasable buoyant line or other means to secure it to a lifejacket worn by another person in the water.

2.2.1.17 A lifejacket shall be provided with a suitable means to allow a rescuer to lift the wearer from the water into a survival craft or rescue boat.

2.2.3 Lifejacket lights

2.2.3.1 Each lifejacket light shall:

.1 have a luminous intensity of not less than 0.75 cd in all directions of the upper hemisphere;

.2 have a source of energy capable of providing a luminous intensity of 0.75 cd for a period of at least 8 h;

.3 be visible over as great a segment of the upper hemisphere as is practicable when attached to a lifejacket; and

.4 be of white colour.

2.2.3.2 If the light referred to in paragraph 2.2.3.1 is a flashing light, it shall, in addition:

.1 be provided with a manually operated switch; and

.2 flash at a rate of not less than 50 flashes and not more than 70 flashes per minute with an effective luminous intensity of at least 0.75 cd.”

Check Point

-

①Lighting, whistle

-

②Letter Marking & Appearance

7.6 Immersion suit

Guide to Inspection

-

LSA / Ch 2.3

The Guidelines for monthly shipboard inspection of immersion suits and anti-exposure suits (MSC/Circ.1047) are very helpful in identifying obvious problems with a suit, but do not adequately address deterioration of seams and closures (zippers, etc.) which may not be readily apparent by visual inspection. Such deterioration can be detected by pressurization of the suit with air and testing the seams and closures for leaks with a soapy water solution.

2.3 Immersion suits

2.3.1 General requirements for immersion suits

2.3.1.1 An immersion suit shall be constructed with waterproof materials such that: ( Amended by Res.MSC.207(81))

.1 it can be unpacked and donned without assistance within 2 min, taking into account donning of any associated clothing*, donning of a lifejacket if the immersion suit must be worn in conjunction with a lifejacket to meet the requirements of paragraph 2.3.1.2, and inflation of orally inflatable chambers if fitted; ( Replaced by Res.MSC.207(81))

* Refer to paragraph 3.1.3 of the Recommendation on testing of life-saving appliances, adopted by the Maritime Safety Committee of the Organization by resolution MSC.81(70) , as amended.

.2 it will not sustain burning or continue melting after being totally enveloped in a fire for a period of 2 s;

.3 it will cover the whole body with the exception of the face, except that covering for the hands may be provided by separate gloves which shall be permanently attached to the suit; ( Replaced by Res.MSC.207(81))

.4 it is provided with arrangements to minimize or reduce free air in the legs of the suit; and

.5 following a jump from a height of not less than 4.5 m into the water there is no undue ingress of water into the suit.

2.3.1.2 An immersion suit on its own, or worn in conjunction with a lifejacket if necessary, shall have sufficient buoyancy and stability in calm fresh water to: ( Replaced byRes.MSC.207(81))

.1 lift the mouth of an exhausted or unconscious person clear of the water by not less than 120 mm; and ( Replaced by Res.MSC.207(81))

.2 allow the wearer to turn from a face-down to a face-up position in not more than 5 s. ( Replaced by Res.MSC.207(81))

2.3.1.3 An immersion suit shall permit the person wearing it, and also wearing a lifejacket if the immersion suit is to be worn in conjunction with a lifejacket, to:

.1 climb up and down a vertical ladder at least 5 m in length;

.2 perform normal duties associated with abandonment;

.3 jump from a height of not less than 4.5 m into the water without damaging or dislodging the immersion suit or its attachments, or being injured; and ( Amended by Res.MSC.207(81))

.4 swim a short distance through the water and board a survival craft.

Check Point

-

①Condition (glue/zipper/sewing parts, detached or sticked, etc)

-

②Light & whishle condition

8. Main Deck & Cargo Hold(Bulk Carrier and General Dry Cargo Ship) (C/O)

8.1 International shore connection

Guide to Inspection

-

SOLAS / Ch II-2 10.2.1.7 / MSC.98(73)"

The international shore connection is a standard sized flange with nuts, bolts and washers and a coupling for ship’s fittings.

The fitting and joining must be suitable for a working pressure of 10.5 bar. Four bolts are required of 16mm diameter and 50mm length, also eight washers and a gasket of any suitable material.

Check Point

-

①Retaining with required items - Bolt 16mm, 4 pcs with 50mm length - Nut 16mm, 4 pcs - Spanner

8.2 Ventilator

Guide to Inspection

-

ICLL Annex I / Chapter II / Reg. 19

(1) Ventilators in position 1 or 2 to spaces below freeboard decks or decks of enclosed superstructures shall have coamings of steel or other equivalent material, substantially constructed and efficiently connected to the deck. Where the coaming of any ventilator exceeds 900 millimetres 35½ ( inches) in height it shall be specially supported.

(2) Ventilators passing through superstructures other than enclosed superstructures shall have substantially constructed coamings of steel or other equivalent material at the freeboard deck.

