Title Page

-

Site conducted

-

Conducted on

-

Prepared by

-

Location

-

GER

Assessment

undefined

-

Manager's Name

Guest Service

-

Guest greeted within 5 seconds of arriving in front of the Order Menu Board. If asked to hold, re-greeted in 15 seconds or less.

-

A. Greet time within 5 seconds of pulling up to the menu order board (order confirmation screen - OCS).

-

B. If asked to hold, re-greet within 15 seconds after being asked to hold.

-

Drive-thru Order Taker provides warm, friendly greeting and hassle free order taking.

-

A. Team Member greets Guest in a warm friendly manner at the Order Menu Board speaker or by the Outside Order Taker (OOT). Should sound enthusiastic, genuine, non-robotic without attitude, shortness or tone.

-

B. Conversation is hassle free: no language barriers or lack of training preventing smooth order taking process.

-

C. Order taker does not interrupt (multiple times) or rush Guest.

-

EXCEPTIONAL SERVICE AT ORDERING - Exceptional service.

-

A. Genuine, warm and friendly greeting provided. Can feel the smile and friendliness.

-

B. Is Highly Energetic and uses Exceptional Phrases.

-

C. Team Member is enthusiastic about the menu items.

-

D. It is evident that the Team Member clearly enjoys working at Jack in the Box and serving the Guests.

-

ORDER CONFIRMATION - Drive-Thru Order Taker confirms order using order confirmation screen (OCS).

-

A. Team Member confirms order is correct on the screen or fully repeats order for confirmation

-

DT ORDER CONFIRMATION SCREEN (OCS) & SPEAKER - Order confirmation screen (OCS) is clean

-

DRIVE-THRU WINDOW FRIENDLY SERVICE - Team Member warmly re-greets Guest at service window, makes eye contact, smiles and provides a 2-part thank you/farewell.

-

A. Immediately greeted at drive-thru window (within 10 seconds or less).

-

B. Team Member warmly greets Guest in a friendly manner at the Service window. Should sound enthusiastic, genuine, non-robotic without attitude, shortness, or tone.

-

C. Interaction is energizing and shows care for Guest. Body language shows Guest focus. Team Member makes eye contact and smiles during the interaction.

-

D. Team Member provides 2-part thank you/farewell.

-

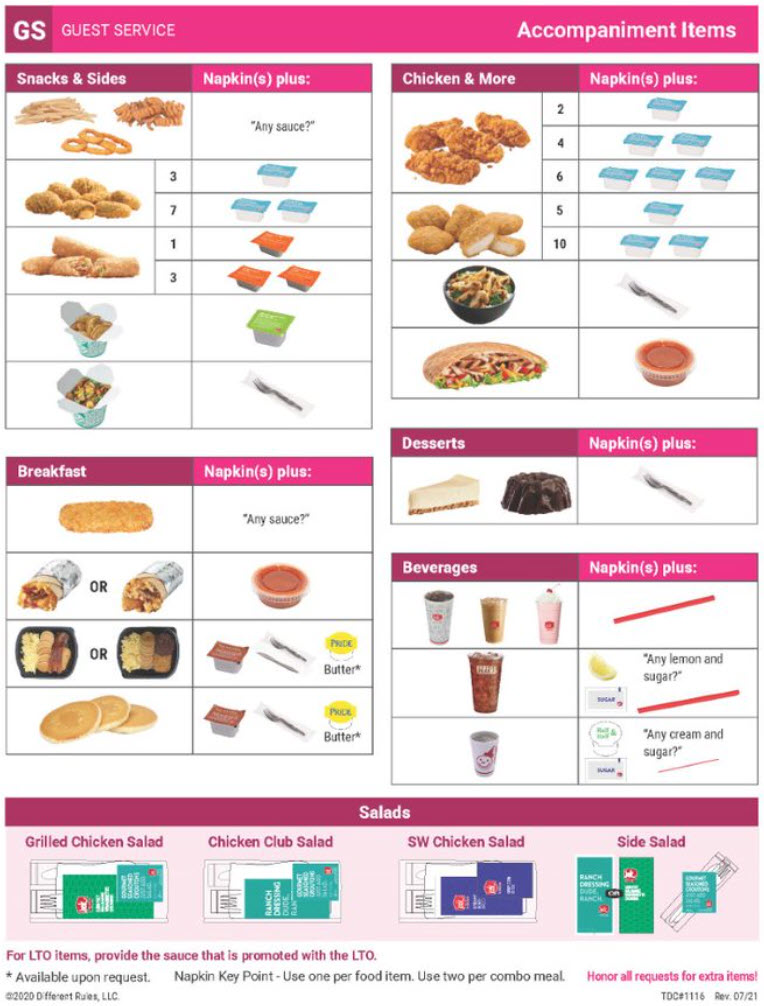

SAUCES & CONDIMENTS OFFERED - Team Member specifically offered sauces/condiments as specified in Accompaniment Items Job Aid

-

A. Team member asks Guest if they would like any sauces for ordered items that don’t have a required recipe sauce/condiment.

-

B. Team Member automatically provides or specifically offers accompaniment condiments (sauce, dressing, salsa, etc.) by name for items that have required sauce/condiment

-

C. Team member automatically provides or specifically offers sauce/condiments that accompany LTO items.

-

BAG CONTENTS COMMUNICATION - Team member verifies and communicates the main contents of each bag to Guest as handed out, including special items.

