Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Department

-

Department Manager:

-

Farm Manager:

-

Reason for Assessment being conducted:

- Workplace inspection (e.g. JHSC workplace inspection, pre-shift inspection, housekeeping inspection, supervisor shift-report)

- Meeting (e.g. JHSC, daily production meeting, management meeting, meeting with regulatory body (Fire dep't, Min of Labour)

- Hazards identified (e.g. in unsafe act/condition reports, hazard alerts, audits, etc.)

-

Is a member of the JHSC present for the Risk assesment?

-

Why is the JHSC not involved in this Risk assessment?

-

Who is the JHSC Member?

-

What department do they represent?

Risk Analysis

-

Use this tool to determine the Risk level rating

RECOGNIZE

-

HAZARD

-

What activity or hazard could cause injury or illness?

-

What hazard groups can cause injury, illness, property damage or damage to the environment? (select all that apply)

- Physical Safety

- MSD

- Chemical

- Physical Agent

- Psychosocial

- Biological

- Manual Material Handeling

-

What is the source of the hazard to the associate/environment?

- Compressed Air

- High Pressure Fluids

- Confined Space

- Driving

- Electrical

- Material Handling

- Material Storage

- Molten Material

- Machine or Equipment

- Slip or Trip

- Temperature

- Vehicular Hazards

- Working at Heights

-

What is the potential outcome of exposure to the hazard?

- Skin injection

- Skin injection

- Asphyxiation

- Engulfment

- Entrapment

- Explosion

- Collision

- Contact with pedestrian

- Other

- Stress

- Violence

- Arc flash

- Electrocution

- Fire hazard

- Crushing

- Fire hazard

- Laceration

- Puncture or injection

- Sharp edges - laceration/contusion

- Struck by

- Worker contact

- Fire hazard

- Trip hazard

- Worker contact

- Burn

- Fire

- Flying particles/materials - impact or injection

- Full body pinch point - crushing

- Grinding/Sanding - friction & abrasion

- Impact - stabbing & puncture

- In-running nip - entanglement, drawing in

- Moving part - entanglement, cutting, shear

- Pinch point - crushing or shear

- Rotating or sharp part - cutting or shearing

- Rotation - entanglement

- Sharp edges - laceration/contusion

- Worker contact – laceration/contusion/puncture/other

- Falls to same height

- Burn/Scald

- Falling to surface below

- Objects falling on workers below

- Other

-

What is the source of the hazard to the associate/environment?

- Awkward Posture

- High Force Demands

- Poor Tool or Equipment Design

- Poor Workstation Design

- Repetition

- Static Posture

-

What is the potential outcome of exposure to the hazard?

- MSD injury

- Other

-

What is the source of the hazard to the associate/environment?

- Combustible

- Compressed Gas

- Corrosive

- Flammable

- Reactivity

- Toxic

-

What is the potential outcome of exposure to the hazard?

- Fire/Explosion

- Violent release of energy/gas

- Acid - skin burn/mucous membrane exposure

- Acid/base incompatibility reaction

- Alkaline - skin burn/mucous membrane exposure

- Liquid - Fire/explosion

- Gas - Fire/explosion

- Dangerous reaction

- Absorption - Illness

- Dermatitis

- Ingestion – Illness

- Ingestion – Carcinogen

- Inhalation – Illness

- Inhalation - Carcinogen

- Injection – Illness

- Injection - Carcinogen

-

If Hazardous materials are present, are there SDS sheets available to associates at all times and are associates trained in WHMIS 2015?

-

What SDS sheet or training is required?

-

What is the source of the hazard to the associate/environment?

- Extreme Cold

- Extreme Heat

- Lighting

- Noise

- UV Exposure

- Vibration

-

What is the potential outcome of exposure to the hazard?

- Cold stress

- Heat stress

- Hazard exposure due to lack of visibility

- Eye strain

- Hearing loss

- Skin or eye damage

- Hand/Arm - MSD or vascular disorder

- Whole body - Back pain

-

What is the source of the hazard to the associate/environment?

- Boredom

- Harassment

- Stress

- Violence

- Work overload

- Long hours

-

What is the potential outcome of exposure to the hazard?

- Mental Illness

- Violent Situation

- Physical Health Decline

-

What is the source of the hazard to the associate/environment?

- Bacteria

- Mold

- Viral

-

What is the potential outcome of exposure to the hazard?

-

What is the source of the hazard to the associate/environment?

- Bending

- Lifting

- Pushing or Pulling

-

What is the potential outcome of exposure to the hazard?

-

Hazard Images and DIagrams

-

Additional Comments

ASSES

-

Assessment

-

What is the probability of an incident occurring?

-

How often is the job task interacting with the hazard?

-

How severe could an incident be?

-

What is the risk level? (Probability + Frequency x Severity)

- Class E (1-6): A condition or practice that is likely to result in minor non disabling injury or illness (first aid, property damage)

- Class D (7-12): A condition or practice that is likely to result in minor non disabling injury or illness (first aid, property damage).