(3) Ventilators in position 1 the coamings of which extend to more than 4.5 m (14.8 feet) above the deck, and in position 2 the coamings of which extend to more than 2.3 m (7.5 feet) above the deck, need not be fitted with closing arrangements unless specifically required by the Administration. IACS UI LL 58

(4) Except as provided in paragraph (3) of this Regulation ventilator openings shall be provided with efficient weathertight closing appliances. In ships of not more than 100 m (328 feet) in length the closing appliances shall be permanently attached; where not so provided in other ships, they shall be conveniently stowed near the ventilators to which they are to be fitted. Ventilators in position 1 shall have coamings of a height of at least 900 millimetres ( 35½ inches) above the deck; in position 2 the coamings shall be of a height at least 760 millimetres (30 inches) above the deck. IACS UI LL 52 and LL 58

Check Point

-

①Damper moving/corrosion (Free-up)

-

②Coaming

-

③Vent cover

-

④Inside inspection hole (if fitted)

-

8.3 Air pipe (Vent)

Guide to Inspection

-

ICLL Annex I / Chapter II / Reg. 20

Where air pipes to ballast and other tanks extend above the freeboard or superstructure decks, the exposed parts of the pipes shall be of substantial construction; the height from the deck to the point where water may have access below shall be at least 760 mm (30 inches) on the freeboard deck and 450 millimetres ( 17½ inches) on the superstructure deck. Where these heights may interfere with the working of the ship, a lower height may be approved, provided the Administration is satisfied that the closing arrangements and other circumstances justify a lower height. Satisfactory means permanently attached, shall be provided for closing the openings of the air pipes.

Check Point

-

①Any missing of sounding cap

-

②Floating Ball or floater condition and Rubber packing condition

-

③Marking

8.4 Fire main line

Guide to Inspection

-

SOLAS / Ch II-2 / Reg.10.2. Water supply

2.1.6 Pressure at hydrants

With the two pumps simultaneously delivering water through the nozzles specified in paragraph 2.3.3, with the quantity of water as specified in paragraph 2.1.3, through any adjacent hydrants, the following minimum pressures shall be maintained at all hydrants:

.2 for cargo ships,

6,000 gross tonnage and upwards 0.27 N/mm²

less than 6,000 gross tonnage; 0.25 N/mm² and

.3 the maximum pressure at any hydrant shall not exceed that at which the effective control of a fire hose can be demonstrated.

Check Point

-

①Hole or any leakage (Normal pressure during Anchor wash)

-

②Corrosion

-

③Valve moving

-

④Patching (Any doubling)

8.5 Main deck

-

①Corrosion/hole

-

②No crack

-

③Paint condition

8.6 Small hatch

Guide to Inspection

-

ICLL Annex I / Chapter II / Reg. 18

(1) Manholes and flush scuttles in position 1 or 2 or within superstructures other than enclosed superstructures shall be closed by substantial covers capable of being made watertight. Unless secured by closely spaced bolts, the covers shall be permanently attached.

(2) Openings in freeboard decks other than hatchways, machinery space openings, manholes and flush scuttles shall be protected by an enclosed superstructure, or by a deckhouse or companionway of equivalent strength and weathertightness. Any such opening in an exposed superstructure or in the top of a deckhouse on the freeboard deck which gives access to a space below the freeboard deck or a space within an enclosed superstructure shall be protected by an efficient deckhouse or companionway. Doorways in such deckhouses or companionways shall be fitted with doors complying with the requirements of Regulation 12 (1).

IACS UI LL 46

Check Point

-

① Weathertight (Packing, cover frame deformation)

-

② Closing Device (Dog bolt free-up)

-

③ Corrosion and hole: Visual and hammer test

-

④ Packing : dropping and damage

-

⑤ ETC: Marking, Coaming Corrosion and hole

8.7 Hatch cover

Guide to Inspection

-

ICLL, Annex I, Ch-II, Reg.16

Hatchway Coamings

(1) At positions 1 and 2 the height above the deck of hatchway coamings fitted with weathertight hatch covers of steel or other equivalent material fitted with gaskets and clamping devices shall be as specified in Regulation 15(1). The height of these coamings may be reduced, or the coamings omitted entirely, on condition that the Administration is satisfied that the safety of the ship is not thereby impaired in any sea conditions. Where coamings are provided they shall be of substantial construction.

Weathertight Covers

(2) Where weathertight covers are of mild steel the strength shall be calculated with assumed loads not less than 1.75 metric tons per square metre (358 pounds per square foot) on hatchways in position 1, and not less than 1.30 metric tons per square metre (266 pounds per square foot) on hatchways in position 2, and the product of the maximum stress thus calculated and the factor of 4.25 shall not exceed the minimum ultimate strength of the material. They shall be so designed as to limit the deflection to not more than 0.0028 times the span under these loads. Mild steel plating forming the tops of covers shall be not less in thickness than one per cent of the spacing of stiffeners or 6 millimetres (0.24 inches) if that be greater. The provisions of Regulation 15(5) are applicable for ships of not more than 100 metres (328 feet) in length.

(3) The strength and stiffness of covers made of materials other than mild steel shall be equivalent to those of mild steel to the satisfaction of the Administration.

Check Point

-

①Corrosion/hole

-

②Packing (Deform and damage)

-

③Weathertightness - Hose Test, Water pressure

8.8 Hatch coaming, stay, stiffener

Guide to Inspection

-

ICLL / Annex I / Chapter II / Reg. 16

Means for Securing Weathertightness