-

A. The same Team Member that checks the bag for accuracy also communicates the bag contents to the Guest at drive-thru and front counter.

-

B. Team Member communicates the main combo items, including modifications, special requests when handing out the bag(s) to the Guest.

-

C. Bagged combos are repeated by main combo item name, not by combo numbers, including any modifications.

-

D. If the contents in the bag(s) is not a combo, all contents in the bag is repeated to the Guest, including any modifications.

-

RECEIPT PROVIDED - Guest provided a receipt without asking for one.

-

A. The correct/legible receipt is automatically provided to the Guest without the Guest having to ask for it.

-

EXCEPTIONAL SERVICE AT DT WINDOW - Exceptional service at drive-thru service window.

-

A. Team Member goes above and beyond in some way to connect with Guest and or provide exceptional, differentiated service.

-

B. Team member makes Guest feel truly appreciated for visiting this Jack in the Box.

-

C. It is obvious that the Team Member clearly loves their job and serving the Guest, the enthusiasm can be observed.

-

FRENCH FRIES - Hot, fresh, properly salted French Fries are assembled and served according to specifications and at the correct temperature.

-

Enter temperature

-

A. Temperature reading ≥ 150° Fahrenheit.

-

B. Salted - Fries have salted taste.

-

C. Texture - Taste is slightly crispy on the outside and soft on the inside.

-

D. Appearance - Fries appear golden brown: not overly dark or less than fully cooked. Fries hold form, not limp or soggy.

-

E. Portion - Bag is full/properly portioned.

-

Enter temperature

-

Burgers

-

BURGERS - Hot, fresh, juicy burgers served to specifications.

-

Beef patty temperature

-

A. Temperature - Beef patty temperature is ≥ 125°F.

-

B. Beef patty tastes juicy and fresh not dried out.

-

C. Fresh produce and ingredients are used.

-

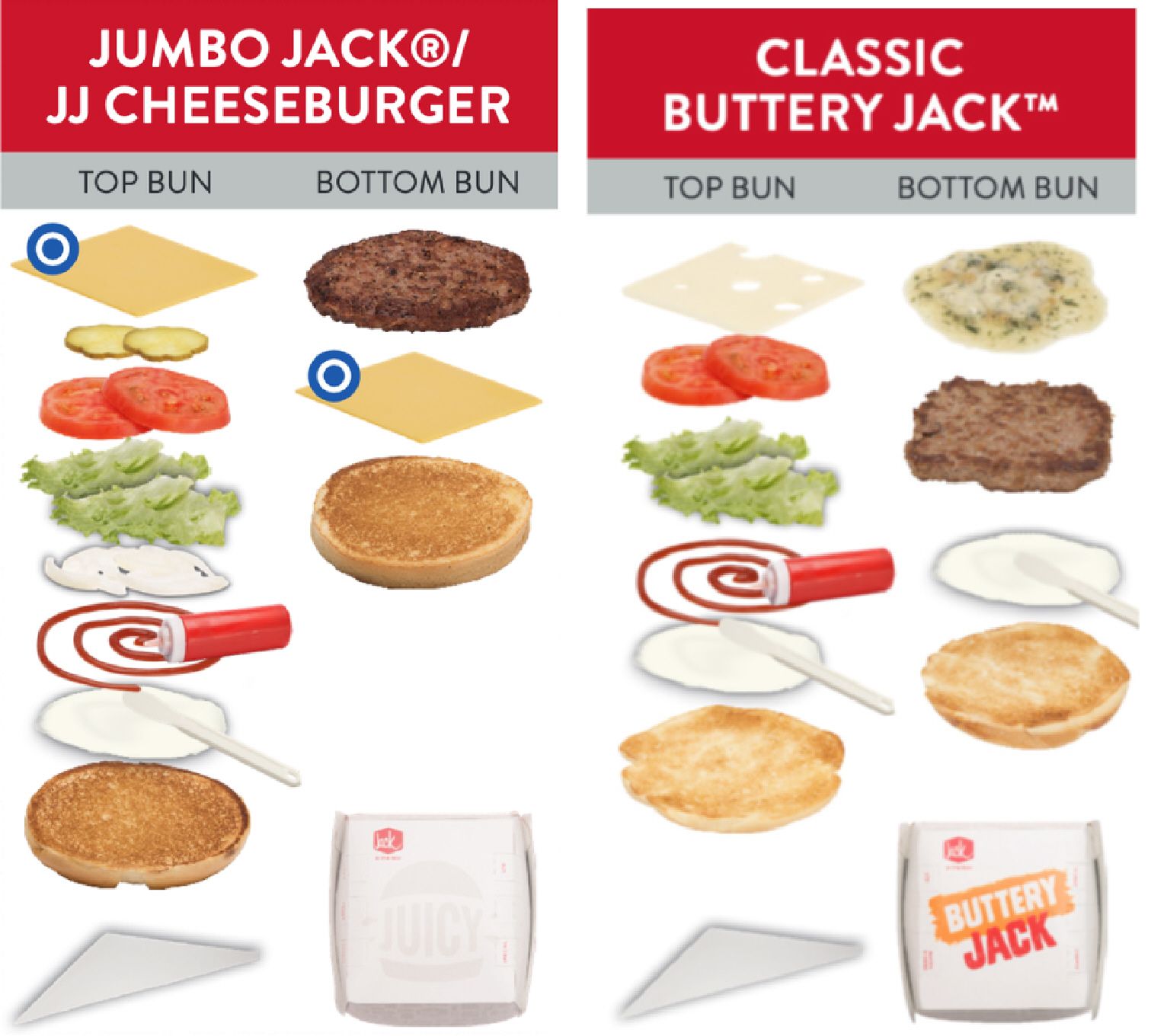

D. Burger is neatly assembled, with correct ingredients, and order of build

-

Beef patty temperature

-

PACKAGING, BAGGING, SERVING - Guest order placed neatly in the bag and packaged to specifications.

