Title Page

-

Engineers Full Name Pay Roll number and Tech Code

-

Conducted on

-

Prepared by

Introduction

-

The following Tool box Talk (TbT) details the procedure for removing the current ladder locks (where fitted) from all Triple 12 & 14 ladders. The manufacturer is working on a new type of locking system which can be a retrospective fit once the locks have been tested and properly trialled with Engineers in conjunction with the health and safety team. Further communications will be sent out as appropriate.

Why do we have ladder locks?

-

Ladder locks were first fitted by manufacturers in 2015 as it became a European Standard to have locks fitted to extension ladders under EN 131. The reason why this standard was introduced was to try and stop the ladder sections from unintentionally coming apart when being carried/transported or in use. Like all changes the intention is to make activities safer and not introduce additional or alternative risks.

Reason for removing the locks

-

The reason the Health and Safety Team are authorising the ladder locks to be removed from all Triple 12 & 14 ladders is as a result of near misses and incidents where the top ladder section has disengaging while retracting the sections. The contributing factor in these incidents is the lock and the position it is in whilst lowering. The safety and wellbeing of all Sky personnel is the upmost importance and this is why we have taken this decision to remove the current locks.

Lock removal process

-

1. TM to meet each Engineer within their team at a suitable location to carry out this TbT.

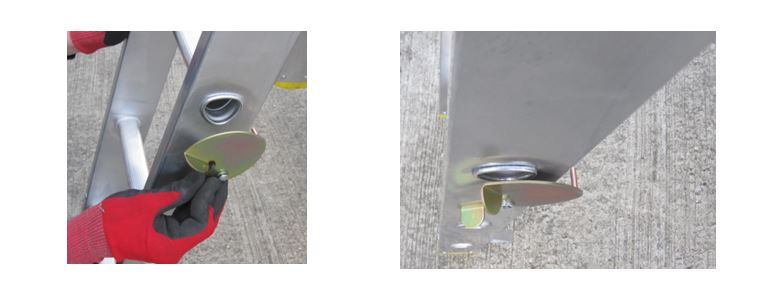

2. Engineer to undo locking nut and remove the bolt and lock on both the top and middle ladder sections using Home Service supplied tools.

3. The manufacturer has confirmed that the removal of the locks does not affect the structural integrity of the ladder and the holes do not require covering.

4. Engineer to return all ladder lock components to UTL BagintonB for appropriate disposal.

5. TbT confirmation of understanding to be signed by the Engineer and TM to complete the lock removal process.

6. TbT confirmation to be retained by TM for future records.

7. Once all Engineer’s within your team have removed the locks please email the author of this TbT as final confirmation so this can be recorded. -

Briefing delivered by

-

Name & Position

-

Signature

Confirmation of understanding

-

I confirm that I understand and have carried out the lock removal process contained within this TbT.

-

Name

-

Tech Number

-

Signature