Title Page

-

Conducted on

-

Conducted by

-

Area inspected:

- Production

- Raw Materials

- Shipping

- Maintenance

- Offices

- Labs

- 201 Building

- Training Center / Resisto Warehouse

-

Please list any safety improvements since last assessment.

Emergency

-

Are all emergency exits lights clearly visible, functioning correctly, properly lit up, and clear of obstructions?<br>

-

Are emergency exits free of obstacles?<br>

-

Are all fire extinguishers accessible, clearly visible, and recently inspected?<br>

-

Are all 1st Aid Kits accessible and properly stocked?<br>

-

Are eye wash stations capped and working properly when tested? Are emergency showers clean and accessible?<br><br>

-

Are tornado areas identified, accessible, and clear of obstacles?<br>

-

Are spill kits available and properly stocked?<br>

General

-

Are all employees wearing required PPE? (This includes ANSI rated eyewear in the plant and yard, and hearing protection in the winder area)<br>

-

General housecleaning: Is the area clean and in good order?<br>

-

Are all walkways, floors, and stairs clear of objects, obstructions, spills, and slip/trip hazards?<br>

-

Are wastes properly segregated?<br>

-

Are all secondary containers properly labeled?<br>

-

Are water heaters and furnaces clear of obstructions (3' min) and any flammable/combustible objects? (also check customer service storage closet)<br>

-

Are all equipment and machine guards in place and in good condition?<br>

-

Are all manufacturing and warehouse doors, gates, and chains in good condition and properly closed, secured, or latched? (include especially upper level closures)<br>

-

Are floors, outdoor areas, equipment, and other surfaces clear of any excessive dust, dirt, rust, or loose materials? <br>

-

Are propane valves locked in the off position?<br>

-

There are no unusually strong odors or decrease in air quality today.<br>

-

There are no visible emissions coming from the plant or any associated building or tank.<br>

Electricity

-

Are all electrical panels properly closed, secured, and labeled/tagged (LOTO, if applicable)?<br>

-

Are all areas in front of electrical enclosures (36") clear of obstructions?<br>

-

Are all electrical cords safe and in good condition (not frayed,exposed, or damaged, and not creating a trip hazard)?<br>

-

Are lights off in unoccupied areas and unused equipment powered down?<br>

Storage

-

Are all racks and shelving units secure, safe, and properly loaded?<br>

-

Are all hazardous materials and haz mat wastes labeled and stored in proper areas/containers?<br>

-

Are all liquid/gas cylinders in good condition and properly secured and capped? Are they properly segregated?<br>

-

Are all tanks and waste barrels under retention? Are they showing any sign of leaking or damage?<br>

-

Are all materials safely stored, not stacked too high, and not posing a fall over risk?<br>

-

Are flam cabinets neat, organized, free of spills and rusty parts or containers? Are the tops clear of all items?<br>

-

Are flam cabinets grounded, below rated capacities, and have an updated inventory list posted?<br>

Vehicles and Pedestrians

-

Are pedestrian lanes clearly marked, unfaded, free of objects, obstacles, and debris?<br>

-

Are traffic lanes and storm drains in good condition, free of obstacles and debris including ice or water?<br>

-

Are lift drivers operating at an appropriate speed, honoring stop signs and slowing/honking at intersections or when reversing?<br>

-

Are external truck operators driving at an appropriate speed, wearing reflective clothing, and using proper load/unload safety measures? (Orange barrel and airline lock for full truck load. Wheel chocks and orange barrel for LTL)<br>

Specific Checks

-

Shipping Inspector: Are the silo access areas (ladders, etc) secured? Are shut off valves near silos in good condition? Look for cracks, breaks and corrosion.<br>

-

Shipping Inspector: Are the silos, asphalt pump house, and retention pond areas tidy and free of leaks, debris, and emissions?<br>

-

Production, Resisto Warehouse Inspectors: Emergency sprinkler system locked in on position?<br>

-

Maintenance Inspector: Are grinder wheels the required distance from grinder tables?<br>

Miscellaneous

-

Additional observations:

-

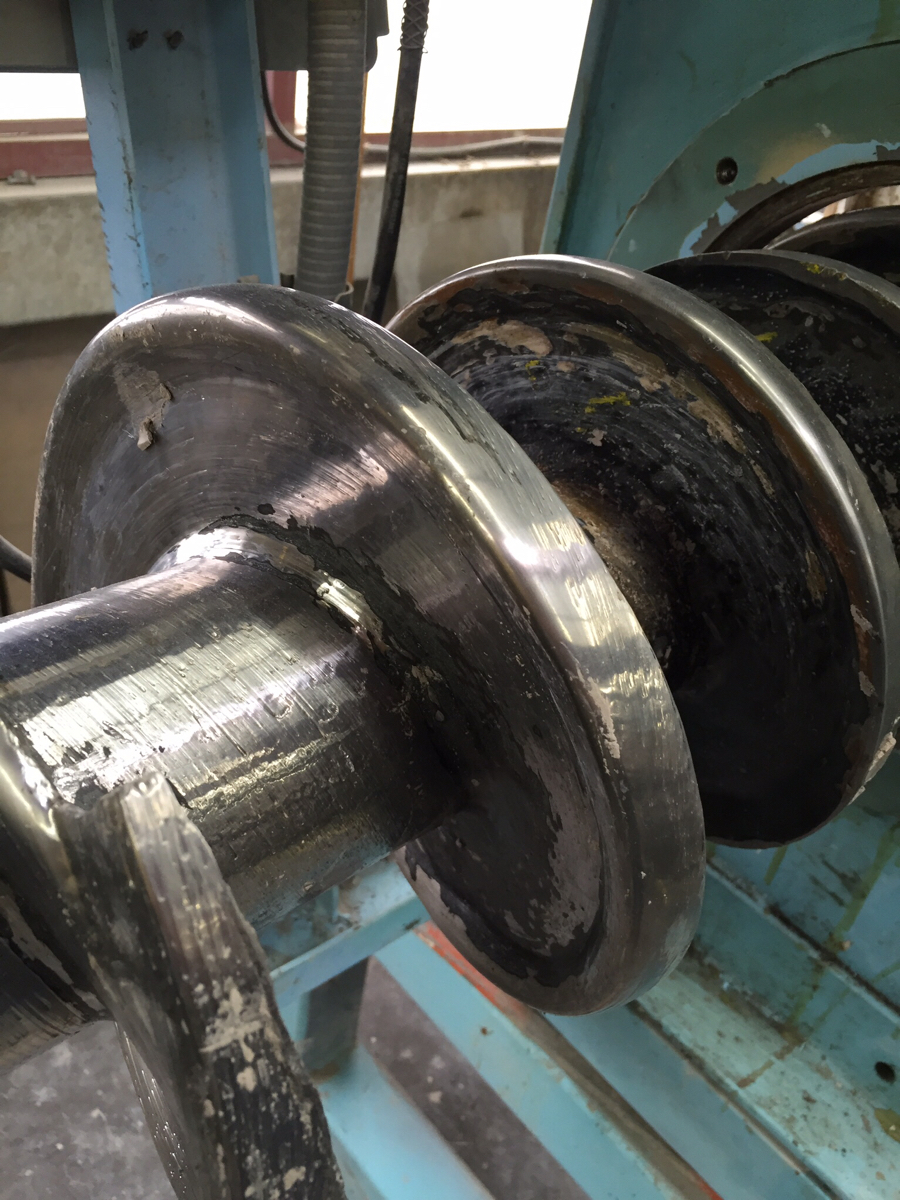

Add media