-

A. Correct product tabs pressed to identify item.

-

B. Separate bags used for each combo and for custom orders.

-

C. Hot and cold items are in separate bags.

-

D. Food in bags should look neat (not more than 6 loose French fries in the bag).

-

E. Food boxes should be in good condition, closed, sealed correctly.

-

F. Food and packaging not smashed or coming apart.

-

G. Packaging or carryout bags should be free of excessive grease.

-

H. Condiments or dip cups are not torn, opened, or sticky on the outside.

-

I. Tamper proof stickers are properly placed on all delivery orders with receipt attached.

-

J. Tacos should be placed in bag correct side up.

-

Accompaniment items

-

CORRECT SAUCES & CONDIMENTS - Team Member provided Guest with the correct sauces/condiments.

-

A. Guest received correct sauces ordered and (or) per Accompaniment Job Aid TDC #1116.

-

B. Guest automatically received correct accompaniment condiments for all items.

-

C. Team Member provided additional or other sauces/condiments requested by the Guest.

-

D. Team member automatically provides sauce/condiments that accompany LTO items.

-

NAPKINS, UTENSILS, & STRAWS PROVIDED - Team Member provides napkins, utensils, and straws with order.

-

A. The order includes napkins, utensils, and straws as required (and except where prohibited).

-

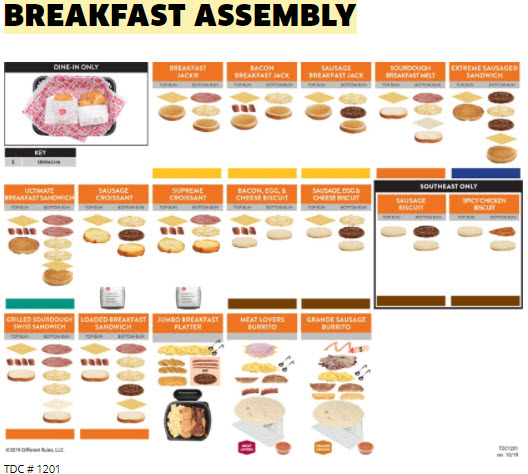

3.8 Breakfast

-

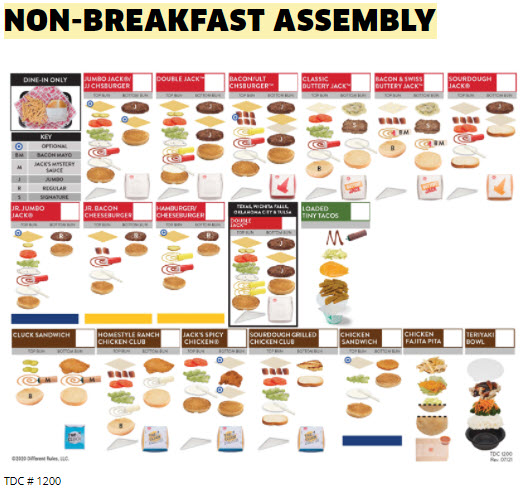

3.8 Non-Breakfast

-

ORDER IS CORRECT - Guests receive the correct food and beverage order.

-

A. All items were provided were correct

-

B. All items include the correct ingredients.

-

C. Special/custom requests are made correctly.

-

SPECIAL REQUESTS CORRECTLY IDENTIFIED - Special requests/modifications are properly identified.

-

BEVERAGES - Beverages have the proper flavor, level of ice, carbonation, and beverage fill.

-

A. Flavor is to standard.

-

B. Correct carbonation.

-

C. Ice fill level to standard.

-

D. Lid is correctly secure and no spillage outside of beverage cup.

-

E. Desired beverage flavor is available.

-

Enter name of beverage ordered

BACK OF THE HOUSE - QUALITY

-

Fried Products

-

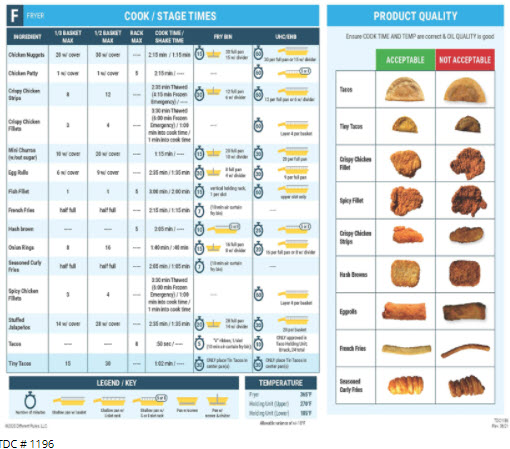

FRIED PRODUCTS HOLDING CABINET PROCEDURES - Holding Cabinet staging procedures meet specifications for all fried products.

-

A. Hold times are “on” for all held fried products.

-

B. All fried products are within proper hold time – no expired items.

-

C. Resetting times for held products not observed.

-

D. Based on visual observation ingredient(s) look fresh and meet quality standards

-

E. FIFO used to use oldest product first.

-

F. All fried products should have correct times programmed

-

G. All fried products are in correct slots to match programmed names (check all).

-

H. Correct quantities held in a single pan - i.e. 12 egg rolls per pan / 6 per side (check all).

-

I. Fried products are NOT held with a metal lid.

-

J. Fried products are staged/held correctly in drawers.

-

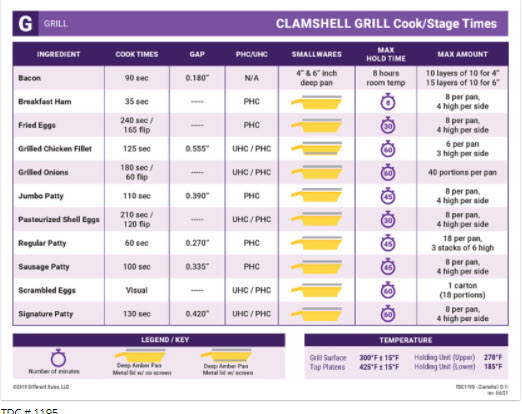

Clamshell

-

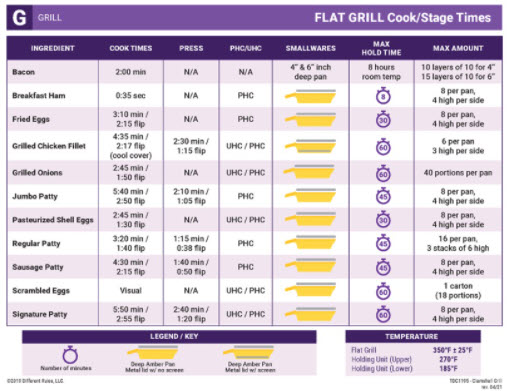

Flat grill

-

GRILLED PRODUCTS HOLDING CABINET PROCEDURES - Holding cabinet staging procedures meet specifications for all grilled products.

-

A. Hold times are “on” for all held grilled products.

-

B. All grilled products are within proper hold time – no expired items.

-

C. Resetting times for held products not observed.

-

D. Based on visual observation ingredient(s) look fresh and meet quality standards.

-

E. FIFO used to use oldest product first.

-

F. All grilled products should have correct times programmed.

-

G. All grilled products are in correct slots to match programmed names (check all).

-

H. Correct quantities held in a single pan (check all grilled products in holding cabinet).

-

I. Grilled products are held with a metal lid (check all).

-

J. Grilled products are staged/held correctly in drawers.

-

CRISPY CHICKEN - Crispy chicken is hot, crispy, juicy, and meets 'Quality' specifications. (Temp and evaluate one crispy chicken fillet, one spicy chicken fillet and one chicken strip from the holding cabinet)

-

A. Crispy Chicken Fillet is slightly crispy on the outside, fried to a golden brown color, is warm to hot on the inside <br> and moist / juicy. Temperature is 140°F or higher.

-

B. Spicy Chicken Fillet is slightly crispy on the outside, fried to a golden brown color, is warm to hot on the inside <br> and moist / juicy. Temperature is 145°F or higher .

-

C. Crispy Chicken strips are slightly crispy on the outside, fried to a golden brown color, is warm to hot on the inside <br> and moist / juicy. Temperature is 140°F or higher.

-

Crispy Chicken Fillet Temperature

-

Spicy Chicken Fillet Temperature

-

Crispy Chicken Strip Temperature

-

HOLDING CABINET TEMPERATURES - All holding cabinets maintain required temperature.

-

A. Long Stem Surface Prove Thermometer must be available to evaluate temperature of holding units.

-

FRY BIN - Fry bin (fried) items staging procedures meet specifications.

-

A. Hold times are “on” for all holding products.

-

B. All products are within proper hold time – no expired items (unless used for an order on the screen).

-

C. All products should have correct hold times programmed.

-

D. Resetting times for held products not observed.

-

E. FIFO practiced to use oldest product first.

-

F. Based on visual observation ingredient(s) look fresh and meet quality standards.

-

G. Products not stored in packaging unless there is an order on the screen for immediate use.

-

H. Products staged in correct smallwares and correct quantities.

-

Taco

-

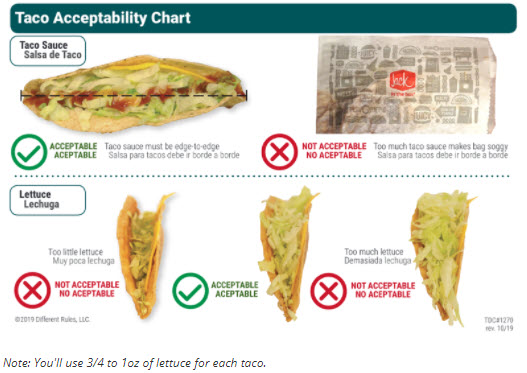

TACOS - Hot, fresh, and crispy tacos fried, assembled, and staged per specifications; taco station maintained for quality and quick.

-

A. Tacos not held past hold time

-

B. Correct hold times are programmed and in use to ensure 5 minute hold time in the fry bin.

-

C. Once fried, rack tilted sideways for 5 to 10 seconds to allow excess oil to drain into fryer (and minimize <br> greasiness of tacos).