- Class C (13-79): A condition or practice with moderate likelihood to cause permanent disability, loss of life or body part with moderate likely hood of occurrence

- Class B (80-159): A condition or practice that is likely to cause permanent disability, loss of life or body part with moderate likely hood of occurrence - High Priority

- Class A (160-200): A condition or practice that is likely to cause permanent disability, loss of life or body part with high likely hood of occurrence - Immediate action must be taken

-

If immediate action is required; issue a work order from the app to the Maintenance Manager of the location.

-

What is being done immediately to prevent an incident?

-

What is the Risk Priotrity?

-

Additional Comments:

CONTROLS AND RECCOMENTDATIONS

-

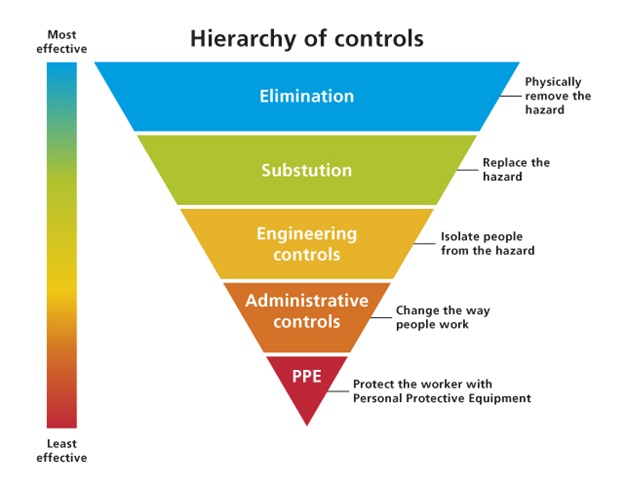

Use this tool when considering control implementation and recommendations.

Control and Recommendation

-

What legal requirements, codes, benchmarks or standards apply to the identified hazards, work processes or work activities?

- OHSA

- CSA

- Electrical

- Fire/Building

- Other

-

What legal requirement is in non-coompliance?

-

What is currently being done to eliminate or control the hazard?

-

RECCOMENDED ACTION - What future actions are needed to eliminate or control hazards? Indicate recommendations here - include diagrams and photos if necessary.

-

Who is responsible for overseeing the change?

-

Are controls immediately put into place or recommended introducing a new hazard? (congestion, confined space, etc.)

-

Describe in detail what the new hazard identified is:

-

Will new training be required for the new controls put into place?

-

What training will be required?

-

Are any labels, signs or decals required if controls are put in place?

-

What labels, signs or decals are required?

-

Is additional PPE required?

-

What PPE is required?

-

Is a Safety Alert required or alteration to a hazard checklist?

-

What action is required?

-

What CSA Standard is in non-compliance?

-

What is currently being done to eliminate or control the hazard?

-

RECCOMENDED ACTION - What future actions are needed to eliminate or control hazards? Indicate recommendations here - include diagrams and photos if necessary.

-

Who is responsible for overseeing the change?

-

What electrical code item is non-compliant?

-

What is currently being done to eliminate or control the hazard?

-

RECCOMENDED ACTION - What future actions are needed to eliminate or control hazards? Indicate recommendations here - include diagrams and photos if necessary.

-

Who is responsible for overseeing the change?

-

What fire/building code item is non-compliant?

-

What is currently being done to eliminate or control the hazard?

-

RECCOMENDED ACTION - What future actions are needed to eliminate or control hazards? Indicate recommendations here - include diagrams and photos if necessary.

-

Who is responsible for overseeing the change?

-

Describe the non-compliance

-

What is currently being done to eliminate or control the hazard?

-

RECCOMENDED ACTION - What future actions are needed to eliminate or control hazards? Indicate recommendations here - include diagrams and photos if necessary.

-

Who is responsible for overseeing the change?

-

Recommended timeline of completion:

-

Additional Comments:

EVALUATE

-

Evaluation

-

Following recommended control implementation, how likely is the hazard to cause injury or illness now?

-

Following recommended control implementation, how often is the job task interacting with the hazard?

-

Following recommended control implementation, how severe could an incident be?

-

Following recommended control implementation, what is the level of risk? (Probability + Frequency x Severity)

- Class E (1-6): A condition or practice that is likely to result in minor non disabling injury or illness (first aid, property damage)

- Class D (7-12): A condition or practice that is likely to result in minor non disabling injury or illness (first aid, property damage).

- Class C (13-79): A condition or practice with moderate likelihood to cause permanent disability, loss of life or body part with moderate likely hood of occurrence

- Class B (80-159): A condition or practice that is likely to cause permanent disability, loss of life or body part with moderate likely hood of occurrence - High Priority

- Class A (160-200): A condition or practice that is likely to cause permanent disability, loss of life or body part with high likely hood of occurrence - Immediate action must be taken

-

Additional Comments:

Signatures

-

Auditor:

-

JHSC Rep:

-

Supervisor/Manager of the Department:

-

Farm Manager:

-

Responsible Party for Controls Implementation: