Title Page

-

Date of audit

-

Scope the audit

-

Prepared by:

General Information

-

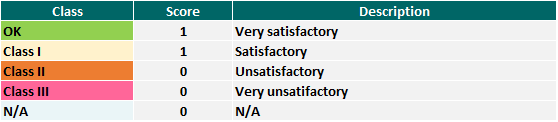

Score Ranking

-

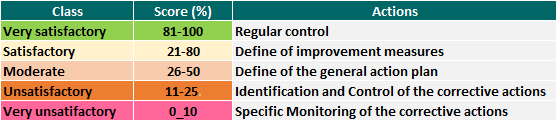

Evaluation Chart

-

All the items with Class III score must be defined at least one corrective action.

-

In the items with Class II & III score should be added an evidence or the issue description

A) PV Plant

-

The questions marked with "C" (critical question), the section of Class III will be taken as Failed response in the final result of the audit

1.0 Buildings (MV / Inverters / Substation / Wharehouse)

-

1.1. Check the global state of conservation of the buildings and equipments

-

1.2. Check the global state of cleanliness

-

1.3. Condition of grid meters

-

1.4. Condition of sensors and meteo stations

-

1.5. Check safety signs (emergency posters, extinguishers posters, electrical risk, first-aid kit posters, signs of do not enter ins restricted areas, evacuation map, coordenates map of the site...)

-

1.6. Check First-aid kit (take a picture of the First-aid kit, add comments)

-

1.7 Validate the fire extinguishers state (take a picture to one of them, add comments)

-

Checked accessibility, good apparent condition of conservation, insurance, seals, inscriptions, hose, etc.

Checked the state of charge (weight and pressure) of the extinguisher and the gas pump bottle (if any) state of the mechanical parts (nozzles, valves, hoses, etc)

Check the correct fire control system, fire dections, (if is aplicable) -

Other types of facilities on site audited

- SET

- PV PLANT

- WTG

- WAREHOUSE

- N/A

1.8 SET AUDITED

-

1.8.1 Check the outside general state (lighting, fences, vegetation…)

-

1.8.2 State of transformers (leaks, silica, tap changer, ventilation…)

-

1.8.3 Check the state of electrical equipment "C"

1.9 WAREHOUSE AUDITED

-

1.9.1 Check the global state of cleanliness

-

1.9.2 State of the hazard substances. Containers, labels, MSDS, signaling "C"

-

1.9.3 Check the state of fire estinguisher equipments "C"

-

1.9.4 Check safety signs (emergency posters, extinguishers posters, electrical risk, first-aid kit posters, signs of do not enter ins restricted areas, evacuation map, coordenates map of the site...)

2.0 MV Switchgears, Q.SS.AA, Inverters

-

2.1. Check the general aspect of switchgears

-

2.2. Check the correct identification of all MV switchgears

-

2.3. Check the correct operation of tension detectors/indicators and SF6 indicators "C"

-

2.4. Check the general aspect of electric switchboard (QSSAA and others)

-

2.5. Operation of inverters

-

2.6. Verification of ventilation, fans of the inverters

3.0 Comunications, alarms and SCADA

-

3.1. Check communications<br>

-

3.2. SCADA conditions

-

3.3. Alarms (MV proteccions, SCADA, etc)

-

3.4. Remote access (To SCADA, CCTV, etc)

4.0 Field Inspection (String Boxes, structure, DC cables, PV panels)

-

4.1. Visual Inspection (corrosion, excessive dirt…)

-

4.2. Identification labels (If applicable)

-

4.3. State of PV panels

-

4.4. Cleanliness of PV panels

-

4.5. General state of the metallic structure

-

4.6. General state of DC cables

-

4.7. General state of vegetation and possible shadows

-

4.8. Earth connections of the structure

-

PV Plant with trackers?

-

4.8.1 Verify the state of motors and electrical connections

-

4.8.2 Verify the state of axis, traction cables and metal parts

-

4.8.3 Verify abnormal inclinations

-

4.8.4 Verify state of control boxes

-

4.8.5 Verify operation of tracker wind sensors

-

General subjective evaluation

-

Obs.:

5.0 Roads, Drainage and Fences

-

5.1. Condition of roads and accesses

-

5.2. Condition of the aqueducts and gutters

-

5.3. Condition of fences all around PV farm (Electrical fences included)

B) O&M Activities

-

Select if O&M Questionnaire applies

6. General

-

6.1. Indicate who are the main O&M providers, what are their responsabilities (Preventive/corective work for: Civil work, BoP, electrical infrastucture)

-

6.2. How often is carried out MV and HV preventive maintenance ? Please describe the scope

-

6.3. Is there oil sample available of the HV transformers ?

-

Precise last sample analysis result date

-

6.4. How often is carried out civil work maintenance? if is necessary add notes

-

6.5. Is there any noise or visual impact claim from any neighbour? if is necessary add notes

-

6.6. Is there any specific legal obligation to conduct environmental follow up? if is necessary add notes

7. O&M Structure

-

7.1. Are there spare parts for electrical infrastructure components (extra switch gear…) ?

-

7.2. Is there any agreement for 24/7 corrective maintenance with limited response time?

-

7.3. What is the response time during the working hours, night and weekend?

-

7.4. Describe the role of the Asset manager/owner (control center, remote/local operation, on site personal)

-

7.5. Is there 24/7 Control center and how can they operate remotely the substation ? If yes, indicate the provider in notes

-

7.6. Describe the security measures of the site (CCTV, guards…)

8. Control and Scada of Inverters and substation

-

8.1 What SCADA version is installed in the plant?

-

Provide Screenshot of the SCADA

-

8.2 What SCADA version is installed in the substation?

-

Provide Screenshot of the substation SCADA

-

8.3. Indicate remote access possibilities

-

8.4. Describe how Power factor is controlled

-

8.5 Are there OPC/ODBC ports available ?

C) Summary and Signature

-

Other Comments

-

Site Manager/ Supervisor

-

Auditor