-

D. Taco packaging is clean and presentable (free of excessive taco sauce or grease).

-

E. Tacos are not served with broken shells or cracks greater than 1 ½".

-

F. Tacos are sauced edge-to-edge.

-

G. Shredded lettuce on assembled Tacos is portioned correctly (3/4 ounces to 1 ounce). Refer to visual on the Taco <br> Acceptability Chart (TDC# 1270).

-

H. Shredded lettuce at Taco Assembly station is fresh, crisp, and dry.

-

I. Only thoroughly defrosted tacos are fried.

-

J. Fried in correct fry rack.

-

K. Taco assembly rack in place and used for lettuce, cheese portioning, assembly of tacos.

-

FRIED PRODUCTS - DRAINING & REMOVING - Fried products are properly drained and removed to ensure quality and presentation.

-

A. After fry cycle, baskets are gently shaken to drain the oil from the products.

-

B. Fried products are immediately packaged or staged and not left in fry baskets or racks.

-

C. Fried products are transferred with tongs. Ingredients are not dumped directly into packaging to prevent <br> excessive oil from getting onto packaging.

-

D. French fries are properly salted.

-

OIL QUALITY - Oil quality maintained to ensure fresh tasting fried products.

-

A. Skimming – fryer oil skimmed as needed to prevent oil degradation and remove particles from sticking to other <br> products that are being fried.

-

B. Smoking Oil – oil not smoking excessively, which often indicates expired oil.

-

C. Oil Temperature at 365° +/- 15°F. Evaluate at least one vat using the restaurant’s infrared thermometer or an <br> immersion probe.

-

D. Oil Level – oil quantity is at approximately the correct level as indicated by the min/max lines in the fry vats.

-

E. Equipment being maintained – clear evidence of ongoing filtering, cleaning, and heavy carbon removal.

-

PREPPED ITEMS READY FOR "GRAB & PLACE" - All prepped items at the assembly line meet quality and are ready for "grab & place".

-

A. Prep items are ready for "grab and place" for Assembly Team Member.

-

B. Quality to standard – team member does not have to sort through or discard unacceptable product.

-

C. Slice tomatoes are stacked flat, not sideways to protect slice integrity.

-

D. Ingredients not filled higher than fill line on pans.

-

BREADS - Buns stored, handled, buttered, and toasted to specifications.

-

A. Split Top and Regular buns, are held in closed / sealed bags – except for what is being used for current shift / <br> next hour.

-

B. Buns are not smashed after toasting.

-

C. Buns are toasted to order, not staged at/or near toaster if no orders appear on the kitchen (KDS) monitor.

-

D. Proper buttering procedure followed with BFVO (Butter Flavored Vegetable Oil).

-

E. Teflon sheet in the contact toaster is free of buildup and in good condition.

-

F. Split Top and Regular buns are toasted with a full and even coat of butter applied, 80%+ of surface toasted to a <br> golden brown, not burnt, bun not smashed after coming out of contact toaster.

-

BREADS - BRIOCHE, CROISSANTS, & BISCUITS - Brioche, croissants, and biscuits are stored, handled, buttered (only biscuits), and toasted to specifications.

-

A. Brioche buns, croissants, and biscuits, are held in closed / sealed bags – except for what is being used for <br> current shift / next hour.

-

B. Buns/breads are not smashed after toasting.

-

C. Buns should be toasted to order, not staged at/or near toaster if no orders appear on the kitchen (KDS) monitor.

-

D. Batch toaster spatula is stored under crumb tray when not in use.

-

E. Bread items are toasted to standards.

-

BREADS - SOURDOUGH - Sourdough bread is stored, handled, buttered, and toasted to specifications.

-

A. Sourdough bread is held in closed / sealed bags – except for what is being used for current shift / next hour.

-

B. Sourdough bread is not smashed after toasting.

-

C. Sourdough bread is toasted to order, not staged if no orders appear on the kitchen (KDS) monitor.

-

D. Teflon sheet in the bread griller is free of buildup and in good condition.

-

E. Proper buttering procedure followed with BFVO (Butter Flavored Vegetable Oil).

-

F. Sourdough bread slices are buttered and toasted to standard.

-

SAUCING EDGE-TO-EDGE - Saucing on sandwiches is 'edge-to-edge'.

