Information

-

Document No.

-

Audit Title

-

Client / Site

-

Conducted on

-

Prepared by

-

Location

-

Personnel

Organisation Details

-

Organisation Name

-

Billing Address

-

Contact Name

-

Contact Number

-

Contact Position

Project Details

-

Customer Name

-

Project

-

Working Area

-

Activity

Scaffold erection, alteration or dismantle onsite at above mentioned project.

This SWMS is to be used in conjunction with a task specific risk assessment.

To be completed daily prior to commencing work or prior to commencing each new specific task.

Equipment used

Plant and equipment used on site includes but is not limited to:

Fixed and Mobile scaffold, basic tools (level, podger, hammer, tool belt, tape measure, shifter)

Maintenance Checks

Visual inspection prior to use and as per installers recommendations. Equipment is to be signed off (Scaff tagged). -

This SWMS has been approved by :

-

Position

-

Signature

-

Date

-

Legislation, Regulations, Codes and Standards applicable to the works:

AS1576-7 Scaffolding

AS 6001 Working platforms for domestic construction

NSW WHS Act 2011

Environmental Protection Act 1986

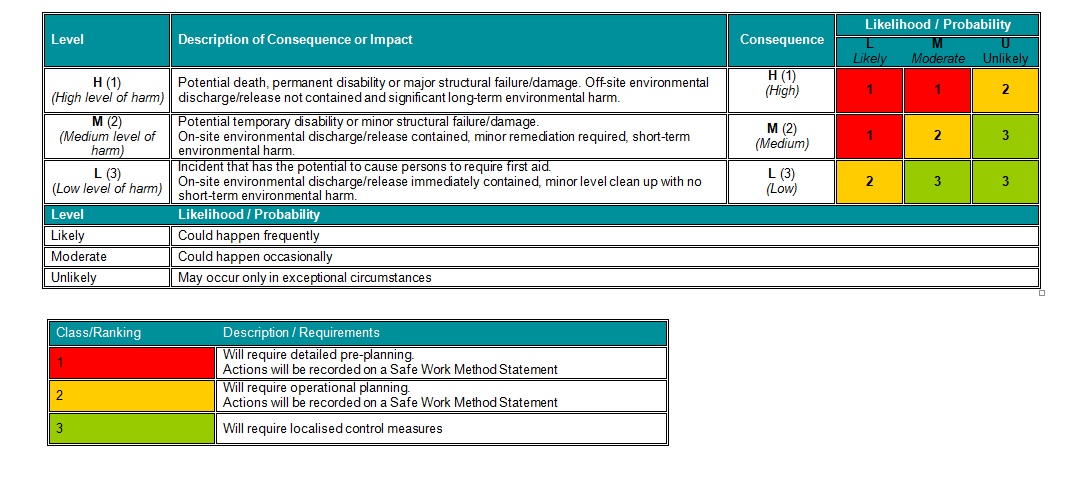

Risk Matrix

Qualifications and experience required to complete the task

-

- National Certificate of Competency WP

- Trained in Installation of Scaffold

- Training in OHS Risk Management for Supervisors and Managers

- Experience in EWP industry

- Certificate IV in OHS

- Training in OHS Risk Management for Supervisors and Managers.

- OHS Consultation Course

- Experience in Scaffold industry

Personnel, Duties and Responsibilities (Supervisory staff and others)

-

Scaffold Labour

Installation of Scaffolding, involved in all toolbox meetings and filling out JSRA forms, reporting all issues to site and Botany Access’ Management.

Botany Access Supervision

Supervision and regular safety checks carried out on Scaffold crews involved in operations onsite. Involved in preparation and improvements to Botany Access’ Management Systems.

Managing Director

Ensure that company procedures are being followed as per OHS management system. Keep abreast of industry related regulations. Make changes to management systems where required. Review all site safety checks carried out onsite and put any corrective actions in place.

Ultimately responsible in ensuring the safety and welfare of all employees whilst working onsite.

Training required to complete work

-

Site induction, Botany Access’ induction, inducted into this SWMS

Work Process

1. Exposure to natural elements

-

Risk

Sun-burn and dehydration due to exposure to sun. Sickness and loss of production due to cold weather. -

Controls

- UV sunscreen to be onsite and used when required

- Fresh drinking water must be available to all personnel

- Wear wide brim on hard hat and long clothing to reduce exposure to sun when required

- Ensure adequate clothing worn to suit cold conditions

- Ensure operator warms up prior to manual activity

2. Manual Handling

-

Risk

Injury to personnel -

Controls

- Follow manual handling procedures

- Team lift where appropriate

- Use mechanical lifting devices/objects or materials if not safe to lift

3. Safety Information

-

Risk

Failure to have adequate emergency equipment, PPE or amenities.

Failure to know various safety procedures e.g. Evacuation points. -

Controls

- Ensure first aided onsite at all times

- PPE required to be worn at all times (hard hats, safety boots, hi visibility vest or clothing are mandatory and other PPE where required

- Ensure all evacuation points, site amenities and first aid points are known prior to entering site

4. Changes to SWMS/ JSRA

-

Risk

Lack of communication of changes made to SWMS/JSRA -

Controls

- Consult with workforce on changes or amendments to be made to SWMS/JSRA with workforce and ensure everyone has signed off

5. Access with vehicle onsite

-

Risk

Vehicles and plant moving around site. Including restraining of equipment on vehicles -

Controls

- All persons entering site must be site inducted and follow all directions given in this induction including correct PPE

- Follow all site rules / speed limits for particular site

- Ensure Load is checked before removing chains/webbing straps.

- If Load has shifted ensure it is safe or attain additional machinery support before removing chains/webbing straps.

6. Access and egress to and from site by walking

-

Risk

Heavy plant and vehicle movements, slippery or uneven surface, hot, cold or wet conditions -

Controls

- Follow directions as per site induction

- Don’t work or walk behind vehicles or plant where you cannot be seen

- Ensure eye contact made with plant operators prior to approaching plant work zone.

- Ensure hi visibility clothing worn at all times onsite

- Maintain high level of housekeeping in work area.

- Wear appropriate clothing, sunscreen & PPE for weather and site conditions

7. Erection, Alterations or Dismantling Scaffold

-

Risk

Working at heights, Pedestrian movements -

Controls

- When erecting, altering or dismantling of scaffold is to be carried out adjacent to an opening or edge of a structure where a person is at risk of falling 2m or more, a safety harness must be worn before being exposed to the risk (e.g. Awning, hoarding, excavation)

- An exclusion zone must be provided to prevent people accessing the work area. The work area includes the area directly below where the scaffolders are working including where people can access up to:

o 3m for scaffold 0-5m high

o 4m for scaffold over 5m high

(Horizontal measurement from the base of the scaffold)

- The exclusion zone can be maintained by barricades and/or spotter

- Access the scaffold by ladder or stairs

- Do not climb the standards

- Scaffold must not exceed the design load.

8. House keeping

-

Risk

Working at heights, pedestrian movements -

Controls

- Always maintain tidy work area

- Always remove scaffold items from decks and palletise

- Do not leave loose materials on deck

- Do not throw scaffold items

- Stacked and palletised material to be clear of pedestrian access ways

- Stacked and palletised material to be clear of moving plant on site. -

Responsible Person

Sign Off

-

This SWMS has been developed through consultation with our employees and has been read, understood and signed by all employees undertaking the works

-

Select date

-

Add signature

-

Select date

-

Add signature

-

Select date

-

Add signature

-

Select date

-

Add drawing

-

Select date

-

Add signature

-

Select date

-

Add signature

-

Select date

-

Add drawing

-

Select date

-

Add drawing

-

Select date

-

Add signature

-

Select date

-

Add signature