-

A. Saucing is evenly spread from edge-to-edge of breads and buns.

-

B. Mayonnaise is evenly spread across bun or bread.

-

C. Sauce bottles on line have correct tips

-

Microwave

-

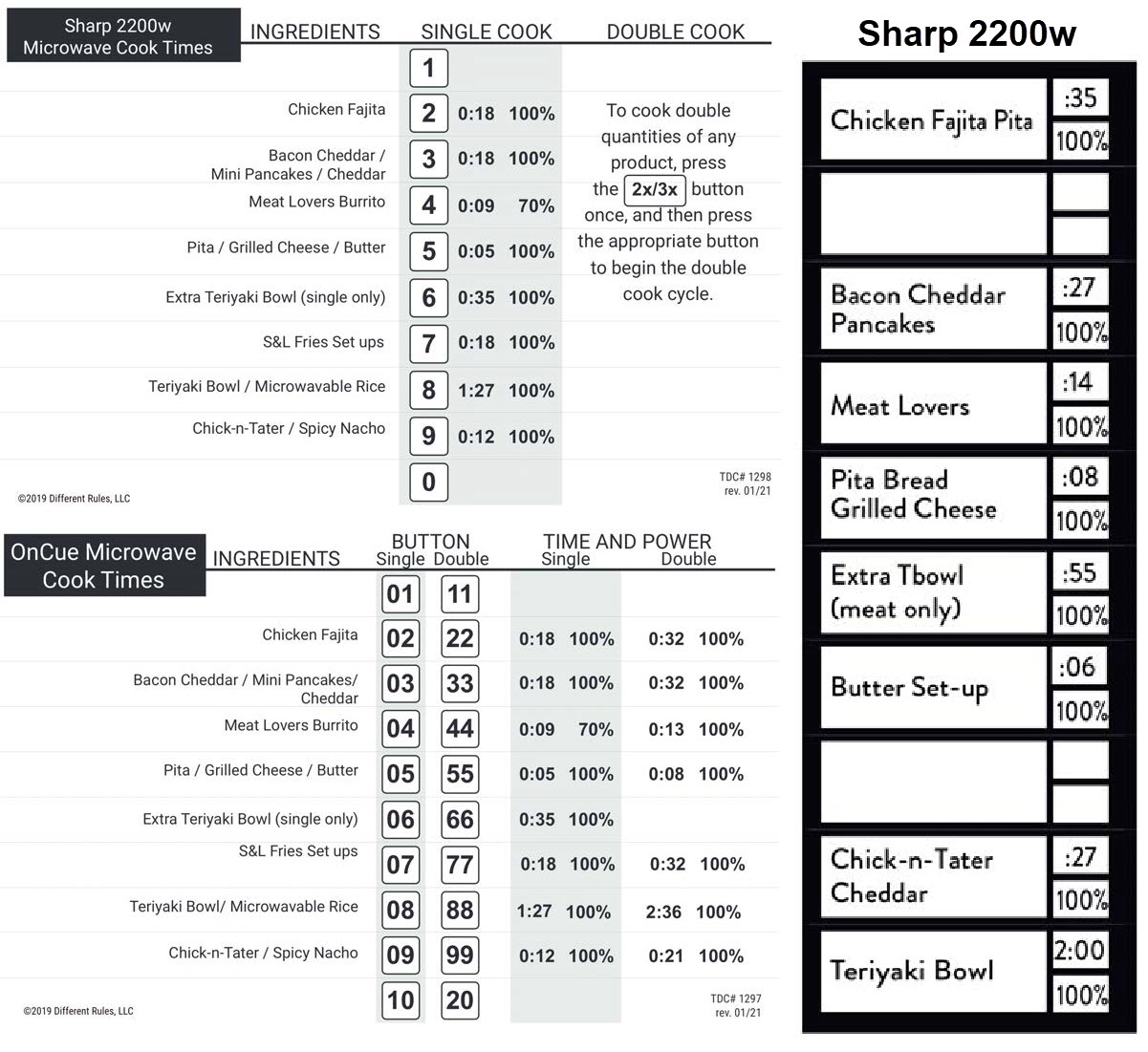

MICROWAVE - Microwave cook times are used correctly.

-

A. Team members pressing correct buttons to fully melt/cook ingredients.

-

Grilled Products are cooked to specifications

BACK OF THE HOUSE - QUICK

-

RUSH READY - TEAM - Team and restaurants are rush ready and in primary positions to support peak volumes. Daily planners are posted, used, 4+ headsets in use.

-

A. Team Workstation Daily Planners in place and in use.

-

B. ‘All hands-on deck’ in guest service positions during peak periods

-

C. 4+ headsets are in use (PIC, Fryer, Grill, and drive-thru Team Member) or BOH kitchen drive-thru speaker is on and can be <br> clearly heard.

-

BUILD-TO CHARTS - Precooking/staging/build-to in place including posting, adjusting, and using build-to charts

-

A. Build-to and precooking are in place. Cook to order practices are generally not observed, except for zero <br> items on the Build-to charts.

-

B. Team members using build to chart system – pre-cooked amount of product on build to chart are staged in <br> holding cabinets and fry bins.

-

C. Build-to charts are posted for correct day and daypart. Adjusted if applicable.

-

D. "Stop and Drop” is used for “zero” items within 30 seconds of being ordered by guest or instructed by PIC or <br> Guest Service Team Member.

-

BUILD-TO CHART & STAGING TEAM MEMBER KNOWLEDGE

-

A. Grill or Fryer Team Member can explain build to and staging procedures.

-

To evaluate – ask the questions below:

• How do they use build-to charts and correctly stage product?

• Why is using the build-to important? -

STOP & DROP TEAM MEMBER KNOWLEDGE

-

A. Grill or Fryer Team Members can explain when to stop and drop and ‘zero’ items.

-

To evaluate – ask the question below:

• What do you do when a "zero" item is ordered by a Guest? (Item not populated to be precooked and staged on build-to report.) -

FULLY STAFFED WITH PROFICIENT TEAM - Restaurant shift is fully staffed with proficient Team Members to achieve all Brand Standards.

-

A. Team should be staffed to effectively take, make, or serve majority of orders within Quick standards. (Refer <br> to kitchen display screen to evaluate Order to Delivery times. (Few to no orders should be more than 6 <br> minutes).

-

B. Guests are not put on hold.

-

C. Team Members are proficient in their primary positions to achieve Guest Quick times and maintain clean <br> standards. Allow for training of a new Team Member. However, the Team Members currently working the <br> shift should be proficient with a sense of urgency and minimal mistakes or confusion.

-

WORKSTATION POSITIONING - Workstation position principles (deployment) and Guest priority sequence in place to enable 'Quick' and Guest standards.

-

A. Team members are Guest focused and slide deploying - Team Members getting orders out for Guests before completing other duties. Team slide deploys to help one another get each order completed quicker and balance their workload.

-

B. Workstation Chart is posted for current day and daypart.

-

C. Deployment on Workstation Position Chart is assigned in consecutive order without skipping any numbers

-

D. Team Members are working their designated positions.

-

PIC LEADING TEAM - PIC is actively leading the shift and team to achieve 'Quick' and Guest Experience standards

-

A. PIC is in 'manager zone' – this means being in primary positions of #3, #5, or #7 at least 75% of the time to maximize leadership impact.

-

B. PIC can be seen and heard leading this shift.

-

C. PIC Daily Planner is current, posted, and in use during the shift.

-

D. PIC is observed verifying (verbally or visually) build-to levels during the shift.

-

E. PIC observed completing or ensuring the Guest Expectation Travel Path gets complete at least once during the review.

-

F. Role models/monitors cash handling procedures (employee meals, voided orders, item cancels, one person per drawer, large bills)

-

G. Can pass Food Safety audit

-

PIC LEADERSHIP KNOWLEDGE QUESTION

-

A. Tell me how you lead a shift to ensure a consistently great Guest Experience?

-

B. Tell me, how do you handle Guest complaints?

-

ALL TEAM MEMBERS, INCLUDING PIC ARE IN GUEST READY UNIFORM

-

A. All employees have complete and approved uniform

-

B. Uniforms are clean, free of stains and excessive fading or damage

-

C. Uniforms fit proper;y (not too tight or too loose)

-

D. Jackets or sweaters are Jack beanded or solid black or gray (unbranded)

-

E. Name tags are correct and visible - even if wearing an apron, jacket or sweater

DINING ROOM - CLEAN

-

DINING ROOM - CEILING VENTS, & LIGHTING - Dining room ceiling tiles, vents, and lighting is clean

-

A. Ceiling vents are clean.

-

B. Lighting clean

-

DINING ROOM - WALLS & DÉCOR - Dining room walls and décor are clean

-

A. Walls (to include) exterior fireplace walls) are clean

-

B. Décor is clean

-

DINING ROOM - WINDOW LEDGES, SILLS, & BLINDS - Dining room window ledges, sills, and blinds are clean

-

A. Window sills/ledges are clean

-

B. Blinds are clean

-

DINING ROOM - FLOORS - Dining room floors, corners, and areas under tables, covings, baseboards, and mats are clean; wet floors signs are clean, used only when floor is wet.

-

A. Floors, corners, areas under tables, covings, baseboards, and mats are clean, free of buildup.

-

B. Wet floor signs are clean. Being used appropriately and not left out after floors are dry.

-

C. Spills are quickly addressed.

-

DINING ROOM - TABLES, CHAIRS, & TRASH RECEPTACLES - Dining room table, seats, highchairs, dividers, and trash receptacles are clean. Trash receptacles not full.

-

A. Tables are clean (no more than 3 dirty tables for longer than 5 minutes).

-

B. Dining room seating, chairs, and high chairs are clean. Minimum of 2 high chairs are available.

-

C. Table and chair legs are free from buildup.

-

D. Dining room dividers are clean.

-

E. Trash receptacles are clean, and not full or overflowing.

-

FRONT COUNTER AREAS - Menu board, front counter drink, and condiment stations stocked and are reasonably clean

-

A. All front counter Point of Purchase (POP) is clean, current (no hand- written or unapproved typed signs).

-

B. Menu board is fully lit, clean.

-

C. Front counter Point of Sale (POS) elements and monitors are clean, free of dust buildup.

-

D. Drink machine and condiment stations are reasonably clean.

-

E. Drink machine and condiment stations stocked

-

BACK OF THE HOUSE & KITCHEN VIEW - Kitchen view of back of house is clean, organized, and with minimal internal guest facing team messaging.

-

A.The kitchen appears clean, organized, and clear of unnecessary clutter from Guest view.

-

B. Guest facing posted job aids are minimal (less than 5), legible, clean, and relevant to positions.

-

DINING ATMOSPHERE & AMBIANCE - Dining atmosphere and ambiance are comfortable, dining room is free of abnormal odors.

-

A. Temperature (not unreasonably warm or cold).

-

B. Music (not missing, too low, or too loud).

-

C. Clean smell – no abnormal odors.

-

D. Team Member dialogue professional – not overly loud, disruptive to Guest experience.

-

RESTROOMS - Restrooms are clean, stocked. All fixtures, mirrors, sinks, toilets, soap dispensers and paper towel holders / hand dryers are clean.

-

A. Restrooms are clean and free of buildup on floors, doors/kick plates, fixtures, sinks, toilets/ urinals, walls, partitions, etc.

-

B. Restrooms are properly stocked (soap, towel dispensers, toilet paper).

-

C. Trash receptacles are clean, lined, and not overflowing.

-

D. All lighting is clean.

-

E. Sanitary receptacles in place (if applicable), clean and not overflowing.

-

F. Restroom mirrors and frames are clean.

-

G. Restrooms ventilation/fan covers are clean.

-

H. Handwashing job aid (TDC#1041) is posted.

EXTERIOR - CLEAN & CONDITION

-

EXTERIOR SIGNAGE & LIGHTING - All exterior brand signage, lighting clean.

-

A. All exterior signage (to include: directional signage, handicap signs, parking stall signage, building and monument signage) is reasonably clean, free of stains and buildup.

-

B. All exterior poles and support items connected to signage is clean.

-

C. All lighting is turned on after dark (including any signage lighting).

-

D. No handwritten or unapproved typed signs in Guest view unless allowed by brand.

-

EXTERIOR POP - Exterior POP elements are current, clean, in good condition, not faded, and correctly applied.

-

A. All POP is current, clean, and in good condition, free of fading, bubbles, and pealing corners.

-

RESTAURANT EXTERIOR - Building exterior walls, roof, reasonably clean. 3 or fewer total minor individual items can be missed. Note: Standard will not be met if ONE MAJOR OR EXTERME issue is observed.

-

A. Building exterior walls are reasonably clean and in good condition (i.e. free of buildup, grime, or splatters).

-

B. Back door(s) are reasonably clean and in good condition. Back door area clear of pallets, bread racks, or miscellaneous items.

-

C. Exterior building roof, awnings, fascia, mansard, soffit, rain gutters, and down spout reasonably clean, in good condition, and free of bird’s nests.

-

D. Perimeter fencing reasonably clean.

-

DOORS, WINDOWS, & LEDGES - Doors, windows, and ledges all around the building are clean.

-

A. Doors, door frames, push bars, and thresholds reasonably clean

-

B. Back doors are closed when not in use

-

C. Windows and exterior window ledges all the way around the building are reasonably clean.

-

D. Entry door is not over cluttered with POP, clings, signage.

-

PARKING LOT - Parking lot is clean

-

A. Parking lot is clean. Four or fewer total of the following: pieces of trash, spills/messes, and also 4 or fewer total cigarette butts and 4 or fewer gum buildup.

-

SIDEWALK, PATIO, & EXTERIOR FURNITURE - Sidewalk, patio, and exterior furniture are clean.

-

A. Four or fewer pieces of trash, cigarette butts, or buildup areas (grime, stains, unscraped gum buildup) on sidewalk areas all around the building, including patio areas and furniture.

-

B. Wet floor signage or cones in Guest view are in active use (not left out on dry surfaces).

-

EXTERIOR TRASH RECEPTACLES - Trash receptacles, not full.

-

A. Exterior trash cans/receptacles and cigarette receptacles are not full, overflowing.

-

B. Trash cans/receptacles are reasonably clean and free of grime.

-

LANDSCAPING - Landscaping area is reasonably clean.

-

A. Landscaping reasonably clean.

-

B. Four or fewer total pieces of trash throughout all landscaping areas.

-

C. Minimal to no cigarette butts (10 or fewer) in one area such as the drive-thru menu board landscaping area.

-

DRIVE-THRU PREVIEW BOARD - Drive-thru preview board and all components are clean, free of buildup

-

A. Drive-thru preview board and components are reasonably clean (plexiglass, T-bars/dividers, hardware, metal plastic, numbers, etc.).

-

B. Free of excessive dust/dirt, buildup, stains, stickers, or gum.

-

C. Menu Panels, T-bars/dividers, numbers are straight, not crooked.

-

DRIVE-THRU ORDER MENU BOARD - Drive-thru menu board and all components are clean, free of buildup.

-

A. Drive-thru order menu board, confirmation screen, speaker, and all other components are reasonably clean (plexiglass, T-bars/dividers, hardware, metal plastic, numbers, etc.).

-

B. Menu boards are illuminated after dark.

-

C. Free of excessive dust/dirt, buildup, stains, stickers, or gum.

-

D. Order menu panels, T-bars/dividers, numbers are straight, not crooked.

-

DRIVE-THRU LANE & CURBS - Drive-thru lane and curbs clean.

-

A. Three or fewer pieces of trash, spills, stains, soil/grease buildup in the drive-thru lane, cement, asphalt, and curbs.

-

B. Drive-thru lane, cement, asphalt, and curbs are free of weeds, and excessive (10 or fewer) unscraped gum buildup.

-

DRIVE-THRU SERVICE WINDOW - Drive-thru service window area clean. Evaluate for 3 or fewer minor issues of dust, adhesive residue, spills, or stains.

-

A. Drive-thru windows, window frames, window ledges, and POP hardware is clean.

-

B. Wall area around and cement area below service window are clean.

-

C. No handwritten or unapproved typed signs.

TRAINING & KEY SYSTEMS IN PLACE

-

TRAINING & CERTIFICATION - Management and Team trained and certified on required brand standards.

-

A. Training tablet is charged.

-

B. Training system in place to certify Team Members on brand operating standards.

-

C. Certified Team members know the correct standards and are certified for proficiency.

-

D. PIC can show proof of certification in training system for Team Members working the shift.

-

E. PIC or Team Member can correctly explain training process or refer to Jenius.

-

PROMOTION TRAINING & CERTIFICATION - Current Promotion Training and Certification to specifications.

-

A. Team Members demonstrating correct behaviors and execution of new products.

-

B. Team Members have been certified in Jenius for current promotion.